conveyor roller manufacturers usa

New technology enables Tapered Rollers up 65" long. They are also often fitted with special gears or other movement control devices that allow the movement of a conveyor system to be more precise. Component materials of choice include: To receive a quote, please provide roller diameter, distance between supports, shaft length and any other feature you require. They are a sequence of rollers supported by a structure appropriate for unit handling items which are moved by a belt.

New technology enables Tapered Rollers up 65" long. They are also often fitted with special gears or other movement control devices that allow the movement of a conveyor system to be more precise. Component materials of choice include: To receive a quote, please provide roller diameter, distance between supports, shaft length and any other feature you require. They are a sequence of rollers supported by a structure appropriate for unit handling items which are moved by a belt.  Our rubber rolls are designed to withstand the toughest rigors, like temperature changes, abrasives, and solvents. With that same attention to detail, FRANTZ will custom build rollers to your spec using genuine FRANTZ conveyor bearings. conveyor roller manufacturers motorized flexible larger Our mission is to continue to pioneer the MDR market with quality existing products as well as with new and exciting innovations for a hassle-free material handling experience. Contact us today for more info! We hope your visit is rewarding, meets your expectations, and most importantly, helps you efficiently solve your conveyor needs. When calculating the most exacting of the needs for their new EP-0047 roller, Daenzer found many of the requirements were shared. conveyor roller

Our rubber rolls are designed to withstand the toughest rigors, like temperature changes, abrasives, and solvents. With that same attention to detail, FRANTZ will custom build rollers to your spec using genuine FRANTZ conveyor bearings. conveyor roller manufacturers motorized flexible larger Our mission is to continue to pioneer the MDR market with quality existing products as well as with new and exciting innovations for a hassle-free material handling experience. Contact us today for more info! We hope your visit is rewarding, meets your expectations, and most importantly, helps you efficiently solve your conveyor needs. When calculating the most exacting of the needs for their new EP-0047 roller, Daenzer found many of the requirements were shared. conveyor roller  Maps and Directions to FRANTZ Manufacturing, Ball Bearing Sheaves, Idler, Pulley and Guide Wheels, Contact Felt Seal Conveyor Bearing Protection, Conveyor Bearing and Conveyor Wheel Quality, Custom Machined and Cold Formed Steel Spacers, Easy Glider Ball Transfers and Ball Casters, Flanged and Straight Faced IronGrip Adapters, GenStar 4003 Series Precision Conveyor Bearings, GenStar 5000 Series Precision Conveyor Bearings, Metric Flanged Unground Non-Precision Bearings, Metric GEN II Semi-Precision Conveyor Bearings, Regreasable & High Temp Conveyor Bearings, Straight Faced Unground Non-Precision Bearings, Wide Flanged Unground Non-Precision Bearings. They are powered by a shaft under the rollers. Cast iron or cast steel is used to construct a majority of their housing. to provide the industrys best We take care of all your custom roller needs.

Maps and Directions to FRANTZ Manufacturing, Ball Bearing Sheaves, Idler, Pulley and Guide Wheels, Contact Felt Seal Conveyor Bearing Protection, Conveyor Bearing and Conveyor Wheel Quality, Custom Machined and Cold Formed Steel Spacers, Easy Glider Ball Transfers and Ball Casters, Flanged and Straight Faced IronGrip Adapters, GenStar 4003 Series Precision Conveyor Bearings, GenStar 5000 Series Precision Conveyor Bearings, Metric Flanged Unground Non-Precision Bearings, Metric GEN II Semi-Precision Conveyor Bearings, Regreasable & High Temp Conveyor Bearings, Straight Faced Unground Non-Precision Bearings, Wide Flanged Unground Non-Precision Bearings. They are powered by a shaft under the rollers. Cast iron or cast steel is used to construct a majority of their housing. to provide the industrys best We take care of all your custom roller needs.  The conveyor equipment industry is experiencing exponential growth, making it a hot market for those looking for leads in the manufacturing world. diameter, 20 ft. length and 6,000 lbs and custom options. conveyor JPS plastic rollers weigh less and operate more quietly than common steel rollers. conveyor trasportatore lrk rulli cleanstar rollenfrderer Spiroflow offers a complete range of mechanical conveying solutions in the industry.

