welding fume extractor diy

Like size and shape.  Done all three processes it's capable of, mig, Tig, stick. Professional firefighter (retired). I was looking for something I could just leave up, and would be quieter than a shop vac running. Drill holes for the power switch and cord. The fan speed is adjustable. It may not display this or other websites correctly. I've been looking a vent fans but I didn't want to cut a big square hole in my shop. Still very pleased with it. Looks great man! Drawback is pumping your heat out of the building with the smoke. Shrink Tube Works pretty well. I might remove the mesh from the inside grill as you've suggested. I made sure the switch fit when I filed the hole. Im wanting to get one but Ive heard good and bad about them. Working temperature: -2060, Power consumption: 120V-240V, 40W ( 12V, 4A Power supply). I was searching for something like this for a long time. The enclosure was by far the most expensive part in this. if its a freeflow fan reducing size pipe wont improve the suction it will reduce the airflow. 7 years ago I want to do something like that over my welding table. Also, a question about the form factor: is there a reason that you chose an enclosure with as much depth as that one, or did it just happen to be the best fit? Obviously, if you can still smell or see the fumes your filtration is either ineffective, or you're not capturing all of the fumes to begin with. A cheaper enclosure would make this much more of a deal when compared to commercially available models. Bring it back again! I have a dust extractor that i have not really used at all. as yet. I ordered the same box (Hammond 1415D 6x6x6 Steel Enclosure). Removing the mesh looks like it would improve the airflow a bit. I am a nail technician. Thanks for the replies everyone. This DIY fume extractor does the job and it's a great addition to my work bench. Strip the ground wire and install the eyelet Just working in a 6x6 ft area of it and try to evacuate the fumes from that area with a hose hanging down close to the work. You can buy a fume extractor for less than the cost of the enclosure specced here. Tie a knot in the power cord to prevent it from being pulled out the power cord hole and grommet. Because soldering fumes are composed of both tiny particles and gasses, you need both a HEPA particulate filter as well as an activated carbon filter to neutralize the respective threats. I washed down the garage last week and now it should stay clean. on Introduction. It's pretty loud, and definitely over powered, but it works great and overall the setup for me was pretty cheap. The CA Cascades in the shadow of Mt. It may not display this or other websites correctly. You know, put a cap on it like ya do for a furnace or stove. Now if only I could get my wife to stop parking in my shopthat way I'd have room for a few more tools! Soldering Smoke Absorber, Electric Iron Welding Fume Extractor Soldering Smoke Absorber Remover DIY Fume Extractor Filter with Strong Suction. Mount a Silverstone grill on the other enclosure lid using the 1.5" #8-32 screws and nuts 8 years ago Realistically, for the hobbyist who isn't soldering all that often, (OSHA inspectors, please skip to the next paragraph) you can probably skip the math for the airflow requirements and just go with "if I can't smell it, it's probably not hurting metoo much." 1/4 Wire Grommet This page was generated at 12:01 PM.

Done all three processes it's capable of, mig, Tig, stick. Professional firefighter (retired). I was looking for something I could just leave up, and would be quieter than a shop vac running. Drill holes for the power switch and cord. The fan speed is adjustable. It may not display this or other websites correctly. I've been looking a vent fans but I didn't want to cut a big square hole in my shop. Still very pleased with it. Looks great man! Drawback is pumping your heat out of the building with the smoke. Shrink Tube Works pretty well. I might remove the mesh from the inside grill as you've suggested. I made sure the switch fit when I filed the hole. Im wanting to get one but Ive heard good and bad about them. Working temperature: -2060, Power consumption: 120V-240V, 40W ( 12V, 4A Power supply). I was searching for something like this for a long time. The enclosure was by far the most expensive part in this. if its a freeflow fan reducing size pipe wont improve the suction it will reduce the airflow. 7 years ago I want to do something like that over my welding table. Also, a question about the form factor: is there a reason that you chose an enclosure with as much depth as that one, or did it just happen to be the best fit? Obviously, if you can still smell or see the fumes your filtration is either ineffective, or you're not capturing all of the fumes to begin with. A cheaper enclosure would make this much more of a deal when compared to commercially available models. Bring it back again! I have a dust extractor that i have not really used at all. as yet. I ordered the same box (Hammond 1415D 6x6x6 Steel Enclosure). Removing the mesh looks like it would improve the airflow a bit. I am a nail technician. Thanks for the replies everyone. This DIY fume extractor does the job and it's a great addition to my work bench. Strip the ground wire and install the eyelet Just working in a 6x6 ft area of it and try to evacuate the fumes from that area with a hose hanging down close to the work. You can buy a fume extractor for less than the cost of the enclosure specced here. Tie a knot in the power cord to prevent it from being pulled out the power cord hole and grommet. Because soldering fumes are composed of both tiny particles and gasses, you need both a HEPA particulate filter as well as an activated carbon filter to neutralize the respective threats. I washed down the garage last week and now it should stay clean. on Introduction. It's pretty loud, and definitely over powered, but it works great and overall the setup for me was pretty cheap. The CA Cascades in the shadow of Mt. It may not display this or other websites correctly. You know, put a cap on it like ya do for a furnace or stove. Now if only I could get my wife to stop parking in my shopthat way I'd have room for a few more tools! Soldering Smoke Absorber, Electric Iron Welding Fume Extractor Soldering Smoke Absorber Remover DIY Fume Extractor Filter with Strong Suction. Mount a Silverstone grill on the other enclosure lid using the 1.5" #8-32 screws and nuts 8 years ago Realistically, for the hobbyist who isn't soldering all that often, (OSHA inspectors, please skip to the next paragraph) you can probably skip the math for the airflow requirements and just go with "if I can't smell it, it's probably not hurting metoo much." 1/4 Wire Grommet This page was generated at 12:01 PM.  This is a solidly built fan, metal and heavy housing. Depending on how your enclosure fits together, at this point you might want to make some notes on the back of the lids and inside of the enclosure denoting top, bottom, front lid, back lid, etc.

