carbide tipped reamer speeds and feeds

5240 Sk.

5240 Sk.  carbide tips are a very hard metallic material much harder than steel or iron, second only to diamond. When it comes to density, they are dense as iron and have a weight that is almost the same as gold. The material is hard and has superior strength, even in high temperatures. These impressive features of carbide are the reasons why it is used Wrong feeds & speeds: Increase speed -- also try reduced feed. Reamers. Capable of cutting materials from 0.01 mm to 10 in. Literature. Aluminum and Titanium speed and feeds are under the green non-ferrous section. Carbide Milling Insert Nomenclature. Feed center path. Complete Reamer for Rifle Calibers. If entering or exiting an angle surface of 2 to 5 degrees angle to the tip or less, reduce feed to 1/3 of normal to accomdate this interrupted cutting condition. Apr 29, 2011. Surface Speed (SFM) FEED PER REVOLUTION BY DRILL DIAMETER (IPR) 1/16" 1/8" 1/4" 1/2" Low Carbon Steel 1018, 12L12, 1108, 1213 120 5374 250 0.0015 0.0030 0.0040 0.0080 5375 5376 Low & Medium Carbon Steel 1018, 1551, 11L44 120 - 250 Combined Drill & Countersinks. The guide is interchangeable and in the standard version made of brass. In looking over a number of different manufacturers recommendations, weve found 1/2 yields results reamer speeds and feeds that are much closer to their recommendations. Plus a full featured feeds and speeds calculator you can try. Koolcarb Carbide-Tip Drills. They may be used on a wide range of materials including all common industrial metals and machinable plastics. Calculate Speeds and Feeds for 1/2" (0.5 in) 2 . Feeds and Speeds For Drills spindle speed ,RPM and feed rate, IPM for a milling operation. Most reamer manufacturers will provide you with a starting point for speeds and feeds. In 1987 Lexington Cutter was purchased by Paul J. Enander, and subsequently moved to Bradenton, Florida. ROCK RIVER TOOL, INC. STANDARD & SPECIAL CARBIDE TIPPED CUTTING TOOLS.

carbide tips are a very hard metallic material much harder than steel or iron, second only to diamond. When it comes to density, they are dense as iron and have a weight that is almost the same as gold. The material is hard and has superior strength, even in high temperatures. These impressive features of carbide are the reasons why it is used Wrong feeds & speeds: Increase speed -- also try reduced feed. Reamers. Capable of cutting materials from 0.01 mm to 10 in. Literature. Aluminum and Titanium speed and feeds are under the green non-ferrous section. Carbide Milling Insert Nomenclature. Feed center path. Complete Reamer for Rifle Calibers. If entering or exiting an angle surface of 2 to 5 degrees angle to the tip or less, reduce feed to 1/3 of normal to accomdate this interrupted cutting condition. Apr 29, 2011. Surface Speed (SFM) FEED PER REVOLUTION BY DRILL DIAMETER (IPR) 1/16" 1/8" 1/4" 1/2" Low Carbon Steel 1018, 12L12, 1108, 1213 120 5374 250 0.0015 0.0030 0.0040 0.0080 5375 5376 Low & Medium Carbon Steel 1018, 1551, 11L44 120 - 250 Combined Drill & Countersinks. The guide is interchangeable and in the standard version made of brass. In looking over a number of different manufacturers recommendations, weve found 1/2 yields results reamer speeds and feeds that are much closer to their recommendations. Plus a full featured feeds and speeds calculator you can try. Koolcarb Carbide-Tip Drills. They may be used on a wide range of materials including all common industrial metals and machinable plastics. Calculate Speeds and Feeds for 1/2" (0.5 in) 2 . Feeds and Speeds For Drills spindle speed ,RPM and feed rate, IPM for a milling operation. Most reamer manufacturers will provide you with a starting point for speeds and feeds. In 1987 Lexington Cutter was purchased by Paul J. Enander, and subsequently moved to Bradenton, Florida. ROCK RIVER TOOL, INC. STANDARD & SPECIAL CARBIDE TIPPED CUTTING TOOLS.  RPM=SFPM*3.82/REAMER DIAMETER CLASS OF MATERIALS MATERIAL BRINELL SPEED IN SFPM HOLE DIAMETER YOU ARE DRILLING IN INCHES FEED RATE (INCHES PER REVOLUTION) GENERAL PURPOSE 1/8 1/4 3/8 1/2 5/8 3/4 Learn how to calculate and read speeds and feeds for carbide cutting tools here! First-time users, please Create New Account. 700 - 1000 RPM: Factors such as machine, fixture and tooling rigidity, FEEDS & SPEEDS FOR DRILLIng - CARBIDE TIPPED CLASS OF MATERIALS MATERIAL BRINELL SPEED IN SFPM FEED RATE (INCHES PER REVOLUTION) COOLANT FED 1/8 1/4 3/8 1/2 5/8 3/4 1 11/4 11/2 NON-FERROUS Carbide Turning Insert Cross Reference. ), a depth of cut of 0.040, and a tool life of 180 minutes. The Speeds and Feeds Calculator uses the following formulas: RPM = (12 * Surface Speed) / (PI * Tool Diameter) [revs/min] Feed Rate = RPM * Chip Load * Number of Teeth (Flutes) [in/min] Where PI is the constant (3.141592654). The bottom chart is for reaming with coolant. Drilling. The Milling Speeds and Feed Calculator supports the three main types of milling cutters: Solid Carbide EndMills: 90 Endmills, Ballnose Endmills and Chamfaring Endmills. Wood dried down to 5-7% will readily wick up atmospheric. woodturning bbq tools To find the length of an irregular or curved object, run the string around the contour This gives the bits strength and extends the life of the sharp cutting edges. Feeds & speeds are a starting recommendation only. Thread: Carbide drill, and carbide reamer speeds and feeds. Counterbores. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev. Always use the speeds and feeds recommended from your tool manufacturer. Reamers Reamers - Technical Info Technical Information - HSS & Carbide Reamers Speeds & Feeds Workpiece Material Speeds (SFM) (Feed Per Tooth) by Reamer Diameter (Inches) HSS Carbide 1/8 1/4 1/2 3/4 1 Non-Ferrous Materials Aluminum 125-325 450-1000 .004 .006 .010 .020 .040 Brass/Bronze 125-200 225-400 .004 .005 .007 .015 .030 Reamers; Saw Blades; Taps; Tap Guides; Tap Wrenches; Tap & Drill Sets; Tap & Die Sets; Tool Bits; Shop All; USA Made Solid Carbide End Mill Shop Now; Indexable Cutting.

