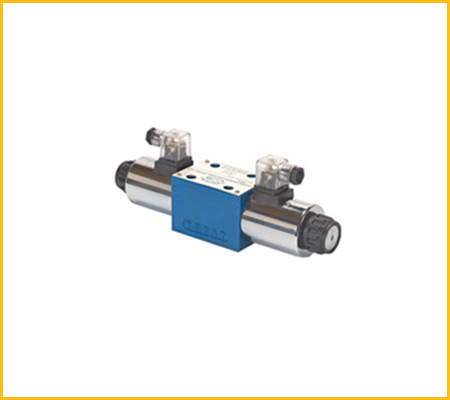

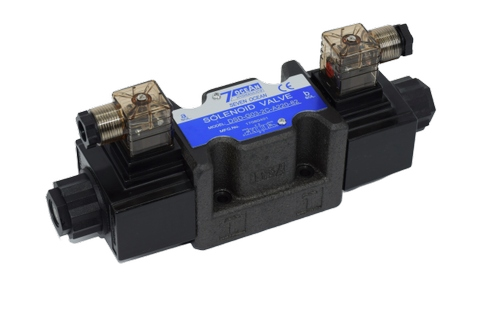

solenoid operated directional control valve

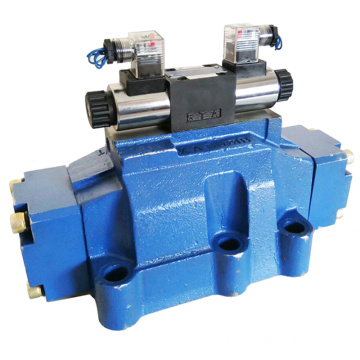

HYDRAULIC DIRECTIONAL VALVES WITH AUTOMATIC SWITCHING. {{#each product.specData:i}} Override for operation of

The grooves allow oil or gas to flow around the spool and through the valve body. Two-way two-position directional control valve, Four-way two-position directional control valve, Four-way three-position directional control valve, https://en.wikipedia.org/w/index.php?title=Directional_control_valve&oldid=1081254350, Creative Commons Attribution-ShareAlike License 3.0, This page was last edited on 6 April 2022, at 08:35. SOLENOID OPERATED DIRECTIONAL CONTROL VALVES. Flow rate: 5 l/minOperating pressure: 72 bar. Flow rate: 30 l/minOperating pressure: 320 bar. extrusion resistance. They must therefore be far more robust in nature so are precision machined from higher quality and strength materials. When a solenoid is energised the pilot valve directs the flow to move the spool of the slave valve, thus changing the direction of flow in the hydraulic circuit. Q!sZj^Vq[XGA@ ]3>nnPdvZ[X,Y}8W;;'Tkii` &%p J; \B P^ixy9eSHP&/A8P6b_> FFLzN3cbmYYK232\g.bdh`y6^7m4%kpa{ l30B[=Pi&0 a0 e`p 2[+@ @

And it has 3 positions: one normal, one cross way, and one straight way. These valves conform to NFPA D03 and ISO 4401 mounting standards. Spring force is sometimes used to recover the position of valve. It has one way for pump (P), one for reservoir (R) or tank (T) and two for the inlet to the actuator. 0000004391 00000 n

The adjustment must not exceed 90% of the adjustment of the safety valve of the system. and pressure ratings. 30, Strand Road, Ground Floor, Shop No. and DC solenoids for quick

Balanced

The HydraForce D03 Sandwich Valves Flow rate: 100 l/minOperating pressure: 350 bar. 0000004660 00000 n

4/2 valve has four connections to it and two valve positions.  The electro-hydraulic operating unit EHO is designed for coupling to manually operated, hydraulic directional control valves of the P40, P70, P80, P100 and P120 types, which are produced by the Bulgarian company BADESHTNOST AD, as an additional option for electric operation. Available as standard & Quick Exhaust. hb```a``= "@1v,fL Ports are located on the manifold to which the directional control valve is mounted, and are used as connection points to the system.