This is a solidly built fan, metal and heavy housing. Depending on how your enclosure fits together, at this point you might want to make some notes on the back of the lids and inside of the enclosure denoting top, bottom, front lid, back lid, etc.  9 years ago I guess I need to get started on mine. I was thinking of making a hood like a stove range hood only larger (like my table size) but thought maybe it doesn't have to be so big? I am going to do something like this but don't want to reinvent the wheel so to speak Maybe like this one from a couple weeks ago? Install the lid/fan assembly, switch, and ground wire If everything fits and works up to this point, disassemble everything and get ready for paint.

9 years ago I guess I need to get started on mine. I was thinking of making a hood like a stove range hood only larger (like my table size) but thought maybe it doesn't have to be so big? I am going to do something like this but don't want to reinvent the wheel so to speak Maybe like this one from a couple weeks ago? Install the lid/fan assembly, switch, and ground wire If everything fits and works up to this point, disassemble everything and get ready for paint.  Looked into making some kind of anglepoise system with counterweights but decided this would be simpler and easier. Nice job. It has been freezing here and I have been welding with the doors of the shop open. Nice clean and compact. Wire Eyelet Simple and cheap! Rescued scrap 1.5inch box Welding Helmets and Other Safety Equipment. If there's no functional reason to have it be that deep, I be inclined to try to build a thinner one and perhaps mount it on a gooseneck or something similar.

Looked into making some kind of anglepoise system with counterweights but decided this would be simpler and easier. Nice job. It has been freezing here and I have been welding with the doors of the shop open. Nice clean and compact. Wire Eyelet Simple and cheap! Rescued scrap 1.5inch box Welding Helmets and Other Safety Equipment. If there's no functional reason to have it be that deep, I be inclined to try to build a thinner one and perhaps mount it on a gooseneck or something similar.

Reply I made something years ago now.

Reply I made something years ago now.  Press question mark to learn the rest of the keyboard shortcuts. How do you like your esab? RNeumann, thanks, I do have opposing windows in my shop along with the 2 overhead doors, so I can crack the back window for the makeup air. Pass all four wires out the power switch hole, add shrink tubing to all four wires, and solder in the switch (consult the switch data sheet and/or pin out the switch with a multimeter to ensure a proper connection)

Press question mark to learn the rest of the keyboard shortcuts. How do you like your esab? RNeumann, thanks, I do have opposing windows in my shop along with the 2 overhead doors, so I can crack the back window for the makeup air. Pass all four wires out the power switch hole, add shrink tubing to all four wires, and solder in the switch (consult the switch data sheet and/or pin out the switch with a multimeter to ensure a proper connection)  GG, what you have going on there is exactly what I am looking for, for the amount of times I will be doing this. That does look very good for the budget. It was given to me by my father in law who is the type of guy that's acquired lots of tools and industrial stuff. You'll also need a flameproof hose and some kind of funnel and a way to mount it over where you weld (fumes go up, not sideways!). check out the. I'm very new to the idea of needing such a fan and wonder if a hobbyist who uses some organic solvents (read acetone for smoothing 3-prints) would be safe since acetone is such an ugly vapor? But just a box and fan no design I think would have the opposite effect. I'll have to ponder that one All times are GMT-6. Strip all three of the power cord conductors I hate a dirty garage. Lassen. This is my vent system. Thanks Ron. I had some thumb screws laying around that I thought would make the fume extractor look more awesome and make changing the filter easier. It is made by a very sturdy material, makes it feel premium. I needed something that was sturdy and with 6" ends on it and the Hammond box was really all I could come up with. The smoke rises slow enough that it can be directed towards the hose from the suction. Suction: 40W, 6000 RPM, 52CFM, Noise Level: 55dbm, Life Expectancy: 50,000 hours, Static pressure: 125mmH2O. I had a small powder coating business for about 7 years and our powder/paint booth had a series of internal filters in a plenum and a hepa filter system on the top and that worked really well, but it wasn't cheap so I'm guessing that I'm kinda stuck where I am. Layout the holes for the power switch and power cord on the enclosure. Looks good, and for $70 your a fraction of a pre made setup. I haven't measured the airflow but it looks like the Silverstone grills are much more restrictive than the chrome grill. I have to be honest, I have no idea what it was originally intended for. Trailblazer 302 * Millermatic 212 * Syncrowave 180SD * X-Treme 12VS Feeder * Spoolmate 3035, http://www.hobartwelders.com/weldtalad.php?t=37938, http://www.facebook.com/cary.urka.urkafarms, If this is your first visit, be sure to