The conveyor equipment industry is experiencing exponential growth, making it a hot market for those looking for leads in the manufacturing world. diameter, 20 ft. length and 6,000 lbs and custom options. conveyor JPS plastic rollers weigh less and operate more quietly than common steel rollers. conveyor trasportatore lrk rulli cleanstar rollenfrderer Spiroflow offers a complete range of mechanical conveying solutions in the industry.  This can be especially important during complex manufacturing processes. conveyor Conveyor rollers are manufactured from an assortment of different rubber, metal and other materials and are available in various sizes and durability levels. OurPulse Geared Drive (PGD) is an affordable, compact, and powerful 24VDC motor drive used in material handling, assembly, automation, and other applications requiring repeatable, linear motion control, +1-800-764-6356 With our 225+ years combined experience we are one of the best in the industry. Our world-class conveyor systems and material handling solutions bring millions of products to people world-wide. Conveyor rollers are cylindrical tools that make possible the movement of objects along conveyor belts and other conveyor systems. Belt, roller, chain, timing belt and many other conveyor types are available. CNC leader producing custom-designed, high-precision turned and milled components. Building the perfect pallet conveyor just got easiernot to mention smarter, faster, safer, and more cost-efficient. Conductive plastic or stainless steel conveyor pulleys minimize noise and vibration. In business for over 40 years Shuttleworth Inc., of Huntington, IN, supplies conveyor systems used in a wide variety of applications in numerous industries, for more information visit their website at www.shuttleworth.com. conveyor Rubber conveyor rollers can be made out of many materials; just a few examples are polyurethane and silicone. When the weather starts to get cooler, I like to delve into more spicy dishes and one of my favorites is Kung Pao Chicken. Our precision roller bearings provide smooth conveyor operation and long service life.

This can be especially important during complex manufacturing processes. conveyor Conveyor rollers are manufactured from an assortment of different rubber, metal and other materials and are available in various sizes and durability levels. OurPulse Geared Drive (PGD) is an affordable, compact, and powerful 24VDC motor drive used in material handling, assembly, automation, and other applications requiring repeatable, linear motion control, +1-800-764-6356 With our 225+ years combined experience we are one of the best in the industry. Our world-class conveyor systems and material handling solutions bring millions of products to people world-wide. Conveyor rollers are cylindrical tools that make possible the movement of objects along conveyor belts and other conveyor systems. Belt, roller, chain, timing belt and many other conveyor types are available. CNC leader producing custom-designed, high-precision turned and milled components. Building the perfect pallet conveyor just got easiernot to mention smarter, faster, safer, and more cost-efficient. Conductive plastic or stainless steel conveyor pulleys minimize noise and vibration. In business for over 40 years Shuttleworth Inc., of Huntington, IN, supplies conveyor systems used in a wide variety of applications in numerous industries, for more information visit their website at www.shuttleworth.com. conveyor Rubber conveyor rollers can be made out of many materials; just a few examples are polyurethane and silicone. When the weather starts to get cooler, I like to delve into more spicy dishes and one of my favorites is Kung Pao Chicken. Our precision roller bearings provide smooth conveyor operation and long service life.  Intelligrated, also called Honeywell Intelligrated, has exploded onto the conveying equipment scene in recent years.

Intelligrated, also called Honeywell Intelligrated, has exploded onto the conveying equipment scene in recent years.  conveyor conveyors conveyor rollers diameter Read More. Posted by IndustrySelect on Wednesday, March 16, 2022, Reach U.S. manufacturers, suppliers, and industrial service providers with, IndustrySelect is the Industrial Database, Sales Marketing Recruiting Research, Looking to contact decision makers in the U.S. conveyor industry or in the manufacturing world at large? Since many customers processes involved annealing, extreme temperature resistance was mandatory. Harwood Rubber Products provides top quality rubber rollers and a variety of custom products. Contact REDCO today! If you're like many of our customers looking for low-cost alternatives to servo motors, actuators or solenoids, your search is over. On the shaft are a number of spools, for each roller there is one spool.

conveyor conveyors conveyor rollers diameter Read More. Posted by IndustrySelect on Wednesday, March 16, 2022, Reach U.S. manufacturers, suppliers, and industrial service providers with, IndustrySelect is the Industrial Database, Sales Marketing Recruiting Research, Looking to contact decision makers in the U.S. conveyor industry or in the manufacturing world at large? Since many customers processes involved annealing, extreme temperature resistance was mandatory. Harwood Rubber Products provides top quality rubber rollers and a variety of custom products. Contact REDCO today! If you're like many of our customers looking for low-cost alternatives to servo motors, actuators or solenoids, your search is over. On the shaft are a number of spools, for each roller there is one spool.  conveyor exporters tradeindia Ultimation's conveyor systems are installed in the facilities of many of the world's leading brands. Molding processes involve heating an elastomeric material and forming it in a mold. Light duty rollers are manufactured from the same high quality PVC pipe, but in the smaller diameters. The Slideways Solution: Since water is an excellent lubricant for UHMW, Slideways recommended replacing the steel rollers with an all-plastic roller constructed with PVC tubing and UHMW bearings.The rollers have been in service for years with no maintenance. Further reading:In-Demand Industrial Products & Services This Week. The Challenge: Rollers used in a commercial composting facility were failing prematurely due to the damp, corrosive environment. Choosing the right conveyor roller material is important to the safe and effective operation of a conveyor system. Rubber conveyor rollers are usually produced by either injection or compression molding, though extrusion is also a possibility.

