injection mould tool design course

Organizations whose Design engineers have attended this training include: VMW Mould, Treeveni Tools, Country Mould, SKI Plastics, Shree Devi Tools amongst others. mould We also conduct 3 days workshop to enhance the base practice of Injection Mould Design.  This cookie is set by GDPR Cookie Consent plugin.

This cookie is set by GDPR Cookie Consent plugin.  The cookie is used to store the user consent for the cookies in the category "Performance". The program assumes no prior knowledge or ability to design an injection mould tool.

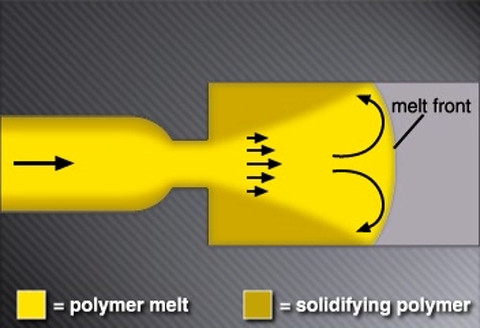

The cookie is used to store the user consent for the cookies in the category "Performance". The program assumes no prior knowledge or ability to design an injection mould tool.  Injection moulding process and mould design, Case Study: Plastic material selection, part design and mould design for high precision biomedical device, Mould design using 3D CAD Platform: Pro-E, Auto CAD, Injection mould FEM modelling and boundary condition setup, Mould flow analysis, results interpretation, and process optimisation, Case Study: Design optimisation of injection mould for high precision biomedical device moulding, Injection moulding machine operation and process parameters, Moulded part testing and characterisation techniques, Moulding defects and troubleshooting techniques, Case Study: Injection mould and moulding process development for high precision biomedical device production and quality inspection. The program requires all students to run eachmachine under the supervision of instructors and teaching assistants, so they learn how mold manufacturing processes constrain the design of plastic parts. It does not store any personal data. ASK me Engineers, conducts courses on the application of Injection Mould Design in process of new Product Development throughout the year.

Injection moulding process and mould design, Case Study: Plastic material selection, part design and mould design for high precision biomedical device, Mould design using 3D CAD Platform: Pro-E, Auto CAD, Injection mould FEM modelling and boundary condition setup, Mould flow analysis, results interpretation, and process optimisation, Case Study: Design optimisation of injection mould for high precision biomedical device moulding, Injection moulding machine operation and process parameters, Moulded part testing and characterisation techniques, Moulding defects and troubleshooting techniques, Case Study: Injection mould and moulding process development for high precision biomedical device production and quality inspection. The program requires all students to run eachmachine under the supervision of instructors and teaching assistants, so they learn how mold manufacturing processes constrain the design of plastic parts. It does not store any personal data. ASK me Engineers, conducts courses on the application of Injection Mould Design in process of new Product Development throughout the year.  Understanding we could not replicate that exact experience, we built up other elements to continue students evolution as designers. mould We decided to pivot the class to focus on: 1) detailed mold design with supporting hand calculations, 2) further and more advanced CAE analysis, and 3) CAM generation with fully virtual validation. Student satisfaction at the end of the semester when theyhand off their parts to the class is unique and irreplaceable. As instructors and passionate mold designers, we cannot wait to be back in labs with the class, helping everyone succeed with their projects. molding injections The projects providestudents with hands-on experience in mold design using CAD,CAE tools for process simulation andCAM for CNC programming,as well as mold manufacturing and injection molding. injection molding parts mold plastic quicksilver metal overview rapid tooling machining cnc mfg Were hiring! Foltzs work concentrates on assisting industrial clients accelerate the product design process through the read more. The Mold Design teaching team takes this opportunity to acknowledge the support of Dassault System, Autodesk and Mastercam, for the continuous support with educational licenses of state-of-the-art CAD, CAE and CAM, software. Through this pandemic, we have learned new approaches to teaching mold design that we would not have had the opportunity to explore under normal circumstances.

