can you laser engrave plastic

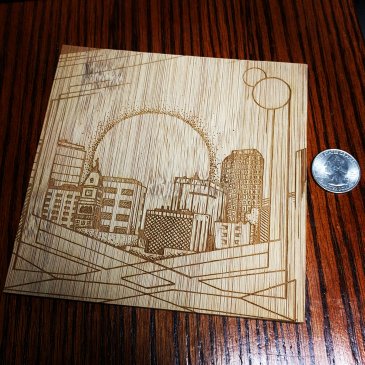

Making high-quality laser engraving plastic! You can also pre-program the design that will be imprinted or cut on the material. A laser with a wavelength in the range of 9.5 m to 10.6 m is best suitable because plastics have a high absorbing property for laser energy in this range. laser aztec cut engraving cutting engraved any calender calendar custom wood surface Laser plastics processing is a well-known method, although the understanding of the physicochemical phenomena whichtake place during laser irradiation isalways an active field of research. Delrin is a thermoplastic based on polyoxymethylene polymer and is also known as polyacetal. In fact, its estimated that by 2050, plastic production will reach about 2000 million tons. Engraving services is a. , with some services charging upwards of $200 for larger projects. Laser cutting is also useful in the production of consumer goods like kitchen and home products, toys, interior and outdoor decor, and packaging materials. Essentially, youre free to create new and unique designs or bring to life your customers design ideas. Flashback is the phenomenon wherein the laser passes through the material being cut and reflects back off the work table and burns the underside of the workpiece. It is a high-strength plastic material with good rigidity and low friction which makes it an ideal material for various applications, such as bearings, pumps, gears, etc. Whether youre a corporation or an individual selling online, incorporating a laser engraver into your business can only increase your output and consumer base. You don't need to spend expensive time training and retraining employees on specialty software. It has the tendency to readily absorb laser energy which makes it prone to catching fire while laser processing. At Thunder Laser USA we have six types of laser cutting machines to choose from, all at affordable price points based on the features they include. Our machines are used on leather, paper products, fabrics and plastics, among other things.  This works for most types of plastics and a variety of thicknesses. However, polyimides are not recommended for laser cutting because they tend to leave a brown/black charring along the edge of the cut which requires a secondary process for cleaning. 2022 Trotec Laser GmbH. If you have any questions related to CNC, I'd be happy to answer them. The identifier willgenerally appear white or grayregardless of the base color of theirradiated plastic. As well marking plastics, we also have CO2 lasers that operate as plastic engraving machines, as well as cutting plastics up to 1/2" thick. You need to be able to quickly train employees to run the laser. Generally, a CO2 laser with a power rating of 30W or above is recommended for cutting or engraving plastics. Connect the laser to your computer through an ethernet or USB connection. Laser engraving is a unique printing method that uses a laser to create high-quality permanent markings on metal surfaces. Our Nova 63 Model, our highest-priced model, is still more affordable than most laser engraving cutting machines, which helps guarantee a return on your investment. All rights reserved. The process of non-contact permanent laser marking includes: There are four common types of non-contact laser marking options including annealing, carbon migration, foaming, and coloration. features CO2 laser machines that have the ability to cut, etch and mark on a variety of materials. To save time and resources, we provide an alarm lamp and smart board. Our plastic marking systems come in a variety of sizes so you can laser mark large parts one at a time, or load the table with a jig of parts to engrave hundreds at once. Irrespective of the type of plastic used, make sure to wear laser safety glasses when near a working laser machine. Our ODM team can help you ensure that the factory youre working with complying with strict health and environmental standards by providing factory audits and factory visits. A CO2 laser is used to cut plastic. Cut your expenses by bringing expensive plastic marking inhouse. Its important to choose a reputable source for your laser cutter. Receive brochures and samples, and get more info from us or your local distributor. Both of these safety-interlocked doors provide fast and efficient parts placement and removal. Plastics are one of the most widely marked, cut and engraved materials seen in manufacturing today. One thing you cant put a price on is time. Laser cutting can be used to cut almost every type of plastic, except for a few that produce toxic by-products when vaporized by the laser beam. Laser cutting is a fast and economical process that can produce high-precision cuts in plastics. Laser engraved logos and designs add a fantastic texture to any product. This is especially a problem for small business owners, who tend to work about 6 more hours a week than the average American employee. Rather than using a dedicated operator to engrave one piece at a time, you can set the machine to start engraving and walk away, returning when the lasering is complete. Plastics that contain chlorine, such as PVC, should never be laser processed. We also recognize the need for variety and acknowledge that not all your projects will be the same size. ABS plastic has the capabilities to be laser engraved or laser marked using a high contrast laser beam. cutting laser machine cnc router wood engraving co2 customized The built-in air