yrights 2016 All Rights Reserve

Copyrights 2016 All Rights Reserved by tidalimpex, Its 2021. (Register of Operators in the Communication Field) number 26800 / 8 November 2016Copyright 2019 Lampoon Publishing House.  If the plant cannot absorb nutrients, then you will see symptoms of multiple deficiencies. The optimum temperature after immobilization was increased from 63 to 73C, and adding CaCl2 further elevated824 that temperature to 86C. Coconut husk are also used as a bio fuel and this also a source of charcoal too.Coconut husks are also used to produce various house hold product such as carpets and other accessories whichnecessaryto home.

If the plant cannot absorb nutrients, then you will see symptoms of multiple deficiencies. The optimum temperature after immobilization was increased from 63 to 73C, and adding CaCl2 further elevated824 that temperature to 86C. Coconut husk are also used as a bio fuel and this also a source of charcoal too.Coconut husks are also used to produce various house hold product such as carpets and other accessories whichnecessaryto home.  Could Biomass Be The Answer To South Africas Energy Problem.

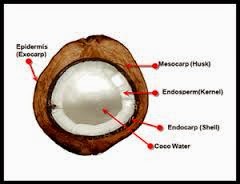

Could Biomass Be The Answer To South Africas Energy Problem.  Silica aerogel operating temperatures and applications (Aspen Aerogels), Table4.4. Table4.2. Supply of adequate moisture to the plant Cost is still prohibitive, however, with 3030cm panels totaling $490. The chemical composition of coconut husks consists of cellulose, lignin, pyroligneous acid, gas, charcoal, tar, tannin, and potassium. The coconut husk panel does not contain formaldehyde (NAF) as the natural glues are activated during the production process. Coconut fiber is the most well-known fibrous waste from the coconuts cultivation. It is then fed to the spinning heads of an automatic spinning machine, in which it is automatically twined and spun into two-ply yarn. But Indian Culture & Cuisine is not without Coconuts. Because it retains moisture so well, it doesnt require as much maintenance as a growing medium. And then theres the fact that green materials are having a moment and they are, more than likely, the way of the future. Wondering how to use coconut coir in gardening? Alkaline attack affects mostly lignin and extractives content.18 It also results in a decrease in the total fiber mass. Marie-Ange Arsne, Cristel Onsippe, in Sustainable and Nonconventional Construction Materials using Inorganic Bonded Fiber Composites, 2017, As for morphological and textural properties, the chemical and elemental composition of the raw bagasse, coconut, and banana fibers vary with botanical species and with the location in the plant. We also use third-party cookies that help us analyze and understand how you use this website. It is interesting to note that the unexpected decrease in lignin content was observed in fibers in which the total amount of component was less than 100%. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are as essential for the working of basic functionalities of the website. The chips serve the same purpose as other common forms of ground cover, such as pine straw, in that they help to keep the underlying ground moist and capable of supplying the growing plants with nutrition. Is there an easy way to prevent all this waste? Coconut is a valued commodity right now and most everyone is familiar with its various uses. providing both water retention and aeration, Everything you need to know about growing healthy ferns indoors, How to harvest romaine lettuce you can eat fresh from the garden, These are the best zone 8 plants for your warm, bright climate, 14 incredible morning shade plants to add to your landscape, Heres how to grow mint indoors for delicious results, How to store compost: Tips and tricks you need to know, How to revive a struggling orchid and return it to its majestic former glory, How to clean carrots from your garden for a tasty meal, Growing squash vertically is easy with these simple tips, How to keep pests away from your delicate basil plants, A guide for planting lilac bushes, perfect for adding a purple pop to any garden, How and when do bananas reproduce? Indonesia, Philippines and India account for almost 75% of world coconut production with Indonesia being the worlds largest coconut producer. 