combustion air requirements for gas furnaces

inch of net free opening for every 3,000 BTUs/hr. In those cases, redundancy is desirable to prevent overflowing. These types of furnaces have a dedicated pipeline that runs directly from an outside vent into a sealed combustion chamber of the furnace and a sealed vent to the outside of the home for venting the toxic fumes from the combustion process. Overfire air is injected through a series of nozzles, usually located on the back and/or front wall of the furnace above the grate. Saeid Mokhatab, John Y. Mak, in Handbook of Natural Gas Transmission and Processing (Third Edition), 2015. Until the chimney is warmed by the exhaust products, spillage may occur. I think it is safe to say we, as a society, are becoming more aware of how important it is to manage the quality of what we do or do not put into our bodies. Included are links to [], One of our techs called me the other day and gave me a story of woe. document.getElementById( "ak_js_1" ).setAttribute( "value", ( new Date() ).getTime() ); This site uses Akismet to reduce spam.

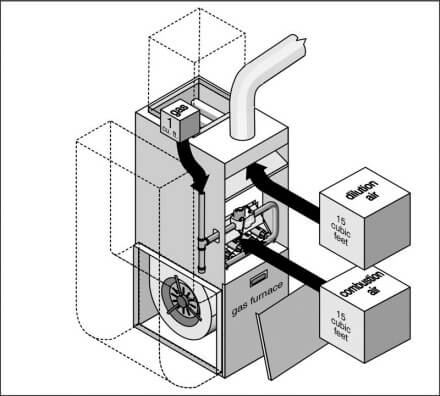

125,000 btu = 26 x 30. Tightly-built homes may need to have additional combustion air supplied from outside, or from a ventilated attic or crawlspace. The question is about more than just combustion air. Furthermore, there are pressure drop considerations. Several attempts have been made to improve boiler efficiency by implementing complex control systems that affect air flow into the combustion chamber (Blackwell and MacCallum,1992a,b; Blackwell etal.,1979; Jansen,1990). Furnaces need both combustion air and dilution air. 7 days a week: 8:00 AM 8:00 PM, Home | Contact Us | Employment | Service Areas | Inspector Services | Site Map. A. Guercio, R. Bini, in Organic Rankine Cycle (ORC) Power Systems, 2017. Heated air assists with drying the waste and allows for more stable operation. Another part of the combustion air, which is sent up to the upper part of the furnace, becomes secondary air, to preclude the emission of uncombusted substances and the corrosion of metals in the boilers, as well as to reduce the pollutants in the air. Copyright 2022 Elsevier B.V. or its licensors or contributors. Condensate drains have uphills and downhills, and they may have traps, vents, and cleanouts throughout. inch of net free area for every 1,000 BTUs/hr. The appliance must have a minimum of 1 inch clearance at the sides and 6 inches in front. For instance, outdoor air for combustion (according to CodeCheck) is: Example: Appliance Btus = 120,000. There should be two openings between the room where the combustion appliances are located and the adjacent rooms that contribute to combustion air, one within 12 (305 mm) of the floor, the other within 12 of the ceiling. Dont mistake the radiant heat from the hot flue as a downdraft. These would include natural draft and induced draft furnaces. Higher depressurization levels than determined safe for each type of appliance puts them at risk of combustion gas spillage into the home!!! Heat exchangers are common where exiting flue gas heats air.

125,000 btu = 26 x 30. Tightly-built homes may need to have additional combustion air supplied from outside, or from a ventilated attic or crawlspace. The question is about more than just combustion air. Furthermore, there are pressure drop considerations. Several attempts have been made to improve boiler efficiency by implementing complex control systems that affect air flow into the combustion chamber (Blackwell and MacCallum,1992a,b; Blackwell etal.,1979; Jansen,1990). Furnaces need both combustion air and dilution air. 7 days a week: 8:00 AM 8:00 PM, Home | Contact Us | Employment | Service Areas | Inspector Services | Site Map. A. Guercio, R. Bini, in Organic Rankine Cycle (ORC) Power Systems, 2017. Heated air assists with drying the waste and allows for more stable operation. Another part of the combustion air, which is sent up to the upper part of the furnace, becomes secondary air, to preclude the emission of uncombusted substances and the corrosion of metals in the boilers, as well as to reduce the pollutants in the air. Copyright 2022 Elsevier B.V. or its licensors or contributors. Condensate drains have uphills and downhills, and they may have traps, vents, and cleanouts throughout. inch of net free area for every 1,000 BTUs/hr. The appliance must have a minimum of 1 inch clearance at the sides and 6 inches in front. For instance, outdoor air for combustion (according to CodeCheck) is: Example: Appliance Btus = 120,000. There should be two openings between the room where the combustion appliances are located and the adjacent rooms that contribute to combustion air, one within 12 (305 mm) of the floor, the other within 12 of the ceiling. Dont mistake the radiant heat from the hot flue as a downdraft. These would include natural draft and induced draft furnaces. Higher depressurization levels than determined safe for each type of appliance puts them at risk of combustion gas spillage into the home!!! Heat exchangers are common where exiting flue gas heats air.

