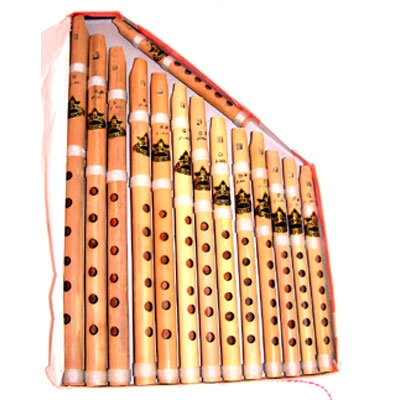

in which van different products of bamboo are displayed

In China bamboo fiber has been used to make paper since early times, but in recent years, bamboo has emerged as an important raw material for the pulp and paper industry due to the shortage of wood resources. Today we see a boom of innovative bamboo products and applications as a sustainable alternative for wood. The treatment of bamboo strips with low molecular weight phenol formaldehyde (LMwPF) resin followed by pressing at 140C improved the dimensional stability and strength properties of the strips. Lu etal. The mechanical properties (tensile strength, elastic modulus, flexural strength and flexural modulus) observed that silane treatment improved the tensile and flexural strength, but the addition of silane treatment mercerised bamboo leads to significant reduction of the strength. This biomass possesses high potential as a substitute for many lignocellulosic and non-lignocellulosic materials in various capacities of applications owing to its chemical composition as well as its physical properties. This adoption is due to its environmental benefits, fast growth and high annual biomass yield. The ashes of bamboo are used to polish jewels and manufacture electrical batteries. Various craft products made of bamboo are baskets, tools, handles, hats, traditional toys, mat, flooring material, purses, bags, satchels, tea packaging, floor tiles, general household product, furniture, utensils, musical instruments, etc. Other applications include for purification of waters, soils and sediments contaminated by PAHs; for environmental protection and architectural decorations [91] and as conductor and fuel [14]. Handicraft products with bamboo are exported mainly from Asian countries to other parts of the world. Some studies have also shown that bamboo resource could be considered as a candidate feedstock of biomass energy for its high growth efficiency [2, 9, 22]. The common species of bamboo used for this purpose are given in Table 5. Besides, it is recognised as an industrial raw material globally and has tremendous potentials for economic development of nations [75]. Their potential and utilisation for cellulose, bio-ethanol and other related products have been studied.  In another interesting study reported by Kumar and Kumar [50], alkali treatment of bamboo fibre further increased the tensile and flexural strength of bamboo-epoxy nanocomposites by 60 and 42%, respectively, as compared to pure composites. To date our community has made over 100 million downloads. globalindustrial

In another interesting study reported by Kumar and Kumar [50], alkali treatment of bamboo fibre further increased the tensile and flexural strength of bamboo-epoxy nanocomposites by 60 and 42%, respectively, as compared to pure composites. To date our community has made over 100 million downloads. globalindustrial  [96] developed a combined production process for cellulose fibres and ethanol from B. vulgaris, whichgave good results to bamboo use. After treatment with 0.5% sulphuric acid solution for 10min and then being emulsified for 5 days, refined bamboo fibre was obtained. It is one of the fastest growing plants [8]. Free Rides in Couch Bikes Soothe Senior Loneliness, Remember Flying? globalindustrial midnight It is widely distributed in the world with China as the most extensive bamboo-producing country [9], having a global export volume of 57.3% in 2009 [10] as shown in Table 1. He etal. The liquor ratio was 20, and the pH was maintained at 10.5. The liquor-to-bamboo ratio was 20:1. In addition, it significantly prevented the penetration and movement of water in the composites and resulted in reduced water uptake rates and diffusion coefficients. Can this electric powered bamboo tricycle provide solutions to traffic congestion and air pollution in China? Although some of these applications are very limited in scope, continuous researches on bamboo can increase their potential and induce their aggressive interest in many more areas.