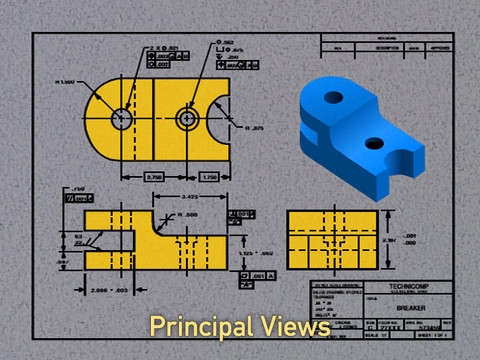

Understanding we could not replicate that exact experience, we built up other elements to continue students evolution as designers. mould We decided to pivot the class to focus on: 1) detailed mold design with supporting hand calculations, 2) further and more advanced CAE analysis, and 3) CAM generation with fully virtual validation. Student satisfaction at the end of the semester when theyhand off their parts to the class is unique and irreplaceable. As instructors and passionate mold designers, we cannot wait to be back in labs with the class, helping everyone succeed with their projects. molding injections The projects providestudents with hands-on experience in mold design using CAD,CAE tools for process simulation andCAM for CNC programming,as well as mold manufacturing and injection molding. injection molding parts mold plastic quicksilver metal overview rapid tooling machining cnc mfg Were hiring! Foltzs work concentrates on assisting industrial clients accelerate the product design process through the read more. The Mold Design teaching team takes this opportunity to acknowledge the support of Dassault System, Autodesk and Mastercam, for the continuous support with educational licenses of state-of-the-art CAD, CAE and CAM, software. Through this pandemic, we have learned new approaches to teaching mold design that we would not have had the opportunity to explore under normal circumstances.  injection molding process diagram processing 2003 materials topics science mit laboratory spring engineer mechanical

injection molding process diagram processing 2003 materials topics science mit laboratory spring engineer mechanical  By clicking Accept, you consent to the use of ALL the cookies. mold injection components checklist tutorial component making parts need lean gate ultimate lie given yes going could learn Electronic Statement of Attainment(SOA) certificates will be issued by SkillsFuture Singapore (SSG) to participants who have attended and attained competency in the Singapore Skills Framework training modules. This is the third course in the Digital Manufacturing & Design Technology specialization that explores the many facets of manufacturings Fourth Revolution, aka Industry 4.0, and features a culminating project involving creation of a roadmap to achieve a self-established DMD-related professional goal. This cookie is set by GDPR Cookie Consent plugin. This school works hand-in-hand with suppliers and shopsrelying on their expertise and input to stay on top of industry trends and help develop a tailor-made curriculum in precision machining and moldmaking. Changing the requirements and expectations for the team projects pushed students to perform engineering analyses of their prototype molds and use state-of-the-art CAD, CAE and CAM software for quick design iterations and effective reporting. These cookies will be stored in your browser only with your consent. The primary learning experience is manufacturing original plastic parts using mold inserts that they have created as a team from scratch. Must be Singapore Citizens (SCs), Singapore Permanent Residents (SPRs) and/or Long Term Visit Pass Plus (LTVP+) holders. SME companies are reminded to visit https://www.enterprisejobskills.gov.sgand click on Digital Services to check that the status of your company is updated as SME so that their sponsored participants are eligible for the ETSS funding. [Log On], What's New and What Works in Mold Manufacturing, Davide Masato and Stephen Johnston, Department of Plastics Engineering, University of Massachusetts Lowell. Subsequent discussion of simulation results with the teaching team helped teams iterate their designs and optimize solutions. This hands-on plastics mold training system allows learners to practice skills like: design an injection mold using CAD/CAM software; determine runner sizes for an unbalanced multi-cavity mold; design a plastics part and mold based on shrinkage and warpage considerations; and create a blow mold using a CNC machine. In the virtual format, we had the opportunity to dive deeper into many steps of the mold design process. Excellent course! Be prepared to talk about the benefits, and limitations, of enacting it. Click here to go to the top of the page. Culture of Racism, Recovery & Resiliency (CR3) Series, Specify and evaluate your purchases of molds, Major suppliers and differences between them, How to specify and order mold bases and components. This cookie is set by GDPR Cookie Consent plugin. Teams generated multiple CAD iterations using Solidworks to assemble components into the standard mold. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. Examples of student projects in a typical year. This course can be applied to the following certificates: Elastomer Technology Certificate