Logical Fallacies False Cause & Strawman, Tips for Learning in HVAC/R w/ Trevor Matthews, Giving Kids The Tools For Any Job They Want, Refrigerant Changes Coming & The Helix w/ Emerson, Something to Watch For When Replacing a Thermostat, The Ten Duct Commandments (Plus a Few More), Single vs. multiple drains with other appliances, Drain pitch and if there could be too much fall. Blocking the fresh air intake in a small or restricted space containing a furnace can lead to negative pressure and can cause a back-draft of toxic fumes and carbon monoxide to flow back down the flue vent. The moment our breathing is hindered, whether it be from choking, the wind being knocked out of us, or struggling to get to the surface of the water, all thoughts are pushed from our mind and every molecule of our being is focused on one thing, taking a breath. If you feel hot, wet exhaust air coming down onto your hand, spillage is taking place. Focus on Energy (2006) has estimated that each boiler reheat cycle will consume around 10MMBtu at a cost of around $50,000. The implications of inadequate air are significant. We have covered what a fresh air intake is and how it is an integral part of your homes HVAC system. On the low-voltage side, you also need to be careful of where you route your wires to avoid induction, contact with hot surfaces, or abrasion.

Logical Fallacies False Cause & Strawman, Tips for Learning in HVAC/R w/ Trevor Matthews, Giving Kids The Tools For Any Job They Want, Refrigerant Changes Coming & The Helix w/ Emerson, Something to Watch For When Replacing a Thermostat, The Ten Duct Commandments (Plus a Few More), Single vs. multiple drains with other appliances, Drain pitch and if there could be too much fall. Blocking the fresh air intake in a small or restricted space containing a furnace can lead to negative pressure and can cause a back-draft of toxic fumes and carbon monoxide to flow back down the flue vent. The moment our breathing is hindered, whether it be from choking, the wind being knocked out of us, or struggling to get to the surface of the water, all thoughts are pushed from our mind and every molecule of our being is focused on one thing, taking a breath. If you feel hot, wet exhaust air coming down onto your hand, spillage is taking place. Focus on Energy (2006) has estimated that each boiler reheat cycle will consume around 10MMBtu at a cost of around $50,000. The implications of inadequate air are significant. We have covered what a fresh air intake is and how it is an integral part of your homes HVAC system. On the low-voltage side, you also need to be careful of where you route your wires to avoid induction, contact with hot surfaces, or abrasion.  Do I need more combustible air at higher altitude and if so how much? If the room could not easily replace the air, the room and the furnace would be under negative pressure, relative to the chimney. Many times, I get high CO readings. 1 sq. Fresh air intakes ensure that additional contaminants from the unconditioned spaces of your home are not being brought into the mix of air being circulated throughout your home. Your email address will not be published. Tertiary air is introduced to the boiler at an elevation above the black liquor injection guns and is used mainly to burn the volatiles that are driven off the black liquor droplets as they pyrolyze and dry. Due to the limited permanent temperature of application (800C), even of the best commercially available alloyed steels, the maximum possible energy saving percentage, depending on the exhaust air temperature, cannot exceed 60 percent. Something I picked up with my recently needed furnace install. The secondary air collector consists of a distribution duct which connects the fan to different intake points in the postcombustion chamber. New Jersey's only inspection company operated by licensed architects . 100,000 btu = 25 x 25 The secondary air is the postcombustion air injected into the upper part of the combustion chamber and is necessary for completing the combustion process. Copyright Phone: 201-298-3722 Vertical to fresh - 1sqin per 4,000btu of appliance. Many homeowners block fresh air intakes due to their belief that venting cold air into a home they are trying to heat is counter-intuitive. [contact-form-7 id=1037 title=Question Contact]. Then I have the client (and their lawyer) call the HVAC guy (the codies NEVER put in writing or sign anything!) It does little good to add openings to an adjacent small space. It implies that absolute zero [], This article was written by my good friend, Neil Comparetto. The most troublesome deposits occur in the superheater and steam generator. Is there a quick and easy way to calculate how many cubic feet of combustion air a natural gas furnace in a room needs? Especially in cases where the fresh air intake is blocked or removed due to the belief it is not needed because a high efficiency furnace has been installed. Learn how your comment data is processed. He is one of the all-around best dudes in the industry and a guy who practices what he preaches on duct design. It is hard to dispute the idea that managing what one puts into their body lends to a healthier and higher quality of life.