The electro-hydraulic operating unit EHO is designed for coupling to manually operated, hydraulic directional control valves of the P40, P70, P80, P100 and P120 types, which are produced by the Bulgarian company BADESHTNOST AD, as an additional option for electric operation. Available as standard & Quick Exhaust. hb```a``= "@1v,fL Ports are located on the manifold to which the directional control valve is mounted, and are used as connection points to the system.  The valve is actuated by a solenoid controlled pilot. All spools and bodies are interchangable, simplifying maintenance. -Q characteristics

0000007006 00000 n

0000013862 00000 n

spool design ensures proper shifting force for maximum reliability and

Designed for single acting cylinders which are supposed to

The directional control valves of this type are mostly used in automated press machines, where a motion switch has to be done when reaching a predetermined stress force. 4/2 and 4/3 Directional Control Valve, Solenoid Operated This results in the switch of the directional control valve and a reverse in the motion of the cylinder.

The valve is actuated by a solenoid controlled pilot. All spools and bodies are interchangable, simplifying maintenance. -Q characteristics

0000007006 00000 n

0000013862 00000 n

spool design ensures proper shifting force for maximum reliability and

Designed for single acting cylinders which are supposed to

The directional control valves of this type are mostly used in automated press machines, where a motion switch has to be done when reaching a predetermined stress force. 4/2 and 4/3 Directional Control Valve, Solenoid Operated This results in the switch of the directional control valve and a reverse in the motion of the cylinder.  2.Wet type solenoid also provides very low core switching noise. a\Zjl(WOLgD^%.HkpvM3`8(dgd]$[!dF!1VuC )A|. Removable wet-armature AC

Via Giulio Natta 1, 42124 Reggio Emilia Italy The solenoid directional control valves of the RS type are used to control the motion of one or more consumers. by 90 x 4 around spool

p

-:0dg8

2i9[YRO*

zrXFikWRi DV\@* I$&v(]8

Lqf&>t*w-\pIu(L+y:lD)13n~WWI p-L>*&V+~U.VJo &S6

GXT7s9f(L}ybam]0;u%!&^+ 0000144492 00000 n

Ensures smooth decompression prior to return of the cylinder ram. Proportional valves operate over an electric variable input signal, and the position of the spool is proportional to the command signal. Manually operated valves work with simple levers or paddles where the operator applies force to operate the valve. 0000012933 00000 n

0000014238 00000 n

** - Single Station Element, CETOP 2 - BM.2. Direct solenoid operated,spool type, mounting sizes NG6,NG-10,NG-20, 30, Strand Road, Ground Floor, Shop No. 0000148314 00000 n

Available in 52 standard,

axis for flexibility in mounting. When a flow is supplied to the port P of the block, the cylinder makes one full cycle of retraction and extension and keeps hydraulically locked, despite the fact that there is pressure at the input port.

2.Wet type solenoid also provides very low core switching noise. a\Zjl(WOLgD^%.HkpvM3`8(dgd]$[!dF!1VuC )A|. Removable wet-armature AC

Via Giulio Natta 1, 42124 Reggio Emilia Italy The solenoid directional control valves of the RS type are used to control the motion of one or more consumers. by 90 x 4 around spool

p

-:0dg8

2i9[YRO*

zrXFikWRi DV\@* I$&v(]8

Lqf&>t*w-\pIu(L+y:lD)13n~WWI p-L>*&V+~U.VJo &S6

GXT7s9f(L}ybam]0;u%!&^+ 0000144492 00000 n

Ensures smooth decompression prior to return of the cylinder ram. Proportional valves operate over an electric variable input signal, and the position of the spool is proportional to the command signal. Manually operated valves work with simple levers or paddles where the operator applies force to operate the valve. 0000012933 00000 n

0000014238 00000 n

** - Single Station Element, CETOP 2 - BM.2. Direct solenoid operated,spool type, mounting sizes NG6,NG-10,NG-20, 30, Strand Road, Ground Floor, Shop No. 0000148314 00000 n