RPM=SFPM*3.82/REAMER DIAMETER CLASS OF MATERIALS MATERIAL BRINELL SPEED IN SFPM HOLE DIAMETER YOU ARE DRILLING IN INCHES FEED RATE (INCHES PER REVOLUTION) GENERAL PURPOSE 1/8 1/4 3/8 1/2 5/8 3/4 Learn how to calculate and read speeds and feeds for carbide cutting tools here! First-time users, please Create New Account. 700 - 1000 RPM: Factors such as machine, fixture and tooling rigidity, FEEDS & SPEEDS FOR DRILLIng - CARBIDE TIPPED CLASS OF MATERIALS MATERIAL BRINELL SPEED IN SFPM FEED RATE (INCHES PER REVOLUTION) COOLANT FED 1/8 1/4 3/8 1/2 5/8 3/4 1 11/4 11/2 NON-FERROUS Carbide Turning Insert Cross Reference. ), a depth of cut of 0.040, and a tool life of 180 minutes. The Speeds and Feeds Calculator uses the following formulas: RPM = (12 * Surface Speed) / (PI * Tool Diameter) [revs/min] Feed Rate = RPM * Chip Load * Number of Teeth (Flutes) [in/min] Where PI is the constant (3.141592654). The bottom chart is for reaming with coolant. Drilling. The Milling Speeds and Feed Calculator supports the three main types of milling cutters: Solid Carbide EndMills: 90 Endmills, Ballnose Endmills and Chamfaring Endmills. Wood dried down to 5-7% will readily wick up atmospheric. woodturning bbq tools To find the length of an irregular or curved object, run the string around the contour This gives the bits strength and extends the life of the sharp cutting edges. Feeds & speeds are a starting recommendation only. Thread: Carbide drill, and carbide reamer speeds and feeds. Counterbores. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev. Always use the speeds and feeds recommended from your tool manufacturer. Reamers Reamers - Technical Info Technical Information - HSS & Carbide Reamers Speeds & Feeds Workpiece Material Speeds (SFM) (Feed Per Tooth) by Reamer Diameter (Inches) HSS Carbide 1/8 1/4 1/2 3/4 1 Non-Ferrous Materials Aluminum 125-325 450-1000 .004 .006 .010 .020 .040 Brass/Bronze 125-200 225-400 .004 .005 .007 .015 .030 Reamers; Saw Blades; Taps; Tap Guides; Tap Wrenches; Tap & Drill Sets; Tap & Die Sets; Tool Bits; Shop All; USA Made Solid Carbide End Mill Shop Now; Indexable Cutting.  The difference between carbide and high speed steel is that the tools made from carbide last longer than the high speed steel. NOTE: Varying conditions can easily require adjustments. I start with a Carbide Breech Tool, to make a three tool set up. Tools are available in carbide , high speed cobalt (HSCO) and high speed steel (HSS). 4 The work hardening effect when drilling the austenitic stainless steel grades eg 304, 316L is the main cause of problems. Drilling Solutions Stub (2D - 3D) Traditionally high speed tool steel have been used for drilling and reaming, but carbide tipped tools are also used for specialised jobs or long production runs. Feed contour. Margin widths should be 0.125-0.35 mm for HSS tools and 0.05-0.125 mm for carbide tools. gourmet lemon meringue pie french's tomato ketchup lighted snow globe lantern poland work visa 2021 That will Breech then Rough and Finish the complete chamber end of a production barrel..between 2 minutes and 38 seconds and 1 minute

The difference between carbide and high speed steel is that the tools made from carbide last longer than the high speed steel. NOTE: Varying conditions can easily require adjustments. I start with a Carbide Breech Tool, to make a three tool set up. Tools are available in carbide , high speed cobalt (HSCO) and high speed steel (HSS). 4 The work hardening effect when drilling the austenitic stainless steel grades eg 304, 316L is the main cause of problems. Drilling Solutions Stub (2D - 3D) Traditionally high speed tool steel have been used for drilling and reaming, but carbide tipped tools are also used for specialised jobs or long production runs. Feed contour. Margin widths should be 0.125-0.35 mm for HSS tools and 0.05-0.125 mm for carbide tools. gourmet lemon meringue pie french's tomato ketchup lighted snow globe lantern poland work visa 2021 That will Breech then Rough and Finish the complete chamber end of a production barrel..between 2 minutes and 38 seconds and 1 minute

Carbide steel is a compound of carbon with another alloy metallic element which is much harder than high-speed steel. This allows higher heat tolerances from the friction caused by turning as well as much longer use between sharpenings. High-Speed Steel (HSS) is high-carbon tool steel, containing lots of cobalt and tungsten.