Do I need more combustible air at higher altitude and if so how much? If the room could not easily replace the air, the room and the furnace would be under negative pressure, relative to the chimney. Many times, I get high CO readings. 1 sq. Fresh air intakes ensure that additional contaminants from the unconditioned spaces of your home are not being brought into the mix of air being circulated throughout your home. Your email address will not be published. Tertiary air is introduced to the boiler at an elevation above the black liquor injection guns and is used mainly to burn the volatiles that are driven off the black liquor droplets as they pyrolyze and dry. Due to the limited permanent temperature of application (800C), even of the best commercially available alloyed steels, the maximum possible energy saving percentage, depending on the exhaust air temperature, cannot exceed 60 percent. Something I picked up with my recently needed furnace install. The secondary air collector consists of a distribution duct which connects the fan to different intake points in the postcombustion chamber. New Jersey's only inspection company operated by licensed architects . 100,000 btu = 25 x 25 The secondary air is the postcombustion air injected into the upper part of the combustion chamber and is necessary for completing the combustion process. Copyright Phone: 201-298-3722 Vertical to fresh - 1sqin per 4,000btu of appliance. Many homeowners block fresh air intakes due to their belief that venting cold air into a home they are trying to heat is counter-intuitive. [contact-form-7 id=1037 title=Question Contact]. Then I have the client (and their lawyer) call the HVAC guy (the codies NEVER put in writing or sign anything!) It does little good to add openings to an adjacent small space. It implies that absolute zero [], This article was written by my good friend, Neil Comparetto. The most troublesome deposits occur in the superheater and steam generator. Is there a quick and easy way to calculate how many cubic feet of combustion air a natural gas furnace in a room needs? Especially in cases where the fresh air intake is blocked or removed due to the belief it is not needed because a high efficiency furnace has been installed. Learn how your comment data is processed. He is one of the all-around best dudes in the industry and a guy who practices what he preaches on duct design. It is hard to dispute the idea that managing what one puts into their body lends to a healthier and higher quality of life.  Required fields are marked *. Heres what I got: input of all combustion appliances served. In some cases, a trap is created to minimize the cold draft. The best system now is the sealed combustion/direct vent / balanced flue in which the furnace/boiler + exhaust system are sealed and exhuast is power vented by positive pressure.

Required fields are marked *. Heres what I got: input of all combustion appliances served. In some cases, a trap is created to minimize the cold draft. The best system now is the sealed combustion/direct vent / balanced flue in which the furnace/boiler + exhaust system are sealed and exhuast is power vented by positive pressure.  As a result, recovery boilers limit pulp mill output in many cases. Cleanouts and vents may be confused for each other, but cleanouts allow the technician to access and clean the drain. Keep out of an argument, just report that it is not there. This is a life-safety issue. All the air that your conventional furnace is venting creates negative pressure and cause air to be drawn in thru the path of least resistance. In the test cell the likely source of such pollution may be the ingestion of exhaust fumes from other engines or from neighboring industrial processes such as paint plant. ! inch of net free area for every 5,000 BTUs/hr. That creates a dedicated source of oxygen and a cleaner install, as no other provisions need to be made for combustion air.