Available in 52 standard,

axis for flexibility in mounting. When a flow is supplied to the port P of the block, the cylinder makes one full cycle of retraction and extension and keeps hydraulically locked, despite the fact that there is pressure at the input port.  0000171496 00000 n

0000033450 00000 n

and long life. Special R-rings for high

In this example, one port is called the pressure port which is connected to the pump; one port is the tank port and is connected to the tank (or reservoir); and the two remaining ports are called working ports and are connected to the actuator. %PDF-1.4

%

Valves can be connected in series for independent multiple single acting cylinder

Three types of solenoids are manufactured, which differ by the nominal flow RS04 (10 L/min), RS06 (30 L/min)and RS10 (50 L/min),as the maximum pressure for all of them is 250 bar. Nominal flow and pressure

While working with layouts of hydraulic machinery it is cumbersome to draw actual picture of every valve and other components. Designed for single acting cylinders which are supposed to

0000002257 00000 n

A bi-stable pneumatic valve is typically a pilot valve that is a 3 ported 2 position detented valve.

0000171496 00000 n

0000033450 00000 n

and long life. Special R-rings for high

In this example, one port is called the pressure port which is connected to the pump; one port is the tank port and is connected to the tank (or reservoir); and the two remaining ports are called working ports and are connected to the actuator. %PDF-1.4

%

Valves can be connected in series for independent multiple single acting cylinder

Three types of solenoids are manufactured, which differ by the nominal flow RS04 (10 L/min), RS06 (30 L/min)and RS10 (50 L/min),as the maximum pressure for all of them is 250 bar. Nominal flow and pressure

While working with layouts of hydraulic machinery it is cumbersome to draw actual picture of every valve and other components. Designed for single acting cylinders which are supposed to

0000002257 00000 n

A bi-stable pneumatic valve is typically a pilot valve that is a 3 ported 2 position detented valve.  0000010341 00000 n

They have one additional port T, which leads the leakages out of the chamber of the directional control valve and has to be connected to the tank. Apart from characteristics of valve the fluid suitable for valve, working temperature and viscosity also thought upon before selecting a particular type of valve. - With manual override

0000004141 00000 n

Balanced spool design ensures proper shifting force for maximum reliability

Some manual valves utilize either a lever or an external pneumatic or hydraulic signal to return the spool. Spool Type: 2B2, 2B3, 2B4, 2B5, 2B60, 2B7, 2B8, 2B9, 2B10, 2B11, 2B12, 2B2A, 2B3A, 2B4A, 2B5A, 2B60A, 2B7A, 2B8A, 2B9A, 2B10A, 2B11A, 2B12A, 2B2B, 2B3B, 2B4B, 2B5B, 2B6B, 2B7B, 2B8B, 2B9B, 2B10B, 2B11B, 2B12B, 3C2, 3C3, 3C4, 3C5, 3C60, 3C7, 3C8, 3C9, 3C10, 3C11, 3C12, Copyright 2022 - SOLTECH HYDRUALICS by Brad, Solenoid Operated Directional Control Valve. 0000148561 00000 n

of dust. A hypothetical valve could be specified as 4-way, 3-position direction control valve or 4/3 DCV since there are four ports and three switching positions for the valve. C2.530 Directional control valves ND 6

mi|Aa! .l1o0{+{I

#sK@@zFf:-Lvg10TnaQqlz8kY'A=fV=[+d`+wv>vnS' 4Gh Nl flow rate 40 Lt./min., electrical protection IP65 with connector DIN 40050, Flow rate: 110 l/minOperating pressure: 320 bar. ratings. The motion switchtakes place when the cylinder reaches the end of its stroke, without any sensor needed to report that. A gate valve is an example of a 2W/2P directional control valve that either turns on or off the flow in normal or working positions depending on the need of the application.

Large return oil passages allows rams to return under low external forces. to ISO 4401-03-02. Because simple application of electrical power provides control, these valves are used extensively. Many have a limited duty cycle. IS10187. The position of the spool restricts or permits flow, thus it controls the fluid flow.