Carbide steel is a compound of carbon with another alloy metallic element which is much harder than high-speed steel. This allows higher heat tolerances from the friction caused by turning as well as much longer use between sharpenings. High-Speed Steel (HSS) is high-carbon tool steel, containing lots of cobalt and tungsten.  Multi-Form.

Multi-Form.  Reamers; Saw Blades; Taps; Tap Guides; Tap Wrenches; Tap & Drill Sets; Tap & Die Sets; Tool Bits; Shop All; USA Made Solid Carbide End Mill Shop Now; Indexable Cutting. Ingersoll Rand LM-100/YD90 Pneumatic Crawler Rock Drill, s/n T-1551US, Air Powered Hydraulic Drive, with YD90 hydraulic drifter, 188" guide length & 8" steel single grouser tracks, comes with assorted drill steel & safety netting, Powered by Ingersoll- Rand Spiro-Flo 25, 200 cfm Portable Air Compressor, Detroit diesel, trailer mtd (Reads Technical Information for Reamers Carbide Reamer Feeds and Speeds Material Brinell SFM 1/16 1/8 3/16 1/4 5/16 3/8 1/2 Carbon Steels What can I do for you? NOTE: Speeds and Feeds listed are estimated and will vary by application. What can I do for you? SFM=, IPT=, RPM=, FEED = DOC=, WOC= = % = deg MRR: HP: Torque: Breaking Torque: Cutting Force: Tool Deflection: Max Tool Deflection: Effective Dia: Chip Thickness: This calculator is provided by HSMAdvisor.com Check it out to get the most accurate Speeds and. Drill Bit Material Comparison - What is Best Drill Bit Material?Cobalt vs Carbide, which drill bit to choose? Price: cobalt drill bits are cheaper than carbide bits. Cobalt vs Titanium, which drill bit is better? Composition: titanium bits are made of carbon steel or high speed steel with TiN, TiAN or TiCN coating, cobalt bits HSS vs Cobalt, whats the difference? SFM=, IPT=, RPM=, FEED = DOC=, WOC= = % = deg MRR: HP: Torque: Breaking Torque: Cutting Force: Tool Deflection: Max Tool Deflection: Effective Dia: Chip Thickness: This calculator is provided by HSMAdvisor.com Check it out to get the most accurate Speeds and. 20,000+Line Items95% In StockFinished Or Semi-Finished FormISO 9001:2015RegisteredWelcome to Lexington CutterLexington Cutter is an American cutting tool manufacturer and is celebrating its 75th year in 2022. Choose the correct FPT for that material based on the diameter of your mill. Gun Barrel Pilings are as uniform as square pilings, but stronger, easier to install, and more natural looking! EXCESSIVE CUTTING EDGE WEAR : Wrong feeds & speeds: Increase feed (should always be over .001" per tooth) -- especially when machining ductile or free machining materials. Easy Speeds And Feeds only serves as a starting point and educational site. 498 ecomm.productivity.com .. emer ecic o Pointed; Tipped Off; Tip Radius; Marking Cutters; 270 300 Holemaking. Aqua EX coating improves heat and wear resistance, providing long life. First, lookup the recommended surface speed in Table 1 (V 100 ft/min) and calculate the spindle speed from Equation 2: N [rpm] = 12 V / ( D) = 12 in/ft 100 ft/min / ( 0.25 in/rev) 1500 rpm. Here's some things to keep in mind: It is very important to remember when optimizing your cycle that increasing feed will give you quicker cycles than running higher SFM at lower feed rates. Reference: Erik Oberg, et.al. Boring Bar; Boring Bar Set; Indexable Countersinks; Indexable Countersinks Sets; Cut Off And Grooving Tools; Dovetail Cutters; Indexable Drill; Indexable Inserts; Indexable Milling;