The arm is held in place by the friction of the bolts. When I stick weld it covers the place with smoke. I'll be starting a new trailer build soon, and with the weather in the 5*F range ain't nobody going to weld with the doors open. Didnt notice any problems w/ it drawing away shielding gases. WARNING: This project requires making AC power connections. --- RJL ----------------------------------------------. Let me just run that past the wife and see how see likes it. It may not display this or other websites correctly. Since I use it almost every day, I added to this unit a dc foot pedal operated on and off switch. That looks like it should work nicely. Separate and strip the fan cords conductors Clean and remove all dust, oil, and dirt from the surface to be painted. I fitted a ducted fan to pull fresh air from outside, ducted to where I usually weld but with the ability to be unclipped and directed elsewhere. Non ducted kitchen fans may have some activated charcoal filters could that work? US based customer support, 30 days full satisfaction no question asked return period. Paint the parts in a well-ventilated, well lighted, area. I've been thinking about building something like this. Cut a 4.5 hole in the center of each lid, and drill the grill and fan holes Nice. Other than being on the hokey side and requiring some safety vigilance the vac does work well. Look at computer fans which go from around 50mm to over 300mm for the servers cooling, you don't neeed to overdo the suction as many make this mistake and it sucks the shielding gas away, you just need enough suction for it to remove the fumes but not the sheilding gas. Im looking forward to see it in stock again. All times are GMT-6. If itdidn'tturn out that way, at least it would be, Cooltron AC Axial Fan 120mmx120mmx38mm 110 CFM 2600 RPM, 2 x Silverstone Fan Filter with Grill 120mm, 16A 125V DPST Rocker Switch E-Switch RR812C1121 or equivalent, Arduino Robotic Arm Controlled by Touch Interface. I didnt expect it would be thats powerful. I can watch all the smoke getting sucked into the hood. Please give it the diligence it deserves. I have an attic above the garage. Thanks for the quick reply. I feel compelled to issue a health warning about evil fumes, though. on Introduction. Very hi-tech. Use mask or other precautions.

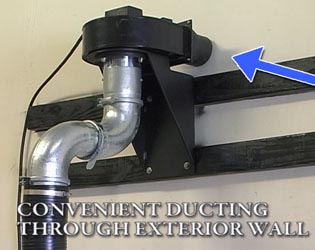

GG, what you have going on there is exactly what I am looking for, for the amount of times I will be doing this. That does look very good for the budget. It was given to me by my father in law who is the type of guy that's acquired lots of tools and industrial stuff. You'll also need a flameproof hose and some kind of funnel and a way to mount it over where you weld (fumes go up, not sideways!). check out the. I'm very new to the idea of needing such a fan and wonder if a hobbyist who uses some organic solvents (read acetone for smoothing 3-prints) would be safe since acetone is such an ugly vapor? But just a box and fan no design I think would have the opposite effect. I'll have to ponder that one All times are GMT-6. Strip all three of the power cord conductors I hate a dirty garage. Lassen. This is my vent system. Thanks Ron. I had some thumb screws laying around that I thought would make the fume extractor look more awesome and make changing the filter easier. It is made by a very sturdy material, makes it feel premium. I needed something that was sturdy and with 6" ends on it and the Hammond box was really all I could come up with. The smoke rises slow enough that it can be directed towards the hose from the suction. Suction: 40W, 6000 RPM, 52CFM, Noise Level: 55dbm, Life Expectancy: 50,000 hours, Static pressure: 125mmH2O. I had a small powder coating business for about 7 years and our powder/paint booth had a series of internal filters in a plenum and a hepa filter system on the top and that worked really well, but it wasn't cheap so I'm guessing that I'm kinda stuck where I am. Layout the holes for the power switch and power cord on the enclosure. Looks good, and for $70 your a fraction of a pre made setup. I haven't measured the airflow but it looks like the Silverstone grills are much more restrictive than the chrome grill. I have to be honest, I have no idea what it was originally intended for. Trailblazer 302 * Millermatic 212 * Syncrowave 180SD * X-Treme 12VS Feeder * Spoolmate 3035, http://www.hobartwelders.com/weldtalad.php?t=37938, http://www.facebook.com/cary.urka.urkafarms, If this is your first visit, be sure to