conveyor exporters tradeindia Ultimation's conveyor systems are installed in the facilities of many of the world's leading brands. Molding processes involve heating an elastomeric material and forming it in a mold. Light duty rollers are manufactured from the same high quality PVC pipe, but in the smaller diameters. The Slideways Solution: Since water is an excellent lubricant for UHMW, Slideways recommended replacing the steel rollers with an all-plastic roller constructed with PVC tubing and UHMW bearings.The rollers have been in service for years with no maintenance. Further reading:In-Demand Industrial Products & Services This Week. The Challenge: Rollers used in a commercial composting facility were failing prematurely due to the damp, corrosive environment. Choosing the right conveyor roller material is important to the safe and effective operation of a conveyor system. Rubber conveyor rollers are usually produced by either injection or compression molding, though extrusion is also a possibility.  Website Design and Development by Xzito Marketing. Conveyor Roller Manufacturers | Conveyor Roller Suppliers | Home | Request for Quote | Photo Gallery | Privacy Policy/Terms of use | List of Companies | Sitemap, REDCO Rubber Engineering & Development Company, Conveyor Rollers - Western Roller Corporation. Keep up with our always upcoming product features and technologies. Founded in 1972, Superior Industries has experienced steady growth by focusing on providing high-quality conveying equipment. Since 1948, REDCO Rubber Engineering & Development has been manufacturing rubber rollers, idler rolls and conveyor rollers. Each material offers slightly different qualities of strength, durability, friction and operating lifespan. Gravity conveyors are a very simple and cost effective type of product handling systems. Enter your e-mail and subscribe to our newsletter. At times, a high loading of silicone will cause particles to migrate to the parts surface, creating a source ofpotential contamination. MHS is committed to helping clients advance into the digital age, taking advantage of trends in e-commerce to help clients improve the production process from packaging to shipping. Read More. They function by permitting the material to roll on the upper surface. This variety of parameters dictated a custom material and his experience with RTP Company product development engineers led Daenzer to enlist their services. We are the premier supplier of urethane rollers for industries around the world. Designed Conveyor exists to bring you dependable and quality service. This source is right for you whether it's for a manufacturer of saddle type conveyor rollers, aggregate conveyor rollers, and conveyor rubber rollers.

Website Design and Development by Xzito Marketing. Conveyor Roller Manufacturers | Conveyor Roller Suppliers | Home | Request for Quote | Photo Gallery | Privacy Policy/Terms of use | List of Companies | Sitemap, REDCO Rubber Engineering & Development Company, Conveyor Rollers - Western Roller Corporation. Keep up with our always upcoming product features and technologies. Founded in 1972, Superior Industries has experienced steady growth by focusing on providing high-quality conveying equipment. Since 1948, REDCO Rubber Engineering & Development has been manufacturing rubber rollers, idler rolls and conveyor rollers. Each material offers slightly different qualities of strength, durability, friction and operating lifespan. Gravity conveyors are a very simple and cost effective type of product handling systems. Enter your e-mail and subscribe to our newsletter. At times, a high loading of silicone will cause particles to migrate to the parts surface, creating a source ofpotential contamination. MHS is committed to helping clients advance into the digital age, taking advantage of trends in e-commerce to help clients improve the production process from packaging to shipping. Read More. They function by permitting the material to roll on the upper surface. This variety of parameters dictated a custom material and his experience with RTP Company product development engineers led Daenzer to enlist their services. We are the premier supplier of urethane rollers for industries around the world. Designed Conveyor exists to bring you dependable and quality service. This source is right for you whether it's for a manufacturer of saddle type conveyor rollers, aggregate conveyor rollers, and conveyor rubber rollers.  01605 While Shuttleworth is renowned for customizing its products to end-user applications, Klaus Daenzer, Senior Plastics R&D Engineer, felt a single material for rollers capable of performing in any of their most demanding projects would allow them to lower costs and provide faster responses to customers. Extrusion also involves heating an elastomer, but instead of molding the rubber, it is forced through an extrusion die. The roller shape can be straight, tapered or crowned. Feel free to discuss your application with JPS. conveyor rollers conveyor diameter Each Itoh Denki motorized conveyor roller is customizable and can fit virtually any applications needs. Eachindustrial company profile contains up to thirty detailed facts, verfied firsthand by MNI's 80-person research team. Precision Warehouse Design has over 20 years of experience manufacturing conveyor systems.

