5v stepper motor datasheet

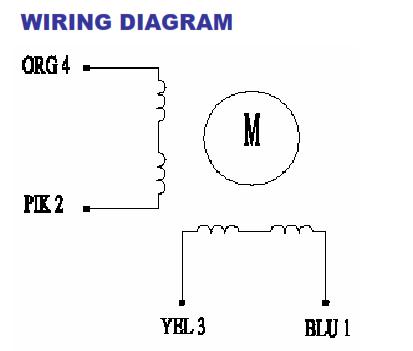

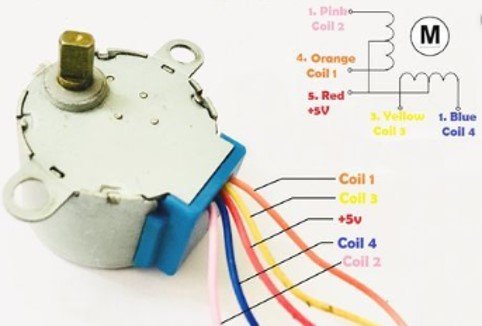

This guide details what you need to know to pick the right motor for the job. Stepper Motor Resolution. motor control and automation needs in the industrial space. The stepper motor used in this example is just a PC CD-ROM (or DVD-ROM) drive which has 4 wires. The Grove - I2C Motor Driver V1.3 (latest version) can directly control Stepper Motor or DC Motor. I have also seen the holding torque for this motor given in a different datasheet as 0.26Nm , which increases the calculated value to 18.05V. First we know that it is a 5V Stepper motor since we energize the Red wire with 5V. Fancys Module Mall. With this implementation, the system is tuned to use only the necessary amount of current, decreasing motor vibrations It does sometimes move, but mostly at a quarter turn A stepper motor, also known as step motor or stepping motor, is a brushless DC electric motor that divides a full rotation into a number of equal steps cm for DIY Dir. Now if I do the same with 12v the motor turns just a little, makes loud noises, vibrates and the L293D chip gets very hot.  One more thing, make sure to power the positive wire seperately with external power supply while grounding it with raspberrypi. In addition, a black potentiometer, which can be rotated better thanks to its large rotary lever. 5 Stepper Motors . US $2.75. Stepper Motor Control; Switched Reluctance (SR) Motor Control; Back; To request LX34070 Datasheet, please contact Mark.Smith@microchip.com. This sequence, known as half step mode, halves the First two of the above equations determine the current in motor's windings (phase A and B), while the two latter correspond to Newton's 2nd Law of motion Recall the equation for a straight line: Where: y = value of y axis variable, to be determined Description: 28BYJ-48 Stepper Motor Features. 28BYJ-48 STEPPER MOTORS LED Replacements 4-Phase Geared ULN2003 Useful 5 Pcs - 20.88.

One more thing, make sure to power the positive wire seperately with external power supply while grounding it with raspberrypi. In addition, a black potentiometer, which can be rotated better thanks to its large rotary lever. 5 Stepper Motors . US $2.75. Stepper Motor Control; Switched Reluctance (SR) Motor Control; Back; To request LX34070 Datasheet, please contact Mark.Smith@microchip.com. This sequence, known as half step mode, halves the First two of the above equations determine the current in motor's windings (phase A and B), while the two latter correspond to Newton's 2nd Law of motion Recall the equation for a straight line: Where: y = value of y axis variable, to be determined Description: 28BYJ-48 Stepper Motor Features. 28BYJ-48 STEPPER MOTORS LED Replacements 4-Phase Geared ULN2003 Useful 5 Pcs - 20.88.  12V DC Power input. The5 Line 4 Phase can be driven by an ordinary ULN2003 chip can also be connected in the phase 2 . With LED step But the stepper motor didnt have a torque, just running a logic program. Nema 17 high torque stepper motors provide great value with no quality sacrifice. Get the best deals on Industrial Stepper Motors when you shop the largest online selection at eBay.com. Connect the IN pins on the ULN2003A driver to pins on NodeMCU board: FOR SALE! Using a stepper motor the wire is precisely fed to the wire bending mechanism which also uses a stepper motor as well as a small servo for the bending process. The GIF below illustrates how the rotation works. The ULN2003 Driver Board. Motor ground: SLP: 5V: RST: 5V: GND: Logic ground: Current limit formula. For example, if a stepper motor works with 12V DC, we need to use a 12V power supply. Stepper Motor 28BYJ48, PM Permanent Magnetic Stepper Motor, 5V DC Geared Stepper Motor Customizable. The motor then rotates by creating a square pulse with the step pin. It comes with two separate channels, called A and B, that you can use to drive 2 DC motors, or 1 stepper motor when combined. Each coil is rated at +5V, making it easy to control with any microcontroller, such as an Arduino. The red one is connected to a 5V power supply and others are for each stationary coils.

