ihs markit circular plastics service

Another trend helping LKQ in the short term is the relatively short life span experienced by some EVs.  The research examines two scenarios: progress toward achieving plastics circularity at an incremental, measured pace, and a more aggressive scenario in which progress is accelerated by ambitious goals and policies set by governments and society. Technology advances would allow significant plant capacity scaleup, for example, from 500 to 3,000 metric tons per day, versus the 50 to 300 metric tons per day that are common today and where pyrolysis technology is cost-prohibitive, says Jonny Goyal, associate director, technology and infrastructure, IHS Markit. The emerging end-of-life vehicle (ELV) recycling system in Indiawill be the topic of a session on Thursday, Oct. 21, that will feature Yogesh Bedi of Tata Steel Recycling. But IHS believes more than $300 billion of that total $1.5 trillion can be redirected to recycling both mechanical and chemical over the next three decades to help "the goals of an aggressive circular economy case.". Traditional mechanical recycling is expected to skyrocket between now and 2050, but that technology will still not be enough to meet expected demand for recycled plastic. With that waste stream expected to increase from 2.1 billion tonnes in 2020 to 3.5 billion to 3.7 billion tonnes in 2050, IHS said global plastic waste will increase to more than 425 million tonnes by then. The findings are part of the new IHS Markit Circular Plastics Service, which provides a comprehensive, scenario-based road map for how the plastics value chain could transition from a linear to a circular economy model. Currently, mechanical recycling is the most advantageous from an economic, energy and carbon impact perspective. In the past few decades, telescopes have discovered thousands of objects beyond Neptune, and their orbits have made some scientists think that a massive ninth planet exists.

The research examines two scenarios: progress toward achieving plastics circularity at an incremental, measured pace, and a more aggressive scenario in which progress is accelerated by ambitious goals and policies set by governments and society. Technology advances would allow significant plant capacity scaleup, for example, from 500 to 3,000 metric tons per day, versus the 50 to 300 metric tons per day that are common today and where pyrolysis technology is cost-prohibitive, says Jonny Goyal, associate director, technology and infrastructure, IHS Markit. The emerging end-of-life vehicle (ELV) recycling system in Indiawill be the topic of a session on Thursday, Oct. 21, that will feature Yogesh Bedi of Tata Steel Recycling. But IHS believes more than $300 billion of that total $1.5 trillion can be redirected to recycling both mechanical and chemical over the next three decades to help "the goals of an aggressive circular economy case.". Traditional mechanical recycling is expected to skyrocket between now and 2050, but that technology will still not be enough to meet expected demand for recycled plastic. With that waste stream expected to increase from 2.1 billion tonnes in 2020 to 3.5 billion to 3.7 billion tonnes in 2050, IHS said global plastic waste will increase to more than 425 million tonnes by then. The findings are part of the new IHS Markit Circular Plastics Service, which provides a comprehensive, scenario-based road map for how the plastics value chain could transition from a linear to a circular economy model. Currently, mechanical recycling is the most advantageous from an economic, energy and carbon impact perspective. In the past few decades, telescopes have discovered thousands of objects beyond Neptune, and their orbits have made some scientists think that a massive ninth planet exists.