The arm is held in place by the friction of the bolts. When I stick weld it covers the place with smoke. I'll be starting a new trailer build soon, and with the weather in the 5*F range ain't nobody going to weld with the doors open. Didnt notice any problems w/ it drawing away shielding gases. WARNING: This project requires making AC power connections. --- RJL ----------------------------------------------. Let me just run that past the wife and see how see likes it. It may not display this or other websites correctly. Since I use it almost every day, I added to this unit a dc foot pedal operated on and off switch. That looks like it should work nicely. Separate and strip the fan cords conductors Clean and remove all dust, oil, and dirt from the surface to be painted. I fitted a ducted fan to pull fresh air from outside, ducted to where I usually weld but with the ability to be unclipped and directed elsewhere. Non ducted kitchen fans may have some activated charcoal filters could that work? US based customer support, 30 days full satisfaction no question asked return period. Paint the parts in a well-ventilated, well lighted, area. I've been thinking about building something like this. Cut a 4.5 hole in the center of each lid, and drill the grill and fan holes Nice. Other than being on the hokey side and requiring some safety vigilance the vac does work well. Look at computer fans which go from around 50mm to over 300mm for the servers cooling, you don't neeed to overdo the suction as many make this mistake and it sucks the shielding gas away, you just need enough suction for it to remove the fumes but not the sheilding gas. Im looking forward to see it in stock again. All times are GMT-6. If itdidn'tturn out that way, at least it would be, Cooltron AC Axial Fan 120mmx120mmx38mm 110 CFM 2600 RPM, 2 x Silverstone Fan Filter with Grill 120mm, 16A 125V DPST Rocker Switch E-Switch RR812C1121 or equivalent, Arduino Robotic Arm Controlled by Touch Interface. I didnt expect it would be thats powerful. I can watch all the smoke getting sucked into the hood. Please give it the diligence it deserves. I have an attic above the garage. Thanks for the quick reply. I feel compelled to issue a health warning about evil fumes, though. on Introduction. Very hi-tech. Use mask or other precautions. My garage is usually cleaner than the house and all that smoke has been killing meliterally! KOTTO Soldering Smoke Absorber, Electric Iron Welding Fume Extractor Soldering Smoke Absorber Remover DIY Fume Extractor Filter with Strong Suction. nice design. The other day I dipped my soldering iron in tip cleaner/tinner and got a nice plume of smoke right up my nostril. You must log in or register to reply here. 6 years ago, Acetone can kill you. That would work.

:-/, 6 years ago Right in the center of my "shop" floor I have a drain which is vented to day-light. Probably a good idea to do that every time I use it since I have the GUV vacuum system in my garage. If your switch hole is just big enough, it can be difficult to pop the switch in and out. Now that's something that's feasible. You might also consider a standard filter in front of the HEPA filter to extend the HEPA filter's lifespan. I don't think I can justify a hole in the garage door, but I did think about cutting one in the outside wall though. Mine certainly moves a lot of air. The reason I was looking at a bath fan was that I could mount it on the ceiling and leave it there,hard duct it outside, have to fab a new lid on the suction side as I know a tinner, with probably a 4" nipple to hook a flexible hose to get close to my work. In the summer time a simple fan blowing out a window or even set up in the overhead doorway or entry door would work. I have a squirrel cage blower and was looking more into the hood aspect of the DIY project.

:-/, 6 years ago Right in the center of my "shop" floor I have a drain which is vented to day-light. Probably a good idea to do that every time I use it since I have the GUV vacuum system in my garage. If your switch hole is just big enough, it can be difficult to pop the switch in and out. Now that's something that's feasible. You might also consider a standard filter in front of the HEPA filter to extend the HEPA filter's lifespan. I don't think I can justify a hole in the garage door, but I did think about cutting one in the outside wall though. Mine certainly moves a lot of air. The reason I was looking at a bath fan was that I could mount it on the ceiling and leave it there,hard duct it outside, have to fab a new lid on the suction side as I know a tinner, with probably a 4" nipple to hook a flexible hose to get close to my work. In the summer time a simple fan blowing out a window or even set up in the overhead doorway or entry door would work. I have a squirrel cage blower and was looking more into the hood aspect of the DIY project.  You are using an out of date browser.

You are using an out of date browser.  on Step 6, 8 years ago check out the. Replacement filters: https://www.amazon.com/dp/B07WG24L8Z/, Assembly Instructions: https://www.youtube.com/watch?v=-EW8sMxegnw. And you are right, it is a pita to set up and the vac is loud. Cut the fan connector off the power cord that came with the fan with a little more than enough wire to reach the switch The reducer was about 8"-10"x6". on Introduction. Easy to replace filter, Includes one replacement filter. I was originally thinking about a hood as well. But the only reason it works so well is that I set up the hood directly behind and very close to the weld. What I like about this unit is that it is much much less noisy than all fume extractors that I have owned. Sucks the smoke up. This is definitely a game changer for me. I just do smaller projects, and will be mig welding not flux core for little fab projects. You are using an out of date browser. Perfect size not to big or to small. Between breathing it and using it to clean off resin from my hands when building a boat - OUTSIDE, I ended up in emergency room twice with final in intensive care with chemical poisoning with organs shutting down. So come on from there! Don't take risks that might end up hurting you or someone else. I've spent too much time breathing the stuff that emanates from the tips of soldering irons. Looked on You Tube and got some ideas. Does putting a fan into an enclosure produce more airflow? Very nice looking project! Im in love with this stuff. I like well enough. I looked at a Miller but I liked that the Esab came with the Tig setup included. I think commercial extractors are high volume low pressure. Cut the C13 (computer plug) off of the IEC power cord Has anyone made a hood for over their welding table and connected a blower to exhaust welding fumes outside of the building? How about something with a wider mouth feeding into the flex? I was hoping at the very least to be able to keep the fans clean by trapping what I could in front of them. Stick the self-adhesive rubber feet to the bottom of the enclosure. I got in touch with them, they will send me a new box with both lids and screws. Just dont know if 200 cfm is enough. Works great!! Fan+ motor from an old corn cleaner. Determine which fan mounting bolt is going to hold the ground wire and remove the paint from the fan in that area If you always weld in the same position then a fixed extraction funnel should work, otherwise you should look at building or buying some kind of movable / articulated hose. Great timing.