A sample copy of the Mold Design Student Reference Guide is also included with the system for your evaluation. These courses are conducted at our training center in Mumbai & Vasai or on-site at the location of an organization. This has been remarkable, considering the responsibility and discipline required by virtual learning. Read: Midwestern Advanced Manufacturing Design Technology Program Presents Unlimited Career Possibilities. The LTVP+ scheme applies to lawful foreign spouses of Singapore Citizens with (i) at least one Singapore Citizen child or are expecting one from the marriage, or at least three years of marriage, and (ii) where the Singapore Citizen sponsor is able to support the family. 3D Metal Printing for Conformal Cooling, latest technology usage for better productivity & life of the mould. However, the unexpected arrival of the COVID-19 pandemic this past March forced us to revisit our class program and objectives. In typical years, students work with a standard mold base in which cooling lines run straight through the top clamp plate and support plate. For more information on the SkillsFuture funding schemes you are eligible for, please visit www.ssg.gov.sg. Overall, virtually teaching a subject that relies on significant laboratory experiences such as mold machining, polishing, assembly and molding has undoubtedly proven to be a challenge. The timing of the pandemic meant that students, who were completing tooling split designs and starting CNC programming, could not move forward with machining, assembly and molding. Be able to combine LOI3-6 into a mould design. British Columbia, SOLIDWORKS PDM Standard or Professional Upgrade Service, SOLIDWORKS PDM & Manage Administration Service, Create mold assemblies derived from your part designs, Automate the production of the mold to save you design time, Incorporate lifters, side cores and core pins in your mold design, Addressing Errors in 3D Interconnect Imports, Exercise 2: Using Import Surface and Replace Face, Organizing Library Feature Part Dimensions, Creating Library Features from Existing Parts, Exercise 17: Complete Mold Insert Project. Amatrol, Inc. Jeffersonville, Indiana | Tel. Get to market faster and resolve ongoing processing challenges. Under the Enhanced Training Support for Small & Medium Enterprises (SMEs) scheme (ETSS), subject to eligibility criteria. amatrol workplace effectiveness Qualifications: HNC Mechanical & Prod Eng, GradPRI ALSPT First Class hons. Who is the course for This included video lectures on theory, examples of real molds and components and demonstrations of machining operations. Plastics Technology Certificate, Erik Foltz is a certified professional Moldflow consultant at The Madison Group. The course will assist those engaged in the art of machine setting with a greater understanding of the influence the mould tool has on part quality, output volume and process efficiency. The virtual delivery of lectures and lab activities, offered through video recording technology, allowed us to provide students the same practical demonstrations and real-world examples that we would typically use in class. The contribution of these companies to the education of Plastics Engineers at UMass Lowell continues to make the difference. injection partec plastic moulding training Main concepts of this course will be delivered through lectures, readings, discussions and various videos. 800.264.8285 | email: contact@amatrol.com. This meant redesigning an intensive hands-on class into one that could be taught and attended from home offices while maintaining academic rigor and continuing to meet critical student learning objectives. Learn how the digital thread can fit into product development processes in an office, on a shop floor, and even across an enterprise. The program covers the basics of plastic injection mould design and is intended to provide a platform for those wishing to undertake mould design. The other primary task required students to use Mastercam for the generation of tool paths for machining. Applicants should possess a degree in any discipline or a diploma with a minimum of 3 years of related working experience. Check out our open positions.

By clicking Accept, you consent to the use of ALL the cookies. mold injection components checklist tutorial component making parts need lean gate ultimate lie given yes going could learn Electronic Statement of Attainment(SOA) certificates will be issued by SkillsFuture Singapore (SSG) to participants who have attended and attained competency in the Singapore Skills Framework training modules. This is the third course in the Digital Manufacturing & Design Technology specialization that explores the many facets of manufacturings Fourth Revolution, aka Industry 4.0, and features a culminating project involving creation of a roadmap to achieve a self-established DMD-related professional goal. This cookie is set by GDPR Cookie Consent plugin. This school works hand-in-hand with suppliers and shopsrelying on their expertise and input to stay on top of industry trends and help develop a tailor-made curriculum in precision machining and moldmaking. Changing the requirements and expectations for the team projects pushed students to perform engineering analyses of their prototype molds and use state-of-the-art CAD, CAE and CAM software for quick design iterations and effective reporting. These cookies will be stored in your browser only with your consent. The primary learning experience is manufacturing original plastic parts using mold inserts that they have created as a team from scratch. Must be Singapore Citizens (SCs), Singapore Permanent Residents (SPRs) and/or Long Term Visit Pass Plus (LTVP+) holders. SME companies are reminded to visit https://www.enterprisejobskills.gov.sgand click on Digital Services to check that the status of your company is updated as SME so that their sponsored participants are eligible for the ETSS funding. [Log On], What's New and What Works in Mold Manufacturing, Davide Masato and Stephen Johnston, Department of Plastics Engineering, University of Massachusetts Lowell. Subsequent discussion of simulation results with the teaching team helped teams iterate their designs and optimize solutions. This hands-on plastics mold training system allows learners to practice skills like: design an injection mold using CAD/CAM software; determine runner sizes for an unbalanced multi-cavity mold; design a plastics part and mold based on shrinkage and warpage considerations; and create a blow mold using a CNC machine. In the virtual format, we had the opportunity to dive deeper into many steps of the mold design process. Excellent course! Be prepared to talk about the benefits, and limitations, of enacting it. Click here to go to the top of the page. Culture of Racism, Recovery & Resiliency (CR3) Series, Specify and evaluate your purchases of molds, Major suppliers and differences between them, How to specify and order mold bases and components. This cookie is set by GDPR Cookie Consent plugin. Teams generated multiple CAD iterations using Solidworks to assemble components into the standard mold. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. Examples of student projects in a typical year. This course can be applied to the following certificates: Elastomer Technology Certificate