01605 While Shuttleworth is renowned for customizing its products to end-user applications, Klaus Daenzer, Senior Plastics R&D Engineer, felt a single material for rollers capable of performing in any of their most demanding projects would allow them to lower costs and provide faster responses to customers. Extrusion also involves heating an elastomer, but instead of molding the rubber, it is forced through an extrusion die. The roller shape can be straight, tapered or crowned. Feel free to discuss your application with JPS. conveyor rollers conveyor diameter Each Itoh Denki motorized conveyor roller is customizable and can fit virtually any applications needs. Eachindustrial company profile contains up to thirty detailed facts, verfied firsthand by MNI's 80-person research team. Precision Warehouse Design has over 20 years of experience manufacturing conveyor systems.  The JPS flange bearing safety cap is designed to fit many manufacturers bearings for the particular series. CDLR (Chain Driven Live Roller) Selection Guide, Roller Conveyor vs Skatewheel Conveyor Selection Guide. Ashland Conveyor is your source for replacement rollers. Improvements in conveying equipment typically result in accelerated production rates regardless of industry, prompting more investment in conveying equipment.

The JPS flange bearing safety cap is designed to fit many manufacturers bearings for the particular series. CDLR (Chain Driven Live Roller) Selection Guide, Roller Conveyor vs Skatewheel Conveyor Selection Guide. Ashland Conveyor is your source for replacement rollers. Improvements in conveying equipment typically result in accelerated production rates regardless of industry, prompting more investment in conveying equipment.  conveyor conveyors They can be applied in both carry and return applications. Looking back on my childhood, sometimes I think it is a wonder some of us survived. Founded in 1947, Hytrol has a long history indicative of the company's commitment to its clients. info@slideways.com. In response, RTP Company formulated anRTP 1300 Seriesconductive and lubricated polyphenylene sulfide (PPS) compound. conveyor Molding processes involve heating an elastomeric material and forming it in a mold. The recipe I use calls for real Szechuan peppercorns and Ancho chillies - I splurge for the real things and it does make a difference. Using a silicone additive is the traditional approach to decrease friction between surfaces in contact with one another. There is a saying that all good things must come to an end. For some things it is too soon and for others, not soon enough. 6.) The industrial marketplace IndustryNet has seen searches for conveyor systems surge in recent months. In 1975, we developed the motor driven roller (MDR) for conveyor systems and in 1986 we developed the first brushless DC powered roller; the Power Moller 24, which included the rollers motor and gearbox set inside its tube creating an energy efficient solution for our customers. conveyor trustworthy roller warehouse suppliers manufacturer stainless In particular, I have been charged with keeping the technical documentation accurate, up-to-date, and properly formatted for the look and feel of our PULSEROLLER brand. My mother had 5 children and worked full time as a nurse. JPS plastic rollers come in light duty and medium duty designs with many mounting options, the most common being a spring loaded shaft. This heavy duty roller conveyor may be combined with transfers for angular transfer in roller conveyor systems. Conveyor rollers are often grooved in order to make the gripping of conveyor belts easier. excel

conveyor conveyors They can be applied in both carry and return applications. Looking back on my childhood, sometimes I think it is a wonder some of us survived. Founded in 1947, Hytrol has a long history indicative of the company's commitment to its clients. info@slideways.com. In response, RTP Company formulated anRTP 1300 Seriesconductive and lubricated polyphenylene sulfide (PPS) compound. conveyor Molding processes involve heating an elastomeric material and forming it in a mold. The recipe I use calls for real Szechuan peppercorns and Ancho chillies - I splurge for the real things and it does make a difference. Using a silicone additive is the traditional approach to decrease friction between surfaces in contact with one another. There is a saying that all good things must come to an end. For some things it is too soon and for others, not soon enough. 6.) The industrial marketplace IndustryNet has seen searches for conveyor systems surge in recent months. In 1975, we developed the motor driven roller (MDR) for conveyor systems and in 1986 we developed the first brushless DC powered roller; the Power Moller 24, which included the rollers motor and gearbox set inside its tube creating an energy efficient solution for our customers. conveyor trustworthy roller warehouse suppliers manufacturer stainless In particular, I have been charged with keeping the technical documentation accurate, up-to-date, and properly formatted for the look and feel of our PULSEROLLER brand. My mother had 5 children and worked full time as a nurse. JPS plastic rollers come in light duty and medium duty designs with many mounting options, the most common being a spring loaded shaft. This heavy duty roller conveyor may be combined with transfers for angular transfer in roller conveyor systems. Conveyor rollers are often grooved in order to make the gripping of conveyor belts easier. excel  In 1996, Itoh Denki USA Inc. opened their doors to provide MDR material handling solutions to customers in the North and South American market. There are applications - food processing comes to mind - when the ability to washdown a conveyor system is absolutely mandatory. Our rollers are made in-house, and customization is available upon request. They are applied in a variety of industries listed below: When choosing a roller conveyor it is important to consider the following: It is important to pay attention to the height, width, length, and weight since the technical specifications of the system are ultimately dependent on these characteristics. An easy connection to reach conveyor roller companies through our fast request for quote form is provided on our website. American Urethane is the premier supplier of urethane rollers for industries around the world.