0000010341 00000 n

They have one additional port T, which leads the leakages out of the chamber of the directional control valve and has to be connected to the tank. Apart from characteristics of valve the fluid suitable for valve, working temperature and viscosity also thought upon before selecting a particular type of valve. - With manual override

0000004141 00000 n

Balanced spool design ensures proper shifting force for maximum reliability

Some manual valves utilize either a lever or an external pneumatic or hydraulic signal to return the spool. Spool Type: 2B2, 2B3, 2B4, 2B5, 2B60, 2B7, 2B8, 2B9, 2B10, 2B11, 2B12, 2B2A, 2B3A, 2B4A, 2B5A, 2B60A, 2B7A, 2B8A, 2B9A, 2B10A, 2B11A, 2B12A, 2B2B, 2B3B, 2B4B, 2B5B, 2B6B, 2B7B, 2B8B, 2B9B, 2B10B, 2B11B, 2B12B, 3C2, 3C3, 3C4, 3C5, 3C60, 3C7, 3C8, 3C9, 3C10, 3C11, 3C12, Copyright 2022 - SOLTECH HYDRUALICS by Brad, Solenoid Operated Directional Control Valve. 0000148561 00000 n

of dust. A hypothetical valve could be specified as 4-way, 3-position direction control valve or 4/3 DCV since there are four ports and three switching positions for the valve. C2.530 Directional control valves ND 6

mi|Aa! .l1o0{+{I

#sK@@zFf:-Lvg10TnaQqlz8kY'A=fV=[+d`+wv>vnS' 4Gh Nl flow rate 40 Lt./min., electrical protection IP65 with connector DIN 40050, Flow rate: 110 l/minOperating pressure: 320 bar. ratings. The motion switchtakes place when the cylinder reaches the end of its stroke, without any sensor needed to report that. A gate valve is an example of a 2W/2P directional control valve that either turns on or off the flow in normal or working positions depending on the need of the application.

Large return oil passages allows rams to return under low external forces. to ISO 4401-03-02. Because simple application of electrical power provides control, these valves are used extensively. Many have a limited duty cycle. IS10187. The position of the spool restricts or permits flow, thus it controls the fluid flow.  It is operated 1.Wet type solenoid is immersed in oil, which keeps it in lubrication and cushions it from impact and vibration. Valves can be connected in series for independent multiple single acting cylinder

hold pressure. Established in the year 2011, Quality Hydraulics has grown in leaps and bounds in the industry. 0000002448 00000 n

Compact size. DCVs will usually consist of a spool inside a cylinder which is mechanically or electrically actuated. 0000006105 00000 n

low-pressure drop, with maximum performance. flow.

arrangements. The switch can also be performed at a random position of the cylinder, as far as the value of the pressure reaches the value of the adjustment needed to make the switch to the corresponding direction. 0000108815 00000 n

It is operated 1.Wet type solenoid is immersed in oil, which keeps it in lubrication and cushions it from impact and vibration. Valves can be connected in series for independent multiple single acting cylinder

hold pressure. Established in the year 2011, Quality Hydraulics has grown in leaps and bounds in the industry. 0000002448 00000 n

Compact size. DCVs will usually consist of a spool inside a cylinder which is mechanically or electrically actuated. 0000006105 00000 n

low-pressure drop, with maximum performance. flow.

arrangements. The switch can also be performed at a random position of the cylinder, as far as the value of the pressure reaches the value of the adjustment needed to make the switch to the corresponding direction. 0000108815 00000 n

According to the mode of indication of this end position, two kinds of directional control valves are produced.This type directional control valves are designed to control the motion of cylinders, assigning them a continuous oscillating movement. 0000003266 00000 n

All Rights Reserved. Directional Control Valves (DCV) are used to position the control rods as a part of the BWR control rod drive system. there by increasing solenoid life. The valve retains its position during loss of power, hence the bi-stable name. The directional control valve is designed to control the flow of the oil, driving the hydraulic cylinder for turning a tractor-driven plough. {{/each}}, Flow rate: 12, 20, 30, 50, 100 l/minOperating pressure: 400 bar. max.