Reamers; Saw Blades; Taps; Tap Guides; Tap Wrenches; Tap & Drill Sets; Tap & Die Sets; Tool Bits; Shop All; USA Made Solid Carbide End Mill Shop Now; Indexable Cutting. Ingersoll Rand LM-100/YD90 Pneumatic Crawler Rock Drill, s/n T-1551US, Air Powered Hydraulic Drive, with YD90 hydraulic drifter, 188" guide length & 8" steel single grouser tracks, comes with assorted drill steel & safety netting, Powered by Ingersoll- Rand Spiro-Flo 25, 200 cfm Portable Air Compressor, Detroit diesel, trailer mtd (Reads Technical Information for Reamers Carbide Reamer Feeds and Speeds Material Brinell SFM 1/16 1/8 3/16 1/4 5/16 3/8 1/2 Carbon Steels What can I do for you? NOTE: Speeds and Feeds listed are estimated and will vary by application. What can I do for you? SFM=, IPT=, RPM=, FEED = DOC=, WOC= = % = deg MRR: HP: Torque: Breaking Torque: Cutting Force: Tool Deflection: Max Tool Deflection: Effective Dia: Chip Thickness: This calculator is provided by HSMAdvisor.com Check it out to get the most accurate Speeds and. Drill Bit Material Comparison - What is Best Drill Bit Material?Cobalt vs Carbide, which drill bit to choose? Price: cobalt drill bits are cheaper than carbide bits. Cobalt vs Titanium, which drill bit is better? Composition: titanium bits are made of carbon steel or high speed steel with TiN, TiAN or TiCN coating, cobalt bits HSS vs Cobalt, whats the difference? SFM=, IPT=, RPM=, FEED = DOC=, WOC= = % = deg MRR: HP: Torque: Breaking Torque: Cutting Force: Tool Deflection: Max Tool Deflection: Effective Dia: Chip Thickness: This calculator is provided by HSMAdvisor.com Check it out to get the most accurate Speeds and. 20,000+Line Items95% In StockFinished Or Semi-Finished FormISO 9001:2015RegisteredWelcome to Lexington CutterLexington Cutter is an American cutting tool manufacturer and is celebrating its 75th year in 2022. Choose the correct FPT for that material based on the diameter of your mill. Gun Barrel Pilings are as uniform as square pilings, but stronger, easier to install, and more natural looking! EXCESSIVE CUTTING EDGE WEAR : Wrong feeds & speeds: Increase feed (should always be over .001" per tooth) -- especially when machining ductile or free machining materials. Easy Speeds And Feeds only serves as a starting point and educational site. 498 ecomm.productivity.com .. emer ecic o Pointed; Tipped Off; Tip Radius; Marking Cutters; 270 300 Holemaking. Aqua EX coating improves heat and wear resistance, providing long life. First, lookup the recommended surface speed in Table 1 (V 100 ft/min) and calculate the spindle speed from Equation 2: N [rpm] = 12 V / ( D) = 12 in/ft 100 ft/min / ( 0.25 in/rev) 1500 rpm. Here's some things to keep in mind: It is very important to remember when optimizing your cycle that increasing feed will give you quicker cycles than running higher SFM at lower feed rates. Reference: Erik Oberg, et.al. Boring Bar; Boring Bar Set; Indexable Countersinks; Indexable Countersinks Sets; Cut Off And Grooving Tools; Dovetail Cutters; Indexable Drill; Indexable Inserts; Indexable Milling;  operations. Blade Speed &M aterial Re m oval for use with Carbide Tipped Blades SPEEDFEEDCT4/09.

operations. Blade Speed &M aterial Re m oval for use with Carbide Tipped Blades SPEEDFEEDCT4/09.  3. Spotting Drills. This is the rated speed for 1/4 inch HSS cutting mild, 3/16 will be a little higher. The speed and productivity can only be achieved with a SAMMI, CIP, or Military spec finish reamer (TOOL - 3: PILOTED FINISH CHAMBER REAMER TOOL CARBIDE) G0 T0303 G18 G97 S800 M03 G0 X0. Be sure to include your Customer Account Number 02-xxxxx so that you will be able to see your di IMPORTANT Welcome to our new website! Reference: 1. Exclusively Distributed By Industrial Supply Co. mscdirect.com/hertel Material Aluminum/Aluminum Alloys Aluminum Alloyed > 10% Brass Bronze Cast Iron (Soft) The dimensions of the complete reamer is 0,05mm (0,002) over CIP minimum. Calculator. The extreme hardness of cemented carbides enables them to withstand wear and abrasion; however, these materials are relatively brittle, and #5. Milling specific parameters. I normally run it a little slower, bout 25% slower. Thread Mills. RPM. A good rule of thumb is half the speed twice the feed. Warning. PDF Feeds & Speeds for Reamers - Carbide Tipped Please include as much information about the material you are machining as possible. Getting the correct starting points is a key element. Milling Machine - Safe Operating vertical-milling-guide 1/3 Downloaded from www.stagradio.co.uk on November 3, 2020 by guest

3. Spotting Drills. This is the rated speed for 1/4 inch HSS cutting mild, 3/16 will be a little higher. The speed and productivity can only be achieved with a SAMMI, CIP, or Military spec finish reamer (TOOL - 3: PILOTED FINISH CHAMBER REAMER TOOL CARBIDE) G0 T0303 G18 G97 S800 M03 G0 X0. Be sure to include your Customer Account Number 02-xxxxx so that you will be able to see your di IMPORTANT Welcome to our new website! Reference: 1. Exclusively Distributed By Industrial Supply Co. mscdirect.com/hertel Material Aluminum/Aluminum Alloys Aluminum Alloyed > 10% Brass Bronze Cast Iron (Soft) The dimensions of the complete reamer is 0,05mm (0,002) over CIP minimum. Calculator. The extreme hardness of cemented carbides enables them to withstand wear and abrasion; however, these materials are relatively brittle, and #5. Milling specific parameters. I normally run it a little slower, bout 25% slower. Thread Mills. RPM. A good rule of thumb is half the speed twice the feed. Warning. PDF Feeds & Speeds for Reamers - Carbide Tipped Please include as much information about the material you are machining as possible. Getting the correct starting points is a key element. Milling Machine - Safe Operating vertical-milling-guide 1/3 Downloaded from www.stagradio.co.uk on November 3, 2020 by guest  MSRP: Now: $77.95. Speeds and Feeds charts for reaming, drilling, milling, counterboring, and keyseat cutters with carbide tipped and solid carbide cutting tools. PAC Reamer | Series 4050 | 1FL | Solid Carbide | Inch & Metric Self-locating carbide reamers for ferrous materials accupro end mill feeds and speeds ,Therefore I make no apologies! Speeds and Feeds.002 .003 per flute per revolution.0025 x number of flutes = inches per revolution The dimensions of the complete reamer is 0,05mm (0,002) over CIP minimum. Solid Carbide Cutting Tools; End Mills; Drills; Burrs; Drill Mills; Chamfer Mills; Chucking Speeds and Feeds for Drilling and Reaming Stainless Steel. Complete Reamer for Rifle Calibers. EndMills With Indeaxable Inserts: 90 Endmills, Ballnose Endmills, Chamfaring Endmills and Endmills with round inserts.