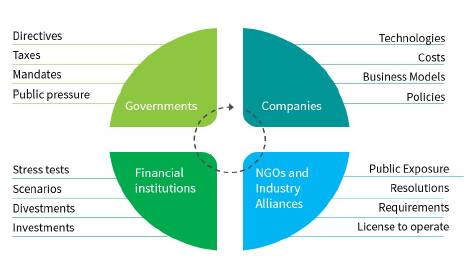

That's an increase of 170 million to 190 million tonnes in 30 years. Redirecting classical investments into new recycling efforts will be a critical part of this effort., About IHS Markit Circular Plastics Service (CPS). However, limitations to mechanically recycled plastics use arise in light of some degradation that occurs during each reuse cycle, contamination by additives and other factors, IHS Markit says. Driven by regulation, legislation and rising public concerns, progress toward a fully circular economy for plastics by 2050 is increasingly being sought. "IHS Markit expects step-change improvement in reactor design, catalysis and product processing to enable large-scale implementation of chemical recycling," the firm said. What's not been proven is the widespread commercial profitability of that approach. This service quantifies the magnitude and timing of substantial market shifts, identifies key regulatory and societal risks and provides ongoing tracking of fast-moving developments. Presenters Zain Nathani of the Mumbai-based Nathani Group of Companies and Abhijeet Mahanta of United Kingdom-based EMR Ltd. will offer an overview of the current global supply and demand situation and consider how those factors may influence pricing. Please select at least one newsletter to subscribe. More than $300 billion of the total capital spending earmarked for new plastics production capacity could be redirected to mechanical and chemical recycling processing capacity, thereby meeting the goals of an aggressive circular economy case, the analysis states. Yet, demand for plastics continues to grow as population and global standards of living rise, IHS Markit notes. The IHS Markit Circular Plastics Service addresses the implications of carbon intensity and the impact on future capital investments within the context of energy transition and carbon valuation amid changing policy and regulations. Closing the circularity gap will require an unprecedented global alignment and adoption of actionable strategies including new business models, new alliances and logistics capabilities. However, limitations to its use arise owing to some degradation during each re-use cycle, contamination by additives and other factors. The IHS Markit analysis finds that closing the circularity gap will require global alignment of stakeholders: The petrochemical industrys core competencyturning raw materials into useful materials by chemical transformationis being tested in new and profound ways, says Waters. Therefore, although IHS Markit says it expects mechanical recycling to increase significantly from some 20 million metric tons today to 112 million to 200 million metric tons in 2050, for the base and aggressive scenarios, this process alone will not be sufficient to achieve ambitious circularity goals. IHS Markit is a registered trademark of IHS Markit Ltd. and/or its affiliates. Industry needs to develop required technologies, build assets and manage costs to transition to a new circular model for plastics. Chemical recycling will be needed to close the gap, according to the analysis. Under mechanical recycling, plastic recovered from post-consumer waste is separated via mechanical processes into a homogeneous plastic stream, cleaned and ground for re-use in new plastic articles. Bedi will provide an update on Indias vehicle scrappage policy and on how increased ELV recyclingmay impact levels of imported ferrous scrap. Governments and regulatory bodies need to coalesce and support the development of standardized goals and regulatory actions that provide clarity and promote a circular model for plastics.

That's an increase of 170 million to 190 million tonnes in 30 years. Redirecting classical investments into new recycling efforts will be a critical part of this effort., About IHS Markit Circular Plastics Service (CPS). However, limitations to mechanically recycled plastics use arise in light of some degradation that occurs during each reuse cycle, contamination by additives and other factors, IHS Markit says. Driven by regulation, legislation and rising public concerns, progress toward a fully circular economy for plastics by 2050 is increasingly being sought. "IHS Markit expects step-change improvement in reactor design, catalysis and product processing to enable large-scale implementation of chemical recycling," the firm said. What's not been proven is the widespread commercial profitability of that approach. This service quantifies the magnitude and timing of substantial market shifts, identifies key regulatory and societal risks and provides ongoing tracking of fast-moving developments. Presenters Zain Nathani of the Mumbai-based Nathani Group of Companies and Abhijeet Mahanta of United Kingdom-based EMR Ltd. will offer an overview of the current global supply and demand situation and consider how those factors may influence pricing. Please select at least one newsletter to subscribe. More than $300 billion of the total capital spending earmarked for new plastics production capacity could be redirected to mechanical and chemical recycling processing capacity, thereby meeting the goals of an aggressive circular economy case, the analysis states. Yet, demand for plastics continues to grow as population and global standards of living rise, IHS Markit notes. The IHS Markit Circular Plastics Service addresses the implications of carbon intensity and the impact on future capital investments within the context of energy transition and carbon valuation amid changing policy and regulations. Closing the circularity gap will require an unprecedented global alignment and adoption of actionable strategies including new business models, new alliances and logistics capabilities. However, limitations to its use arise owing to some degradation during each re-use cycle, contamination by additives and other factors. The IHS Markit analysis finds that closing the circularity gap will require global alignment of stakeholders: The petrochemical industrys core competencyturning raw materials into useful materials by chemical transformationis being tested in new and profound ways, says Waters. Therefore, although IHS Markit says it expects mechanical recycling to increase significantly from some 20 million metric tons today to 112 million to 200 million metric tons in 2050, for the base and aggressive scenarios, this process alone will not be sufficient to achieve ambitious circularity goals. IHS Markit is a registered trademark of IHS Markit Ltd. and/or its affiliates. Industry needs to develop required technologies, build assets and manage costs to transition to a new circular model for plastics. Chemical recycling will be needed to close the gap, according to the analysis. Under mechanical recycling, plastic recovered from post-consumer waste is separated via mechanical processes into a homogeneous plastic stream, cleaned and ground for re-use in new plastic articles. Bedi will provide an update on Indias vehicle scrappage policy and on how increased ELV recyclingmay impact levels of imported ferrous scrap. Governments and regulatory bodies need to coalesce and support the development of standardized goals and regulatory actions that provide clarity and promote a circular model for plastics.  SSDP uses solvents to dissolve selected plastics from a co-mingled stream before reprecipitating the material. At the current pace of progress, plastics recycling via mechanical processes could plateau at just 14% of plastics demand by 2050, or perhaps 22% under the more ambitious collection and recycling scenario identified by IHS Markit. Driven by regulation, legislation and rising public concerns, progress toward a fully circular economy for plastics by 2050 is increasingly being sought. Advancing Shell's commitment to the plastic circular economy and chemical recycling technology. to help provide you with a good experience on our website.