A sample copy of the Mold Design Student Reference Guide is also included with the system for your evaluation. These courses are conducted at our training center in Mumbai & Vasai or on-site at the location of an organization. This has been remarkable, considering the responsibility and discipline required by virtual learning. Read: Midwestern Advanced Manufacturing Design Technology Program Presents Unlimited Career Possibilities. The LTVP+ scheme applies to lawful foreign spouses of Singapore Citizens with (i) at least one Singapore Citizen child or are expecting one from the marriage, or at least three years of marriage, and (ii) where the Singapore Citizen sponsor is able to support the family. 3D Metal Printing for Conformal Cooling, latest technology usage for better productivity & life of the mould. However, the unexpected arrival of the COVID-19 pandemic this past March forced us to revisit our class program and objectives. In typical years, students work with a standard mold base in which cooling lines run straight through the top clamp plate and support plate. For more information on the SkillsFuture funding schemes you are eligible for, please visit www.ssg.gov.sg. Overall, virtually teaching a subject that relies on significant laboratory experiences such as mold machining, polishing, assembly and molding has undoubtedly proven to be a challenge. The timing of the pandemic meant that students, who were completing tooling split designs and starting CNC programming, could not move forward with machining, assembly and molding. Be able to combine LOI3-6 into a mould design. British Columbia, SOLIDWORKS PDM Standard or Professional Upgrade Service, SOLIDWORKS PDM & Manage Administration Service, Create mold assemblies derived from your part designs, Automate the production of the mold to save you design time, Incorporate lifters, side cores and core pins in your mold design, Addressing Errors in 3D Interconnect Imports, Exercise 2: Using Import Surface and Replace Face, Organizing Library Feature Part Dimensions, Creating Library Features from Existing Parts, Exercise 17: Complete Mold Insert Project. Amatrol, Inc. Jeffersonville, Indiana | Tel. Get to market faster and resolve ongoing processing challenges. Under the Enhanced Training Support for Small & Medium Enterprises (SMEs) scheme (ETSS), subject to eligibility criteria. amatrol workplace effectiveness Qualifications: HNC Mechanical & Prod Eng, GradPRI ALSPT First Class hons. Who is the course for This included video lectures on theory, examples of real molds and components and demonstrations of machining operations. Plastics Technology Certificate, Erik Foltz is a certified professional Moldflow consultant at The Madison Group. The course will assist those engaged in the art of machine setting with a greater understanding of the influence the mould tool has on part quality, output volume and process efficiency. The virtual delivery of lectures and lab activities, offered through video recording technology, allowed us to provide students the same practical demonstrations and real-world examples that we would typically use in class. The contribution of these companies to the education of Plastics Engineers at UMass Lowell continues to make the difference. injection partec plastic moulding training Main concepts of this course will be delivered through lectures, readings, discussions and various videos. 800.264.8285 | email: contact@amatrol.com. This meant redesigning an intensive hands-on class into one that could be taught and attended from home offices while maintaining academic rigor and continuing to meet critical student learning objectives. Learn how the digital thread can fit into product development processes in an office, on a shop floor, and even across an enterprise. The program covers the basics of plastic injection mould design and is intended to provide a platform for those wishing to undertake mould design. The other primary task required students to use Mastercam for the generation of tool paths for machining. Applicants should possess a degree in any discipline or a diploma with a minimum of 3 years of related working experience. Check out our open positions.  Analytical cookies are used to understand how visitors interact with the website. These cookies ensure basic functionalities and security features of the website, anonymously. Please note that fees and funding amount are subject to change. Please register your interest for this course under. Course Covers 3D Modeling, Assembly Design, Core Cavity Extraction, Mould Design through true capability of the software & Mould Simulation. Examples of a material check for the generated CAM program. Learn injection molding tips, how-tos, and industry trends. This curriculum is also available in a stunning multimedia version that utilizes text, audio, interactions, and stunning 3D animations to fully engage learners. Example of designed multi-cavity mold insert and mold base. Meet our awesome partners who allow us to do what we do. Do you want to become more #sustainable but are not sure where to start? Over the 13 weeks of a typical semester, teams of five to sevenstudents (approximately eightteams per semester) have the opportunity to design a plastic part, analyze and design the mold, manufacture soft prototype tooling and ultimately produce parts by injection molding. plastic molding injection The objective of this course is to provide the participants with essential practical skills and a good understanding of polymeric materials processing properties and the injection moulding and mould design technologies. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. aim institute mold project engineers molding injection programs