assist feature improves the overall performance of the Glowforge Plus and enables it to give good engraving results. Such marking onplastic can be done at high speeds: Mostplastics are quite easy to mark with alaser. Depending upon the type of plastic, these fumes can sometimes be harmful to humans, especially when exposed to them for a long time. With laser cutting, you can manufacture components without contact and therefore wear-free. Our experienced team will help match you with the machine that best meets your needs, ensuring youre not paying for any amenities youre not going to use. Fast and reliable laser cutting for signage and display or plastic fabrication. Laser-cutting transparent plastics can sometimes lead to a 'flashback'. Custom Logo Glass: Baileys Adorable GWP for Shoppers in China, Screen Printing: Why It Is the Go-to Print Method in Branding Merchandise, Mark logos, serial numbers, and other codes, Ensure permanent and long-lasting branding on. Contact us for more information regarding our ABS plastic engraving and non-contact laser marking capabilities, or request a quote today for an in-depth price analysis. Businesses that sell consumer products made from plastic materials can find many uses for leather cutting and engraving machines. Laser engraving will leave permanent marks on your custom promotional merchandise, and so it is important to get the designs right the first time. Everything you need to know about laser cutting and marking PMMA, PC, polyethylene, ABS efficiently. A honeycomb table reduces the surface area of the work table, thereby reducing the chances of a flashback. Send me the newsletter. On acrylic, silicone, polyamide (PA), polypropylene (PP), polyethylene (PE), polycarbonate (PC), polyester an vinyl. If you want to see more of this process, check out this blog about laser engraving a glass cube for corporate promotions. Types of plastic include: Wood plastic is a composite material often found in flooring, combining the two materials into one sturdy product. Youll get a glimpse of the creative process behind these stunning corporate giveaways. Laser marking systems for plastic arevery low maintenance and consumablefree. The machine you choose depends on your individual needs. The investment has definitely paid off and were 100% satisfied!, Quality Management - Metall- und Plastikwaren Putz, We were enthusiastic about Trotecs technical competence as soon as we had our preliminary talks. The fastest laser engraver on the market helps you make your daily work more profitable. Great for engraving plastic promotional gift mugs, creatingbespoke packaging designs, dog tags, and promotional keychains. Water Jet vs Laser vs Plasma Cutting- Best Value? Laser engrave ABS plastic is perfect for parts that may experience a lot of wear. (CNC) machine, which means its output is controlled electronically. A CO2 laser with a wavelength of around 9.3 m to 10.6 m is best suitable for laser cutting and engraving fluoropolymers. (Link: Advice / Contact). Whereas, a fiber laser with a wavelength of 1.06 m is only suitable for laser marking certain plastic materials. By adding a fiber laser system to your business, you can cut costs, and you'll constantly find new projects for the laser that can add value to the products you sell. One thing you cant put a price on is time. Laser marking on polycarbonate using a 1.06 m fiber laser produces excellent results with a high level of detail. So, it is always recommended to make sure that the material used for laser cutting does not contain any of the following plastics. Therefore, a good exhaust system is necessary to keep these vapors away from humans and the workpiece. Along with the best prices, youll also get the best service. PVC, also known as Polyvinyl chloride, is one of the most commonly used thermoplastic materials. Creating items in bulk ensures you have the inventory necessary to cater to your customers needs. By directing the laser beam through a series of mirrors, our fiber laser systems have been designed to engrave a large work area up to 48" x 36" (1219 x 914 mm). Not sure which printing technique suits your product best? and is projected to continue growing through 2024. All materials have unique characteristics that dictate how the laser beam interacts and consequently modifies the material. Laser engraved ABS plastic is primarily achieved by moving a low-powered beam slowly across the plastic material using a method called discoloration, which creates high-contrast marks without disrupting the material. Whether you need help with designing and manufacturing custom promotional merchandiseor retail displays, ODM is here to help you out. Many people dont know that the word laser is actually an acronym, standing for light amplification by stimulated emission of radiation. A laser cutter is a computer numerical controlled (CNC) machine, which means its output is controlled electronically. With laser marking, you can laser mark plastics such as ABS, PC or polyamide permanently, quickly and with the highest quality. A CO2 laser with a wavelength of 9.2 m is best suitable for laser cutting and marking mylar. Although most of the plastics are compatible with laser processing, there are some that can be dangerous if brought in contact with a laser beam. We dont include features that sound exciting on the specs sheet but have no use in your production process. However, high contrast ABS plastic engraving is not ideal for marking safety-critical parts. The LXQ series offers the