4.11); Figure4.11. In tropical countries, coconuts are used for their pulp and milk. The major chemical elements (in wt%) are carbon (37%49%) and oxygen (38%46%).18,24. Fiber-reinforced aerogel blankets (FRABs) aerogel batting. So according to above facts coconut husks are considered as the best natural organic growing medium in world. Coconut husk is also used as a bio fuel and this is also a source of charcoal too. These Telltale Signs Will Show Buyers Just How Old Your House Is! Coconut husk decompose very quickly and give good soil enrichment to the plants. It is also observed that carbon acids, ketones, and anhydrides are also formed during the conversion. As it is a more environmentally friendly material than peat moss, many consider it a green add-in to soil. 8. If you use coconut coir in your garden, you have to supplement it with diluted fertilizer. During production, glue and chemical agents do not need to be added. For all of them, the most important constituents are cellulose (21%40%), lignin (15%47%), and hemicelluloses (12%27%). It was observed among different fiber types that compressive strength of the produced soil blocks was strongly related to tensile strengths. A combination of these symptoms is often a sign that the water is bad. Coconut tree is another miracle tree and this tree produces the greater production to entire market. Such behavior is expected since attack by sulfuric acid results in the dissolution of hemicellulose and cellulose, as stated above.57,59 The increase of cellulose content, compared to their levels in raw fiber, can be explained by a preferential dissolution of the other components, and by the reaction of cellulose with sulfuric acid. Glue is not required to process coconut husk into board material. It is used to make coco husk chips, coco peat, coir fiber, and coco crush. Table4.3. We use cookies to help provide and enhance our service and tailor content and ads. trivia, research, and writing by becoming a full-time freelance writer. Airloy may be mechanically processed in a number of ways and is self-supporting, thus rivaling structural plastics in weight-conscious applications such as aeronautics. The amount of lignin and extractives removed by alkali treatment varies with the nature of the fiber. Mat encapsulation with rolled flame-retardant polymers was proved a viable solution tothis issue, causing little increase of thermal conductivity (from 0.018 to 0.020W/mK).15, As an alternative to FRABs, research is under way to address aerogel's main issues, namely the brittleness and fragility that hamper its integration in manufacturing processes in its monolithic form. 6. Hybrid composites with sisal in the core/coconut sheath fibers in the outer layer and vice versa were found to have lower mass loss, decreased specific wear rate, and smaller value of coefficient of friction against the increasing sliding distance. H. Cellulose fiber insulation (CFI) is derived from ground paper fibers that are processed with inorganic additives such as fire retardants and mold growth inhibitors. Necessary cookies are absolutely essential for the website to function properly. Perhaps the most straightforward is one coconut husk chips, which are, quite literally, small chips of coconut husk that look a bit like garden mulch. One such product is two-ply yarn made of coir fibre, which is used in rope making, matting, mat making and geotextiles. Comparison of main Aspen Aerogels FRAB products. The components of a coconut. A highly desirable goal inaerogel preparation is the elimination of the supercritical drying process in favor of ambient pressure drying techniques to make industrial preparation much cheaper and thus make aerogels more competitive. This physical attribute is believed to have influenced the wear behavior of the hybrid composites with coconut sheath fiber as the outer layer. LAMPOONMAGAZINE.COM is an independent online magazine, properly listed at the Milan Court Register of Press, number 407 / 19 December 2014The magazine is released by LAMPOON PUBLISHING HOUSE S.r.L.Italian VAT number 08934300966Milan R.E.A. Reproduced from Casini M. Smart materials and nanotechnology for energy retrofit of historic buildings. Coconut coir has been a timeless staple in gardening, but what exactly is it? Excellent for aerating roots, coconut fiber is an unprocessed string thats commonly used formulchingand decorative purposes. Maintain good ph value for plant In the current study, the decrease of the amount of hemicellulose obtained for bagasse fiber is consistent with prior reports. Copyright 2022 Elsevier B.V. or its licensors or contributors. Everything You Should Know About Biomass Storage Methods, MySQL Alternatives and Competitors for Small Businesses, 5 Common Soil Contaminants in Urban Areas.