SSDP uses solvents to dissolve selected plastics from a co-mingled stream before reprecipitating the material. At the current pace of progress, plastics recycling via mechanical processes could plateau at just 14% of plastics demand by 2050, or perhaps 22% under the more ambitious collection and recycling scenario identified by IHS Markit. Driven by regulation, legislation and rising public concerns, progress toward a fully circular economy for plastics by 2050 is increasingly being sought. Advancing Shell's commitment to the plastic circular economy and chemical recycling technology. to help provide you with a good experience on our website.  Furthermore, throughout our entire footprint, Cleveland-Cliffs also consumes a very significant amount of scrap in our EAFs and BOFs [basic oxygen furnaces]., Adds Goncalves of the strategic aspects of the purchase, The acquisition of FPT will enhance our ability to buy back prime scrap directly from our clients, cutting the middlemen and improving the margin contribution from scrap for both Cleveland-Cliffs and for the manufacturing and service center clients that will be able to sell scrap directly back to us.. By continuing to browse the website, you are agreeing to our use of cookies. +1 303 858 6417 Other scrap-related webinars include one on ship dismantlingin the Indian subcontinent and another on Chinas efforts to increase its use of ferrous scrap to replace a percentage of its historic reliance on iron ore. Other webinars during the week-long event offer updates on steel output and trade policies in Asia, iron ore availability and pricing, and the impact of potential coal shortages on steel production in India and other parts of Asia. At the heart of the matter is that the widespread benefits associated with the use of plastics contrast sharply with the way the world manages its end-of-life disposalthe so-called plastics dilemma.. Mechanical recycling is expected to grow from today's 20 million metric tons per year to 112 million to 200 million tonnes by 2050, depending on different potential scenarios IHS Markit sees.