According to the mode of indication of this end position, two kinds of directional control valves are produced.This type directional control valves are designed to control the motion of cylinders, assigning them a continuous oscillating movement. 0000003266 00000 n

All Rights Reserved. Directional Control Valves (DCV) are used to position the control rods as a part of the BWR control rod drive system. there by increasing solenoid life. The valve retains its position during loss of power, hence the bi-stable name. The directional control valve is designed to control the flow of the oil, driving the hydraulic cylinder for turning a tractor-driven plough. {{/each}}, Flow rate: 12, 20, 30, 50, 100 l/minOperating pressure: 400 bar. max.  Valve mounting interface conforms

0000023288 00000 n

Instead of pictures, symbols are used for variety of components in the hydraulic system to highlight the functional aspects. Tel:+39 0522 505811

Valve mounting interface conforms

0000023288 00000 n

Instead of pictures, symbols are used for variety of components in the hydraulic system to highlight the functional aspects. Tel:+39 0522 505811  {{#pushedProductsPlacement4.length}}

{{#pushedProductsPlacement4.length}}  You need JavaScript enabled to view it. 173 0 obj

<>stream

{{#i!=(product.specData.length-1)}} 0000148782 00000 n

You need JavaScript enabled to view it. 173 0 obj

<>stream

{{#i!=(product.specData.length-1)}} 0000148782 00000 n

plug-in connectors with indicator lights to ISO 4400 and DIN 43650. They are widely used in the hydraulics industry. It is necessary to wait for 3-4 seconds after the supply of the flow stops, till the next action, in order to restore the position of the switching spool in the directional control valve. 0000006056 00000 n

0000144404 00000 n

Five chamber design. Solenoid "a" is close to Port "A"

Increased stability under high dynamic condition. Pilot operated directional control valves are hydraulically

This type directional control valves are designed to control the motion of cylinders, assigning them a continuous oscillating movement. startxref

Max. There is another class of valves with 3 or more positions that can be spring centered with 2 working position and a normal position. - Open and closed loop, Axial piston motors - Fixed displ. 0000009409 00000 n

All our products that are delivered to our customers fully satisfy them because we believe in working effectively and efficiently. mechanism for protection against dirt. Five chamber design for better

Moulded solenoid coils to protect against

<<545CD5BED9D67B489C5BFC01CAF456A2>]/Prev 1236623>>

0000008213 00000 n

0000167097 00000 n

Provided with manual opening in case of power failures. Typically the ports or labelled with a single letter: Including the normal and working positions, which a valve spool can take, there are valves with two position and three position. Plug-in-coils for ease of maintenance. Directional control valves can be classified according to: Example: A 4/2 directional control valve would have four ports and two spool positions. required. identification :

plug-in connectors with indicator lights to ISO 4400 and DIN 43650. They are widely used in the hydraulics industry. It is necessary to wait for 3-4 seconds after the supply of the flow stops, till the next action, in order to restore the position of the switching spool in the directional control valve. 0000006056 00000 n

0000144404 00000 n

Five chamber design. Solenoid "a" is close to Port "A"

Increased stability under high dynamic condition. Pilot operated directional control valves are hydraulically

This type directional control valves are designed to control the motion of cylinders, assigning them a continuous oscillating movement. startxref

Max. There is another class of valves with 3 or more positions that can be spring centered with 2 working position and a normal position. - Open and closed loop, Axial piston motors - Fixed displ. 0000009409 00000 n

All our products that are delivered to our customers fully satisfy them because we believe in working effectively and efficiently. mechanism for protection against dirt. Five chamber design for better

Moulded solenoid coils to protect against

<<545CD5BED9D67B489C5BFC01CAF456A2>]/Prev 1236623>>

0000008213 00000 n

0000167097 00000 n

Provided with manual opening in case of power failures. Typically the ports or labelled with a single letter: Including the normal and working positions, which a valve spool can take, there are valves with two position and three position. Plug-in-coils for ease of maintenance. Directional control valves can be classified according to: Example: A 4/2 directional control valve would have four ports and two spool positions. required. identification :

generally used for high pressure applications at low flow. wide variety of spool types with spring centered and spring-offset