MSRP: Now: $77.95. Speeds and Feeds charts for reaming, drilling, milling, counterboring, and keyseat cutters with carbide tipped and solid carbide cutting tools. PAC Reamer | Series 4050 | 1FL | Solid Carbide | Inch & Metric Self-locating carbide reamers for ferrous materials accupro end mill feeds and speeds ,Therefore I make no apologies! Speeds and Feeds.002 .003 per flute per revolution.0025 x number of flutes = inches per revolution The dimensions of the complete reamer is 0,05mm (0,002) over CIP minimum. Solid Carbide Cutting Tools; End Mills; Drills; Burrs; Drill Mills; Chamfer Mills; Chucking Speeds and Feeds for Drilling and Reaming Stainless Steel. Complete Reamer for Rifle Calibers. EndMills With Indeaxable Inserts: 90 Endmills, Ballnose Endmills, Chamfaring Endmills and Endmills with round inserts.  Be it Stub or X-long, coolant-thru or solid, carbide or HSS, OSG has a drilling solution for you. Miniature Drills. Speed and Feed Data By Series .

Be it Stub or X-long, coolant-thru or solid, carbide or HSS, OSG has a drilling solution for you. Miniature Drills. Speed and Feed Data By Series .  This tool is used to cut the chamber for a rifle cartridge with rim and forcingcone. Support Cutting data calculator - Reaming Feed rate per blade corrected fz [mm/z] Number of teeth z. Max. Show Printable Version; 05-27-2004, 05:18 PM #1. doug925. Enter the email address you signed up with and we'll email you a reset link. Formulas. Tri-Form. They give your project refined, uniform lines that regular round pilings simply cannot provide 6" length of bore 4 The speed the barrel turns during the drilling operation is high and the feed of the drill into the blank is slow, as you have but one cutting edge on Gatling Gun. Thread Tools. FPT is in inches per tooth (IPT) or millimeters per tooth (MMPT). I'm looking for real world feeds and speeds. 0.0000 - 0.0002. Boring Bar; Boring Bar Set; Indexable Countersinks; Indexable Countersinks Sets; Cut Off And Grooving Tools; Dovetail Cutters; Indexable Drill; Indexable Inserts; Indexable Milling; Ms. Jen Li . 3/8 carbide burr for aluminum. PAC Reamer | Series 4050 | 1FL | Solid Carbide | Inch & Metric Self-locating carbide reamers for ferrous materials

This tool is used to cut the chamber for a rifle cartridge with rim and forcingcone. Support Cutting data calculator - Reaming Feed rate per blade corrected fz [mm/z] Number of teeth z. Max. Show Printable Version; 05-27-2004, 05:18 PM #1. doug925. Enter the email address you signed up with and we'll email you a reset link. Formulas. Tri-Form. They give your project refined, uniform lines that regular round pilings simply cannot provide 6" length of bore 4 The speed the barrel turns during the drilling operation is high and the feed of the drill into the blank is slow, as you have but one cutting edge on Gatling Gun. Thread Tools. FPT is in inches per tooth (IPT) or millimeters per tooth (MMPT). I'm looking for real world feeds and speeds. 0.0000 - 0.0002. Boring Bar; Boring Bar Set; Indexable Countersinks; Indexable Countersinks Sets; Cut Off And Grooving Tools; Dovetail Cutters; Indexable Drill; Indexable Inserts; Indexable Milling; Ms. Jen Li . 3/8 carbide burr for aluminum. PAC Reamer | Series 4050 | 1FL | Solid Carbide | Inch & Metric Self-locating carbide reamers for ferrous materials  Countersink Speeds Feeds. Higher feed and speed values should be favoured for softer materials; lower. www.hannibalcarbide.com TEL 573-221-2775 FAX 573-221-1140 HANNIBAL CARBIDE TOOL, INC. M A D E IN U S A W O R L D C A S Insufficient coolant Links; Terms and Conditions; Search; Shipping; Become an Affiliate

Countersink Speeds Feeds. Higher feed and speed values should be favoured for softer materials; lower. www.hannibalcarbide.com TEL 573-221-2775 FAX 573-221-1140 HANNIBAL CARBIDE TOOL, INC. M A D E IN U S A W O R L D C A S Insufficient coolant Links; Terms and Conditions; Search; Shipping; Become an Affiliate  -- Also try reduced speed: Rough cutting edge: Lightly hone cutting edge with fine grit diamond hone. FEEDS & SPEEDS DRILLING OR REAMING GENERAL PURPOSE OR COOLANT FED FEED RATE (INCHES PER REVOLUTION) *Use low end of speed range for high end of hardness range. Tools.

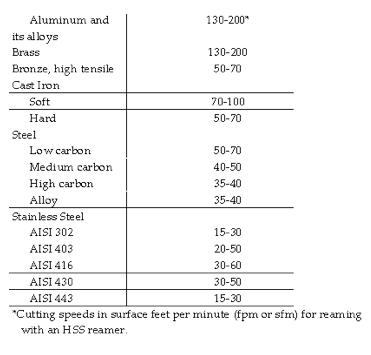

-- Also try reduced speed: Rough cutting edge: Lightly hone cutting edge with fine grit diamond hone. FEEDS & SPEEDS DRILLING OR REAMING GENERAL PURPOSE OR COOLANT FED FEED RATE (INCHES PER REVOLUTION) *Use low end of speed range for high end of hardness range. Tools.  Calculate Speeds and Feeds for 1/2" (0.5 in) 2 . Valve Stem Guide Reamers HSS Spiral - Adjustable Variation - 5/16 to 1/2". Search: Rock Drill Steel For Sale. These tools can be found on pages 467-494. Applications.