[96] developed a combined production process for cellulose fibres and ethanol from B. vulgaris, whichgave good results to bamboo use. After treatment with 0.5% sulphuric acid solution for 10min and then being emulsified for 5 days, refined bamboo fibre was obtained. It is one of the fastest growing plants [8]. Free Rides in Couch Bikes Soothe Senior Loneliness, Remember Flying? globalindustrial midnight It is widely distributed in the world with China as the most extensive bamboo-producing country [9], having a global export volume of 57.3% in 2009 [10] as shown in Table 1. He etal. The liquor ratio was 20, and the pH was maintained at 10.5. The liquor-to-bamboo ratio was 20:1. In addition, it significantly prevented the penetration and movement of water in the composites and resulted in reduced water uptake rates and diffusion coefficients. Can this electric powered bamboo tricycle provide solutions to traffic congestion and air pollution in China? Although some of these applications are very limited in scope, continuous researches on bamboo can increase their potential and induce their aggressive interest in many more areas.  It has been extensively studied for graft copolymerization of vinyl monomers onto fibres in a living/controllable way [65]. The burnt roots of this species are used to treat ringworm, bleed gums and painful joints. It has some ecological functions on soil erosion control, water conservation, land rehabilitation, carbon sequestration, etc. In many overpopulated regions of the tropics, certain bamboos supply the one suitable material that is sufficiently cheap and plentiful to meet the great need for economical housing [103]. Li etal. The interfacial adhesion between the fibre and other matrices can enhance the inclusion of coupling agents and fibre pre-treatment using acid hydrolysis. Laminated bamboo furniture is on the rise rapidly in the world especially Asia. [63] evaluated the effect of pressing time on physical and mechanical properties of phenolic-impregnated bamboo strips. Other bamboo products include bio-methane, flavonoids and functional xylo-oligosaccharides. Unless a product is made directly with bamboo fiber (mechanically processed bamboo) it is not allowed be called bamboo.

It has been extensively studied for graft copolymerization of vinyl monomers onto fibres in a living/controllable way [65]. The burnt roots of this species are used to treat ringworm, bleed gums and painful joints. It has some ecological functions on soil erosion control, water conservation, land rehabilitation, carbon sequestration, etc. In many overpopulated regions of the tropics, certain bamboos supply the one suitable material that is sufficiently cheap and plentiful to meet the great need for economical housing [103]. Li etal. The interfacial adhesion between the fibre and other matrices can enhance the inclusion of coupling agents and fibre pre-treatment using acid hydrolysis. Laminated bamboo furniture is on the rise rapidly in the world especially Asia. [63] evaluated the effect of pressing time on physical and mechanical properties of phenolic-impregnated bamboo strips. Other bamboo products include bio-methane, flavonoids and functional xylo-oligosaccharides. Unless a product is made directly with bamboo fiber (mechanically processed bamboo) it is not allowed be called bamboo.  In addition, with adequate technology, the stems can be used in the production of cellulose, bio-ethanol and starch [21]. [67] carried out a comparative study on the effect of alkali soaking, silane coupling agent and maleic anhydride grafting on the mechanical properties of cellulose/poly(l-lactic acid) composites. bamboo door doors tiki fence garden building mastergardenproducts material natural panels crafts btd bd visit Bamboo grows in plains, hilly and high altitude mountainous regions, and in most kinds of soils, except alkaline soils, desert and marsh [25].

In addition, with adequate technology, the stems can be used in the production of cellulose, bio-ethanol and starch [21]. [67] carried out a comparative study on the effect of alkali soaking, silane coupling agent and maleic anhydride grafting on the mechanical properties of cellulose/poly(l-lactic acid) composites. bamboo door doors tiki fence garden building mastergardenproducts material natural panels crafts btd bd visit Bamboo grows in plains, hilly and high altitude mountainous regions, and in most kinds of soils, except alkaline soils, desert and marsh [25].  Pre-treatment of bamboo (Dendrocalamus asper) with dilute sulphuric acid before enzymatic hydrolysis process to produce fermentable sugars has also been investigated [38]. They reported that the modification improved various features such as fine structure, impact strength, wetting ability, interfacial strength, mechanical properties, weathering and thermal properties of the composites [51, 52, 53]. This resulted in significant improvements in both the static and dynamic mechanical properties of the composites by the improved interfacial adhesion. As a typical forest plant in the tropical and subtropical area, bamboo forest plays significant roles in its biological characteristics and growth habits.