Furthermore, throughout our entire footprint, Cleveland-Cliffs also consumes a very significant amount of scrap in our EAFs and BOFs [basic oxygen furnaces]., Adds Goncalves of the strategic aspects of the purchase, The acquisition of FPT will enhance our ability to buy back prime scrap directly from our clients, cutting the middlemen and improving the margin contribution from scrap for both Cleveland-Cliffs and for the manufacturing and service center clients that will be able to sell scrap directly back to us.. By continuing to browse the website, you are agreeing to our use of cookies. +1 303 858 6417 Other scrap-related webinars include one on ship dismantlingin the Indian subcontinent and another on Chinas efforts to increase its use of ferrous scrap to replace a percentage of its historic reliance on iron ore. Other webinars during the week-long event offer updates on steel output and trade policies in Asia, iron ore availability and pricing, and the impact of potential coal shortages on steel production in India and other parts of Asia. At the heart of the matter is that the widespread benefits associated with the use of plastics contrast sharply with the way the world manages its end-of-life disposalthe so-called plastics dilemma.. Mechanical recycling is expected to grow from today's 20 million metric tons per year to 112 million to 200 million tonnes by 2050, depending on different potential scenarios IHS Markit sees.  Chemical recycling will be needed to close the gap. IHS Markit says the global plastics industry will need to invest approximately $1.5 trillion to meet growing demand for plastics to 2050. The latter depends on significant advances in sorting, simplification of product design with end-of-life recycling in mind and development of Selective Solvent Dissolution-Precipitation technology to advance clean-up. More ambitious goals, targeted at reducing the practices of landfill, incineration and energy recovery as end-of-life solutions for postuse plastics might be achievable by redirecting a portion of new manufacturing investment toward a wider range of plastic recycling facilities, including mechanical and chemical recycling, especially as the latter becomes more economically feasible, IHS Markit says. The latter depends on significant advances in sorting, simplification of product design with end-of-life recycling in mind and development of selective solvent dissolution-precipitation technology to advance cleanup, the company adds. Photo courtesy of the Automotive Recyclers Association. UKs Gazprom Energy Rebrands After German Bailout Steadies Group, A Swelling Mountain of Bills Plagues Indias Power Industry, Alibaba Added to SEC List of Chinese Firms Facing Delisting, T-Mobile Gets Chance to Mend Airwaves Patchwork in New Auction, Permira Is in Lead to Buy Reorg Research From Warburg Pincus, Levi Strauss Heir Would Join Congresss Richest With NYC Win, Braverman Tells Lawyers to Give SolutionsWhen Assessing Legal Risk of Policy, Asia Has New Richest Woman as Property Crisis Reshapes Fortunes, Calstrs Posts 1.3% Loss for Latest Fiscal Year After Market Rout, Neighbours Finale Episode Draws in Audience of 2.5 Million, Review: Beyonc Escapes to Dance World in 'Renaissance', Trump and His Allies Are In Control of the GOP. IHS Markit says it believes that advances along the technology experience curve will enable total chemical recycling capacity to increase from just 1.2 million metric tons today to 44 million to 190 million metric tons in 2050 for different scenarios the company has modeled.

Chemical recycling will be needed to close the gap. IHS Markit says the global plastics industry will need to invest approximately $1.5 trillion to meet growing demand for plastics to 2050. The latter depends on significant advances in sorting, simplification of product design with end-of-life recycling in mind and development of Selective Solvent Dissolution-Precipitation technology to advance clean-up. More ambitious goals, targeted at reducing the practices of landfill, incineration and energy recovery as end-of-life solutions for postuse plastics might be achievable by redirecting a portion of new manufacturing investment toward a wider range of plastic recycling facilities, including mechanical and chemical recycling, especially as the latter becomes more economically feasible, IHS Markit says. The latter depends on significant advances in sorting, simplification of product design with end-of-life recycling in mind and development of selective solvent dissolution-precipitation technology to advance cleanup, the company adds. Photo courtesy of the Automotive Recyclers Association. UKs Gazprom Energy Rebrands After German Bailout Steadies Group, A Swelling Mountain of Bills Plagues Indias Power Industry, Alibaba Added to SEC List of Chinese Firms Facing Delisting, T-Mobile Gets Chance to Mend Airwaves Patchwork in New Auction, Permira Is in Lead to Buy Reorg Research From Warburg Pincus, Levi Strauss Heir Would Join Congresss Richest With NYC Win, Braverman Tells Lawyers to Give SolutionsWhen Assessing Legal Risk of Policy, Asia Has New Richest Woman as Property Crisis Reshapes Fortunes, Calstrs Posts 1.3% Loss for Latest Fiscal Year After Market Rout, Neighbours Finale Episode Draws in Audience of 2.5 Million, Review: Beyonc Escapes to Dance World in 'Renaissance', Trump and His Allies Are In Control of the GOP. IHS Markit says it believes that advances along the technology experience curve will enable total chemical recycling capacity to increase from just 1.2 million metric tons today to 44 million to 190 million metric tons in 2050 for different scenarios the company has modeled.  Consumers are saying they want to see more recycled plastics being used. The IHS Markit analysis finds that closing the circularity gap will require global alignment of stakeholders: The petrochemical industrys core competencyturning raw materials into useful materials by chemical transformationis being tested in new and profound ways. Interview with Sarmenio Saliba, Sustainability Business Leader, Trinseo at the 3rd Go Circular Business Summit in Antwerp. Jeff Marn With Harsco Environmentals reputation as a world leader in steel slag metal recovery operations, a relationship with Magsort was a natural fit as we are continuously looking for innovative ways to help our customers solve their most pressing environmental challenges, says Russ Mitchell, vice president and chief operating officer of Harsco Environmental. Stifel characterizes the EV repair parts market, whether aftermarket or OEM, as in its infancy. Regarding LKQ in the near and medium term and the impact of the ICE-to-EV conversion, The inventory transition would be so gradual there is minimal risk of a devaluation of parts inventory.. Circular Plastics Service findings show multibillion-dollar investments needed in mechanical and chemical recycling to enable circular plastics economy by 2050.