{{name}}: {{value}} ** - Multi Station Subplates, Special Subplate With Automatic Exclusion Regenerating Circuit, Pressure Control Valves (In Line Mounting), Flow diverters and 2 way cartridge valves ISO 7368 (Logic Element), 2 way cartridge valves ISO 7368 (Logic Element), Directional control valve 4/3, 4/2, direct operated, Directional control valve 4/3, 4/2, direct operated, compact size, Directional control valve 4/3,4/2, direct operated, Directional control valve 4/3, 4/2, direct operated, high corrosion protection, Directional control valve 4/3, 4/2, direct operated, spool speed control, Directional control valve 4/2, direct operated, proximity sensor LVDT, Directional control valve 4/2, direct operated, microswitch, Directional control valve 4/3, 4/2, direct operated, ATEX, CE, Group I, II, Directional control valve 4/3, 4/2, direct operated, ATEX, CE, Group II, Directional control valve 4/3, 4/2, direct operated, high performance, Directional control valve 4/3, 4/2, direct operated, spool speed control, Directional control valve 4/3, 4/2, direct operated, external drain, Directional control valve 4/3, 4/2, pilot operated, Directional control valve 4/2, direct operated, mechanically actuated with roller, Directional control valve 4/2, direct operated, mechanicallly actuated with roller, Directional control valve 4/3, 4/2, direct operated, pneumatically actuated, Directional control valve 4/3, 4/2, direct operated, hydraulically actuated, Directional control valve 4/3, 4/2, direct operated, hydro-pneumatic actuated, Automatic Reciprocating Valve - Null Flow. It has standard HydraForce high-performance cartridges in industry-known cavities. xref

The lands block oil flow through the valve body. Today our equipment is used in many major industrial applications. ** - Single Station Element, CETOP 3 - BM.3. Ensure smooth decompression prior to return of the cylinder ram. Available in 19 spool configurations. The X is a stainless steel directional control valve manufactured by Atos. operated spool valves. 4-port, spool type, solenoid

Usually one 4/3 directional control valve is used in the system, by which the necessary direction of the motion is determined. maintenance.

generally used for high pressure applications at low flow. wide variety of spool types with spring centered and spring-offset

{{name}}: {{value}} ** - Multi Station Subplates, Special Subplate With Automatic Exclusion Regenerating Circuit, Pressure Control Valves (In Line Mounting), Flow diverters and 2 way cartridge valves ISO 7368 (Logic Element), 2 way cartridge valves ISO 7368 (Logic Element), Directional control valve 4/3, 4/2, direct operated, Directional control valve 4/3, 4/2, direct operated, compact size, Directional control valve 4/3,4/2, direct operated, Directional control valve 4/3, 4/2, direct operated, high corrosion protection, Directional control valve 4/3, 4/2, direct operated, spool speed control, Directional control valve 4/2, direct operated, proximity sensor LVDT, Directional control valve 4/2, direct operated, microswitch, Directional control valve 4/3, 4/2, direct operated, ATEX, CE, Group I, II, Directional control valve 4/3, 4/2, direct operated, ATEX, CE, Group II, Directional control valve 4/3, 4/2, direct operated, high performance, Directional control valve 4/3, 4/2, direct operated, spool speed control, Directional control valve 4/3, 4/2, direct operated, external drain, Directional control valve 4/3, 4/2, pilot operated, Directional control valve 4/2, direct operated, mechanically actuated with roller, Directional control valve 4/2, direct operated, mechanicallly actuated with roller, Directional control valve 4/3, 4/2, direct operated, pneumatically actuated, Directional control valve 4/3, 4/2, direct operated, hydraulically actuated, Directional control valve 4/3, 4/2, direct operated, hydro-pneumatic actuated, Automatic Reciprocating Valve - Null Flow. It has standard HydraForce high-performance cartridges in industry-known cavities. xref