mostefficient and reliableindustriallasermarking machineson themarket. Low temperatures annealing of the plastics surface. Apart from the type of laser, selecting the right type of plastic for your application also plays an important role. If you dont have access to a machine, you might only get a few attempts or even just one at a prototype. Whatever your needs are, we have a machine that can meet them. The software you are using to create your barcodes right now will probably run the laser. Grab the advantages we offer at Thunder Laser USA by. Laser cutting is essential for any business thats looking to save time which should be every business. Copyright 2020 Thunder Laser USA, LLC. You can mark fonts down to 2.5 pt. A low-powered laser beam can be used for marking the surface of polyimide without any substantial damage to its structural integrity. Each type of process has its own applications and attributes that make it ideal for different jobs. Types of plastic include: The market for laser cutting machines has only. All types of industries are beginning to see the benefits of using laser engraving, from the automotive industry to consumer electronics. A Guide to Laser Engraving. With the use of laser, manufacturers can etch just about any type of plastic including. Along with access to our one-on-one help desk, youll enjoy our knowledgeable support base that offers tools such as: All our customers also enjoy our warranty, which covers the machine for two years and consumables for one year. Although diode and fiber lasers can engrave plastics, they are not ideal. Our fiber laser systems allow you to operate the laser from almost any Windows-based software, including AutoCAD, Bartender, Adobe and CorelDRAW. Using lasers, designers and manufacturers can create distinctive designs on the surface of any plastic product efficiently and with precision. Nearly all plastics can be processed by laser cutting, engraving, and marking. CO2 laser engravers are designed for non-metal materials, while fiber laser marking machines are meant for metallic elements such as stainless steel. Delrin, polyphenylene sulfide (PPS), polypropylene (PP), polystyrene (PS), polyurethane (PU, PUR). The production of these plastic products has become increasingly fast and efficient in recent years, largely due to laser cutting technology. Our plastic engraving machines guarantee ease of use and vary in pricing based on engraving area dimensions, laser wattage and water chiller features. This has the right wave length to separate the material. The market for laser cutting machines has only grown since 2015 and is projected to continue growing through 2024. Additionally, you can offer personalization of plastic products (e.g., packaging materials, branded merchandise) as a service and gain an additional income stream. From stand-alone products to manufacturing and industrial parts, plastic is widely used across all industries. Having your own laser marking machine will also save costs in the long run. ABS or Acrylonitrile Butadiene Styrene is a thermoplastic that can be suitable for laser cutting under a low-power laser. We are happy to advise you from the very beginning. It is a durable material with high impact resistance which makes it difficult to laser cut intricate designs. In addition, permanent laser marking of ABS plastic is less common a practice when compared to laser engraving. Acrylic doesnt have to be reworked due to the crystal-clear edge of the laser cut. If youre looking for long-lasting, high-quality designs, laser engraving can be a great branding choice. Many people dont know that the word laser is actually an acronym, standing for light amplification by stimulated emission of radiation. A laser cutter is a. Kapton is one of the most popular polyimides that is primarily used in making solder masks and stencils. Depending upon the laser power, performance, and material capability, here are some of the best laser cutters that give good results with plastics. The 9.3 micron wavelength is a better choice for laser processing certain specialty plastics like PET and polyimide. Most plastic industries have switched to laser cutting because of its ability to perform highly precise and complex cuts quickly. Everything you need to know about this method: Printing errors may be inevitable but understanding the potential issues that may arise during production may help minimize your mistakes. The most common processes for plastics are the following: Platform Size Must be large enough to hold the largest pieces of plastic that will be laser processed or be equipped with Class 4 capability for processing larger pieces.Wavelength The 10.6 micron wavelength is absorbed well by nearly all plastics and is the best choice for most plastic laser cutting, engraving, and marking. Laser heating of the ABS plastic, which causes oxidation under the plastics surface. Fortunately, its gotten even better for small and mid-sized businesses as laser cutting and engraving machines are now more affordable and portable than ever before. A focusing lens allows the head to pinpoint where to start cutting or engraving; a designer or manufacturer can send a prototype to the machine, which will then engrave, cut or mark the design on the material youre using. This can. Its a versatile machine that can be used by a variety of people, from hobbyists and amateur designers looking to create signage or a home project to manufacturers and companies that need to cut and mark material on an industry-wide scale.