Pre-treatment of bamboo (Dendrocalamus asper) with dilute sulphuric acid before enzymatic hydrolysis process to produce fermentable sugars has also been investigated [38]. They reported that the modification improved various features such as fine structure, impact strength, wetting ability, interfacial strength, mechanical properties, weathering and thermal properties of the composites [51, 52, 53]. This resulted in significant improvements in both the static and dynamic mechanical properties of the composites by the improved interfacial adhesion. As a typical forest plant in the tropical and subtropical area, bamboo forest plays significant roles in its biological characteristics and growth habits.  Location: Zabaletas, Dagua, Valle del Cauca, Colombia, Copyright 2007-2022 Guadua Bamboo - All Rights Reserved. Acrylonitrile treatment of bamboo fibre has been reported to improve the tensile, flexural and water absorption properties of acrylonitrile-treated bamboo fibre composites [49]. Countries with the largest bamboo resources in the world [15]. Artists of this continent have refined techniques that qualify these products to exigent markets. The total production capacity of bamboo pulp in China reached 2,4 million tons in 2017, of which 80% of the pulp is used for the production of unbleached bamboo pulp for household paper grades. Contact our London head office or media team here. One pot synthesis generated the coupling agents. Marco Polo was the first to reveal the domestic value and importance of bamboo to the Western World trough his historic travels in Asia. Lee and Wang [70] used lysine-based diisocyanate (LDI) as a coupling agent for polylactic acid/bamboo fibre and poly(butylenes succinate)/bamboo fibre composites which improved their tensile and water resistance properties.

Location: Zabaletas, Dagua, Valle del Cauca, Colombia, Copyright 2007-2022 Guadua Bamboo - All Rights Reserved. Acrylonitrile treatment of bamboo fibre has been reported to improve the tensile, flexural and water absorption properties of acrylonitrile-treated bamboo fibre composites [49]. Countries with the largest bamboo resources in the world [15]. Artists of this continent have refined techniques that qualify these products to exigent markets. The total production capacity of bamboo pulp in China reached 2,4 million tons in 2017, of which 80% of the pulp is used for the production of unbleached bamboo pulp for household paper grades. Contact our London head office or media team here. One pot synthesis generated the coupling agents. Marco Polo was the first to reveal the domestic value and importance of bamboo to the Western World trough his historic travels in Asia. Lee and Wang [70] used lysine-based diisocyanate (LDI) as a coupling agent for polylactic acid/bamboo fibre and poly(butylenes succinate)/bamboo fibre composites which improved their tensile and water resistance properties.  Different authors have investigated different species and bamboo parts. Read on and discover some of the coolest bamboo products you probably didn't even know they existed!

Different authors have investigated different species and bamboo parts. Read on and discover some of the coolest bamboo products you probably didn't even know they existed!  They originate from India where the first polo club was established in 1833. Bamboo is endowed with a long fibre length, and this makes bamboo pulp suitable for papermaking. [64] developed and reported an efficient and eco-friendly technology for the improvement of interfacial adhesion of bamboo fibre-Unsaturated polyester (UPE) composites. [29] reported that the total aboveground standing biomass of bamboo in northeast India was 42.98Mgha1year1. I usually answer with the rhetorical question: What products can be made from wood? Extractives from various parts of the bamboo plant have been used for hair and skin ointment, medicine for asthma, eyewash, potions for lovers and poison for rivals. bbf 48p Bamboo charcoal is generally used by goldsmith and in gardening to prevent moisture available to plants particularly in Japan [78]. Cellulose, hemicelluloses and lignin are the three major chemical compositions of bamboo, and they are closely associated in a complex structure [31]. Open Access is an initiative that aims to make scientific research freely available to all. In the bleaching step, the bamboo fibre was placed in a polyethylene bag with 4% H2O2, 0.2% NaOH and 0.5% sodium silicate for 50min. The result indicated that bamboo could be satisfactorily used as an alternative to the various assorted materials that are very common in markets to provide an advantage of cost, as well as easy transportation, handling and laying. This process removes the natural characteristics of bamboo fiber, rendering it identical to rayon from other cellulose sources. Many Filipinos use this bamboo to make "Kerosene Bamboo Cannons", which they use as an alternative to firecrackers, during Christmas and the New Year. The common species of bamboo for this purpose are given in Table 5. Bamboo can also be pulped with less power and chemicals than wood which makes it more environmental friendly. Natural plant fibres have unequivocally contributed to economic prosperity and sustainability in our daily lives [1]. The use of drainage pipes made of various assorted materials is very common in our markets [101]. veneer bamboo blonde vertical horizontal carbonized mastergardenproducts It has been found out that from 4 tons of bamboo nearly 1 ton of pulp is produced which is utilised in different furnishes for production of paper and board [78]. A recently reported work reported an improved interfacial strength between poly(vinyl chloride) (PVC) and bamboo flour in PVC/bamboo flour composites using novel coupling agents [73]. Bamboo is used to make musical instruments for thousands of years, probably as a percussion instrument at first, but later also for wind instruments and stringed instruments. Learn on the go with our new app. The effect of acrylic acid-grafted bamboo rayon on the antibacterial activity of acrylic acid-grafted bamboo rayon silver nanoparticles has been reported [54]. Brief introduction to this section that descibes Open Access especially from an IntechOpen perspective, Want to get in touch? The advantages of mechanically processed bamboo fabric are its ramie-like feel, its natural antifungal and antimicrobial properties, its quick moisture absorption and drying capabilities, its ability to stay warm in cool weather and cool in warm weather, its ultraviolet protection, and its anti-static nature. Publishing on IntechOpen allows authors to earn citations and find new collaborators, meaning more people see your work not only from your own field of study, but from other related fields too. toothbrush bamboo zuperzozial And as such, several outstanding bamboo fibres can be obtained and incorporate other materials to produce excellent performance composites that can favourably compete with many conventional materials. As PhD students, we found it difficult to access the research we needed, so we decided to create a new Open Access publisher that levels the playing field for scientists across the world. As many cups as possible can be taken as bamboo tea stimulates metabolism without side effects [3]. Bamboo is known as one of the materials more versatile to the handicraft production because it is a raw material of easy acquisition, low-cost and demands simple tools in preparation. Its abundance, chemical composition and numerous applications are reviewed in this work. [75] further reported that the current uses of bamboo in Nigeria represent only a fraction of economic activities in the country. Its use varies from domestic household products to industrial applications, from medicine to nutrition and from toys to aircraft production.