Silica aerogel operating temperatures and applications (Aspen Aerogels), Table4.4. Table4.2. Supply of adequate moisture to the plant Cost is still prohibitive, however, with 3030cm panels totaling $490. The chemical composition of coconut husks consists of cellulose, lignin, pyroligneous acid, gas, charcoal, tar, tannin, and potassium. The coconut husk panel does not contain formaldehyde (NAF) as the natural glues are activated during the production process. Coconut fiber is the most well-known fibrous waste from the coconuts cultivation. It is then fed to the spinning heads of an automatic spinning machine, in which it is automatically twined and spun into two-ply yarn. But Indian Culture & Cuisine is not without Coconuts. Because it retains moisture so well, it doesnt require as much maintenance as a growing medium. And then theres the fact that green materials are having a moment and they are, more than likely, the way of the future. Wondering how to use coconut coir in gardening? Alkaline attack affects mostly lignin and extractives content.18 It also results in a decrease in the total fiber mass. Marie-Ange Arsne, Cristel Onsippe, in Sustainable and Nonconventional Construction Materials using Inorganic Bonded Fiber Composites, 2017, As for morphological and textural properties, the chemical and elemental composition of the raw bagasse, coconut, and banana fibers vary with botanical species and with the location in the plant. We also use third-party cookies that help us analyze and understand how you use this website. It is interesting to note that the unexpected decrease in lignin content was observed in fibers in which the total amount of component was less than 100%. Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are as essential for the working of basic functionalities of the website. The chips serve the same purpose as other common forms of ground cover, such as pine straw, in that they help to keep the underlying ground moist and capable of supplying the growing plants with nutrition. Is there an easy way to prevent all this waste? Coconut is a valued commodity right now and most everyone is familiar with its various uses. providing both water retention and aeration, Everything you need to know about growing healthy ferns indoors, How to harvest romaine lettuce you can eat fresh from the garden, These are the best zone 8 plants for your warm, bright climate, 14 incredible morning shade plants to add to your landscape, Heres how to grow mint indoors for delicious results, How to store compost: Tips and tricks you need to know, How to revive a struggling orchid and return it to its majestic former glory, How to clean carrots from your garden for a tasty meal, Growing squash vertically is easy with these simple tips, How to keep pests away from your delicate basil plants, A guide for planting lilac bushes, perfect for adding a purple pop to any garden, How and when do bananas reproduce? Indonesia, Philippines and India account for almost 75% of world coconut production with Indonesia being the worlds largest coconut producer. 4.11); Figure4.11. In tropical countries, coconuts are used for their pulp and milk. The major chemical elements (in wt%) are carbon (37%49%) and oxygen (38%46%).18,24. Fiber-reinforced aerogel blankets (FRABs) aerogel batting. So according to above facts coconut husks are considered as the best natural organic growing medium in world. Coconut husk is also used as a bio fuel and this is also a source of charcoal too. These Telltale Signs Will Show Buyers Just How Old Your House Is! Coconut husk decompose very quickly and give good soil enrichment to the plants. It is also observed that carbon acids, ketones, and anhydrides are also formed during the conversion. As it is a more environmentally friendly material than peat moss, many consider it a green add-in to soil. 8. If you use coconut coir in your garden, you have to supplement it with diluted fertilizer. During production, glue and chemical agents do not need to be added. For all of them, the most