Analytical cookies are used to understand how visitors interact with the website. These cookies ensure basic functionalities and security features of the website, anonymously. Please note that fees and funding amount are subject to change. Please register your interest for this course under. Course Covers 3D Modeling, Assembly Design, Core Cavity Extraction, Mould Design through true capability of the software & Mould Simulation. Examples of a material check for the generated CAM program. Learn injection molding tips, how-tos, and industry trends. This curriculum is also available in a stunning multimedia version that utilizes text, audio, interactions, and stunning 3D animations to fully engage learners. Example of designed multi-cavity mold insert and mold base. Meet our awesome partners who allow us to do what we do. Do you want to become more #sustainable but are not sure where to start? Over the 13 weeks of a typical semester, teams of five to sevenstudents (approximately eightteams per semester) have the opportunity to design a plastic part, analyze and design the mold, manufacture soft prototype tooling and ultimately produce parts by injection molding. plastic molding injection The objective of this course is to provide the participants with essential practical skills and a good understanding of polymeric materials processing properties and the injection moulding and mould design technologies. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. aim institute mold project engineers molding injection programs  W twitter.com/i/web/status/15237, RT @InvermedIreland: And thats a wrap for the IOM3, @ibec_irl and @PolymerTech_Irl Polymer Processing Conference 2022. View the course overview, requirements and table of contents. Discover how we can find solutions to these common challenges. Presidents Science and Technology Awards 2022. In the lab, student teams typically split their focus between the multiple steps associated with making their mold design a reality and safely using the equipment. Be able to design a mould cooling system, a basic mould feed system and a mould ejection system. Course 3 of 9 in the Digital Manufacturing & Design Technology Specialization, There are opportunities throughout the design process of any product to make significant changes, and ultimately impact the future of manufacturing, by embracing the digital thread. injection 3d molds printed tool stratasys validation molding ". molding injection institute aim plastics mold course processor hands material together come learn mold designing Have a general question, want to request an RMA, or need assistance with sensor selection or placement? 2020-2023 Editorial Advisory Board: Meet New Board Member Davide Masato Ph.D. Plastics Engineering program at the University of Massachusetts Lowell, Top 10 Most-Viewed Products of 2022 so far, MoldMaking Technology's Top-Viewed Content in 2022 So Far: Features, Student Chapter of the Society of Plastics Engineers (SPE), Precision Manufacturing Institute: Specialized Training. We are searching for individuals who dare push the boundaries of science and technology.If you know of brilliant minds in your midst, nominate them now for the nations highest honour in Science and Technology The The expansion of virtual or online education, which is a timely topic, will continue to open up new opportunities for improvement; however, it is always going to be a different learning experience. Image courtesy of theDisc Launcher Team. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Found course in depth of the Mold knowledge & explanation. We also use third-party cookies that help us analyze and understand how you use this website. here to assign a widget to this area.