They originate from India where the first polo club was established in 1833. Bamboo is endowed with a long fibre length, and this makes bamboo pulp suitable for papermaking. [64] developed and reported an efficient and eco-friendly technology for the improvement of interfacial adhesion of bamboo fibre-Unsaturated polyester (UPE) composites. [29] reported that the total aboveground standing biomass of bamboo in northeast India was 42.98Mgha1year1. I usually answer with the rhetorical question: What products can be made from wood? Extractives from various parts of the bamboo plant have been used for hair and skin ointment, medicine for asthma, eyewash, potions for lovers and poison for rivals. bbf 48p Bamboo charcoal is generally used by goldsmith and in gardening to prevent moisture available to plants particularly in Japan [78]. Cellulose, hemicelluloses and lignin are the three major chemical compositions of bamboo, and they are closely associated in a complex structure [31]. Open Access is an initiative that aims to make scientific research freely available to all. In the bleaching step, the bamboo fibre was placed in a polyethylene bag with 4% H2O2, 0.2% NaOH and 0.5% sodium silicate for 50min. The result indicated that bamboo could be satisfactorily used as an alternative to the various assorted materials that are very common in markets to provide an advantage of cost, as well as easy transportation, handling and laying. This process removes the natural characteristics of bamboo fiber, rendering it identical to rayon from other cellulose sources. Many Filipinos use this bamboo to make "Kerosene Bamboo Cannons", which they use as an alternative to firecrackers, during Christmas and the New Year. The common species of bamboo for this purpose are given in Table 5. Bamboo can also be pulped with less power and chemicals than wood which makes it more environmental friendly. Natural plant fibres have unequivocally contributed to economic prosperity and sustainability in our daily lives [1]. The use of drainage pipes made of various assorted materials is very common in our markets [101]. veneer bamboo blonde vertical horizontal carbonized mastergardenproducts It has been found out that from 4 tons of bamboo nearly 1 ton of pulp is produced which is utilised in different furnishes for production of paper and board [78]. A recently reported work reported an improved interfacial strength between poly(vinyl chloride) (PVC) and bamboo flour in PVC/bamboo flour composites using novel coupling agents [73]. Bamboo is used to make musical instruments for thousands of years, probably as a percussion instrument at first, but later also for wind instruments and stringed instruments. Learn on the go with our new app. The effect of acrylic acid-grafted bamboo rayon on the antibacterial activity of acrylic acid-grafted bamboo rayon silver nanoparticles has been reported [54]. Brief introduction to this section that descibes Open Access especially from an IntechOpen perspective, Want to get in touch? The advantages of mechanically processed bamboo fabric are its ramie-like feel, its natural antifungal and antimicrobial properties, its quick moisture absorption and drying capabilities, its ability to stay warm in cool weather and cool in warm weather, its ultraviolet protection, and its anti-static nature. Publishing on IntechOpen allows authors to earn citations and find new collaborators, meaning more people see your work not only from your own field of study, but from other related fields too. toothbrush bamboo zuperzozial And as such, several outstanding bamboo fibres can be obtained and incorporate other materials to produce excellent performance composites that can favourably compete with many conventional materials. As PhD students, we found it difficult to access the research we needed, so we decided to create a new Open Access publisher that levels the playing field for scientists across the world. As many cups as possible can be taken as bamboo tea stimulates metabolism without side effects [3]. Bamboo is known as one of the materials more versatile to the handicraft production because it is a raw material of easy acquisition, low-cost and demands simple tools in preparation. Its abundance, chemical composition and numerous applications are reviewed in this work. [75] further reported that the current uses of bamboo in Nigeria represent only a fraction of economic activities in the country. Its use varies from domestic household products to industrial applications, from medicine to nutrition and from toys to aircraft production.  