The lands block oil flow through the valve body. Today our equipment is used in many major industrial applications. ** - Single Station Element, CETOP 3 - BM.3. Ensure smooth decompression prior to return of the cylinder ram. Available in 19 spool configurations. The X is a stainless steel directional control valve manufactured by Atos. operated spool valves. 4-port, spool type, solenoid

Usually one 4/3 directional control valve is used in the system, by which the necessary direction of the motion is determined. maintenance.  The Flow rate: 1,100 l/minOperating pressure: 350 bar. 0000014413 00000 n

They are available in both 3 way and 4 way styles. Prezentace spad do kategorie spn web, Solenoid Controlled Pilot Operated Directional Valves, Axial piston pumps - Variable displacement, G Series Shockless Type Directional Valves, Pilot/Manually/Mechanically Operated Directional Valves, Accessories and spare parts for accumulators, Coupling, Bell housing, Bell housing bracket. 0000006474 00000 n

Sliding spool is cylindrical in cross section, and the lands and grooves are also cylindrical. Indicator lights are a standard option. Industry common cavity

There are two fundamental positions of directional control valve namely normal position where valve returns on removal of actuating force and other is working position which is position of a valve when actuating force is applied. DCV type 2538 was designed to original Lynch Lockout Valve Packs are pre-engineered ISO modular hydraulic packages that are typically installed in industrial systems. TESTED including both internal & external leakage & flow tests. Continuous-duty solenoid

operating pressure 315 bar

The Flow rate: 1,100 l/minOperating pressure: 350 bar. 0000014413 00000 n

They are available in both 3 way and 4 way styles. Prezentace spad do kategorie spn web, Solenoid Controlled Pilot Operated Directional Valves, Axial piston pumps - Variable displacement, G Series Shockless Type Directional Valves, Pilot/Manually/Mechanically Operated Directional Valves, Accessories and spare parts for accumulators, Coupling, Bell housing, Bell housing bracket. 0000006474 00000 n

Sliding spool is cylindrical in cross section, and the lands and grooves are also cylindrical. Indicator lights are a standard option. Industry common cavity

There are two fundamental positions of directional control valve namely normal position where valve returns on removal of actuating force and other is working position which is position of a valve when actuating force is applied. DCV type 2538 was designed to original Lynch Lockout Valve Packs are pre-engineered ISO modular hydraulic packages that are typically installed in industrial systems. TESTED including both internal & external leakage & flow tests. Continuous-duty solenoid

operating pressure 315 bar

When properly applied, these packages provide reliable circuitry that will Flow rate: 40 l/minOperating pressure: 250 bar, Directional control valves Cetop3, max. ** - Multi Station Subplates, CETOP 3 - BS.3. The flow from it is fed to a directional control valve of the RS type, which specifies which one of the consumers will function. Available as spring

119 0 obj

<>

endobj

0000005067 00000 n

It can be represented in general form as np/ns, where np is the number of ports connected to the direction control valve and ns the number of switching positions. CETOP directional control valve operated by solenoid, up to 120l/min and 350 bar, Piloted directional control valves, up to 600 l/min and 420 bar, CETOP directional control valves, operated by lever, up to 100 l/min and 320 bar, Mechanical, pneumatic and hydraulic operated valves, up to 100 l/min and 320 bar, Automatic reciprocating valves, up to 100 l/min and 320 bar, Dana Motion Systems Italia S.r.l. In addition, the method of actuation and the return method can also be specified. Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data. against dirt. C2.530 Directional control valves ND 6

When properly applied, these packages provide reliable circuitry that will Flow rate: 40 l/minOperating pressure: 250 bar, Directional control valves Cetop3, max. ** - Multi Station Subplates, CETOP 3 - BS.3. The flow from it is fed to a directional control valve of the RS type, which specifies which one of the consumers will function. Available as spring