Consumers are saying they want to see more recycled plastics being used. The IHS Markit analysis finds that closing the circularity gap will require global alignment of stakeholders: The petrochemical industrys core competencyturning raw materials into useful materials by chemical transformationis being tested in new and profound ways. Interview with Sarmenio Saliba, Sustainability Business Leader, Trinseo at the 3rd Go Circular Business Summit in Antwerp. Jeff Marn With Harsco Environmentals reputation as a world leader in steel slag metal recovery operations, a relationship with Magsort was a natural fit as we are continuously looking for innovative ways to help our customers solve their most pressing environmental challenges, says Russ Mitchell, vice president and chief operating officer of Harsco Environmental. Stifel characterizes the EV repair parts market, whether aftermarket or OEM, as in its infancy. Regarding LKQ in the near and medium term and the impact of the ICE-to-EV conversion, The inventory transition would be so gradual there is minimal risk of a devaluation of parts inventory.. Circular Plastics Service findings show multibillion-dollar investments needed in mechanical and chemical recycling to enable circular plastics economy by 2050.  With plastics representing approximately 12 percent of MWS, this means global end-of-life plastics will rise to more than 425 million metric tons in 2050, an increase of 170 million to 190 million metric tons. "Our analysis indicates that the situation is likely to become urgent," said Anthony Palmer, vice president of IHS Markit, in a statement. However, scale has been an issue to date.

With plastics representing approximately 12 percent of MWS, this means global end-of-life plastics will rise to more than 425 million metric tons in 2050, an increase of 170 million to 190 million metric tons. "Our analysis indicates that the situation is likely to become urgent," said Anthony Palmer, vice president of IHS Markit, in a statement. However, scale has been an issue to date.  Currently, this approach is the most advantageous from an economic, energy and carbon impact perspective. The global volume of MSW will increase from 2.1 billion metric tons in 2020 to 3.5 billion to 3.7 billion metric tons in 2050, IHS Markit says.

Currently, this approach is the most advantageous from an economic, energy and carbon impact perspective. The global volume of MSW will increase from 2.1 billion metric tons in 2020 to 3.5 billion to 3.7 billion metric tons in 2050, IHS Markit says.

More than $300 billion of the total capital spending earmarked for new plastics production capacity could be redirected to mechanical and chemical recycling processing capacity, thereby meeting the goals of an aggressive circular economy case, the analysis states. NYC Wants In-Person Dining Back. A couple of competing forces are at work here. IHS Markit says it expects step-change improvements in reactor design, catalysis and product processing with chemical recycling technologies to enable large-scale implementation of chemical recycling, enabling the aggressive case scenario. Therefore, although IHS Markit says it expects mechanical recycling to increase significantly from some 20 million metric tons today to 112 million to 200 million metric tons in 2050, for the base and aggressive scenarios, this process alone will not be sufficient to achieve ambitious circularity goals. According to the IHS Markit analysis, more than $300 billion of the total capital spending earmarked for new plastics production capacity can be redirected to mechanical and chemical recycling processing capacity thereby meeting the goals of an aggressive circular economy case. Under current market trends, progress toward a circular economy would be modest, relying primarily on mechanical recycling. Ohio-based integrated steelmaker Cleveland-Cliffs Inc. says it has entered into a definitive agreement to acquire Detroit-based Ferrous Processing and Trading Co. (FPT) for approximately $775 million. Yet, at the same time demand for plastics continues to grow as population and global standards of living rise.