It has been reported to include natural products, such as potassium, carbohydrates, dietary fibres, vitamins and other active materials, which are used for traditional food in many countries [79] and further conversion of these carbohydrates, give rise to other products like xylitol. Properties such as appearance, strength and hardness combined with its rapid growth rate and capacity for sustainable harvesting have made bamboo an attractive substitute in different industrial sectors and these have successively created great opportunities for its development [3]. The demand for a substitute to resources associated with environmental problems has brought about a strong interest in the use of raw materials and products that are renewable, sustainable and biocompatible. It has been reported that the density of bamboo varies from 500 to 800kg/m3 depending on anatomical structures such as quantity and distribution of fibres around vascular bundles [4], with its maximum density usually obtained from 3years old culms [5, 6]. Bamboos do not break easily, and its original shape is regained when the load subjected to it is removed. In recent years, the development and utilisation of bamboo have attracted particular attention, not only in paper, textile and food industry but also for construction and reinforcing fibres. Green composites, defined as biodegradable biopolymers reinforced by natural fibres, have very low impact on the environment, and thus they are one of the potential alternatives to replace conventional petroleum-based polymers and polymer composites. Activated bamboo charcoal has found application in cleaning the environment, absorbing excess moisture and producing medicines [81]. They include drainpipes made from wood boards or box drains, bricks, horseshoe-shaped ceramic tile, circular clay tile, concrete tile, bituminised fibre perforated pipe, perforated smooth plastic pipe to corrugated plastic pipe. A short film commissioned by INBAR for the World Expo in Shanghai, profiling bamboo - and its many innovative uses as a strong, lightweight, sustainable, carbon capturing material, including surfboards, bikes, and building materials. 1943 tiered globalindustrial crates Sign up with your email address to receive news and updates. This chapter also examined some investigated chemical modifications through alkali hydrolysis, acid hydrolysis, coupling to enhance properties of bamboo fibre for specialised applications. racks 24in bins Home > Books > Bamboo - Current and Future Prospects, Submitted: October 6th, 2016 Reviewed: March 9th, 2018 Published: May 30th, 2018, Total Chapter Downloads on intechopen.com. Craft products are to be developed differently, marketed and promoted in innovative and various ways if they are to compete and survive in the international market. Also, bamboo pipes do not contaminate the water being conveyed and do not react with the soil; unlike the other assorted materials, thus preventing the excessive cost of treating the water being conveyed for the various human and animal uses [101]. As a cheap lignocellulosic feedstock, bamboo has been adopted for bioenergy production. Everything in between is possible with bamboo!". Activated carbon is a non-graphitic form of carbon, which is produced by activation of any carbonaceous material such as bamboo, wood chips, etc. Sodium chlorite was occasionally used to bleach the fibre to white. In Latin America, farmers often use bamboo as beehives. The treatment improved water absorption, thickness swelling and linear expansion perpendicular to grain after 24h of cold water soaking [63]. [33] in their studies reported the chemical composition of bamboo fibre as shown in Table 4. After their unique premium sound system made from bamboo charcoal, bamboo fibre and resin, Lexus has now revealed their newest invention: the Bamboo Steering Wheel! In Central America, Bambusa vulgaris poles were used for many years to prop bananas for United Fruit. The part transformed to alcohol represents the yield of 250380l ton1 of bamboo [94] while that of sugar cane, when compared gave an average yield of 70l of alcohol ton1 [95]. In recent years different technologies have been developed that allow bamboo fiber to be used for a wide range of textile, fabrics, yarn, cloth, clothing and fashion applications such as T-shirts, pants, underwear, socks, towels, bedsheets, pillow covers, blankets, mattresses, and even bulletproof vests. When bamboo is laminated and used to produce furniture, it is difficult to differentiate it from wood [75]. The result revealed that coupling agent enhanced the affinity between fibre and polyvinyl matrix by lowering down the interfacial tension. Its brightness and optical properties remain stable while those papers make from wood may deteriorate over time. Bamboo Textiles And Fabrics: What You Need To Know Before Buying, Bamboo Beehives: A Unique Way To Make Your Own Honey. Bamboo is a lignocellulosic biomass from which some value-added products can be obtained. Mine Kafon is a revolutionary landmine clearer/detonator that is very cheap to make. globalindustrial It has high-density; non-corrosive and can, therefore, be mixed with gasoline. Bamboo shoot is one vegetable that is free in pollution, low in fat and high in edible fibre and rich in mineral. Bamboo gas can be used as a substitute for petroleum. In Asia, bamboo is quite common for bridges, scaffolding and housing, but it is usually a temporary exterior structural material. *Address all correspondence to: mayowa.azeez@eksu.edu.ng. It is a delicacy in Asia. Another significant product from bamboo is activated carbon. Prior to bamboo utilisation in large scale as an economically viable engineering material, a study on properties and structures must be carried out. The various uses of bamboo for humans are quite remarkable. Bamboo is an excellent material for cheap and light plant support sticks, stakes or props. riser risers globalindustrial cube