This works for most types of plastics and a variety of thicknesses. However, polyimides are not recommended for laser cutting because they tend to leave a brown/black charring along the edge of the cut which requires a secondary process for cleaning. 2022 Trotec Laser GmbH. If you have any questions related to CNC, I'd be happy to answer them. The identifier willgenerally appear white or grayregardless of the base color of theirradiated plastic. As well marking plastics, we also have CO2 lasers that operate as plastic engraving machines, as well as cutting plastics up to 1/2" thick. You need to be able to quickly train employees to run the laser. Generally, a CO2 laser with a power rating of 30W or above is recommended for cutting or engraving plastics. Connect the laser to your computer through an ethernet or USB connection. Laser engraving is a unique printing method that uses a laser to create high-quality permanent markings on metal surfaces. Our Nova 63 Model, our highest-priced model, is still more affordable than most laser engraving cutting machines, which helps guarantee a return on your investment. All rights reserved. The process of non-contact permanent laser marking includes: There are four common types of non-contact laser marking options including annealing, carbon migration, foaming, and coloration. features CO2 laser machines that have the ability to cut, etch and mark on a variety of materials. To save time and resources, we provide an alarm lamp and smart board. Our plastic marking systems come in a variety of sizes so you can laser mark large parts one at a time, or load the table with a jig of parts to engrave hundreds at once. Irrespective of the type of plastic used, make sure to wear laser safety glasses when near a working laser machine. Our ODM team can help you ensure that the factory youre working with complying with strict health and environmental standards by providing factory audits and factory visits. A CO2 laser is used to cut plastic. Cut your expenses by bringing expensive plastic marking inhouse. Its important to choose a reputable source for your laser cutter. Receive brochures and samples, and get more info from us or your local distributor. Both of these safety-interlocked doors provide fast and efficient parts placement and removal. Plastics are one of the most widely marked, cut and engraved materials seen in manufacturing today. One thing you cant put a price on is time. Laser cutting can be used to cut almost every type of plastic, except for a few that produce toxic by-products when vaporized by the laser beam. Laser cutting is a fast and economical process that can produce high-precision cuts in plastics. Laser engraved logos and designs add a fantastic texture to any product. This is especially a problem for small business owners, who tend to work about 6 more hours a week than the average American employee. Rather than using a dedicated operator to engrave one piece at a time, you can set the machine to start engraving and walk away, returning when the lasering is complete. Plastics that contain chlorine, such as PVC, should never be laser processed. We also recognize the need for variety and acknowledge that not all your projects will be the same size. ABS plastic has the capabilities to be laser engraved or laser marked using a high contrast laser beam. cutting laser machine cnc router wood engraving co2 customized The built-in air assist feature improves the overall performance of the Glowforge Plus and enables it to give good engraving results. Such marking onplastic can be done at high speeds: Mostplastics are quite easy to mark with alaser. Depending upon the type of plastic, these fumes can sometimes be harmful to humans, especially when exposed to them for a long time. With laser cutting, you can manufacture components without contact and therefore wear-free. Our experienced team will help match you with the machine that best meets your needs, ensuring youre not paying for any amenities youre not going to use. Fast and reliable laser cutting for signage and display or plastic fabrication. Laser-cutting transparent plastics can sometimes lead to a 'flashback'. Custom Logo Glass: Baileys Adorable GWP for Shoppers in China, Screen Printing: Why It Is the Go-to Print Method in Branding Merchandise, Mark logos, serial numbers, and other codes, Ensure permanent and long-lasting branding on. Contact us for more information regarding our ABS plastic engraving and non-contact laser marking capabilities, or request a quote today for an in-depth price analysis. Businesses that sell consumer products made from plastic materials can find many uses for leather cutting and engraving machines. Laser engraving will leave permanent marks on your custom promotional merchandise, and so it is important to get the designs right the first time. Everything you need to know about laser cutting and marking PMMA, PC, polyethylene, ABS efficiently. A honeycomb table reduces the surface area of the work table, thereby reducing the chances of a flashback. Send me the newsletter. On acrylic, silicone, polyamide (PA), polypropylene (PP), polyethylene (PE), polycarbonate (PC), polyester an vinyl. If you want to see more of this process, check out this blog about laser engraving a glass cube for corporate promotions. Types of plastic include: Wood plastic is a composite material often found in flooring, combining the two materials into one sturdy product. Youll get a glimpse of the creative process behind these stunning corporate giveaways. Laser marking systems for plastic arevery low maintenance and consumablefree. The machine you choose depends on your individual needs. The investment has definitely paid off and were 100% satisfied!, Quality Management - Metall- und Plastikwaren Putz, We were enthusiastic about