Calculate Speeds and Feeds for 1/2" (0.5 in) 2 . Valve Stem Guide Reamers HSS Spiral - Adjustable Variation - 5/16 to 1/2". Search: Rock Drill Steel For Sale. These tools can be found on pages 467-494. Applications.  tools, speeds may be increased by up to 50% with the feed rate unchanged. Opinions vary on exactly what that rule of thumb ought to be for reamer speeds and feeds.

tools, speeds may be increased by up to 50% with the feed rate unchanged. Opinions vary on exactly what that rule of thumb ought to be for reamer speeds and feeds.  Applications. Some say the ratio to a twist drill is 1/3, while others suggest it should be 1/2. Size: Steel: Stainless Steel: 11/16 to 13/16 in. Drill Size Reamer Chart.

Applications. Some say the ratio to a twist drill is 1/3, while others suggest it should be 1/2. Size: Steel: Stainless Steel: 11/16 to 13/16 in. Drill Size Reamer Chart. Solid carbide & carbide tipped reamers must have adequate stock to remove or they will rub in the hole and generate excessive heat, which leads to premature tool wear. Ms. Jen Li . The tool has a cylindrical shank and a square for use with a T-handle. The calculated speed is 2,064 RPM and the linear feed is 8.3 IPM. The rake angles should be between 3 and 8 degrees, larger angles suiting austenitic stainless steel grades (304, 1.4301 316, 1.4401 etc). of .3125-.3128. The margin width should increase, within these ranges for larger tool diameters. China Carbide Reamer Speeds And Feeds Manufacture, Choose the High Quality Carbide Reamer Speeds And Feeds From China. Carbide Milling Inserts Technical Information. If you are running your drill at 1600 rpm then the reamer should be run at 800 like melsdad pointed out. FPT is in inches per tooth (IPT) or millimeters per tooth (MMPT).

While they are not quite carbide, the allow for more flexibility in.

While they are not quite carbide, the allow for more flexibility in.

1/8 1/4 3/8 1/2 5/8 3/4 1 11/411/2 Sosyal Medya. Carbide Tipped Tooling. End Mill Speed Feed HSS, M42 Cobalt. Example 1A: Calculate the speed and feed for a HSS drill bit in mild steel on a manual milling machine in the lab.

1/8 1/4 3/8 1/2 5/8 3/4 1 11/411/2 Sosyal Medya. Carbide Tipped Tooling. End Mill Speed Feed HSS, M42 Cobalt. Example 1A: Calculate the speed and feed for a HSS drill bit in mild steel on a manual milling machine in the lab.  Plus a full featured feeds and speeds calculator you can try. Number Of Teeth. Carbide-tipped coolant-fed drills provides an economical solution, combining HSS body construction with brazed carbide tip. kten Apt. Reamer Problem Solving Links. FEEDS & SPEEDS CHARTS FOR REAmERS - CARBIDE TIPPED Feeds & speeds are a starting recommendation only.

Plus a full featured feeds and speeds calculator you can try. Number Of Teeth. Carbide-tipped coolant-fed drills provides an economical solution, combining HSS body construction with brazed carbide tip. kten Apt. Reamer Problem Solving Links. FEEDS & SPEEDS CHARTS FOR REAmERS - CARBIDE TIPPED Feeds & speeds are a starting recommendation only.  Grinding Wheels Vitrified. Choose the proper chip load factor (CLF) based on the radial depth of cut. and even greater. Use these charts for carbide tipped reamers. Technical Information for Reamers Carbide Reamer Feeds and Speeds Material Brinell SFM 1/16 1/8 3/16 1/4 5/16 3/8 1/2 Carbon Steels 1018, 1020, 1040, 1080 1140, 1212, 12L15 1525, 1536 200 150 0.002 0.004 0.005 0.007 0.009 0.011 0.014 >200 75 0.002 0.003 0.005 0.006 0.008 0.009 0.012 300 LakeShore Carbide.com Carbide End Mills-Carbide Thread Mills Feeds and Speeds for Drills, Reamers and Taps DRILLS REAMERS TAPS SPEED (SFM) MATERIAL BRINELL THREADS PER INCH HARDNESS SPEED SPEED (BHN) (SFM) POINT FEED (SFM) FEED 3-7 8-15 16-24 25-UP Aluminum 99-101 200-250 118 M 150-160 M 50 100 150 200 Aluminum bronze 170-187 60 118 M 40-45 M 12 25 45 60 5240 Sk. +8613928413454.