In 1996, Itoh Denki USA Inc. opened their doors to provide MDR material handling solutions to customers in the North and South American market. There are applications - food processing comes to mind - when the ability to washdown a conveyor system is absolutely mandatory. Our rollers are made in-house, and customization is available upon request. They are applied in a variety of industries listed below: When choosing a roller conveyor it is important to consider the following: It is important to pay attention to the height, width, length, and weight since the technical specifications of the system are ultimately dependent on these characteristics. An easy connection to reach conveyor roller companies through our fast request for quote form is provided on our website. American Urethane is the premier supplier of urethane rollers for industries around the world.  To make the material ideally suited for ESD (electro-static discharge) sensitive uses, RTP Company engineers added a conductivity package resulting in a volume resistivity of 103ohm-cm maximum and surface resistivity of 105ohm/sq maximum. gravity The low voltage pallet rollers are designed to replace any AC gear motor solution by simply removing the motor/gearbox unit and dropping in the heavy-duty pallet roller with sprockets. Our bearing design tolerates dirt and moisture, two elements that tend to damage ball bearings. conveyor roller degree curved curve bend steel kg capacity stainless feet per conveyors ss india Tubing: plastic, steel, stainless and others, Bearings: UHMW, Nylon, plastic ball bearings, steel ball bearings, Shafting: steel, stainless steel, stub shafts. conveyors There are a number of ways roller conveyors can be utilized and adjusted for different applications, including moving cardboard boxes, boxes, pallets, crates, plastic totes, polybags, trays, and slave boards. Conveyors can even be found in grocery stores to expedite the check-out process. It is updated annually to reflect new statistics and trends. conveyor roller interroll heavy duty tracks bu50 74mm system 3d rs JPS Company makes available many components for roller assembly. 705 Plantation Street They are used to move pallets and other unit items. 580 E. Front Street, Winona, MN 55987-0439, USA. conveyor A roller conveyor system may be constructed to work with a number of ancillary devices like bends, turntables, and gates. The roller shape can be straight, tapered or crowned.

To make the material ideally suited for ESD (electro-static discharge) sensitive uses, RTP Company engineers added a conductivity package resulting in a volume resistivity of 103ohm-cm maximum and surface resistivity of 105ohm/sq maximum. gravity The low voltage pallet rollers are designed to replace any AC gear motor solution by simply removing the motor/gearbox unit and dropping in the heavy-duty pallet roller with sprockets. Our bearing design tolerates dirt and moisture, two elements that tend to damage ball bearings. conveyor roller degree curved curve bend steel kg capacity stainless feet per conveyors ss india Tubing: plastic, steel, stainless and others, Bearings: UHMW, Nylon, plastic ball bearings, steel ball bearings, Shafting: steel, stainless steel, stub shafts. conveyors There are a number of ways roller conveyors can be utilized and adjusted for different applications, including moving cardboard boxes, boxes, pallets, crates, plastic totes, polybags, trays, and slave boards. Conveyors can even be found in grocery stores to expedite the check-out process. It is updated annually to reflect new statistics and trends. conveyor roller interroll heavy duty tracks bu50 74mm system 3d rs JPS Company makes available many components for roller assembly. 705 Plantation Street They are used to move pallets and other unit items. 580 E. Front Street, Winona, MN 55987-0439, USA. conveyor A roller conveyor system may be constructed to work with a number of ancillary devices like bends, turntables, and gates. The roller shape can be straight, tapered or crowned.  Slideways fabricates rollers to your specification, applying our experience in materials and design to provide an economical roller with an extended useful life.

Slideways fabricates rollers to your specification, applying our experience in materials and design to provide an economical roller with an extended useful life.  With our years of experience, Ultimation is one of the major conveyor manufacturers. We manufacture galvanized steel, stainless steel, aluminum, plain steel, and PVC rollers. The bulk of our plastic rollers use a plain / journal (sleeve) type bearing as opposed to ball bearings. Editor's Note: The article was originally published in September 2020. Since our systems keep your business moving, you can be sure our ongoing support is guaranteed.

With our years of experience, Ultimation is one of the major conveyor manufacturers. We manufacture galvanized steel, stainless steel, aluminum, plain steel, and PVC rollers. The bulk of our plastic rollers use a plain / journal (sleeve) type bearing as opposed to ball bearings. Editor's Note: The article was originally published in September 2020. Since our systems keep your business moving, you can be sure our ongoing support is guaranteed.  Thus combined loads are handled at the same time handling axial and radial loads.