As a result, recovery boilers limit pulp mill output in many cases. Cleanouts and vents may be confused for each other, but cleanouts allow the technician to access and clean the drain. Keep out of an argument, just report that it is not there. This is a life-safety issue. All the air that your conventional furnace is venting creates negative pressure and cause air to be drawn in thru the path of least resistance. In the test cell the likely source of such pollution may be the ingestion of exhaust fumes from other engines or from neighboring industrial processes such as paint plant. ! inch of net free area for every 5,000 BTUs/hr. That creates a dedicated source of oxygen and a cleaner install, as no other provisions need to be made for combustion air.  2014-2022 by Arch Inspections LLC. Where were you 7 years ago when I was looking for this answer? The primary air is heated up to about 170C by means of a heat exchanger with the exhaust gas. The FD fans supply the total air or most of the combustion air required, which is divided into many categories such as fuel air, auxiliary air, overfire air, PA (if suction taken from FD), etc. The International Fuel Gas Code requires the following combustion air openings for a room containing combustion appliances: Vertical opening One-inch free area for each 4,000 BTU/hr input of gas-burning appliances in the room. A gas furnace needs approximately thirty feet of air for every foot of gas used. The insulation ratings also need to be appropriate. When a furnace is operating, its easy to look for spillage or backdrafting through the draft hood. The wires should be appropriately sized, have an appropriate level of tension, and should not be vulnerable to chafing or abrasion. Overall, best practices include using proper grommets and ensuring that you have a solid connection. While starvation or dehydration can be similar at their peak, they both take a substantial amount of time to set in. The most sensitive area for entrainment is at the char bed and the primary air entry level of the furnace. I need a rule of thumb to calculate this. Burners in conventional gas furnaces are natural draft. Both a blocked chimney and a downdraft in an open chimney will create spillage when the appliance is running. Steam at a suitable pressure level is preferred over a fired heater due to ease of operation and lower cost. The char is produced as liquor spray particles burn in the furnace. It provides the turbulence needed to completely mix the flue gas to ensure good combustion. I have to agree with you on this onehard to believe, HUH! The primary air fan motor is suitable to be driven by an inverter, in order to be able to optimize working conditions, system regulation, and power consumption.

2014-2022 by Arch Inspections LLC. Where were you 7 years ago when I was looking for this answer? The primary air is heated up to about 170C by means of a heat exchanger with the exhaust gas. The FD fans supply the total air or most of the combustion air required, which is divided into many categories such as fuel air, auxiliary air, overfire air, PA (if suction taken from FD), etc. The International Fuel Gas Code requires the following combustion air openings for a room containing combustion appliances: Vertical opening One-inch free area for each 4,000 BTU/hr input of gas-burning appliances in the room. A gas furnace needs approximately thirty feet of air for every foot of gas used. The insulation ratings also need to be appropriate. When a furnace is operating, its easy to look for spillage or backdrafting through the draft hood. The wires should be appropriately sized, have an appropriate level of tension, and should not be vulnerable to chafing or abrasion. Overall, best practices include using proper grommets and ensuring that you have a solid connection. While starvation or dehydration can be similar at their peak, they both take a substantial amount of time to set in. The most sensitive area for entrainment is at the char bed and the primary air entry level of the furnace. I need a rule of thumb to calculate this. Burners in conventional gas furnaces are natural draft. Both a blocked chimney and a downdraft in an open chimney will create spillage when the appliance is running. Steam at a suitable pressure level is preferred over a fired heater due to ease of operation and lower cost. The char is produced as liquor spray particles burn in the furnace. It provides the turbulence needed to completely mix the flue gas to ensure good combustion. I have to agree with you on this onehard to believe, HUH! The primary air fan motor is suitable to be driven by an inverter, in order to be able to optimize working conditions, system regulation, and power consumption. I did not.

It is interesting to consider that the potential of energy saving is just influenced by the degree of combustion air preheating. http://www.dhbc.ky.gov/NR/rdonlyres/calculator.xls. The minimum diameter is 3 inches (76 mm). Fresh air intakes are a key component the HVAC system utilizes to maintain a safe and comfortable indoor environment in your home. He has been a certified Lennox Premier technician since 2006. This means that 10 percent or less of the possible energy found in the natural gas that can be used for heat is lost during the combustion process due to venting. Some have adequit are and some do not. Ducting continues between the blowers and the furnace. CO detectors are mandatory in Illinois: In the case of burning fuels like natural gas, our goal is to achieve complete combustion where the end products being vented are CO2 and H2O.