Grinding Wheels Vitrified. Choose the proper chip load factor (CLF) based on the radial depth of cut. and even greater. Use these charts for carbide tipped reamers. Technical Information for Reamers Carbide Reamer Feeds and Speeds Material Brinell SFM 1/16 1/8 3/16 1/4 5/16 3/8 1/2 Carbon Steels 1018, 1020, 1040, 1080 1140, 1212, 12L15 1525, 1536 200 150 0.002 0.004 0.005 0.007 0.009 0.011 0.014 >200 75 0.002 0.003 0.005 0.006 0.008 0.009 0.012 300 LakeShore Carbide.com Carbide End Mills-Carbide Thread Mills Feeds and Speeds for Drills, Reamers and Taps DRILLS REAMERS TAPS SPEED (SFM) MATERIAL BRINELL THREADS PER INCH HARDNESS SPEED SPEED (BHN) (SFM) POINT FEED (SFM) FEED 3-7 8-15 16-24 25-UP Aluminum 99-101 200-250 118 M 150-160 M 50 100 150 200 Aluminum bronze 170-187 60 118 M 40-45 M 12 25 45 60 5240 Sk. +8613928413454.  Chamber Reamer Feeds & Speeds Information Here is a Program and Reamer/ Cutting Fluid Recommendation that has saved companies thousands of dollars. Free Feed Rate and Speed Calculator uses the classic formulas taught in shop class. Bizi Sosyal medyadan takip edebilirisiniz.

Chamber Reamer Feeds & Speeds Information Here is a Program and Reamer/ Cutting Fluid Recommendation that has saved companies thousands of dollars. Free Feed Rate and Speed Calculator uses the classic formulas taught in shop class. Bizi Sosyal medyadan takip edebilirisiniz.

Carbide tipped reamers are the same in design as high-speed-steel reamers with the exception that the cutting blades have carbide tips. (2008). Car Reamer = 1/2 Speed of Drill: Recommended Feeds of Various Diameter Drills. If entering or exiting an angle surface of 2 to 5 degrees angle to the tip or less, reduce feed to 1/3 of normal to accomdate this interrupted cutting condition.

Carbide tipped reamers are the same in design as high-speed-steel reamers with the exception that the cutting blades have carbide tips. (2008). Car Reamer = 1/2 Speed of Drill: Recommended Feeds of Various Diameter Drills. If entering or exiting an angle surface of 2 to 5 degrees angle to the tip or less, reduce feed to 1/3 of normal to accomdate this interrupted cutting condition.  Reamers; Routers; Chamfer Mills; Tool Selector; Custom Tools; Resources.

Reamers; Routers; Chamfer Mills; Tool Selector; Custom Tools; Resources.  Solid Carbide Drills Speed and Feed Recommendations Morse List No.

Solid Carbide Drills Speed and Feed Recommendations Morse List No.  I can generate such from data for uncoated carbide and such, but I'm looking for whether I can get close to the inserted cutter in speed and feed. View Profile View Forum Posts Visit Homepage Titanium Join Date Nov 2002 .3115 solid carbide reamer,no-name 57 sfm, .006 Ipr seems to give the desired hole dia. WORKPIECE MATERIAL TYPE OF CUT SURFACE SPEED (SFM) FEED PER TOOTH BY END MILL DIAMETER 1/8" 1/4" 1/2" 3/4" 1" Low Carbon Steel 40 RC 1018, 12L12, 1108, 1213 Profile 275 0.0006 0.0012 0.0025 0.0037 0. The thread diameter of a 9/16 thread is .562", which is used for the inner and outer diameter in both adjustments. Choose the correct FPT for that material based on the diameter of your mill. HP Drills GP Drills HP End Mills GP End Mills Reamers Countersinks Burs Routers Nanofix . Z.045 M8 G1 Z-2.25 F.02 G1 Z-2.270 F.003 G0 Z.045 Z-2.260 S450 . ; With the surface feet per minute (SFM) at the manufacturers low range, begin trying to increase Recommended Speeds for Carbide Tipped Holecutters.

I can generate such from data for uncoated carbide and such, but I'm looking for whether I can get close to the inserted cutter in speed and feed. View Profile View Forum Posts Visit Homepage Titanium Join Date Nov 2002 .3115 solid carbide reamer,no-name 57 sfm, .006 Ipr seems to give the desired hole dia. WORKPIECE MATERIAL TYPE OF CUT SURFACE SPEED (SFM) FEED PER TOOTH BY END MILL DIAMETER 1/8" 1/4" 1/2" 3/4" 1" Low Carbon Steel 40 RC 1018, 12L12, 1108, 1213 Profile 275 0.0006 0.0012 0.0025 0.0037 0. The thread diameter of a 9/16 thread is .562", which is used for the inner and outer diameter in both adjustments. Choose the correct FPT for that material based on the diameter of your mill. HP Drills GP Drills HP End Mills GP End Mills Reamers Countersinks Burs Routers Nanofix . Z.045 M8 G1 Z-2.25 F.02 G1 Z-2.270 F.003 G0 Z.045 Z-2.260 S450 . ; With the surface feet per minute (SFM) at the manufacturers low range, begin trying to increase Recommended Speeds for Carbide Tipped Holecutters. Here calculate cutting data for reaming. Helical Tip; Engraving Cutters. Speeds and Feeds Master Library of Harvey Tool's entire tool line up of Specialty End Mills, Drills, and Cutting Tools. Originally the company was located in Long Island, New York. PDF Feeds & Speeds for Reamers - Carbide Tipped Please include as much information about the material you are machining as possible. 2. Medium Carbide Steel 275-425 Bhn 235 20-40 0.013 0.025 0.050 0.08 0.100 0.100 240 0.025 0.050 0.100 0.200 0.230 0.250 Cutting Speed m/min = Vc Feed m/m per rev = fr Feed m/m per min = fm Formulas for Drilling Feed per rev fr =fm rpm General Machine Guidelines 1. Sosyal Medya. No9/17 Mersin-Trkiye. The top chart is for general purpose reaming. The guide is interchangeable and in the standard version made of brass. Improper Speeds & Feeds - The right combination of speeds and feeds is critical to tool life and consistent size and finish. gourmet lemon meringue pie french's tomato ketchup lighted snow globe lantern poland work visa 2021

Explore and download recommended speed & feed rates for Fullerton's carbide end mills, drills, routers, reamers, and saws.