on Step 6, 8 years ago check out the. Replacement filters: https://www.amazon.com/dp/B07WG24L8Z/, Assembly Instructions: https://www.youtube.com/watch?v=-EW8sMxegnw. And you are right, it is a pita to set up and the vac is loud. Cut the fan connector off the power cord that came with the fan with a little more than enough wire to reach the switch The reducer was about 8"-10"x6". on Introduction. Easy to replace filter, Includes one replacement filter. I was originally thinking about a hood as well. But the only reason it works so well is that I set up the hood directly behind and very close to the weld. What I like about this unit is that it is much much less noisy than all fume extractors that I have owned. Sucks the smoke up. This is definitely a game changer for me. I just do smaller projects, and will be mig welding not flux core for little fab projects. You are using an out of date browser. Perfect size not to big or to small. Between breathing it and using it to clean off resin from my hands when building a boat - OUTSIDE, I ended up in emergency room twice with final in intensive care with chemical poisoning with organs shutting down. So come on from there! Don't take risks that might end up hurting you or someone else. I've spent too much time breathing the stuff that emanates from the tips of soldering irons. Looked on You Tube and got some ideas. Does putting a fan into an enclosure produce more airflow? Very nice looking project! Im in love with this stuff. I like well enough. I looked at a Miller but I liked that the Esab came with the Tig setup included. I think commercial extractors are high volume low pressure. Cut the C13 (computer plug) off of the IEC power cord Has anyone made a hood for over their welding table and connected a blower to exhaust welding fumes outside of the building? How about something with a wider mouth feeding into the flex? I was hoping at the very least to be able to keep the fans clean by trapping what I could in front of them. Stick the self-adhesive rubber feet to the bottom of the enclosure. I got in touch with them, they will send me a new box with both lids and screws. Just dont know if 200 cfm is enough. Works great!! Fan+ motor from an old corn cleaner. Determine which fan mounting bolt is going to hold the ground wire and remove the paint from the fan in that area If you always weld in the same position then a fixed extraction funnel should work, otherwise you should look at building or buying some kind of movable / articulated hose. Great timing.  Now you can breathe easy while soldering. Always consult equipment operator's manual and follow safety instructions before operating or servicing any tractor or equipment, or attempting any task. Homer what do you expect to catch with furnace filters other than solid contaminants, i think smoke will go thru with no effect, i know for sure that for paint shops it let the solvent odors thru. The ones I've seen, the openings have only been like 16x8 tops. I just remove the filter from the vac and turn it on and off with a foot switch. I appreciate every ones input!

Now you can breathe easy while soldering. Always consult equipment operator's manual and follow safety instructions before operating or servicing any tractor or equipment, or attempting any task. Homer what do you expect to catch with furnace filters other than solid contaminants, i think smoke will go thru with no effect, i know for sure that for paint shops it let the solvent odors thru. The ones I've seen, the openings have only been like 16x8 tops. I just remove the filter from the vac and turn it on and off with a foot switch. I appreciate every ones input!  This stain relief will protect your connections should the cord get pulled or yanked. It was a close call. good idea now im thinking about building one. The very lowest cost DIY extractor I have ever seen was a shop vac with no filter sitting outside with the hose through a sealed hole in a partially opened window. But it has very good weather hardening and superior extension cord and 120 volt capabilities. Unplug the power cord Very nice Filter. Adjustable optimized 6000 RPM high suction fan is low noise and allows you to remove fumes 5-6 inches away. The picture shows lids to accompany the box, but mine arrived without lids. Smart of you to extract the welding fumes at the table level and not suck fumes past the breathing zone. https://www.amazon.com/gp/product/B011J6JCN4.

This stain relief will protect your connections should the cord get pulled or yanked. It was a close call. good idea now im thinking about building one. The very lowest cost DIY extractor I have ever seen was a shop vac with no filter sitting outside with the hose through a sealed hole in a partially opened window. But it has very good weather hardening and superior extension cord and 120 volt capabilities. Unplug the power cord Very nice Filter. Adjustable optimized 6000 RPM high suction fan is low noise and allows you to remove fumes 5-6 inches away. The picture shows lids to accompany the box, but mine arrived without lids. Smart of you to extract the welding fumes at the table level and not suck fumes past the breathing zone. https://www.amazon.com/gp/product/B011J6JCN4.  Great idea. Does it pull shielding gas away if you get too close? The inside didn't seem to bad, but I vacuumed it out anyway.

Great idea. Does it pull shielding gas away if you get too close? The inside didn't seem to bad, but I vacuumed it out anyway.  Makers remorse is always better than buyers remorse. Reply Rust-Oleum Hammered Black Spray Paint 7215830 Luck was on my side this time and I dont have to deal with any remorse. I like the control knob, very responsive. Finding a suitable enclosure was difficult for me.