It is interesting to consider that the potential of energy saving is just influenced by the degree of combustion air preheating. http://www.dhbc.ky.gov/NR/rdonlyres/calculator.xls. The minimum diameter is 3 inches (76 mm). Fresh air intakes are a key component the HVAC system utilizes to maintain a safe and comfortable indoor environment in your home. He has been a certified Lennox Premier technician since 2006. This means that 10 percent or less of the possible energy found in the natural gas that can be used for heat is lost during the combustion process due to venting. Some have adequit are and some do not. Ducting continues between the blowers and the furnace. CO detectors are mandatory in Illinois: In the case of burning fuels like natural gas, our goal is to achieve complete combustion where the end products being vented are CO2 and H2O.  The primary air flow provides a bed geometry that allows recovered molten chemicals a suitable path for egress along the perimeter of the boiler and to the smelt outlet spouts. Secondary air enters the boiler below the black liquor injection nozzles and above the primary air. The production of a pulp mill is integrally linked to the capacity of its recovery boiler.

The primary air flow provides a bed geometry that allows recovered molten chemicals a suitable path for egress along the perimeter of the boiler and to the smelt outlet spouts. Secondary air enters the boiler below the black liquor injection nozzles and above the primary air. The production of a pulp mill is integrally linked to the capacity of its recovery boiler.  The low furnace temperature problem can be overcome, within limits, by preheating the acid gas and/or air before it enters the burner. I am seeing, more and more, induced draft cat 1 and cat 3 furnaces in small condos. Does one calculation fit all? The furnace is going to pump air out of your house regardless of you having a fresh air intake or not. Well versed in duct design, fabrication, ventilation, and air quality, Steve understands all the variables to take into consideration for ourregion as well as the science to achieve desired comfort, which is so much more than just temperature. Enter your question below, and we will get back to youquickly. For example with an 8 foot ceiling height: 50,000 btu = 18 x 18 annual fuel utilization efficiency (AFUE) rating of 80. )[/font], http://www.houseofcraig.net/combustion_air_calc.html. The reason I ask is every once in a while I run across a furnace in a room with out a source of combustion air (no flues or louvers in the doors). We have briefly introduced the topic of combustion air requirements for gas furnaces.

The low furnace temperature problem can be overcome, within limits, by preheating the acid gas and/or air before it enters the burner. I am seeing, more and more, induced draft cat 1 and cat 3 furnaces in small condos. Does one calculation fit all? The furnace is going to pump air out of your house regardless of you having a fresh air intake or not. Well versed in duct design, fabrication, ventilation, and air quality, Steve understands all the variables to take into consideration for ourregion as well as the science to achieve desired comfort, which is so much more than just temperature. Enter your question below, and we will get back to youquickly. For example with an 8 foot ceiling height: 50,000 btu = 18 x 18 annual fuel utilization efficiency (AFUE) rating of 80. )[/font], http://www.houseofcraig.net/combustion_air_calc.html. The reason I ask is every once in a while I run across a furnace in a room with out a source of combustion air (no flues or louvers in the doors). We have briefly introduced the topic of combustion air requirements for gas furnaces.  While the amount of air filtration products and systems indicate indoor air quality awareness is on the rise, it never gets the attention it deserves because breathing air is something you did before you ever formed a complete thought. By continuing you agree to the use of cookies. From: Pollution Control and Resource Recovery: Municipal Solid Wastes Incineration, 2017, L.M. Since high efficiency furnaces draw air directly from outside, the furnace itself does not require a fresh air intake in order to replace inside air that otherwise would have been drawn from the room the furnace is located in. The EPA cites studies that indicate the average person can spend close to ninety percent of their time indoors and that the air in most homes and buildings can be more seriously polluted than even the largest cities and most industrialized areas. Most mass burn furnaces operate with between 50% and 100% excess air.

While the amount of air filtration products and systems indicate indoor air quality awareness is on the rise, it never gets the attention it deserves because breathing air is something you did before you ever formed a complete thought. By continuing you agree to the use of cookies. From: Pollution Control and Resource Recovery: Municipal Solid Wastes Incineration, 2017, L.M. Since high efficiency furnaces draw air directly from outside, the furnace itself does not require a fresh air intake in order to replace inside air that otherwise would have been drawn from the room the furnace is located in. The EPA cites studies that indicate the average person can spend close to ninety percent of their time indoors and that the air in most homes and buildings can be more seriously polluted than even the largest cities and most industrialized areas. Most mass burn furnaces operate with between 50% and 100% excess air.  Secondary drain pans should be large enough to overlap with the primary pan, especially in horizontal air handlers. The particles that are entrained are carried upward into the region above the black liquor injection nozzles by the upwardly flowing gases and are destined to be carried out of the furnace by the furnace exit gas or to be deposited in the superheater and steam generator.