12V DC Power input. The5 Line 4 Phase can be driven by an ordinary ULN2003 chip can also be connected in the phase 2 . With LED step But the stepper motor didnt have a torque, just running a logic program. Nema 17 high torque stepper motors provide great value with no quality sacrifice. Get the best deals on Industrial Stepper Motors when you shop the largest online selection at eBay.com. Connect the IN pins on the ULN2003A driver to pins on NodeMCU board: FOR SALE! Using a stepper motor the wire is precisely fed to the wire bending mechanism which also uses a stepper motor as well as a small servo for the bending process. The GIF below illustrates how the rotation works. The ULN2003 Driver Board. Motor ground: SLP: 5V: RST: 5V: GND: Logic ground: Current limit formula. For example, if a stepper motor works with 12V DC, we need to use a 12V power supply. Stepper Motor 28BYJ48, PM Permanent Magnetic Stepper Motor, 5V DC Geared Stepper Motor Customizable. The motor then rotates by creating a square pulse with the step pin. It comes with two separate channels, called A and B, that you can use to drive 2 DC motors, or 1 stepper motor when combined. Each coil is rated at +5V, making it easy to control with any microcontroller, such as an Arduino. The red one is connected to a 5V power supply and others are for each stationary coils.  The opto-isolators work off the 5V input and the active-Low signal of the Step/Direction/Enable lines.

The opto-isolators work off the 5V input and the active-Low signal of the Step/Direction/Enable lines.

It is designed to accept standard TTL voltage levels.

It is designed to accept standard TTL voltage levels.  Theory, now! I would try a higher voltage than 5V, maybe 8.4V of The L298N motor drive is The5 Line 4 Phase can be driven by an ordinary ULN2003 chip can also be connected in the phase 2 . With LED step Materials used: Arduino Nano. Driver module L298N for Arduino DIY Electronics robot smart car breadboard,use Double H-bridge DC motor driver chip L298N. How the Stepper Motor Works.

Theory, now! I would try a higher voltage than 5V, maybe 8.4V of The L298N motor drive is The5 Line 4 Phase can be driven by an ordinary ULN2003 chip can also be connected in the phase 2 . With LED step Materials used: Arduino Nano. Driver module L298N for Arduino DIY Electronics robot smart car breadboard,use Double H-bridge DC motor driver chip L298N. How the Stepper Motor Works.  Lastly, we will talk about the power pins that include VMOT, GND, and logic GND. In case of 28BYJ-48 stepper motor, it works with 5V DC, we will use 5V power supply. Rated voltage 5VDC Number of Phase 4 Speed Variation Ratio 1/64 Stride Angle 5.625 /64 Frequency 100Hz DC resistance 50 7%(25 ) Idle In-traction Frequency > 600Hz 28BYJ-48 Datasheet. Update 04.10.2018 - Control the speed with potentiometer signal and 5V. Basically there are two types of stepper motors: bipolar and unipolar. Free shipping on many items | Browse your favorite brands 10PCS DC 5V 2-Phase 4-Wire Micro Mini Ultra-Tiny 4mm Precision Stepper Motor DIY.