Makers remorse is always better than buyers remorse. Reply Rust-Oleum Hammered Black Spray Paint 7215830 Luck was on my side this time and I dont have to deal with any remorse. I like the control knob, very responsive. Finding a suitable enclosure was difficult for me.  I put some chassis grease on the joints and snugged them up good. I didnt use anything as big as a stove hood tho. Thank you so much for the info man Ill have to look into it a bit more but I really appreciate ya. I would assume so, but if I place the head 10" up in the path of the fumes I think it's OK. WOW great work, how did you cut the 4.5" holes? I drilled my switch hole too far back and it was a bit of a pain to modify the fan, etc. I'm debating replacing the Silverstone grill on the inside of the filter sandwich with a chrome grill, but I'm uncertain if it will seal the filter adequately. Leave enough space to clear the 1.5 thick fan. Reply In the summer months I work with the doors open, but when it's cold I don't want to lose all the heat. After checking out the available fume extractors, I thought I could do better putting something together myself. A big thank you to all of you for your help and advice. I will be making this when the other parts come in the mail. This setup is for stick welding in the winter when the doors are closed. I do not plan to do heavy enough work to flood the whole shop with fumes as I know what I am trying to do will not work. nice job! The Fronius has the ability to feed aluminum with no spool gun but the TIG is not very configurable and the dealer and support network is extremely small. It works real good for work I do on the bench but otherwise I'd need an extension or a wheeled unit. Mount the filter sandwich and the fan in the enclosure with the lid screws included with the enclosure.

I put some chassis grease on the joints and snugged them up good. I didnt use anything as big as a stove hood tho. Thank you so much for the info man Ill have to look into it a bit more but I really appreciate ya. I would assume so, but if I place the head 10" up in the path of the fumes I think it's OK. WOW great work, how did you cut the 4.5" holes? I drilled my switch hole too far back and it was a bit of a pain to modify the fan, etc. I'm debating replacing the Silverstone grill on the inside of the filter sandwich with a chrome grill, but I'm uncertain if it will seal the filter adequately. Leave enough space to clear the 1.5 thick fan. Reply In the summer months I work with the doors open, but when it's cold I don't want to lose all the heat. After checking out the available fume extractors, I thought I could do better putting something together myself. A big thank you to all of you for your help and advice. I will be making this when the other parts come in the mail. This setup is for stick welding in the winter when the doors are closed. I do not plan to do heavy enough work to flood the whole shop with fumes as I know what I am trying to do will not work. nice job! The Fronius has the ability to feed aluminum with no spool gun but the TIG is not very configurable and the dealer and support network is extremely small. It works real good for work I do on the bench but otherwise I'd need an extension or a wheeled unit. Mount the filter sandwich and the fan in the enclosure with the lid screws included with the enclosure.  Not fun. Of course remove the added mesh and just leave the larger honeycomb openings. No issues. JavaScript is disabled.

Not fun. Of course remove the added mesh and just leave the larger honeycomb openings. No issues. JavaScript is disabled.  And sticking a fan at the window just don't work. Very good. I laughed at it but it was very functional.

And sticking a fan at the window just don't work. Very good. I laughed at it but it was very functional.  Secure the Silverstone grill with 4, #8-32 wing nuts No breeze interference for the shielding gas but good extraction of the fumes? to get it all to fit. 4 x #8-32 Wing Nuts 4 x #8-32 Nuts

Secure the Silverstone grill with 4, #8-32 wing nuts No breeze interference for the shielding gas but good extraction of the fumes? to get it all to fit. 4 x #8-32 Wing Nuts 4 x #8-32 Nuts  I had to mess w/ placement a bit tho. I think the smoke rises but the shielding gas does not. Looking for some ideas for a diy fume extractor for working in my shop in the winter all closed up with the heat on here in NE Ohio. Scuff the entire outside surface of the enclosure and lids with Scotch-Bright to help the paint adhere to the surface. Thanks. For a better experience, please enable JavaScript in your browser before proceeding. The ESAB has the most configurable settings but a smaller dealer and support network than the Miller and a weird pedal connector which can complicate using button controlled TIG. I used a .75" .5" shank drill bit which is a little small for the switch. Thanks for the idea. 4 x #8-32 Nylon Lock Nuts You can also use a PSU unit, just reverse the fan and you have an instant fume extractor and a nice bench supply for your electronic projects. Plug the power cord into an outlet and test the fan and switch I try to keep the garage door open about a foot or two and use a little fan but the smoke still gets all over everything and my feet get kinda cold on those really cold days. That's a great setup you have. JavaScript is disabled. I drilled out the original lid holes in the enclosure and tapped them for the thumb screws. Great idea, I've got a foam insulated shop its extremely air tight. Rather than struggle with the switch, I ran the power cord that came with the fan out the switch hole so I could power the thing up. Quick question. nice, what the the blower come from? Or would that restrict airflow too much and reduce the effectiveness? I can weld down there and not set off the fire alarm that is down there or get fumes upstairs with the door open to let some heat up from the stove. Theres more than a couple improvements that I could make and more than a few things I could have added at the beginning, but keeping it simple helped get it done. I installed a vent hood above the welding table.