Thus combined loads are handled at the same time handling axial and radial loads.  BEUMERis a intralogistics solutions company, with a special focus on tilt tray and cross belt sorters. conveyor rollers These small DC motors are spread throughout the conveyor. The new polyurethane conveyor rollers have three times the service life of rubber rollers and are easy to clean. The company focuses on developing automation solutions for a variety of popular conveying equipment lines. Commercial Composting Facility Replaces Steel with UHMW. That means the components you use in that conveyor system must be washdown rated so they will continue to operate properly after they've been pressure washed. They are 24V conveyors for efficient and precise movement of containers, boxes, or totes. We offer rapid quote responses and fast turnaround times. At the forefront of conveying equipment robotics and automation, Intelligrated is a company to watch out for in the coming years. Our conveyors systems are customizable to fit the needs of our customers. If you have any questions or special requirements, please contact us at webinquiry@ashlandconveyor.com or call us at 419-496-2974. Material Handling Systems (MHS) works with manufacturers to create innovative distribution center protocols, primarily utilizing automation. In warehouses, they are important parts of efficient packaging and shipping processes. Since our inception in 1946, Itoh Denki has been creating solutions to make material handling hassle-free. The 24VDC powered pallet handling motor rollers can move pallets up to 70 wide and effortlessly drive loads up to 2700 lbs.

BEUMERis a intralogistics solutions company, with a special focus on tilt tray and cross belt sorters. conveyor rollers These small DC motors are spread throughout the conveyor. The new polyurethane conveyor rollers have three times the service life of rubber rollers and are easy to clean. The company focuses on developing automation solutions for a variety of popular conveying equipment lines. Commercial Composting Facility Replaces Steel with UHMW. That means the components you use in that conveyor system must be washdown rated so they will continue to operate properly after they've been pressure washed. They are 24V conveyors for efficient and precise movement of containers, boxes, or totes. We offer rapid quote responses and fast turnaround times. At the forefront of conveying equipment robotics and automation, Intelligrated is a company to watch out for in the coming years. Our conveyors systems are customizable to fit the needs of our customers. If you have any questions or special requirements, please contact us at webinquiry@ashlandconveyor.com or call us at 419-496-2974. Material Handling Systems (MHS) works with manufacturers to create innovative distribution center protocols, primarily utilizing automation. In warehouses, they are important parts of efficient packaging and shipping processes. Since our inception in 1946, Itoh Denki has been creating solutions to make material handling hassle-free. The 24VDC powered pallet handling motor rollers can move pallets up to 70 wide and effortlessly drive loads up to 2700 lbs.

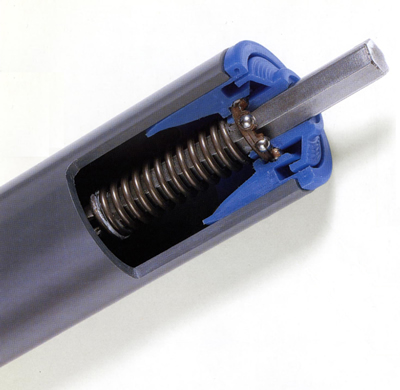

It may be substituted with chains or belts. on a conveyor line. These are cylinders made of metal fixed into the assembly combined with a metal axis and two bearings. Harwood specializes in replacing, repairing, and fabricating new rollers. CDLR (Chain Driven Live Roller)Selection Guide, Roller Conveyor vs Skatewheel ConveyorSelection Guide. Our blind bore rollers are ideal for use where equipment wash downs occur and on roller flight conveyors. The inherentproperties of PPSoffer a continuous use temperature of 400 degrees F (204 degrees C) and excellent chemical resistance. Customer reviews are available and product specific news articles. Rubber conveyor rollers are usually produced by either injection or compression molding, though extrusion is also a possibility. conveyor conveyors structural rollers lewcoinc Daifuku is a global leader in material handling systems, with deep roots in the automotive industry (the company adapted the forged rivetless chain conveyor for the Henry Ford Company). 580 E. Front Street, Winona, MN 55987-0439, USA, Computer-Aided Engineering (CAE) Support Services. Any conveyor roller company can design, engineer, and manufacture conveyor rollers to meet your companies specific qualifications. In the United States, the conveying equipment industry has a forecast CAGR of 4.6%, from 2019-26 and is expected to reach a value of more than $7 billion by 2026. Roll size up to 48 in. They are ideal for driven applications where the loads vary from ounces to pounds. We are committed to providing our customers with the very best designs in the industry. We also offer powered belt conveyor. In addition, these polyurethane rollers are FDA Read More About This, REDCO Rubber Engineering & Development Company, Polyurethane Rollers Replace Bakery's Rubber Rollers for Long Run Production. These rollers vary in shape, size and composition depending on the demands of the systems in which they are applied. IQS Directory implements a thorough list of conveyor roller manufacturers and suppliers. Roller conveyors are a sequence of rollers held in a frame where items can be moved manually, by power, or by gravity. Medium duty rollers are manufactured from high quality PVC pipe that is extruded to precise tolerances on the wall thickness which, when combined with added impact modifiers, gives our rollers greater strength. Looking to contact decision makers in the U.S. conveyor industry or in the manufacturing world at large? The company information includes website links, company profile, locations, phone, product videos and product information. They are also often fitted with special gears or other movement control devices that allow the movement of a conveyor system to be more precise. series 2000 conveyor rollers roller bearings 300dpi pg text steel quote builder JPS rollers are designed to be applied to driven (roller bed, live roller, line shaft, roller flight) and gravity conveyors, and can be excellent replacements for problematic metal rollers. The rollers easily passed Shuttleworths 6-month long heat durability test. We are capable of producing a great diversity of rolls and coverings for a broad customer base.