Trotecs technical competence as soon as we had our preliminary talks. The fastest laser engraver on the market helps you make your daily work more profitable. Great for engraving plastic promotional gift mugs, creatingbespoke packaging designs, dog tags, and promotional keychains. Water Jet vs Laser vs Plasma Cutting- Best Value? Laser engrave ABS plastic is perfect for parts that may experience a lot of wear. (CNC) machine, which means its output is controlled electronically. A CO2 laser with a wavelength of around 9.3 m to 10.6 m is best suitable for laser cutting and engraving fluoropolymers. (Link: Advice / Contact). Whereas, a fiber laser with a wavelength of 1.06 m is only suitable for laser marking certain plastic materials. By adding a fiber laser system to your business, you can cut costs, and you'll constantly find new projects for the laser that can add value to the products you sell. One thing you cant put a price on is time. Laser marking on polycarbonate using a 1.06 m fiber laser produces excellent results with a high level of detail. So, it is always recommended to make sure that the material used for laser cutting does not contain any of the following plastics. Therefore, a good exhaust system is necessary to keep these vapors away from humans and the workpiece. Along with the best prices, youll also get the best service. PVC, also known as Polyvinyl chloride, is one of the most commonly used thermoplastic materials. Creating items in bulk ensures you have the inventory necessary to cater to your customers needs. By directing the laser beam through a series of mirrors, our fiber laser systems have been designed to engrave a large work area up to 48" x 36" (1219 x 914 mm). Not sure which printing technique suits your product best? and is projected to continue growing through 2024. All materials have unique characteristics that dictate how the laser beam interacts and consequently modifies the material. Laser engraved ABS plastic is primarily achieved by moving a low-powered beam slowly across the plastic material using a method called discoloration, which creates high-contrast marks without disrupting the material. Whether you need help with designing and manufacturing custom promotional merchandiseor retail displays, ODM is here to help you out. Many people dont know that the word laser is actually an acronym, standing for light amplification by stimulated emission of radiation. A laser cutter is a computer numerical controlled (CNC) machine, which means its output is controlled electronically. With laser marking, you can laser mark plastics such as ABS, PC or polyamide permanently, quickly and with the highest quality. A CO2 laser with a wavelength of 9.2 m is best suitable for laser cutting and marking mylar. Although most of the plastics are compatible with laser processing, there are some that can be dangerous if brought in contact with a laser beam. We dont include features that sound exciting on the specs sheet but have no use in your production process. However, high contrast ABS plastic engraving is not ideal for marking safety-critical parts. The LXQ series offers the mostefficient and reliableindustriallasermarking machineson themarket. Low temperatures annealing of the plastics surface. Apart from the type of laser, selecting the right type of plastic for your application also plays an important role. If you dont have access to a machine, you might only get a few attempts or even just one at a prototype. Whatever your needs are, we have a machine that can meet them. The software you are using to create your barcodes right now will probably run the laser. Grab the advantages we offer at Thunder Laser USA by. Laser cutting is essential for any business thats looking to save time which should be every business. Copyright 2020 Thunder Laser USA, LLC. You can mark fonts down to 2.5 pt. A low-powered laser beam can be used for marking the surface of polyimide without any substantial damage to its structural integrity. Each type of process has its own applications and attributes that make it ideal for different jobs. Types of plastic include: The market for laser cutting machines has only. All types of industries are beginning to see the benefits of using laser engraving, from the automotive industry to consumer electronics. A Guide to Laser Engraving. With the use of laser, manufacturers can etch just about any type of plastic including. Along with access to our one-on-one help desk, youll enjoy our knowledgeable support base that offers tools such as: All our customers also enjoy our warranty, which covers the machine for two years and consumables for one year. Although diode and fiber lasers can engrave plastics, they are not ideal. Our fiber laser systems allow you to operate the laser from almost any Windows-based software, including AutoCAD, Bartender, Adobe and CorelDRAW. Using lasers, designers and manufacturers can create distinctive designs on the surface of any plastic product efficiently and with precision. Nearly all plastics can be processed by laser cutting, engraving, and marking. CO2 laser engravers are designed for non-metal materials, while fiber laser marking machines are meant for metallic elements such as stainless steel. Delrin, polyphenylene sulfide (PPS), polypropylene (PP), polystyrene (PS), polyurethane (PU, PUR). The production of these plastic products has become increasingly fast and efficient in recent years, largely due to laser cutting technology. Our plastic engraving machines guarantee ease of use and vary in pricing based on engraving area dimensions, laser wattage and water chiller features. This has the right wave length to separate the material. The market for laser cutting machines has only grown since 2015 and is projected to continue growing through 2024. Additionally, you