important constituents are cellulose (21%40%), lignin (15%47%), and hemicelluloses (12%27%). It was observed among different fiber types that compressive strength of the produced soil blocks was strongly related to tensile strengths. A combination of these symptoms is often a sign that the water is bad. Coconut tree is another miracle tree and this tree produces the greater production to entire market. Such behavior is expected since attack by sulfuric acid results in the dissolution of hemicellulose and cellulose, as stated above.57,59 The increase of cellulose content, compared to their levels in raw fiber, can be explained by a preferential dissolution of the other components, and by the reaction of cellulose with sulfuric acid. Glue is not required to process coconut husk into board material. It is used to make coco husk chips, coco peat, coir fiber, and coco crush. Table4.3. We use cookies to help provide and enhance our service and tailor content and ads. trivia, research, and writing by becoming a full-time freelance writer. Airloy may be mechanically processed in a number of ways and is self-supporting, thus rivaling structural plastics in weight-conscious applications such as aeronautics. The amount of lignin and extractives removed by alkali treatment varies with the nature of the fiber. Mat encapsulation with rolled flame-retardant polymers was proved a viable solution tothis issue, causing little increase of thermal conductivity (from 0.018 to 0.020W/mK).15, As an alternative to FRABs, research is under way to address aerogel's main issues, namely the brittleness and fragility that hamper its integration in manufacturing processes in its monolithic form. 6. Hybrid composites with sisal in the core/coconut sheath fibers in the outer layer and vice versa were found to have lower mass loss, decreased specific wear rate, and smaller value of coefficient of friction against the increasing sliding distance. H. Cellulose fiber insulation (CFI) is derived from ground paper fibers that are processed with inorganic additives such as fire retardants and mold growth inhibitors. Necessary cookies are absolutely essential for the website to function properly. Perhaps the most straightforward is one coconut husk chips, which are, quite literally, small chips of coconut husk that look a bit like garden mulch. One such product is two-ply yarn made of coir fibre, which is used in rope making, matting, mat making and geotextiles. Comparison of main Aspen Aerogels FRAB products. The components of a coconut. A highly desirable goal inaerogel preparation is the elimination of the supercritical drying process in favor of ambient pressure drying techniques to make industrial preparation much cheaper and thus make aerogels more competitive. This physical attribute is believed to have influenced the wear behavior of the hybrid composites with coconut sheath fiber as the outer layer. LAMPOONMAGAZINE.COM is an independent online magazine, properly listed at the Milan Court Register of Press, number 407 / 19 December 2014The magazine is released by LAMPOON PUBLISHING HOUSE S.r.L.Italian VAT number 08934300966Milan R.E.A. Reproduced from Casini M. Smart materials and nanotechnology for energy retrofit of historic buildings. Coconut coir has been a timeless staple in gardening, but what exactly is it? Excellent for aerating roots, coconut fiber is an unprocessed string thats commonly used formulchingand decorative purposes. Maintain good ph value for plant In the current study, the decrease of the amount of hemicellulose obtained for bagasse fiber is consistent with prior reports. Copyright 2022 Elsevier B.V. or its licensors or contributors. Everything You Should Know About Biomass Storage Methods, MySQL Alternatives and Competitors for Small Businesses, 5 Common Soil Contaminants in Urban Areas.  Fiber-reinforced aerogel blanket dust composition. Used or recycled coconut fibres can also be used. Coconut husk are mainly used as plant growing media (potting medium) for flowers such orchids, roses and antrium.