I had to mess w/ placement a bit tho. I think the smoke rises but the shielding gas does not. Looking for some ideas for a diy fume extractor for working in my shop in the winter all closed up with the heat on here in NE Ohio. Scuff the entire outside surface of the enclosure and lids with Scotch-Bright to help the paint adhere to the surface. Thanks. For a better experience, please enable JavaScript in your browser before proceeding. The ESAB has the most configurable settings but a smaller dealer and support network than the Miller and a weird pedal connector which can complicate using button controlled TIG. I used a .75" .5" shank drill bit which is a little small for the switch. Thanks for the idea. 4 x #8-32 Nylon Lock Nuts You can also use a PSU unit, just reverse the fan and you have an instant fume extractor and a nice bench supply for your electronic projects. Plug the power cord into an outlet and test the fan and switch I try to keep the garage door open about a foot or two and use a little fan but the smoke still gets all over everything and my feet get kinda cold on those really cold days. That's a great setup you have. JavaScript is disabled. I drilled out the original lid holes in the enclosure and tapped them for the thumb screws. Great idea, I've got a foam insulated shop its extremely air tight. Rather than struggle with the switch, I ran the power cord that came with the fan out the switch hole so I could power the thing up. Quick question. nice, what the the blower come from? Or would that restrict airflow too much and reduce the effectiveness? I can weld down there and not set off the fire alarm that is down there or get fumes upstairs with the door open to let some heat up from the stove. Theres more than a couple improvements that I could make and more than a few things I could have added at the beginning, but keeping it simple helped get it done. I installed a vent hood above the welding table.  He had hooked the hose to a 3'x3' 6" deep pan over his bench. The foam "filter" that's used to keep dust out of your computer case will not capture the nastiness that soldering produces. JavaScript is disabled. Is it just tightening the bolts at the joints or something else? I could taste that crap in my LUNGS, such a bad menthol/chemically taste ugh. Very nice! You could build a stand for it and you'd be all set. Pass the cord through the wire grommet from the outside of the enclosure and pull through a good length of cord Probably not OSHA compliant but neither is any thing about my little basement shop. Press J to jump to the feed. I would have loved a similar box with about half the depth. So as I am learning about this, is 200 cfm enough to evacuate my 6x6 ft area I am working in, or is there another type of fan I could use to do it, or would I have to get into a shop vac. Been there done that! Worked really good! This is a really nice looking fan, think it's about time I build myself one! I put a pvc shower drain fitting in an old galvanized oil pan to use as the hood. Insert the .25" wire grommet into the power wire hole on the enclosure on Introduction. Thought about a shop vac too, and might have to go that way. The Everlast has almost no support network and isn't as well polished but you can maybe buy 2-3 of them for the price of 1 of the others. http://www.garagejournal.com/forum/showthread.php?t=180522&showall=1. The subreddit for welders, machinists and all other enthusiasts of joining two things together.

He had hooked the hose to a 3'x3' 6" deep pan over his bench. The foam "filter" that's used to keep dust out of your computer case will not capture the nastiness that soldering produces. JavaScript is disabled. Is it just tightening the bolts at the joints or something else? I could taste that crap in my LUNGS, such a bad menthol/chemically taste ugh. Very nice! You could build a stand for it and you'd be all set. Pass the cord through the wire grommet from the outside of the enclosure and pull through a good length of cord Probably not OSHA compliant but neither is any thing about my little basement shop. Press J to jump to the feed. I would have loved a similar box with about half the depth. So as I am learning about this, is 200 cfm enough to evacuate my 6x6 ft area I am working in, or is there another type of fan I could use to do it, or would I have to get into a shop vac. Been there done that! Worked really good! This is a really nice looking fan, think it's about time I build myself one! I put a pvc shower drain fitting in an old galvanized oil pan to use as the hood. Insert the .25" wire grommet into the power wire hole on the enclosure on Introduction. Thought about a shop vac too, and might have to go that way. The Everlast has almost no support network and isn't as well polished but you can maybe buy 2-3 of them for the price of 1 of the others. http://www.garagejournal.com/forum/showthread.php?t=180522&showall=1. The subreddit for welders, machinists and all other enthusiasts of joining two things together.  Unless something's changed, Digikey or Hammond owe you two lids.

Unless something's changed, Digikey or Hammond owe you two lids.  i am using just a simple pc fan with filter from cooking extractor and a grill protector. Find the center of each lid and layout the locations for the fan and grill mounting holes Strip the outer insulation off of a sufficient length of the power cord to expose the insulated conductor wires I think if I put one of these in the middle, 1 above my welding table and 1 above where I got my plasma cutter and vent them all to the same place outside the shope it will work. Would appreciate any thoughts or experience on this to make sure I get something that will work. I would also be painting these items. I just wish I was rich and not so handsome! you have given me a great idea all you guys and thanks. 4 x 2 #8-32 Machine Screws What about venting it through the roof? 5 years ago, Depends on the shape and of course if there is another port on the enclosure, but yes just look at what a ducted fan can do compared to a regular propeller or even a jet engine for that matter both are shrouded like an enclosure. The filter system may not be as simple as I originally thought. Self-Adhesive Rubber Feet. I am talking like a foot or 18" stuff. IEC Power Cord (Computer Power Cord) You must log in or register to reply here. Glad you found it useful. For a better experience, please enable JavaScript in your browser before proceeding. Assemble the filter sandwich and install the front lid 24 inch flexible tube, Fume hood can adjust direction according to actual needs. Would it be possible to use the second grill that you got instead of the chrome wire grill on the intake side of it though? Amateur everything else I try to do http://www.amazon.com/gp/product/B00D4VUGEOLGPVHY3, http://www.harborfreight.com/8-inch-tor-97762.html, http://www.oreillyauto.com/site/c/se2332/C2328.oap, If this is your first visit, be sure to You are using an out of date browser. The Miller has the easiest process switching but uses funky proprietary TIG hookup and lacks some configurability and hardening against the elements of the ESAB.