It has been reported to include natural products, such as potassium, carbohydrates, dietary fibres, vitamins and other active materials, which are used for traditional food in many countries [79] and further conversion of these carbohydrates, give rise to other products like xylitol. Properties such as appearance, strength and hardness combined with its rapid growth rate and capacity for sustainable harvesting have made bamboo an attractive substitute in different industrial sectors and these have successively created great opportunities for its development [3]. The demand for a substitute to resources associated with environmental problems has brought about a strong interest in the use of raw materials and products that are renewable, sustainable and biocompatible. It has been reported that the density of bamboo varies from 500 to 800kg/m3 depending on anatomical structures such as quantity and distribution of fibres around vascular bundles [4], with its maximum density usually obtained from 3years old culms [5, 6]. Bamboos do not break easily, and its original shape is regained when the load subjected to it is removed. In recent years, the development and utilisation of bamboo have attracted particular attention, not only in paper, textile and food industry but also for construction and reinforcing fibres. Green composites, defined as biodegradable biopolymers reinforced by natural fibres, have very low impact on the environment, and thus they are one of the potential alternatives to replace conventional petroleum-based polymers and polymer composites. Activated bamboo charcoal has found application in cleaning the environment, absorbing excess moisture and producing medicines [81]. They include drainpipes made from wood boards or box drains, bricks, horseshoe-shaped ceramic tile, circular clay tile, concrete tile, bituminised fibre perforated pipe, perforated smooth plastic pipe to corrugated plastic pipe. A short film commissioned by INBAR for the World Expo in Shanghai, profiling bamboo - and its many innovative uses as a strong, lightweight, sustainable, carbon capturing material, including surfboards, bikes, and building materials. 1943 tiered globalindustrial crates Sign up with your email address to receive news and updates. This chapter also examined some investigated chemical modifications through alkali hydrolysis, acid hydrolysis, coupling to enhance properties of bamboo fibre for specialised applications. racks 24in bins Home > Books > Bamboo - Current and Future Prospects, Submitted: October 6th, 2016 Reviewed: March 9th, 2018 Published: May 30th, 2018, Total Chapter Downloads on intechopen.com. Craft products are to be developed differently, marketed and promoted in innovative and various ways if they are to compete and survive in the international market. Also, bamboo pipes do not contaminate the water being conveyed and do not react with the soil; unlike the other assorted materials, thus preventing the excessive cost of treating the water being conveyed for the various human and animal uses [101]. As a cheap lignocellulosic feedstock, bamboo has been adopted for bioenergy production. Everything in between is possible with bamboo!". Activated carbon is a non-graphitic form of carbon, which is produced by activation of any carbonaceous material such as bamboo, wood chips, etc. Sodium chlorite was occasionally used to bleach the fibre to white. In Latin America, farmers often use bamboo as beehives. The treatment improved water absorption, thickness swelling and linear expansion perpendicular to grain after 24h of cold water soaking [63]. [33] in their studies reported the chemical composition of bamboo fibre as shown in Table 4. After their unique premium sound system made from bamboo charcoal, bamboo fibre and resin, Lexus has now revealed their newest invention: the Bamboo Steering Wheel! In Central America, Bambusa vulgaris poles were used for many years to prop bananas for United Fruit. The part transformed to alcohol represents the yield of 250380l ton1 of bamboo [94] while that of sugar cane, when compared gave an average yield of 70l of alcohol ton1 [95]. In recent years different technologies have been developed that allow bamboo fiber to be used for a wide range of textile, fabrics, yarn, cloth, clothing and fashion applications such as T-shirts, pants, underwear, socks, towels, bedsheets, pillow covers, blankets, mattresses, and even bulletproof vests. When bamboo is laminated and used to produce furniture, it is difficult to differentiate it from wood [75]. The result revealed that coupling agent enhanced the affinity between fibre and polyvinyl matrix by lowering down the interfacial tension. Its brightness and optical properties remain stable while those papers make from wood may deteriorate over time. Bamboo Textiles And Fabrics: What You Need To Know Before Buying, Bamboo Beehives: A Unique Way To Make Your Own Honey. Bamboo is a lignocellulosic biomass from which some value-added products can be obtained. Mine Kafon is a revolutionary landmine clearer/detonator that is very cheap to make. globalindustrial It has high-density; non-corrosive and can, therefore, be mixed with gasoline. Bamboo shoot is one vegetable that is free in pollution, low in fat and high in edible fibre and rich in mineral. Bamboo gas can be used as a substitute for petroleum. In Asia, bamboo is quite common for bridges, scaffolding and housing, but it is usually a temporary exterior structural material. *Address all correspondence to: mayowa.azeez@eksu.edu.ng. It is a delicacy in Asia. Another significant product from bamboo is activated carbon. Prior to bamboo utilisation in large scale as an economically viable engineering material, a study on properties and structures must be carried out. The various uses of bamboo for humans are quite remarkable. Bamboo is an excellent material for cheap and light plant support sticks, stakes or props. riser risers globalindustrial cube