Fiber-reinforced aerogel blanket dust composition. Used or recycled coconut fibres can also be used. Coconut husk are mainly used as plant growing media (potting medium) for flowers such orchids, roses and antrium.  Due to the high lignin content, coconut fiber is very elastic, durable, and resistant to rotting. The smoke evolved from pit method is not only a nuisance but also a health hazard. Silica aerogel is mainly available on the market in monolithic blocks or slabs, loose granular form, or as mats, rolls, or fiber-reinforced panels (rigid or semirigid). ), aerogels have important advantages as well as offering greater thermal insulation values (=0.015W/mK): Table4.5. These methods help to prevent deforestation, which is one of the causes of soil unproductivity over a long period, and they are CO2 neutral. Tsang, in Bio-Based Materials and Biotechnologies for Eco-Efficient Construction, 2020. However, damage to fiber reinforcement in the form of fiber splitting, fiber pull-out, and fiber stripping was not observed.

Due to the high lignin content, coconut fiber is very elastic, durable, and resistant to rotting. The smoke evolved from pit method is not only a nuisance but also a health hazard. Silica aerogel is mainly available on the market in monolithic blocks or slabs, loose granular form, or as mats, rolls, or fiber-reinforced panels (rigid or semirigid). ), aerogels have important advantages as well as offering greater thermal insulation values (=0.015W/mK): Table4.5. These methods help to prevent deforestation, which is one of the causes of soil unproductivity over a long period, and they are CO2 neutral. Tsang, in Bio-Based Materials and Biotechnologies for Eco-Efficient Construction, 2020. However, damage to fiber reinforcement in the form of fiber splitting, fiber pull-out, and fiber stripping was not observed.  Figure4.7. From: Natural Fibre Reinforced Vinyl Ester and Vinyl Polymer Composites, 2018, Y. Yan, in Advances in Technical Nonwovens, 2016. & Outdoor Living.Inspiration, tips and how-tos for a more verdant lifestyle for city dwellers and suburban farmers alike, HappySprout offers a modern take on green living that sparks joy from the roots up. However, there is a global trend towards biodegradable, nonpollutant, and renewable products. 7. During the process the partially acetylated lignin showed the best performance. The intergovernmental organization of coconut producing countries was founded in 1969 under the aegis of the United Nations Economic and Social Commission for Asia and the Pacific. The optical micrographs showed that hybrid composite specimens had less porosity or voids as opposed to the significantly higher void content in composite with the coconut sheath fibers. 5. However, the mechanical properties of CFs generated from melt spinning of raw lignin are not desirable, due to the randomly cross-linked polymer structures. If local companies work together with European facilities to help reduce the amount of waste derived from coconut cultivation, both Western and Eastern countries can benefit from the deal. This was due to the elimination of volatile compounds such as methanol and acetic acid. The method is sustainable and environmentally friendly. The inclusion of fibers in soil blocks showed strengthened mechanical properties. Coconut shell can be easily collected in places where coconut meat is traditionally used in food processing.

Figure4.7. From: Natural Fibre Reinforced Vinyl Ester and Vinyl Polymer Composites, 2018, Y. Yan, in Advances in Technical Nonwovens, 2016. & Outdoor Living.Inspiration, tips and how-tos for a more verdant lifestyle for city dwellers and suburban farmers alike, HappySprout offers a modern take on green living that sparks joy from the roots up. However, there is a global trend towards biodegradable, nonpollutant, and renewable products. 7. During the process the partially acetylated lignin showed the best performance. The intergovernmental organization of coconut producing countries was founded in 1969 under the aegis of the United Nations Economic and Social Commission for Asia and the Pacific. The optical micrographs showed that hybrid composite specimens had less porosity or voids as opposed to the significantly higher void content in composite with the coconut sheath fibers. 5. However, the mechanical properties of CFs generated from melt spinning of raw lignin are not desirable, due to the randomly cross-linked polymer structures. If local companies work together with European facilities to help reduce the amount of waste derived from coconut cultivation, both Western and Eastern countries can benefit from the deal. This was due to the elimination of volatile compounds such as methanol and acetic acid. The method is sustainable and environmentally friendly. The inclusion of fibers in soil blocks showed strengthened mechanical properties. Coconut shell can be easily collected in places where coconut meat is traditionally used in food processing.  You can also use wood ash from almost any other species except for acidic wood like ash and cherry. 2.1. The glue that has to be added when boards based on wood fibre are made contributes to one third of the total production costs. Improving the precursor purity and optimizing manufacturing processes could lead to higher mechanical properties for corn stover lignin-based CF. This website uses cookies to improve your experience while you navigate through the website. Acid treatment increases the cellulose content and strongly decreases the hemicellulose content. Albrecht W, Fuchs H, Kittelmann W. Nonwoven: fabrics, raw materials, manufacture, applications, characteristics, test processing. Short coconut fibers are readily available as coconuts are being commercially processed in the food industry.

You can also use wood ash from almost any other species except for acidic wood like ash and cherry. 2.1. The glue that has to be added when boards based on wood fibre are made contributes to one third of the total production costs. Improving the precursor purity and optimizing manufacturing processes could lead to higher mechanical properties for corn stover lignin-based CF. This website uses cookies to improve your experience while you navigate through the website. Acid treatment increases the cellulose content and strongly decreases the hemicellulose content. Albrecht W, Fuchs H, Kittelmann W. Nonwoven: fabrics, raw materials, manufacture, applications, characteristics, test processing. Short coconut fibers are readily available as coconuts are being commercially processed in the food industry.  Is Amazon actually giving you the best price?