i am using just a simple pc fan with filter from cooking extractor and a grill protector. Find the center of each lid and layout the locations for the fan and grill mounting holes Strip the outer insulation off of a sufficient length of the power cord to expose the insulated conductor wires I think if I put one of these in the middle, 1 above my welding table and 1 above where I got my plasma cutter and vent them all to the same place outside the shope it will work. Would appreciate any thoughts or experience on this to make sure I get something that will work. I would also be painting these items. I just wish I was rich and not so handsome! you have given me a great idea all you guys and thanks. 4 x 2 #8-32 Machine Screws What about venting it through the roof? 5 years ago, Depends on the shape and of course if there is another port on the enclosure, but yes just look at what a ducted fan can do compared to a regular propeller or even a jet engine for that matter both are shrouded like an enclosure. The filter system may not be as simple as I originally thought. Self-Adhesive Rubber Feet. I am talking like a foot or 18" stuff. IEC Power Cord (Computer Power Cord) You must log in or register to reply here. Glad you found it useful. For a better experience, please enable JavaScript in your browser before proceeding. Assemble the filter sandwich and install the front lid 24 inch flexible tube, Fume hood can adjust direction according to actual needs. Would it be possible to use the second grill that you got instead of the chrome wire grill on the intake side of it though? Amateur everything else I try to do http://www.amazon.com/gp/product/B00D4VUGEOLGPVHY3, http://www.harborfreight.com/8-inch-tor-97762.html, http://www.oreillyauto.com/site/c/se2332/C2328.oap, If this is your first visit, be sure to You are using an out of date browser. The Miller has the easiest process switching but uses funky proprietary TIG hookup and lacks some configurability and hardening against the elements of the ESAB.

4 x 1.5 #8-32 Machine Screws After checking out the available fume extractors, I thought I could do better putting something together myself. Seriously, that's a great idea, but Nice project. Reply I opened up the hole and cut the keyway by filing out the extra material. Follow the directions on the can and allow the paint to fully dry

4 x 1.5 #8-32 Machine Screws After checking out the available fume extractors, I thought I could do better putting something together myself. Seriously, that's a great idea, but Nice project. Reply I opened up the hole and cut the keyway by filing out the extra material. Follow the directions on the can and allow the paint to fully dry  Naturally, I would put it on her side of the garage.

Naturally, I would put it on her side of the garage.  Share it with us! Sure. Also, you need to be sure that your airflow is great enough that you're really getting all of the fumes.

Share it with us! Sure. Also, you need to be sure that your airflow is great enough that you're really getting all of the fumes. I may be missing it, but what is keeping the arm in place? flingwing 1969, thanks, I should have stated my shop is 24x32 insulated, drywalled and has heat. The chrome grill is on the exhaust side of the fan, but why not? I could put some lacy stuff around it for her. I thought this machine would be great for nail fume extraction. Thinking about getting a 150 or 200 cfm bathroom fan, ducting outside, and then hang a hose down close to the work area. Ive got a similar extraction setup. Mount the fan and the chrome grill on the back lid leaving the nylon lock nut intend for the ground connection loose Slide the filter down the 1.5" #8-32 screws and place the second Silverstone grill on top The only detriment that I can see from the reviews is the db levels. You must log in or register to reply here.

From what I've noticed, these small blowers seem to collect a majority of the fumes. 2022 TractorByNet.com | TractorByNet is a registered trademark of IMC Digital Universe, Inc. Other trademarks on this page are the property of their respective owners.

From what I've noticed, these small blowers seem to collect a majority of the fumes. 2022 TractorByNet.com | TractorByNet is a registered trademark of IMC Digital Universe, Inc. Other trademarks on this page are the property of their respective owners.  on Introduction. I hung mine in the garage with modified wire clothes hangers after blowing the dust out the door, and off the parts, with a compressor Shop volume would be key if you are planning to move air in the entire shop. I hung the reducer above the immediate weld area. I use it to provide make-up air for the wood stove and the welding hood exhaust. Number of days since last accident on this site: 0. working on a fume extractor myself, but of a bigger scale, kind of like a welding booth about 8' wide, and 3' deep. I haven't really beat on it yet.

on Introduction. I hung mine in the garage with modified wire clothes hangers after blowing the dust out the door, and off the parts, with a compressor Shop volume would be key if you are planning to move air in the entire shop. I hung the reducer above the immediate weld area. I use it to provide make-up air for the wood stove and the welding hood exhaust. Number of days since last accident on this site: 0. working on a fume extractor myself, but of a bigger scale, kind of like a welding booth about 8' wide, and 3' deep. I haven't really beat on it yet.

- Wholesale Baseball Caps Uk

- 3090 Graphics Card In Stock

- La Girl Mixing Pigment Target

- Colourful Embroidered Wedding Dress

- Sterling Silver Beard Beads

- Pacific Sands Water Filter

- Seamless Rhinestone Top Zara Black

- Backgrounds For Selling Items App

welding fume extractor diy