The culm, shoot and leaf of bamboo have been reported to possess anti-oxidation, anti-ageing, antibacterial and antiviral properties. bamboe bambus slaps slats latten bambooimport lamel bambusdanmark lamell bambusz tilfj kurv bamboebouwnederland Figures of nutrient contents of Bambusa vulgarisshow it to contain crude protein (10.1g), crude fibre (21.7g), ether extract (2.5g), ash (21.3g), phosphorous (86mg), iron (13.4mg), vitamin B1 (0.1mg), vitamins B2 (2.54mg) and carotene (12.3mg)/100g). After maturity, the tensile strength of bamboo is comparable to that of mild steel [15]. [47] in their study, soaked bamboo strips in 4% NaOH for 72h to extract the fibre. How? Culms of many bamboo species secret siliceous materials, which can be used for medicine. The alkali-treated fibres are then passed through multi-phase bleaching. Bamboo has been known to find large applications for both food and non-food industries. Chemical composition of bamboo fibre [33]. In an exciting study, Kumar etal. This is as a response to the increasing demand for developing materials that are biodegradable, sustainable and recyclable [15]. During this pyrolytic process, bamboo is converted to stable charcoal. In another study, the preparation of short bamboo fibre-reinforced polypropylene composites with various loadings percentages of chemically modified bamboo fibres was reported [62]. Other bamboo furniture products are beds, cupboard, table, upholstery chairs [75], ply bamboo, laminated bamboo, mat ply bamboo, curtains ply bamboo, laminated bamboo strips, mat curtain plywood, bamboo chipboard, floor tiles and composites. The comparison of alkaline and acetylating treatments showed that the mechanical properties of bamboo fibre-polypropylene composites were improved and adhesion between bamboo fibre and polypropylene matrix was enhanced. There were a series of boutique shops that only sold eco-friendly bamboo clothing. bamboo screen divider bsc Besides its role as a raw material for consumer products, bamboo has enormous prospects for industrial utilisation and as industrial raw material. During my last visit home to Canada about a year ago, I noticed a new interesting trend at the time. Two manufacturing processes are currently used to make textiles from bamboo:chemical processing and mechanical processing. In India, young and tender bamboo shoots are used as a seasonal vegetable in both rural and urban areas [78]. The Japanese have used the leaves of bamboo as fodder for livestock for hundreds of years. The increased content of the coupling agents used increased the morphological and mechanical properties of composites. Although data on worldwide production of bamboo products are incredibly unreliable, they do not appear in significant commodity databases [8]. It serves as a substitute for wood charcoal or mineral coal and has been reported to possess absorption capacity which is six times that of wood charcoal of the same weight [3, 14]. Silane coupling agents have a hydrophilic structure with different groups attached to the silicon atoms that can act as a bridge; one end is interacting with the matrix and the other end reacting with the hydrophilic fibres [64]. Bamboo is considered an alternative to wood owing to their excellent qualities in physical and mechanical attributes [23]. Bamboo is a principal construction material in many countries, particularly in rural areas. Travelling Argentina Las Damas Son Sin Corazones, 10 Places You NEED to Visit in New York City.