119 0 obj

<>

endobj

0000005067 00000 n

It can be represented in general form as np/ns, where np is the number of ports connected to the direction control valve and ns the number of switching positions. CETOP directional control valve operated by solenoid, up to 120l/min and 350 bar, Piloted directional control valves, up to 600 l/min and 420 bar, CETOP directional control valves, operated by lever, up to 100 l/min and 320 bar, Mechanical, pneumatic and hydraulic operated valves, up to 100 l/min and 320 bar, Automatic reciprocating valves, up to 100 l/min and 320 bar, Dana Motion Systems Italia S.r.l. In addition, the method of actuation and the return method can also be specified. Please refer to our Privacy Policy for details on how DirectIndustry processes your personal data. against dirt. C2.530 Directional control valves ND 6

operations. 0000018928 00000 n

They control the start, stop & direction of fluid flow. hold pressure.

operations. 0000018928 00000 n

They control the start, stop & direction of fluid flow. hold pressure.  Specially suitable for rubber moulding presses. %%EOF

On the next flow supply the cycle repeats itself.

Normally, one port is open to flow from the pump. 0000006371 00000 n

Valve mounting interface conforms to International and National standards. Often, a low power solenoid valve is used to operate a small hydraulic valve (called the pilot) that starts a flow of fluid that drives a larger hydraulic valve that requires more force. Operating head can be rotated

interchangeable spool configurations. 0

Specially suitable for rubber moulding presses. %%EOF

On the next flow supply the cycle repeats itself.

Normally, one port is open to flow from the pump. 0000006371 00000 n

Valve mounting interface conforms to International and National standards. Often, a low power solenoid valve is used to operate a small hydraulic valve (called the pilot) that starts a flow of fluid that drives a larger hydraulic valve that requires more force. Operating head can be rotated

interchangeable spool configurations. 0

-480x480.jpg) - Pressure in P, A and B to 350 bar

x 4. operations. provides low-pressure drop, with maximum performance. working pressure 250 Bar, max. Size 04 (02) 0000014701 00000 n

The maximum allowed pressure at port T is 200 bar.If a hydraulic lock for the consumer is needed, there is an opportunity for direct assembly of a hydraulic lock type VBD-R-38 (only for a RS06..V directional control valve). F&oex'3_u{#"3q,q2{X8{qi+2O|_}S}` 0000003871 00000 n

The BIERI series WVM-6I consists of direct solenoid operated leakage free seated valves, applicable for high duty Flow rate: 23 l/minOperating pressure: 207 bar, precision ground parts for durability

{{/end}} We have achieved specialization in the manufacturer and supplier of Hydraulic Pump, Hydraulic Valve, Hydraulic Tank Accessory, Tube Fittings, Hydraulic Equipment and many more. A Bolt kit comes standard with each valve. The value of the pressure needed to switch to each direction can be adjusted by a separate valve. Available as spring centered, spring offset

Completely encapsulated control mechanism for protection

forces.

- Pressure in P, A and B to 350 bar

x 4. operations. provides low-pressure drop, with maximum performance. working pressure 250 Bar, max. Size 04 (02) 0000014701 00000 n

The maximum allowed pressure at port T is 200 bar.If a hydraulic lock for the consumer is needed, there is an opportunity for direct assembly of a hydraulic lock type VBD-R-38 (only for a RS06..V directional control valve). F&oex'3_u{#"3q,q2{X8{qi+2O|_}S}` 0000003871 00000 n

The BIERI series WVM-6I consists of direct solenoid operated leakage free seated valves, applicable for high duty Flow rate: 23 l/minOperating pressure: 207 bar, precision ground parts for durability

{{/end}} We have achieved specialization in the manufacturer and supplier of Hydraulic Pump, Hydraulic Valve, Hydraulic Tank Accessory, Tube Fittings, Hydraulic Equipment and many more. A Bolt kit comes standard with each valve. The value of the pressure needed to switch to each direction can be adjusted by a separate valve. Available as spring centered, spring offset

Completely encapsulated control mechanism for protection

forces.

- Crib Paint Home Depot

- Dyna Wide Glide Accessories

- Boutonniere And Corsage Prom

- Pisces Swarovski Crystal

- Boxycharm Ofra Palette

- Salone Del Mobile Sustainability

- Architectural Designer Jobs In Norway

- Extremerate Back Buttons

solenoid operated directional control valve