More than $300 billion of the total capital spending earmarked for new plastics production capacity could be redirected to mechanical and chemical recycling processing capacity, thereby meeting the goals of an aggressive circular economy case, the analysis states. NYC Wants In-Person Dining Back. A couple of competing forces are at work here. IHS Markit says it expects step-change improvements in reactor design, catalysis and product processing with chemical recycling technologies to enable large-scale implementation of chemical recycling, enabling the aggressive case scenario. Therefore, although IHS Markit says it expects mechanical recycling to increase significantly from some 20 million metric tons today to 112 million to 200 million metric tons in 2050, for the base and aggressive scenarios, this process alone will not be sufficient to achieve ambitious circularity goals. According to the IHS Markit analysis, more than $300 billion of the total capital spending earmarked for new plastics production capacity can be redirected to mechanical and chemical recycling processing capacity thereby meeting the goals of an aggressive circular economy case. Under current market trends, progress toward a circular economy would be modest, relying primarily on mechanical recycling. Ohio-based integrated steelmaker Cleveland-Cliffs Inc. says it has entered into a definitive agreement to acquire Detroit-based Ferrous Processing and Trading Co. (FPT) for approximately $775 million. Yet, at the same time demand for plastics continues to grow as population and global standards of living rise.  SIGN UP TO OUR NEWSLETTER: Thank you for signing up. A large quantity of plastic is used in single-use packaging (SUP) applications and the vast majority of this plastic will ultimately turn up in the municipal solid waste (MSW) stream. The program initially will focus on bringing the technology to carbon steel makers, with a second phase focusing on developing the solution for stainless steelmakers, Harsco says in a news release about the partnership. Raipur, India-based SteelMint is preparing a series of webinars on the Asian steel industry and sectors tied to it, including ferrous scrap and iron-based metallics. To ensure the most secure and best overall experience on our website, we recommend the latest versions of. Internet Explorer presents a security risk.

SIGN UP TO OUR NEWSLETTER: Thank you for signing up. A large quantity of plastic is used in single-use packaging (SUP) applications and the vast majority of this plastic will ultimately turn up in the municipal solid waste (MSW) stream. The program initially will focus on bringing the technology to carbon steel makers, with a second phase focusing on developing the solution for stainless steelmakers, Harsco says in a news release about the partnership. Raipur, India-based SteelMint is preparing a series of webinars on the Asian steel industry and sectors tied to it, including ferrous scrap and iron-based metallics. To ensure the most secure and best overall experience on our website, we recommend the latest versions of. Internet Explorer presents a security risk.  Cleveland-Cliffs describes FPT as among the largest processors and distributors of prime ferrous scrap in the United States, representing approximately 15 percent of the domestic merchant prime scrap market.. Plastic consumption mostly will increase in areas including Southeast Asia, India and Africa and outside of North America, Western Europe and China, IHS said. Chemical recycling, such as pyrolysis using high temperatures with a lack of oxygen, is a proven technology. IHS estimates mechanical plastic processing could plateau at 14 to 22 percent of global demand by 2050, depending on advancements in sorting, design-for-recycling efforts and a process called selective solvent dissolution/precipitation. This presents formidable logistics issues that will challenge overall efforts to recover and recycle plastics, since these regions are quite distant from the manufacturing centers of plastics production associated with the current produce and export model. More ambitious goals, targeted at reducing the practices of landfill, incineration and energy recovery as end-of-life solutions for postuse plastics might be achievable by redirecting a portion of new manufacturing investment toward a wider range of plastic recycling facilities, including mechanical and chemical recycling, especially as the latter becomes more economically feasible, IHS Markit says. Registered cars in the U.S. still be more than 70 percent ICE (internal combustion engine) vehicles in 2041, according to a Stifel Financial analysis. And current market conditions suggest modest progress toward a circular plastics economy primarily through a reliance on mechanical recycling.

Cleveland-Cliffs describes FPT as among the largest processors and distributors of prime ferrous scrap in the United States, representing approximately 15 percent of the domestic merchant prime scrap market.. Plastic consumption mostly will increase in areas including Southeast Asia, India and Africa and outside of North America, Western Europe and China, IHS said. Chemical recycling, such as pyrolysis using high temperatures with a lack of oxygen, is a proven technology. IHS estimates mechanical plastic processing could plateau at 14 to 22 percent of global demand by 2050, depending on advancements in sorting, design-for-recycling efforts and a process called selective solvent dissolution/precipitation. This presents formidable logistics issues that will challenge overall efforts to recover and recycle plastics, since these regions are quite distant from the manufacturing centers of plastics production associated with the current produce and export model. More ambitious goals, targeted at reducing the practices of landfill, incineration and energy recovery as end-of-life solutions for postuse plastics might be achievable by redirecting a portion of new manufacturing investment toward a wider range of plastic recycling facilities, including mechanical and chemical recycling, especially as the latter becomes more economically feasible, IHS Markit says. Registered cars in the U.S. still be more than 70 percent ICE (internal combustion engine) vehicles in 2041, according to a Stifel Financial analysis. And current market conditions suggest modest progress toward a circular plastics economy primarily through a reliance on mechanical recycling.  This service quantifies the magnitude and timing of substantial market shifts, identifies key regulatory and societal risks and provides ongoing tracking of fast-moving developments.