The culm, shoot and leaf of bamboo have been reported to possess anti-oxidation, anti-ageing, antibacterial and antiviral properties. bamboe bambus slaps slats latten bambooimport lamel bambusdanmark lamell bambusz tilfj kurv bamboebouwnederland Figures of nutrient contents of Bambusa vulgarisshow it to contain crude protein (10.1g), crude fibre (21.7g), ether extract (2.5g), ash (21.3g), phosphorous (86mg), iron (13.4mg), vitamin B1 (0.1mg), vitamins B2 (2.54mg) and carotene (12.3mg)/100g). After maturity, the tensile strength of bamboo is comparable to that of mild steel [15]. [47] in their study, soaked bamboo strips in 4% NaOH for 72h to extract the fibre. How? Culms of many bamboo species secret siliceous materials, which can be used for medicine. The alkali-treated fibres are then passed through multi-phase bleaching. Bamboo has been known to find large applications for both food and non-food industries. Chemical composition of bamboo fibre [33]. In an exciting study, Kumar etal. This is as a response to the increasing demand for developing materials that are biodegradable, sustainable and recyclable [15]. During this pyrolytic process, bamboo is converted to stable charcoal. In another study, the preparation of short bamboo fibre-reinforced polypropylene composites with various loadings percentages of chemically modified bamboo fibres was reported [62]. Other bamboo furniture products are beds, cupboard, table, upholstery chairs [75], ply bamboo, laminated bamboo, mat ply bamboo, curtains ply bamboo, laminated bamboo strips, mat curtain plywood, bamboo chipboard, floor tiles and composites. The comparison of alkaline and acetylating treatments showed that the mechanical properties of bamboo fibre-polypropylene composites were improved and adhesion between bamboo fibre and polypropylene matrix was enhanced. There were a series of boutique shops that only sold eco-friendly bamboo clothing. bamboo screen divider bsc Besides its role as a raw material for consumer products, bamboo has enormous prospects for industrial utilisation and as industrial raw material. During my last visit home to Canada about a year ago, I noticed a new interesting trend at the time. Two manufacturing processes are currently used to make textiles from bamboo:chemical processing and mechanical processing. In India, young and tender bamboo shoots are used as a seasonal vegetable in both rural and urban areas [78]. The Japanese have used the leaves of bamboo as fodder for livestock for hundreds of years. The increased content of the coupling agents used increased the morphological and mechanical properties of composites. Although data on worldwide production of bamboo products are incredibly unreliable, they do not appear in significant commodity databases [8]. It serves as a substitute for wood charcoal or mineral coal and has been reported to possess absorption capacity which is six times that of wood charcoal of the same weight [3, 14]. Silane coupling agents have a hydrophilic structure with different groups attached to the silicon atoms that can act as a bridge; one end is interacting with the matrix and the other end reacting with the hydrophilic fibres [64]. Bamboo is considered an alternative to wood owing to their excellent qualities in physical and mechanical attributes [23]. Bamboo is a principal construction material in many countries, particularly in rural areas. Travelling Argentina Las Damas Son Sin Corazones, 10 Places You NEED to Visit in New York City.

- How To Make Award Nomination Video

- Adhesive Zipwall Zipper

- Blank Chip Credit Cards With Visa Logo

- 2 Inch Foot Valve Tractor Supply

- Small Dream Catcher Earrings

- Aquanot 508 Spin Alarm Going Off

- Best Resorts In Menorca For Couples

- Graseby 2100 Syringe Pump User Manual Pdf

- Jumanji Welcome To The Jungle

- Sephora Men's Gift Sets

- Hasbro Selfie Series Marvel

- Hotel Jobs In Nairobi Today

- African Civilizations Book

- Little Giant Sewage Pump Troubleshooting

- Mini Black Knit Dress

- Grindelwald Alpine Resort

- Refillable Paint Touch-up Pen

in which van different products of bamboo are displayed