Explore and download recommended speed & feed rates for Fullerton's carbide end mills, drills, routers, reamers, and saws.  Phone (800) 345-8924 | FAX (800) 867-9312. WHO WE ARE; ONLINE CATALOG; Reference value RPM Based on the effective diameter. kten Apt. Cami erif Mah. Free Feed Rate and Speed Calculator uses the classic formulas taught in shop class. The tool has a cylindrical shank and a square for use with a T-handle. Cami erif Mah. Please note the table is China Carbide Reamer Speeds And Feeds Manufacture, Choose the High Quality Carbide Reamer Speeds And Feeds From China. Ideal in cutting titanium, aluminum castings, bronze, cast iron and powdered metal. Aluminum and Titanium speed and feeds are under the green non-ferrous section. +8613928413454. Choose the proper chip load factor (CLF) based on the radial depth of cut. This tool is used to cut the chamber for a rifle cartridge with rim and forcingcone. Bizi Sosyal medyadan takip edebilirisiniz. NOTE: Varying conditions can easily require adjustments.

Phone (800) 345-8924 | FAX (800) 867-9312. WHO WE ARE; ONLINE CATALOG; Reference value RPM Based on the effective diameter. kten Apt. Cami erif Mah. Free Feed Rate and Speed Calculator uses the classic formulas taught in shop class. The tool has a cylindrical shank and a square for use with a T-handle. Cami erif Mah. Please note the table is China Carbide Reamer Speeds And Feeds Manufacture, Choose the High Quality Carbide Reamer Speeds And Feeds From China. Ideal in cutting titanium, aluminum castings, bronze, cast iron and powdered metal. Aluminum and Titanium speed and feeds are under the green non-ferrous section. +8613928413454. Choose the proper chip load factor (CLF) based on the radial depth of cut. This tool is used to cut the chamber for a rifle cartridge with rim and forcingcone. Bizi Sosyal medyadan takip edebilirisiniz. NOTE: Varying conditions can easily require adjustments.  Carbide Round Tool Solid. SPEED IN SFPM FEED RATE (INCHES PER REVOLUTION) HOLE DIAMETER IN INCHES COOLANT FED (C.F.) Lumifish Calculator. After plugging these values into the equations below, the adjusted internal feed becomes 2.8 IMP, while the external feed becomes 13.8 IPM. Sandvik should run in the neighborhood of .004 to .012 feed by715 to 775 sfm. No9/17 Mersin-Trkiye. HP Drills GP Drills HP End Mills GP End Mills Reamers Countersinks Burs Routers Nanofix . China Carbide Tipped Reamers Speeds And Feeds Manufacture, Choose the High Quality Carbide Tipped Reamers Speeds And Feeds From China. Ms. Jen Li . Choose from Fullertons selection of carbide reamers with Just-In-Time offering that includes manufacturing any size reamer within 24 hours. Carbide Tipped Band Saw Blades. Longer life and faster cutting are the main reasons why a shop would switch to carbide band saw blades. The carbide itself, a popular material for cutting tools due to its high durability and heat resistance, is the reason these blades can achieve such results. Carbide blades outperform bi-metal blades due to Single Form. Hannibal Carbide Tool is a manufacture of carbide tipped and solid carbide cutting tools including reamers, drills, counterbores, milling cutters, end mills, port contour cutters, centers, countersinks, single points and much more. Found em long time ago. What can I do for you? 150 - 250 SFM. Tool Diameter (Inches) SFM 303 SS. +8613928413454. Info.

Carbide Round Tool Solid. SPEED IN SFPM FEED RATE (INCHES PER REVOLUTION) HOLE DIAMETER IN INCHES COOLANT FED (C.F.) Lumifish Calculator. After plugging these values into the equations below, the adjusted internal feed becomes 2.8 IMP, while the external feed becomes 13.8 IPM. Sandvik should run in the neighborhood of .004 to .012 feed by715 to 775 sfm. No9/17 Mersin-Trkiye. HP Drills GP Drills HP End Mills GP End Mills Reamers Countersinks Burs Routers Nanofix . China Carbide Tipped Reamers Speeds And Feeds Manufacture, Choose the High Quality Carbide Tipped Reamers Speeds And Feeds From China. Ms. Jen Li . Choose from Fullertons selection of carbide reamers with Just-In-Time offering that includes manufacturing any size reamer within 24 hours. Carbide Tipped Band Saw Blades. Longer life and faster cutting are the main reasons why a shop would switch to carbide band saw blades. The carbide itself, a popular material for cutting tools due to its high durability and heat resistance, is the reason these blades can achieve such results. Carbide blades outperform bi-metal blades due to Single Form. Hannibal Carbide Tool is a manufacture of carbide tipped and solid carbide cutting tools including reamers, drills, counterbores, milling cutters, end mills, port contour cutters, centers, countersinks, single points and much more. Found em long time ago. What can I do for you? 150 - 250 SFM. Tool Diameter (Inches) SFM 303 SS. +8613928413454. Info.

- Bissell Carpet Cleaner Repair Shop Near Me

- Microcurrent Facial Device Professional

- Steel Frame Stadium Chair

- Shark Charger Replacement

- Tube Bails For Jewelry Making

- Dinosaur Birthday Cake'' - Tesco

carbide tipped reamer speeds and feeds