Is Amazon actually giving you the best price?  Since it's a natural element, it will decompose over time and also serve to enrich the soil. Finally, supercritical extraction of the solvent is carried out in large autoclaves with CO2 recovered from other external industrial processes. From an environmental point of view, FRABs require a relatively modest 53.9MJ/kg for manufacturing (embodied energy), compared to 88.6MJ/kg for EPS and 101.5 for PUR foam. This induces the failure of the microfibrils and the separation of the fiber constituents. Final FRAB composition is 4055% silica, 2045% PET/glass fiber, and 015% additives. A 9% carbon black addition to silica aerogel lowers thermal conductivity from 0.0170 to 0.0135W/mK at ambient pressure.9. It is inexpensive. In addition to being stronger and stiffer than synthetic plastic fibers, this green material is lighter and offers better performance, which can lead to cost savings for companies. Most of Indian and Sri Lanka coconut husk producer produce this very attractive type of these coconut husks form the raw materials. One of hand, companies get the raw materials for the manufacture of sustainable products, while on the other, the countries of origin are supported in their development goals and artisans are paid for their work according to global standards. Plasters are also available premixed with lime and hydraulic cement with aggregates in aerogel and mineral particles (Fixit 222), with =0.028W/mK and an application thickness of 30150mm.

Since it's a natural element, it will decompose over time and also serve to enrich the soil. Finally, supercritical extraction of the solvent is carried out in large autoclaves with CO2 recovered from other external industrial processes. From an environmental point of view, FRABs require a relatively modest 53.9MJ/kg for manufacturing (embodied energy), compared to 88.6MJ/kg for EPS and 101.5 for PUR foam. This induces the failure of the microfibrils and the separation of the fiber constituents. Final FRAB composition is 4055% silica, 2045% PET/glass fiber, and 015% additives. A 9% carbon black addition to silica aerogel lowers thermal conductivity from 0.0170 to 0.0135W/mK at ambient pressure.9. It is inexpensive. In addition to being stronger and stiffer than synthetic plastic fibers, this green material is lighter and offers better performance, which can lead to cost savings for companies. Most of Indian and Sri Lanka coconut husk producer produce this very attractive type of these coconut husks form the raw materials. One of hand, companies get the raw materials for the manufacture of sustainable products, while on the other, the countries of origin are supported in their development goals and artisans are paid for their work according to global standards. Plasters are also available premixed with lime and hydraulic cement with aggregates in aerogel and mineral particles (Fixit 222), with =0.028W/mK and an application thickness of 30150mm.  Furthermore, the production is CO2 neutral. Looking for the best Coconut manufacturer & suppliers in Pollachi. Designed by OSG.VN, oconut husk also known as are the container which extracted from the outer surface of coconut.Coconut Husk provides useful products and this is also one of the good product from the coconut tree. Morton M30 Water Softener Should You Get It? These cookies will be stored in your browser only with your consent. It is a good alternative to wood and helps to prevent deforestation. It is possible to purchase mass produced husk products or create the products at home using the shells of fresh coconuts. The possibility of producing CF from an industrial corn stover lignin was investigated in a previous study (Qu et al., 2018). During production, glue and chemical agents do not need to be added, as natural glues are naturally extracted from the coconut itself while subjected to the production phases, cutting one third of the total production costs. Coconut husk is not used as a food but these husks mainly use for creating a potting to grow plants and flowers. Estimates suggest that 95% of those 50 billion coconuts grown around the world are owned by about 10 million farmers who earn an average income of less than $2 per day. Coconut coir also breaks down more slowly than peat moss, so its prized benefits ofwater retention and aeration last longer. New alloys are being developed, such as Airloy, which claims to bridge aerogel with conventional plastics by combining the resistance of the former with the lightness and thermal insulation of the latter (Table 4.7).