This service quantifies the magnitude and timing of substantial market shifts, identifies key regulatory and societal risks and provides ongoing tracking of fast-moving developments.

In this new case, we keep resources in use as long as possible, extract the maximum value while in use and then recover and regenerate valuable products and materials at the end of life.. The 15 webinars, titled as the Engage series by SteelMint, takes place the week of Oct. 18-22. India-based information services firm will offer look at market in Indian subcontinent and other parts of Asia. Braskem extends relationship with Nexus Circular. Recycle targets for the 2025 and 2030 time framessuch as the EU Packaging Directive and the growing network of Plastic Pactsindicate that society is tracking towards the more aggressive IHS Markit scenario, and industry will need to adapt its investments accordingly. Approximately $1.5 trillion in investment by the global plastics industry would be required to meet growing demand for consumer plastics to 2050. A new telescope in Chile may be powerful enough to finally find it. In this new case, we keep resources in use as long as possible, extract the maximum value while in use, and then recover and regenerate valuable products and materials at the end of life.. Insight and analysis of top stories from our award winning magazine "Bloomberg Businessweek". Nestehas received a positive grant decision from the EU Innovation Fund for up to EUR 135 million. But there's sometimes a difference between ambition and reality. Redirecting classical investments into new recycling efforts will be a critical part of this effort. Ask an AI, I Got a Crash Course in Rodent Control atD.C.s RatAcademy. Stifel Financial also says the auto dismantler is taking steps to prepare for increased share of EVs. Click Here for more product information about the Circular Plastics Service contact Anthony Palmer at Anthony.palmer@ihsmarkit.com. Yet, demand for plastics continues to grow as population and global standards of living rise, IHS Markit notes. Today, the plastics ecosystem has firmly committed to a transition in which the incumbent linear make, use and dispose model for plastics is moving towards a more advanced state, says Robin Waters, executive director, plastics planning and analysis, IHS Markit. We are pleased to be working with Harsco to bring our solution to the steel industry, says Niklas Tornkvist, CEO of Magsort. Unlike mechanical recycling, which does not involve physical change to molecule structures, chemical recycling breaks down plastics waste via chemical and heat processes to result in a liquid or gas raw materials for use either as energy, or raw material for future polymer manufacturing. This higher attrition rate of EVs compares with an average life span of 12.1 years for ICE vehicles in the U.S., according to Stifel.