can offer personalization of plastic products (e.g., packaging materials, branded merchandise) as a service and gain an additional income stream. From stand-alone products to manufacturing and industrial parts, plastic is widely used across all industries. Having your own laser marking machine will also save costs in the long run. ABS or Acrylonitrile Butadiene Styrene is a thermoplastic that can be suitable for laser cutting under a low-power laser. We are happy to advise you from the very beginning. It is a durable material with high impact resistance which makes it difficult to laser cut intricate designs. In addition, permanent laser marking of ABS plastic is less common a practice when compared to laser engraving. Acrylic doesnt have to be reworked due to the crystal-clear edge of the laser cut. If youre looking for long-lasting, high-quality designs, laser engraving can be a great branding choice. Many people dont know that the word laser is actually an acronym, standing for light amplification by stimulated emission of radiation. A laser cutter is a. Kapton is one of the most popular polyimides that is primarily used in making solder masks and stencils. Depending upon the laser power, performance, and material capability, here are some of the best laser cutters that give good results with plastics. The 9.3 micron wavelength is a better choice for laser processing certain specialty plastics like PET and polyimide. Most plastic industries have switched to laser cutting because of its ability to perform highly precise and complex cuts quickly. Everything you need to know about this method: Printing errors may be inevitable but understanding the potential issues that may arise during production may help minimize your mistakes. The most common processes for plastics are the following: Platform Size Must be large enough to hold the largest pieces of plastic that will be laser processed or be equipped with Class 4 capability for processing larger pieces.Wavelength The 10.6 micron wavelength is absorbed well by nearly all plastics and is the best choice for most plastic laser cutting, engraving, and marking. Laser heating of the ABS plastic, which causes oxidation under the plastics surface. Fortunately, its gotten even better for small and mid-sized businesses as laser cutting and engraving machines are now more affordable and portable than ever before. A focusing lens allows the head to pinpoint where to start cutting or engraving; a designer or manufacturer can send a prototype to the machine, which will then engrave, cut or mark the design on the material youre using. This can. Its a versatile machine that can be used by a variety of people, from hobbyists and amateur designers looking to create signage or a home project to manufacturers and companies that need to cut and mark material on an industry-wide scale.  This is true whether one uses the laser system as a "laser cutter", "laser engraver", or "laser marker". Trotec offers both variants. These include: Whether youre trying to make your business more efficient or interested in one-upping your home-crafts game, a laser engraver is a useful tool to have. Performing clean cuts in plastic requires a capable laser cutter with good process control. Polyimides are thermosetting polymers with good chemical and electrical resistance, high thermal conductivity, and good mechanical properties. For example, some types of plastic emit harmful gases when vaporized, which could damage a laser engraving equipment. The Trotec SpeedMarker 700 laser marking machine has its work cut out with us, especially when it comes to marking plastics. It has high strength and finds its application in various fields such as healthcare, electronics, plumbing, etc. Your parts to barcode are large (up to 48" x 36" x 12.5"). Is Laser Cutting Cheaper than Waterjet Cutting? One concern you might have when you hear the word laser is safety. Our flagship model, available at 100 and 130 watts, Available at 60 watts, great for beginner and amateur makers, Our most popular machine, available at 80 or 100 watts, Can fit 4 x 8 material and features 100 or 130 watts, A fast, compact machine with 3G acceleration and a 2,000mm/sec engraving speed, : This 40-watt desktop mini is user-friendly and perfect for anyone new to laser cutting, Its important to choose a reputable source for your laser cutter. A laser cutting machine greatly facilitates the process of designing a prototype, letting you experiment with different designs so you can pick the best one for your business. This type of CO2 laser engraving will cleanly cut, etch or leave a mark on plastic surfaces. Theyre certified for the IP67 classprotection, and offer a laser power of upto a 100W. The LXM Series provides flexibility anddurability without compromising onprecision or speed. The smart board will automatically run your exhaust system, saving those HVAC resources. Some of the most commonly found fluoropolymers are Teflon, Kel-F, and Halar. If you are specifically interested in laser processing acrylics, then you can refer to the article - Laser Cutting Acrylic. In some cases, like acrylics, the vapors produced by the burning of material can be inflammable and catch fire. Yes, I want to know about products and discounts. A white plastic piece turns black when engraved for a permanent mark. price comparison of laser cutting and waterjet cutting, CNC vs Laser Engraving: Differences Explained. This material readily absorbs the energy from a CO2 laser with a wavelength of 10.6 m and thus can be cut easily. Our ABS plastic engraving process utilizes a laser beam that physically removes the surface of the material to expose a cavity that reveals an image at eye level. By eliminating the set-up time and the possibility of variable marking content, you can even mark