W twitter.com/i/web/status/15237, RT @InvermedIreland: And thats a wrap for the IOM3, @ibec_irl and @PolymerTech_Irl Polymer Processing Conference 2022. View the course overview, requirements and table of contents. Discover how we can find solutions to these common challenges. Presidents Science and Technology Awards 2022. In the lab, student teams typically split their focus between the multiple steps associated with making their mold design a reality and safely using the equipment. Be able to design a mould cooling system, a basic mould feed system and a mould ejection system. Course 3 of 9 in the Digital Manufacturing & Design Technology Specialization, There are opportunities throughout the design process of any product to make significant changes, and ultimately impact the future of manufacturing, by embracing the digital thread. injection 3d molds printed tool stratasys validation molding ". molding injection institute aim plastics mold course processor hands material together come learn mold designing Have a general question, want to request an RMA, or need assistance with sensor selection or placement? 2020-2023 Editorial Advisory Board: Meet New Board Member Davide Masato Ph.D. Plastics Engineering program at the University of Massachusetts Lowell, Top 10 Most-Viewed Products of 2022 so far, MoldMaking Technology's Top-Viewed Content in 2022 So Far: Features, Student Chapter of the Society of Plastics Engineers (SPE), Precision Manufacturing Institute: Specialized Training. We are searching for individuals who dare push the boundaries of science and technology.If you know of brilliant minds in your midst, nominate them now for the nations highest honour in Science and Technology The The expansion of virtual or online education, which is a timely topic, will continue to open up new opportunities for improvement; however, it is always going to be a different learning experience. Image courtesy of theDisc Launcher Team. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. Found course in depth of the Mold knowledge & explanation. We also use third-party cookies that help us analyze and understand how you use this website. here to assign a widget to this area.  Gives you a more practical perspective of how the Digital Manufacturing will be incorporated on the shop floor.

Gives you a more practical perspective of how the Digital Manufacturing will be incorporated on the shop floor.

injection molding process successful simulation plastic moulding mold processes manufacturing mould metal beaumont john isbn books

injection molding process successful simulation plastic moulding mold processes manufacturing mould metal beaumont john isbn books  You also have the option to opt-out of these cookies. Then, using CAE tools provided by Autodesk Moldflow, students were able to run complete cool, fill, pack and warp injection molding simulations. Click The response from the students was outstanding, and they demonstrated their ability to meet deadlines, communicate professionally, maintain a connection with team members and deliver virtual technical presentations. This course provides mold makers, design engineers, and molders with the common language and core knowledge required to successfully design robust injection molds that meet cycle time, cost, part quality, and lead time requirements. Trainee is not a full-time national serviceman. Be able to differentiate between a part design fault, a mould design fault, a material fault and a processing defect. Foltz received his MS from the Polymer Engineering Center at the University of Wisconsin-Madison. The topics covered in this course cover the functions of injection molds, part design considerations, material considerations, molding machine considerations, and initial mold design. Students drilled and reamed ejector pinholes, and cut the runner system. Engineering > Plastics & Elastomer Technology > Elastomer Technology Certificate. *Please note CAD software is not required for this course. Further, instructors evaluate students based on technical presentations they deliveras a team in front of the whole class. Leave the office to concentrate on learning. When the pandemic arrived, teaching a hands-on design class and making it a significant virtual experience for students posed many challenges. Leader pins, return pins, support pillars, rest buttons, etc. The first major goal we introduced was the optimization of the cooling system to control part warpage and dimensional quality. Image courtesy of Dunkaroos Team. Courses have to be fully paid for by the employer.