It may be substituted with chains or belts. on a conveyor line. These are cylinders made of metal fixed into the assembly combined with a metal axis and two bearings. Harwood specializes in replacing, repairing, and fabricating new rollers. CDLR (Chain Driven Live Roller)Selection Guide, Roller Conveyor vs Skatewheel ConveyorSelection Guide. Our blind bore rollers are ideal for use where equipment wash downs occur and on roller flight conveyors. The inherentproperties of PPSoffer a continuous use temperature of 400 degrees F (204 degrees C) and excellent chemical resistance. Customer reviews are available and product specific news articles. Rubber conveyor rollers are usually produced by either injection or compression molding, though extrusion is also a possibility. conveyor conveyors structural rollers lewcoinc Daifuku is a global leader in material handling systems, with deep roots in the automotive industry (the company adapted the forged rivetless chain conveyor for the Henry Ford Company). 580 E. Front Street, Winona, MN 55987-0439, USA, Computer-Aided Engineering (CAE) Support Services. Any conveyor roller company can design, engineer, and manufacture conveyor rollers to meet your companies specific qualifications. In the United States, the conveying equipment industry has a forecast CAGR of 4.6%, from 2019-26 and is expected to reach a value of more than $7 billion by 2026. Roll size up to 48 in. They are ideal for driven applications where the loads vary from ounces to pounds. We are committed to providing our customers with the very best designs in the industry. We also offer powered belt conveyor. In addition, these polyurethane rollers are FDA Read More About This, REDCO Rubber Engineering & Development Company, Polyurethane Rollers Replace Bakery's Rubber Rollers for Long Run Production. These rollers vary in shape, size and composition depending on the demands of the systems in which they are applied. IQS Directory implements a thorough list of conveyor roller manufacturers and suppliers. Roller conveyors are a sequence of rollers held in a frame where items can be moved manually, by power, or by gravity. Medium duty rollers are manufactured from high quality PVC pipe that is extruded to precise tolerances on the wall thickness which, when combined with added impact modifiers, gives our rollers greater strength. Looking to contact decision makers in the U.S. conveyor industry or in the manufacturing world at large? The company information includes website links, company profile, locations, phone, product videos and product information. They are also often fitted with special gears or other movement control devices that allow the movement of a conveyor system to be more precise. series 2000 conveyor rollers roller bearings 300dpi pg text steel quote builder JPS rollers are designed to be applied to driven (roller bed, live roller, line shaft, roller flight) and gravity conveyors, and can be excellent replacements for problematic metal rollers. The rollers easily passed Shuttleworths 6-month long heat durability test. We are capable of producing a great diversity of rolls and coverings for a broad customer base.  Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. A reliable source for Conveyor System information and leading Conveyor System Companies & Manufacturers. Our primary rollers are constructed with high quality PVC pipe and low friction plastic sleeve bearings. Continuous rotation dictated thatlubricity and wear resistancebe central properties and, for the needs of the electronics industry, the roller material itself had to be bothelectrically conductiveand free of silicone oil. After creating 300 conveyor roller prototypes for testing and evaluation, the client placed the production order to replace all of its existing rubber rollers which wear out frequently and interrupt production runs.

Our vast product line features a variety of aluminum frame and stainless-steel conveyors that are built to last. A reliable source for Conveyor System information and leading Conveyor System Companies & Manufacturers. Our primary rollers are constructed with high quality PVC pipe and low friction plastic sleeve bearings. Continuous rotation dictated thatlubricity and wear resistancebe central properties and, for the needs of the electronics industry, the roller material itself had to be bothelectrically conductiveand free of silicone oil. After creating 300 conveyor roller prototypes for testing and evaluation, the client placed the production order to replace all of its existing rubber rollers which wear out frequently and interrupt production runs.  conveyor belt suppliers rollers yifan warehouse manufacturer powered Ultimation is the largest integrator for Jervis Webb overhead conveyors and has an extensive range of "quick ship" roller conveyors and belt conveyors. Our PVC roller has a hard surface which reduces the possibility of contaminant adhesion and is much easier to clean should a slight buildup occur. conveyor roller plant steel ask In manufacturing contexts, conveyors are widely used on assembly lines. The different types of roller conveyors include: They let items move on rollers applying the force of gravity in moving the load. These are pedestals which support spinning shafts using various accessories and compatible bearings.