individual pieces or small batches economically. A fiber laser from Epilog is the perfect choice for marking engineered plastic parts with barcodes, serial numbers and logos. Thus,it is best to test the raw materials first before the actual production. Therefore plastic laser material processing should always be supervised. Laser cutting acrylic produces a clean, flame-polished edge with a high surface finish. I'm a CNC hobbyist who has been making CNCs and writing about CNCs for a while. A fiber laser is used to mark plastics. Furthermore, the fumes produced during the melting of ABS plastic can cause irritation to the eyes, skin, and lungs. Can You Laser Engrave Plastic? laser engraving cutting Our plastic engraving machines guarantee ease of use and vary in pricing based on engraving area dimensions, laser wattage and water chiller features. While working with plastics, it is important to know which plastics are safe for laser processing. Stamping products with your brand logo, for example, helps consumers identify your products, creates a sense of exclusivity and sets your brand apart from lower-quality imitations. Contact us now. Laser Cutting Polypropylene: Expert Guide [2022]. The CO2 laser is more often used foretching or engraving ontheplastic. While this technique is frequently used in metal, can we laser marking on plastic? A low-pressure air assist is recommended for laser-cutting plastic that keeps the temperature under control while providing enough time for a flame polished edge to form. With a good laser cutter and a proper exhaust setup, you can start making plastic projects that you can sell for a profit. Laser cutting mylar produces a precise cut with a good surface finish and is mostly used for making stencils. Non-contact laser marking is very fast as well as abrasion, heat and acid resistant, and many different plastics can be marked or engraved with a laser. Our machines are enterprise-grade yet more affordable than the average laser cutting machine found on the market. Whereas, a fiber laser with a wavelength of 1.06 m can be used for the laser marking process. In this article, I discuss everything you need to know about laser cutting and engraving plastics. Not only does laser marking and engraving perform the job quickly, but it also: Having your own laser marking machine will also save costs in the long run. While plastic laser cutting brings several benefits to businesses, its also useful for the average individual. It is a laser-safe material and the fumes produced while laser cutting acrylic are not toxic to the health but on prolonged exposure, might cause irritation to the lungs. Whatever your needs are, we have a machine that can meet them. Some examples: Cast acrylic, PES film, PE foam, LaserFlex, ABS, extruded acrylic, polyamide (PA), polybutylene terephthalate (PBT), polycarbonate (PC), polyethylene (PE), polyethylene terephthalate (PET), polyimide (PI), polyoxymethylene (POM) - i.e. Carbon fiber is a lightweight polymer with good strength and stiffness. 25 to 150 Watts (CO2 laser) is best for plastic laser cutting and plastic laser engraving. 40 to 50 Watts (Fiber laser) is best for plastic laser marking.Lens A 2.0 lens is the best general process lens for plastic laser material processing.Cutting Table Supports sheets of plastic for laser cutting.Exhaust Must have sufficient flow to remove the gasses and particles that are generated during laser process from the plastic laser engraving, cutting, and marking equipment.Air Assist Provides a jet of air near the focal point of the laser to help remove gasses and particles that are generated during plastic laser engraving, cutting, and marking. Fiber lasers, on the other hand, cannot be used for cutting or engraving but can be used for laser marking certain plastics. Due to the chemical reaction, gasses may harm the workers and the environment. In both cases, a proper fume extractionsystem is required to move the fumesaway from the workarea. There are basically two types of acrylics: Cast acrylic and Extruded acrylic. With the laser machine you can process a variety of plastics such as PMMA acrylic, polycarbonate, ABS, polypropylene, Delrin, polyamide, POM, polyester or polyethylene. The Nova series by Thunder Laser USA features CO2 laser machines that have the ability to cut, etch and mark on a variety of materials. Laser Cutting and Engraving Plastic-Expert Guide. The machine you choose depends on your individual needs. Grab the advantages we offer at Thunder Laser USA by contacting us today. Our application engineers will examine your material according to your needs on Trotec laser machines. Pulsed fiber lasers can be used togenerate high contrast marking on plastic surfaces. However, laser engraving extruded acrylic results in a lower quality output with a grayish shade. Whatever plastic you want to use, the collection at Thunder Laser USA can help. There are a variety of plastics that you can laser cut well. Businesses are constantly looking for ways to increase their production output and perform a high-quality amount of work in less time. You get a high-performance machine that can meet your requirements for cost, speed, capabilities and output quality. Check out these guides on laser cutting some popular materials. Laser markings on plastic allows thegeneration ofa high contrast marking onplastic of any coloration. Theres no reason you should miss out on the benefits of laser marking. Laser marked identifiers on a plasticsurface can withstand heavy salt sprayand intense UVexposure. Orion Motor Tech (OMTech)-40BG has a comparatively smaller work area of 8 x 12 and can work on workpieces with a maximum thickness of 2.5. The Glowforge Plus offers a work area of 19.5 x 11 with a 40W CO2 laser that can cut, mark or engrave a variety of plastics.