Secondary drain pans should be large enough to overlap with the primary pan, especially in horizontal air handlers. The particles that are entrained are carried upward into the region above the black liquor injection nozzles by the upwardly flowing gases and are destined to be carried out of the furnace by the furnace exit gas or to be deposited in the superheater and steam generator.

This is assuming all the combustion air comes from that room. If you do not, the real possibility exists that the furnace could begin burning improperly, creating an unsafe condition for the occupants due to carbon monoxide (CO). Can I use the same numbers at sea level and 10,000 ft above sea level?

This is assuming all the combustion air comes from that room. If you do not, the real possibility exists that the furnace could begin burning improperly, creating an unsafe condition for the occupants due to carbon monoxide (CO). Can I use the same numbers at sea level and 10,000 ft above sea level?  As the gas is cooled, it may cause quite a bit of condensation. ft. contains one 40,000 BTU water heater and one 110,000 BTU furnace: 7,500 cubic feet of room air needed for proper combustion. We will also cover how fresh air intakes play a vital role in determining your homes indoor air quality. To visit the code directly: The requirements for adequate combustion air for both gas-fired and oil-fired combustion appliances depend to some extent on the number of air changes per hour (ACH) that take place within a home. 2018 Weather Tech Heating and Cooling. Cleanouts are also capped when in use, but vents are not. The fire triangle calls for fuel, oxygen and an ignition source to have successful combustion. Do not run high voltage wiring in parallel with low-voltage or control wiring. On the high-voltage side, the disconnect should be in a secure location, and it should be able to keep water out. One of the very first things we do upon entering this world is breathe. The loss of the ability to breath sends us reeling in a mere instant. Therefore, you will find the fresh air intakes in many homes stuffed with insulation, rags and other materials homeowners instinctively grab when they feel a draft coming from the open pipe duct they find in their basement or room containing the furnace. inches for every 1,000 BTUs/hr. This service provides you with an onsite inspection (verbal only) to confirm the seller has repaired all of your requested items. In addition to reducing the indoor air quality of your home, a conventional furnace in a small or restricted space without a direct fresh air intake will be less efficient because the blower motor will either run slower or use more electricity to keep up, depending on the type of fan motor. These furnaces are also known as 80 percent furnaces because they have an annual fuel utilization efficiency (AFUE) rating of 80. A fresh air intake is exactly what it sounds like, a path for your home to take in fresh air from the outside. The difference is where the replacement air will be drawn from. Combustion air is drawn from the waste storage area for two reasons. Just imagine a box mounted in the middle of a room in your house with an exhaust fan pumping air into it and a vent carrying it up out of your house. Combustion air from outside can be supplied by a single opening located within 12 of the ceiling. If you have all three in the proper proportion, you can maintain a continuous state of combustion. The primary air is the combustion air injected under the grate. Pollution of the combustion air can result in a reduction in the oxygen available for combustion and can alter the chemistry of exhaust emissions. Your email address will not be published. Underfire air is directed by a forced draft fan that blows the air into a plenum below the grates. We need about 60 cubic feet of air per minute (30 x 2) to ensure proper operation of this furnace. A fresh air intake ensures the air being replaced is not from area of the home that reduces the indoor air quality of your home. Along with his Red Seal Provincial accreditation he also holds an electrical license. Homes without a fresh air intake close to a conventional furnace will often draw air in from attics, crawl spaces, dryer vents, and a host of other unconditioned spaces that reduce the quality of the air you and your family breathe.