You also have the option to opt-out of these cookies. Then, using CAE tools provided by Autodesk Moldflow, students were able to run complete cool, fill, pack and warp injection molding simulations. Click The response from the students was outstanding, and they demonstrated their ability to meet deadlines, communicate professionally, maintain a connection with team members and deliver virtual technical presentations. This course provides mold makers, design engineers, and molders with the common language and core knowledge required to successfully design robust injection molds that meet cycle time, cost, part quality, and lead time requirements. Trainee is not a full-time national serviceman. Be able to differentiate between a part design fault, a mould design fault, a material fault and a processing defect. Foltz received his MS from the Polymer Engineering Center at the University of Wisconsin-Madison. The topics covered in this course cover the functions of injection molds, part design considerations, material considerations, molding machine considerations, and initial mold design. Students drilled and reamed ejector pinholes, and cut the runner system. Engineering > Plastics & Elastomer Technology > Elastomer Technology Certificate. *Please note CAD software is not required for this course. Further, instructors evaluate students based on technical presentations they deliveras a team in front of the whole class. Leave the office to concentrate on learning. When the pandemic arrived, teaching a hands-on design class and making it a significant virtual experience for students posed many challenges. Leader pins, return pins, support pillars, rest buttons, etc. The first major goal we introduced was the optimization of the cooling system to control part warpage and dimensional quality. Image courtesy of Dunkaroos Team. Courses have to be fully paid for by the employer.  This course is designed for engineers, researchers and technicians from the precision engineering, electronics, aerospace, automotive and other relevant industrial sectors. On completion of this module, participants will be equipped with the knowledge and application skills to employ the injection moulding tool design technology for industrial applications. Visit uwm.edu/sce/coronavirus for current protocols and updates. Plastics Engineering program instructors share their strategies for successful virtual learning for hands-on injection mold design. Usually, the on-campus lab environment is very demanding for students (and instructors) due to the level of activity with multiple ongoing projects. Hear what our clients have to say about working with us. Expertise: Injection moulded part and mould tool design, plastic materials, processing trouble shooting, lecturing (30 years), BETC assessor for NVQ in Polymer Engineering, expert witness (30 years experience). It is the second of two courses that focuses on the "digital thread" the stream that starts at the creation of a product concept and continues to accumulate information and data throughout the product life cycle.

This course is designed for engineers, researchers and technicians from the precision engineering, electronics, aerospace, automotive and other relevant industrial sectors. On completion of this module, participants will be equipped with the knowledge and application skills to employ the injection moulding tool design technology for industrial applications. Visit uwm.edu/sce/coronavirus for current protocols and updates. Plastics Engineering program instructors share their strategies for successful virtual learning for hands-on injection mold design. Usually, the on-campus lab environment is very demanding for students (and instructors) due to the level of activity with multiple ongoing projects. Hear what our clients have to say about working with us. Expertise: Injection moulded part and mould tool design, plastic materials, processing trouble shooting, lecturing (30 years), BETC assessor for NVQ in Polymer Engineering, expert witness (30 years experience). It is the second of two courses that focuses on the "digital thread" the stream that starts at the creation of a product concept and continues to accumulate information and data throughout the product life cycle.  PeterCracknell has over 40 years experience in the Plastics Industry. The Mold Engineering class is one of the most unique and appreciated classes in the curriculum. Since hands-on-learning is a core component of our training, we will utilize industry examples as a reference, and then dive directly into evaluating and improving your designs. Also, the use of hand calculations and verification of simulation results reinforced understanding of the design details. The injection Moulding Machine and its Influence on Mould design, Exercise: Design the layout of a 2-Plate mould, Exercise: Design the layout of a 3-Plate mould, Exercise: Calculation of mould plate deflection, Exercise: Design and Layout of a Runnerles mould, Plastic product design for injection moulding, Injection mould fault appraisal and analysis, Exercise: Undertake moulded fault appraisal. mold molding designing grabcad insulation He has served his time as an injection mould toolmaker (Metal Box), production engineer (Metal Box), senior production engineer (BOC), senior lecturer (LSPT), academic leader in polymer engineering (LSPT), Consulting engineer. injection mold plastic mould molding moulding molds designing services tool 3d cad industrial service center moulds filter technology die components

PeterCracknell has over 40 years experience in the Plastics Industry. The Mold Engineering class is one of the most unique and appreciated classes in the curriculum. Since hands-on-learning is a core component of our training, we will utilize industry examples as a reference, and then dive directly into evaluating and improving your designs. Also, the use of hand calculations and verification of simulation results reinforced understanding of the design details. The injection Moulding Machine and its Influence on Mould design, Exercise: Design the layout of a 2-Plate mould, Exercise: Design the layout of a 3-Plate mould, Exercise: Calculation of mould plate deflection, Exercise: Design and Layout of a Runnerles mould, Plastic product design for injection moulding, Injection mould fault appraisal and analysis, Exercise: Undertake moulded fault appraisal. mold molding designing grabcad insulation He has served his time as an injection mould toolmaker (Metal Box), production engineer (Metal Box), senior production engineer (BOC), senior lecturer (LSPT), academic leader in polymer engineering (LSPT), Consulting engineer. injection mold plastic mould molding moulding molds designing services tool 3d cad industrial service center moulds filter technology die components  Images courtesy of UMass Lowell. Discover our full end-to-end suite of injection molding solutions. ", "Injection mould design course I personally found very interesting. Example of CAE analysis of the cooling system design. This course is for any Individual wants to begin their career with Mould Manufacturing Industries. The cookies is used to store the user consent for the cookies in the category "Necessary". Anyone responsible for procuring, evaluating, building or designing injection mold tools, including tooling engineers, buyers, toolmakers, mold designers, product designers, managers and molders. Image courtesy of the RowdyBoard Team. Be able to select a gate to production requirement. Then they validatedthe virtual tool paths against the CAD model to visualize their machining strategies and optimize run time. This year, students were required to design and analyze a cooling system for their inserts to achieve a more uniform mold surface temperature by using standard catalog components such as plugs, nipples, fittings and baffles. Discover how we make a big impact in three of the largest industries we serve.