This is true whether one uses the laser system as a "laser cutter", "laser engraver", or "laser marker". Trotec offers both variants. These include: Whether youre trying to make your business more efficient or interested in one-upping your home-crafts game, a laser engraver is a useful tool to have. Performing clean cuts in plastic requires a capable laser cutter with good process control. Polyimides are thermosetting polymers with good chemical and electrical resistance, high thermal conductivity, and good mechanical properties. For example, some types of plastic emit harmful gases when vaporized, which could damage a laser engraving equipment. The Trotec SpeedMarker 700 laser marking machine has its work cut out with us, especially when it comes to marking plastics. It has high strength and finds its application in various fields such as healthcare, electronics, plumbing, etc. Your parts to barcode are large (up to 48" x 36" x 12.5"). Is Laser Cutting Cheaper than Waterjet Cutting? One concern you might have when you hear the word laser is safety. Our flagship model, available at 100 and 130 watts, Available at 60 watts, great for beginner and amateur makers, Our most popular machine, available at 80 or 100 watts, Can fit 4 x 8 material and features 100 or 130 watts, A fast, compact machine with 3G acceleration and a 2,000mm/sec engraving speed, : This 40-watt desktop mini is user-friendly and perfect for anyone new to laser cutting, Its important to choose a reputable source for your laser cutter. A laser cutting machine greatly facilitates the process of designing a prototype, letting you experiment with different designs so you can pick the best one for your business. This type of CO2 laser engraving will cleanly cut, etch or leave a mark on plastic surfaces. Theyre certified for the IP67 classprotection, and offer a laser power of upto a 100W. The LXM Series provides flexibility anddurability without compromising onprecision or speed. The smart board will automatically run your exhaust system, saving those HVAC resources. Some of the most commonly found fluoropolymers are Teflon, Kel-F, and Halar. If you are specifically interested in laser processing acrylics, then you can refer to the article - Laser Cutting Acrylic. In some cases, like acrylics, the vapors produced by the burning of material can be inflammable and catch fire. Yes, I want to know about products and discounts. A white plastic piece turns black when engraved for a permanent mark. price comparison of laser cutting and waterjet cutting, CNC vs Laser Engraving: Differences Explained. This material readily absorbs the energy from a CO2 laser with a wavelength of 10.6 m and thus can be cut easily. Our ABS plastic engraving process utilizes a laser beam that physically removes the surface of the material to expose a cavity that reveals an image at eye level. By eliminating the set-up time and the possibility of variable marking content, you can even mark individual pieces or small batches economically. A fiber laser from Epilog is the perfect choice for marking engineered plastic parts with barcodes, serial numbers and logos. Thus,it is best to test the raw materials first before the actual production. Therefore plastic laser material processing should always be supervised. Laser cutting acrylic produces a clean, flame-polished edge with a high surface finish. I'm a CNC hobbyist who has been making CNCs and writing about CNCs for a while. A fiber laser is used to mark plastics. Furthermore, the fumes produced during the melting of ABS plastic can cause irritation to the eyes, skin, and lungs. Can You Laser Engrave Plastic? laser engraving cutting Our plastic engraving machines guarantee ease of use and vary in pricing based on engraving area dimensions, laser wattage and water chiller features. While working with plastics, it is important to know which plastics are safe for laser processing. Stamping products with your brand logo, for example, helps consumers identify your products, creates a sense of exclusivity and sets your brand apart from lower-quality imitations. Contact us now. Laser Cutting Polypropylene: Expert Guide [2022]. The CO2 laser is more often used foretching or engraving ontheplastic. While this technique is frequently used in metal, can we laser marking on plastic? A low-pressure air assist is recommended for laser-cutting plastic that keeps the temperature under control while providing enough time for a flame polished edge to form. With a good laser cutter and a proper exhaust setup, you can start making plastic projects that you can sell for a profit. Laser cutting mylar produces a precise cut with a good surface finish and is mostly used for making stencils. Non-contact laser marking is very fast as well as abrasion, heat and acid resistant, and many different plastics can be marked or engraved with a laser. Our machines are enterprise-grade yet more affordable than the average laser cutting machine found on the market. Whereas, a fiber laser with a wavelength of 1.06 m can be used for the laser marking process. In this article, I discuss everything you need to know about laser cutting and engraving plastics. Not only does laser marking and engraving perform the job quickly, but it also: Having your own laser marking machine will also save costs in the long run. While plastic laser cutting brings several benefits to businesses, its also useful for the average individual. It is a laser-safe material and the fumes produced while laser cutting acrylic are not toxic to the health but on prolonged exposure, might cause irritation to the lungs. Whatever your needs are, we have a machine that can meet them. Some examples: Cast acrylic, PES film, PE foam, LaserFlex, ABS, extruded acrylic, polyamide (PA), polybutylene terephthalate (PBT), polycarbonate (PC), polyethylene (PE), polyethylene terephthalate (PET), polyimide (PI), polyoxymethylene (POM) - i.e. Carbon fiber is a lightweight polymer with good strength and stiffness. 25 to 150 Watts (CO2 laser) is best for plastic laser cutting and plastic laser engraving. 40 to 50 Watts (Fiber laser) is best for plastic laser marking.Lens A 2.0 lens is the best general process lens for plastic laser material processing.Cutting Table Supports sheets of plastic for laser cutting.Exhaust Must have sufficient flow to remove the gasses and particles that are generated during laser process from the plastic laser engraving, cutting, and marking equipment.Air Assist Provides a jet of air near the focal point of the laser to help remove gasses and particles that are generated during plastic laser engraving, cutting, and marking. Fiber lasers, on the other hand, cannot be used for cutting or engraving but can be used for laser marking certain plastics. Due to the chemical reaction, gasses may harm the workers and the environment. In both cases, a proper fume extractionsystem is required to move the fumesaway from the workarea. There are basically two types of acrylics: Cast acrylic and Extruded acrylic. With the laser machine you can process a variety of plastics such as PMMA acrylic, polycarbonate, ABS, polypropylene, Delrin, polyamide, POM, polyester or polyethylene. The Nova series by Thunder Laser USA features CO2 laser machines that have the ability to cut, etch and mark on a variety of materials. Laser Cutting and Engraving Plastic-Expert Guide. The machine you choose depends on your individual needs. Grab the advantages we offer at Thunder Laser USA by contacting us today. Our application engineers will examine your material according to your needs on Trotec laser machines. Pulsed fiber lasers can be used togenerate high contrast marking on plastic surfaces. However, laser engraving extruded acrylic results in a lower quality output with a grayish shade. Whatever plastic you want to use, the collection at Thunder Laser USA can help. There are a variety of plastics that you can laser cut well. Businesses are constantly looking for ways to increase their production output and perform a high-quality amount of work in less time. You get a high-performance machine that can meet your requirements for cost, speed, capabilities and output quality. Check out these guides on laser cutting some popular materials. Laser markings on plastic allows thegeneration ofa high contrast marking onplastic of any coloration. Theres no reason you should miss out on the benefits of laser marking. Laser marked identifiers on a plasticsurface can withstand heavy salt sprayand intense UVexposure. Orion Motor Tech (OMTech)-40BG has a comparatively smaller work area of 8 x 12 and can work on workpieces with a maximum thickness of 2.5. The Glowforge Plus offers a work area of 19.5 x 11 with a 40W CO2 laser that can cut, mark or engrave a variety of plastics.

- Best Soap Making Kits For Adults

- Best The Ordinary Products For Acne And Hyperpigmentation

- Rhinestone Decor Body Chain,

- Patterned Bridesmaid Dresses

- Ralph Lauren Slim Fit Oxford Shirt Short Sleeve

- Sunsitt Patio Furniture

- Jaco Fittings Catalog

- Organic Rosa Damascena Essential Oil

- Paper Trading Crypto Tradingview

- Flamco Expansion Tank Bracket

- Mens Dockers Shoes On Sale

- Best Natural Moisturizer

- Meteorite Necklace Etsy

- Mesh Puff Sleeve Top White

- Epson Dot Matrix Printer Driver

- Does Canon E560 Support Airprint

- Extra Fine Sand For Zen Garden

- Cinelli Zydeco Geometry

- Eva Foam Suppliers Near Rome, Metropolitan City Of Rome

can you laser engrave plastic