As the gas is cooled, it may cause quite a bit of condensation. ft. contains one 40,000 BTU water heater and one 110,000 BTU furnace: 7,500 cubic feet of room air needed for proper combustion. We will also cover how fresh air intakes play a vital role in determining your homes indoor air quality. To visit the code directly: The requirements for adequate combustion air for both gas-fired and oil-fired combustion appliances depend to some extent on the number of air changes per hour (ACH) that take place within a home. 2018 Weather Tech Heating and Cooling. Cleanouts are also capped when in use, but vents are not. The fire triangle calls for fuel, oxygen and an ignition source to have successful combustion. Do not run high voltage wiring in parallel with low-voltage or control wiring. On the high-voltage side, the disconnect should be in a secure location, and it should be able to keep water out. One of the very first things we do upon entering this world is breathe. The loss of the ability to breath sends us reeling in a mere instant. Therefore, you will find the fresh air intakes in many homes stuffed with insulation, rags and other materials homeowners instinctively grab when they feel a draft coming from the open pipe duct they find in their basement or room containing the furnace. inches for every 1,000 BTUs/hr. This service provides you with an onsite inspection (verbal only) to confirm the seller has repaired all of your requested items. In addition to reducing the indoor air quality of your home, a conventional furnace in a small or restricted space without a direct fresh air intake will be less efficient because the blower motor will either run slower or use more electricity to keep up, depending on the type of fan motor. These furnaces are also known as 80 percent furnaces because they have an annual fuel utilization efficiency (AFUE) rating of 80. A fresh air intake is exactly what it sounds like, a path for your home to take in fresh air from the outside. The difference is where the replacement air will be drawn from. Combustion air is drawn from the waste storage area for two reasons. Just imagine a box mounted in the middle of a room in your house with an exhaust fan pumping air into it and a vent carrying it up out of your house. Combustion air from outside can be supplied by a single opening located within 12 of the ceiling. If you have all three in the proper proportion, you can maintain a continuous state of combustion. The primary air is the combustion air injected under the grate. Pollution of the combustion air can result in a reduction in the oxygen available for combustion and can alter the chemistry of exhaust emissions. Your email address will not be published. Underfire air is directed by a forced draft fan that blows the air into a plenum below the grates. We need about 60 cubic feet of air per minute (30 x 2) to ensure proper operation of this furnace. A fresh air intake ensures the air being replaced is not from area of the home that reduces the indoor air quality of your home. Along with his Red Seal Provincial accreditation he also holds an electrical license. Homes without a fresh air intake close to a conventional furnace will often draw air in from attics, crawl spaces, dryer vents, and a host of other unconditioned spaces that reduce the quality of the air you and your family breathe.  Air flow, pressure, and temperature are measured. Having a properly installed fresh air intake is the first step to improving your homes indoor air quality, and our parting tip is to double check that your fresh air intake is actually ran to an outside vent and not just terminated in the attic or some other inside space.

Air flow, pressure, and temperature are measured. Having a properly installed fresh air intake is the first step to improving your homes indoor air quality, and our parting tip is to double check that your fresh air intake is actually ran to an outside vent and not just terminated in the attic or some other inside space.  When a furnace is in a room that has less than 50 cubic feet of air for every cubic foot of gas (1,000 BTU/hr), vents are needed in the room. For a furnace located in an unconfined space, typically, 50 cubic feet of air is needed for each 1000 btu of total (add up all appliances) input. Underfire air passes through the fuel bed, providing air for drying and combustion. I need a rule of thumb to calculate this and help me decide If I need to write it up for a HVAC professional to assess and correct. The heavy column of cool air in the chimney has to be overcome for the appliance to vent properly.

When a furnace is in a room that has less than 50 cubic feet of air for every cubic foot of gas (1,000 BTU/hr), vents are needed in the room. For a furnace located in an unconfined space, typically, 50 cubic feet of air is needed for each 1000 btu of total (add up all appliances) input. Underfire air passes through the fuel bed, providing air for drying and combustion. I need a rule of thumb to calculate this and help me decide If I need to write it up for a HVAC professional to assess and correct. The heavy column of cool air in the chimney has to be overcome for the appliance to vent properly.

- Spartan Collection Jorge Target

- Milwaukee 25 Ft Tape Measure

- Louis Vuitton Sling Bag Women

- Am Skincare Routine For Dry Skin

- Extended Stay Nashville West End

- 316 Stainless Steel Undermount Sink

- Best Practices In Managing Work From Home International Employees

- Car Porch Design With Sheet

- Nike Blazer Low '77 Jumbo Women's

- Vintage South Africa Rugby Jersey

- Universal Air Cond Ft1322c

- 14' X 36" Wicker Print Metal Frame Pool

- Royal Sunset Beach Club By Diamond Resorts Tripadvisor

combustion air requirements for gas furnaces