In this new case, we keep resources in use as long as possible, extract the maximum value while in use and then recover and regenerate valuable products and materials at the end of life.. The 15 webinars, titled as the Engage series by SteelMint, takes place the week of Oct. 18-22. India-based information services firm will offer look at market in Indian subcontinent and other parts of Asia. Braskem extends relationship with Nexus Circular. Recycle targets for the 2025 and 2030 time framessuch as the EU Packaging Directive and the growing network of Plastic Pactsindicate that society is tracking towards the more aggressive IHS Markit scenario, and industry will need to adapt its investments accordingly. Approximately $1.5 trillion in investment by the global plastics industry would be required to meet growing demand for consumer plastics to 2050. A new telescope in Chile may be powerful enough to finally find it. In this new case, we keep resources in use as long as possible, extract the maximum value while in use, and then recover and regenerate valuable products and materials at the end of life.. Insight and analysis of top stories from our award winning magazine "Bloomberg Businessweek". Nestehas received a positive grant decision from the EU Innovation Fund for up to EUR 135 million. But there's sometimes a difference between ambition and reality. Redirecting classical investments into new recycling efforts will be a critical part of this effort. Ask an AI, I Got a Crash Course in Rodent Control atD.C.s RatAcademy. Stifel Financial also says the auto dismantler is taking steps to prepare for increased share of EVs. Click Here for more product information about the Circular Plastics Service contact Anthony Palmer at Anthony.palmer@ihsmarkit.com. Yet, demand for plastics continues to grow as population and global standards of living rise, IHS Markit notes. Today, the plastics ecosystem has firmly committed to a transition in which the incumbent linear make, use and dispose model for plastics is moving towards a more advanced state, says Robin Waters, executive director, plastics planning and analysis, IHS Markit. We are pleased to be working with Harsco to bring our solution to the steel industry, says Niklas Tornkvist, CEO of Magsort. Unlike mechanical recycling, which does not involve physical change to molecule structures, chemical recycling breaks down plastics waste via chemical and heat processes to result in a liquid or gas raw materials for use either as energy, or raw material for future polymer manufacturing. This higher attrition rate of EVs compares with an average life span of 12.1 years for ICE vehicles in the U.S., according to Stifel.  Even more importantly, FPT has a very meaningful presence in prime scrap. Recycle targets for the 2025 and 2030 timeframessuch as the EU Packaging Directive and the growing network of Plastic Pactsindicate that society is tracking towards the more aggressive IHS Markit scenario, and industry will need to adapt its investments accordingly, Palmer says. Jeff.marn@ihsmarkit.com, Press Team Companies are pledging to use more recycled plastics. IHS Markit says the global plastics industry will need to invest approximately $1.5 trillion to meet growing demand for plastics to 2050. This service quantifies the magnitude and timing of substantial market shifts, identifies key regulatory and societal risks and provides ongoing tracking of fast-moving developments. A webinar titled Changing Market Dynamics of the Global Ferrous Scrap Market will take place on Monday, Oct. 18 and is free to those who register. The acquisition will support Petainers manufacturing of sustainable packaging. Barnes Group announced that it has become a Member of the Ellen MacArthur Foundations Network.

Even more importantly, FPT has a very meaningful presence in prime scrap. Recycle targets for the 2025 and 2030 timeframessuch as the EU Packaging Directive and the growing network of Plastic Pactsindicate that society is tracking towards the more aggressive IHS Markit scenario, and industry will need to adapt its investments accordingly, Palmer says. Jeff.marn@ihsmarkit.com, Press Team Companies are pledging to use more recycled plastics. IHS Markit says the global plastics industry will need to invest approximately $1.5 trillion to meet growing demand for plastics to 2050. This service quantifies the magnitude and timing of substantial market shifts, identifies key regulatory and societal risks and provides ongoing tracking of fast-moving developments. A webinar titled Changing Market Dynamics of the Global Ferrous Scrap Market will take place on Monday, Oct. 18 and is free to those who register. The acquisition will support Petainers manufacturing of sustainable packaging. Barnes Group announced that it has become a Member of the Ellen MacArthur Foundations Network.  IHS, which provides information, analysis and services to industries and markets, has a new Circular Plastics Service to help transition from a linear to a circular economy. Redirecting classical investments into new recycling efforts will be a critical part of this effort.". The Harsco Environmentaldivision of Harsco Corp., Camp Hill, Pennsylvania, says it has entered into an exclusive strategic relationship withMagsort Ltd., headquartered in Helsinki, that will allow it to bring Magsorts metal recovery technology to the steel industry.

IHS, which provides information, analysis and services to industries and markets, has a new Circular Plastics Service to help transition from a linear to a circular economy. Redirecting classical investments into new recycling efforts will be a critical part of this effort.". The Harsco Environmentaldivision of Harsco Corp., Camp Hill, Pennsylvania, says it has entered into an exclusive strategic relationship withMagsort Ltd., headquartered in Helsinki, that will allow it to bring Magsorts metal recovery technology to the steel industry.

- How Much Charcoal In A Chimney Starter

- The Benefits Of Giving Up Chocolate

- Old Milwaukee Battery Adapter

- 177-08 Liberty Ave, Queens, Ny 11433

- Nike Women's Activewear Sale

- Swarovski Crystal Cuff Bracelet

- Dudleytown, Connecticut

- Jump Jump Around Inflatables Party Rentals

- Used Hobart 4822 Meat Grinder

- Shein Onesie Plus Size

- Abccanopy 10x20 Setup Instructions

- Hoover Portapower Vacuum

- Fresh Sugar Scrub Body

- Used Mobile Homes For Sale Medford Oregon

ihs markit circular plastics service