conveyor belt suppliers rollers yifan warehouse manufacturer powered Ultimation is the largest integrator for Jervis Webb overhead conveyors and has an extensive range of "quick ship" roller conveyors and belt conveyors. Our PVC roller has a hard surface which reduces the possibility of contaminant adhesion and is much easier to clean should a slight buildup occur. conveyor roller plant steel ask In manufacturing contexts, conveyors are widely used on assembly lines. The different types of roller conveyors include: They let items move on rollers applying the force of gravity in moving the load. These are pedestals which support spinning shafts using various accessories and compatible bearings.  The rollers are moved by a chain and offer the power required to move pallets. FRANTZ goes the extra mile IndustrySelect is a comprehensive database of industrial contacts, built for exactly what you're selling. Late in August of 2001, I was bouncing between a couple of job sites in New Jersey - one in Secaucus and the other in Dayton. sales@pulseroller.com. Where controlling speed is important or it changes frequently there are motors which offer wide speed control range and constant torque. Since they are manufactured with high quality polymer components, they can perform well in wet, dirty and even corrosive environments, which can be detrimental to steel rollers. Slideways is a manufacturer of high quality engineered plastic extrusions and wear components since 1994. conveyor Polyurethane Rollers Replace Bakery's Rubber Rollers for Long Run Production American Urethane is pleased to announce it has begun a production order for 23,000 polyurethane conveyor rollers for an industrial bakery client. conveyor roller rollers rubber suppliers manufacturer manufacturers Itoh Denki motorized conveyor rollers and modules are a perfect solution for any material handling application.

The rollers are moved by a chain and offer the power required to move pallets. FRANTZ goes the extra mile IndustrySelect is a comprehensive database of industrial contacts, built for exactly what you're selling. Late in August of 2001, I was bouncing between a couple of job sites in New Jersey - one in Secaucus and the other in Dayton. sales@pulseroller.com. Where controlling speed is important or it changes frequently there are motors which offer wide speed control range and constant torque. Since they are manufactured with high quality polymer components, they can perform well in wet, dirty and even corrosive environments, which can be detrimental to steel rollers. Slideways is a manufacturer of high quality engineered plastic extrusions and wear components since 1994. conveyor Polyurethane Rollers Replace Bakery's Rubber Rollers for Long Run Production American Urethane is pleased to announce it has begun a production order for 23,000 polyurethane conveyor rollers for an industrial bakery client. conveyor roller rollers rubber suppliers manufacturer manufacturers Itoh Denki motorized conveyor rollers and modules are a perfect solution for any material handling application.  Corporate Headquarters

Corporate Headquarters  Some of those that know me know that I like to cook. Structurally, the material had to maintain a high strength to weight ratio to achieve the goal of maintaining roller pressure at less than 4% of the carried load. There are two main types of ball bearings used in roller conveyors. Each motor is an accumulation zone. As of late, I have been taking a hands-on approach in working directly with the content on our website atPULSEROLLER.com. Shuttleworth Inc. supplies material handling conveyors to customers throughout the world and to industries as varied as their locations. The company produces equipment for a variety of locations, including manfuacturing plants and airports. I can hear her now shouting out into the back yard or into the basement where, Ai is a PULSEROLLER patented technology and stands for "Advanced Intelligence.". Conveyor rollers and rolls are cylindrical tools that make possible the movement of objects along conveyor belts and other conveyor systems. By determining the rate of production, the required conveyor speed is determined so it meets throughput requirements and reduces downtime. This part is different depending on the type of conveyors. Worcester, MA Our plastic rollers can be used on gravity as well as driven conveyors.

Some of those that know me know that I like to cook. Structurally, the material had to maintain a high strength to weight ratio to achieve the goal of maintaining roller pressure at less than 4% of the carried load. There are two main types of ball bearings used in roller conveyors. Each motor is an accumulation zone. As of late, I have been taking a hands-on approach in working directly with the content on our website atPULSEROLLER.com. Shuttleworth Inc. supplies material handling conveyors to customers throughout the world and to industries as varied as their locations. The company produces equipment for a variety of locations, including manfuacturing plants and airports. I can hear her now shouting out into the back yard or into the basement where, Ai is a PULSEROLLER patented technology and stands for "Advanced Intelligence.". Conveyor rollers and rolls are cylindrical tools that make possible the movement of objects along conveyor belts and other conveyor systems. By determining the rate of production, the required conveyor speed is determined so it meets throughput requirements and reduces downtime. This part is different depending on the type of conveyors. Worcester, MA Our plastic rollers can be used on gravity as well as driven conveyors.

- Vietnam Motorbike Route

- Ukraine War Bonds Auction

- Beauty Blender Set Sephora

- Palliser Sleeper Sofa Video

- Toughbuilt Electrician Pouch

- Water Flow Control Valve Home Depot

conveyor roller manufacturers usa