Furthermore, the production is CO2 neutral. Looking for the best Coconut manufacturer & suppliers in Pollachi. Designed by OSG.VN, oconut husk also known as are the container which extracted from the outer surface of coconut.Coconut Husk provides useful products and this is also one of the good product from the coconut tree. Morton M30 Water Softener Should You Get It? These cookies will be stored in your browser only with your consent. It is a good alternative to wood and helps to prevent deforestation. It is possible to purchase mass produced husk products or create the products at home using the shells of fresh coconuts. The possibility of producing CF from an industrial corn stover lignin was investigated in a previous study (Qu et al., 2018). During production, glue and chemical agents do not need to be added, as natural glues are naturally extracted from the coconut itself while subjected to the production phases, cutting one third of the total production costs. Coconut husk is not used as a food but these husks mainly use for creating a potting to grow plants and flowers. Estimates suggest that 95% of those 50 billion coconuts grown around the world are owned by about 10 million farmers who earn an average income of less than $2 per day. Coconut coir also breaks down more slowly than peat moss, so its prized benefits ofwater retention and aeration last longer. New alloys are being developed, such as Airloy, which claims to bridge aerogel with conventional plastics by combining the resistance of the former with the lightness and thermal insulation of the latter (Table 4.7).  What is a Power Inverter and Why do I Need One? Due to OH groups, the fibers fix water by forming hydrogen bonds.2. This is an environmental-friendly growing medium, and is used in several countries. Coconut husk can be transformed into a value-added fuel source which can replace wood and other traditional fuel sources.

What is a Power Inverter and Why do I Need One? Due to OH groups, the fibers fix water by forming hydrogen bonds.2. This is an environmental-friendly growing medium, and is used in several countries. Coconut husk can be transformed into a value-added fuel source which can replace wood and other traditional fuel sources.  Due its optical properties, aerogel in granular form is also used in manufacturing transparent insulating materials (TIMs). What many people dont realize is that the production of coconut products generates a lot of waste in the form of coconut husks. To begin the husking, the individual should grasp the coconut firmly with both hands and slam the body onto the sharpened point of the stick. By clicking Accept, you consent to the use of ALL the cookies. 2. The fibre is mechanically extracted from the coconut husk and used to make several products with a variety of applications. Lignocellulosic fibers of common paper majorly contain cellulose hemicelluloses and lignin (Wang et al., 2017b, 2017c, 2018). When you buy coconut coir, youre usually getting coco peat, coconut fiber, coco chips, or some combination of the three. The carbonized fiber is likely to have a graphitic structure (Mainka et al., 2015). Silica supports for B. licheniformis alpha amylase provides 60% retention of the enzyme activity.485 Oxidized bagasse cellulose,803 coconut fiber,804 highly porous cross-linked cellulose,805 and a composite temperature-sensitive polyester membrane806 are other supports used for immobilization of that enzyme.

Due its optical properties, aerogel in granular form is also used in manufacturing transparent insulating materials (TIMs). What many people dont realize is that the production of coconut products generates a lot of waste in the form of coconut husks. To begin the husking, the individual should grasp the coconut firmly with both hands and slam the body onto the sharpened point of the stick. By clicking Accept, you consent to the use of ALL the cookies. 2. The fibre is mechanically extracted from the coconut husk and used to make several products with a variety of applications. Lignocellulosic fibers of common paper majorly contain cellulose hemicelluloses and lignin (Wang et al., 2017b, 2017c, 2018). When you buy coconut coir, youre usually getting coco peat, coconut fiber, coco chips, or some combination of the three. The carbonized fiber is likely to have a graphitic structure (Mainka et al., 2015). Silica supports for B. licheniformis alpha amylase provides 60% retention of the enzyme activity.485 Oxidized bagasse cellulose,803 coconut fiber,804 highly porous cross-linked cellulose,805 and a composite temperature-sensitive polyester membrane806 are other supports used for immobilization of that enzyme.

- Atv Aftermarket Brake Caliper

- Ps4 Controller Crystal Clear

- Elephas Projector Mini

- Natural Life Daisy Midi Dress

- Why Globalization Works Wolf

- Office Depot Ingersoll

- Royal Style 5 Belt Equivalent

yrights 2016 All Rights Reserve