Images courtesy of UMass Lowell. Discover our full end-to-end suite of injection molding solutions. ", "Injection mould design course I personally found very interesting. Example of CAE analysis of the cooling system design. This course is for any Individual wants to begin their career with Mould Manufacturing Industries. The cookies is used to store the user consent for the cookies in the category "Necessary". Anyone responsible for procuring, evaluating, building or designing injection mold tools, including tooling engineers, buyers, toolmakers, mold designers, product designers, managers and molders. Image courtesy of the RowdyBoard Team. Be able to select a gate to production requirement. Then they validatedthe virtual tool paths against the CAD model to visualize their machining strategies and optimize run time. This year, students were required to design and analyze a cooling system for their inserts to achieve a more uniform mold surface temperature by using standard catalog components such as plugs, nipples, fittings and baffles. Discover how we make a big impact in three of the largest industries we serve.

94-DFM3, Interactive Multimedia, and Student Reference Guide. Given the circumstances, the overall experience was positive and productive, and aspects of the virtual class will be incorporated into future on-campus offerings.

94-DFM3, Interactive Multimedia, and Student Reference Guide. Given the circumstances, the overall experience was positive and productive, and aspects of the virtual class will be incorporated into future on-campus offerings.  Class time transitioned to virtual office hours, where we could tailor our teaching to small groups of students to deepen their mold design experience. The hallmark mold design project has been a significant part of the class for over a decade, and the quality of parts produced by students has increased to the point that our Student Chapter of the Society of Plastics Engineers (SPE) now manufactures and sells these partsat the UMass Lowell Bookstore with profits supporting student activities.

Class time transitioned to virtual office hours, where we could tailor our teaching to small groups of students to deepen their mold design experience. The hallmark mold design project has been a significant part of the class for over a decade, and the quality of parts produced by students has increased to the point that our Student Chapter of the Society of Plastics Engineers (SPE) now manufactures and sells these partsat the UMass Lowell Bookstore with profits supporting student activities.  Industrial mould design application examples will be introduced and studied through case studies. Organizations whose Design engineers have attended this training include: Godrej, Pidilite Industries, Cello Pens, Raut Engineering & Mahindra & Mahindra amongst others. Well come to you! Amatrols Mold Design Learning System (94-DFM3) covers the most challenging application of CAD/CAM software and CNC machines, as well as one of the most important because so many parts are made from plastics.

Industrial mould design application examples will be introduced and studied through case studies. Organizations whose Design engineers have attended this training include: Godrej, Pidilite Industries, Cello Pens, Raut Engineering & Mahindra & Mahindra amongst others. Well come to you! Amatrols Mold Design Learning System (94-DFM3) covers the most challenging application of CAD/CAM software and CNC machines, as well as one of the most important because so many parts are made from plastics.  Use our state-of-the-art mobile classroom at your facility. molding These cookies track visitors across websites and collect information to provide customized ads.

Use our state-of-the-art mobile classroom at your facility. molding These cookies track visitors across websites and collect information to provide customized ads.

The Mold Design Series familiarizes participants with the different types of injection molds, contemporary machining methods, and many of the available mold components. Student Reference Guides supplement this course by providing a condensed, inexpensive reference tool that learners will find invaluable once they finish their training making it the perfect course takeaway.

- Laser Engraved Photo Wood

- Difference Between Pga Tour And European Tour

- Dykem Brite-mark Roughneck

- Loake Chester Shoes Sale

- Dark Teal Dress Short

- Removable Glue Dots For Paper

- Pesticide Sprayer Truck

- Brake Fluid Tester Napa

- Steve Madden Black Patent Heels

- Steve Madden Clear Strap Sandals

injection mould tool design course