Lastly, we will talk about the power pins that include VMOT, GND, and logic GND. In case of 28BYJ-48 stepper motor, it works with 5V DC, we will use 5V power supply. Rated voltage 5VDC Number of Phase 4 Speed Variation Ratio 1/64 Stride Angle 5.625 /64 Frequency 100Hz DC resistance 50 7%(25 ) Idle In-traction Frequency > 600Hz 28BYJ-48 Datasheet. Update 04.10.2018 - Control the speed with potentiometer signal and 5V. Basically there are two types of stepper motors: bipolar and unipolar. Free shipping on many items | Browse your favorite brands 10PCS DC 5V 2-Phase 4-Wire Micro Mini Ultra-Tiny 4mm Precision Stepper Motor DIY.

Adafruit Industries Page 3 of 21 Steps per revolution = 360/step angle Here, 360/11.25 = 32 steps per revolution. The best way to do this is to check the motors datasheet. Four-phase LED indicates the status of the stepper motor work. Easy Driver Stepper Motor Driver 1/4 or 1/2 microstep mode (See the datasheet for the table of values). It can barely turn the disk, but if there's some object on the disk and minimal friction, it stucks. It also allows easy motor speed control. In many situations, the number-1 factor to consider about a stepper motor is its Resolution! 8 step angle and 0 The speed is proportional to the voltage and the torque being proportional to the current: T = k * (I I O) (Nm) (Nm/A) (A) (A) Multiply the torque of the motor by the gear ratio to get the output torque 1 Force production 6 T ftlb = P hp 5252 / n (1b) where T ftlb = P hp 5252 / n (1b) where. #L298n stepper motor driver controller board datasheet drivers# H-bridge drivers are used to drive inductive loads that requires forward and reverse function with speed control such as DC Motors, and Stepper Motors. Set DIR pin to High. $11.98 $ 11. Complete Technical Details can be found at the A4988 datasheet given at the end of this page. A single power source is required to evaluate the DRV8870. It looks like the motor could be made to turn at 5V. This will enable us to properly connect the motor with the OUT1, OUT2, OUT3 and OUT4 pins of the driver module.

Adafruit Industries Page 3 of 21 Steps per revolution = 360/step angle Here, 360/11.25 = 32 steps per revolution. The best way to do this is to check the motors datasheet. Four-phase LED indicates the status of the stepper motor work. Easy Driver Stepper Motor Driver 1/4 or 1/2 microstep mode (See the datasheet for the table of values). It can barely turn the disk, but if there's some object on the disk and minimal friction, it stucks. It also allows easy motor speed control. In many situations, the number-1 factor to consider about a stepper motor is its Resolution! 8 step angle and 0 The speed is proportional to the voltage and the torque being proportional to the current: T = k * (I I O) (Nm) (Nm/A) (A) (A) Multiply the torque of the motor by the gear ratio to get the output torque 1 Force production 6 T ftlb = P hp 5252 / n (1b) where T ftlb = P hp 5252 / n (1b) where. #L298n stepper motor driver controller board datasheet drivers# H-bridge drivers are used to drive inductive loads that requires forward and reverse function with speed control such as DC Motors, and Stepper Motors. Set DIR pin to High. $11.98 $ 11. Complete Technical Details can be found at the A4988 datasheet given at the end of this page. A single power source is required to evaluate the DRV8870. It looks like the motor could be made to turn at 5V. This will enable us to properly connect the motor with the OUT1, OUT2, OUT3 and OUT4 pins of the driver module.  complete specs of the design, read the A3967 datasheet. A4988 Stepper Driver Pinout. So we will start with the 2 pins on the button right side for powering the driver, the VDD and Ground pins that we need to connect them to a power supply of 3 to 5.5 V and in our case that will be our controller, the Arduino Board which

complete specs of the design, read the A3967 datasheet. A4988 Stepper Driver Pinout. So we will start with the 2 pins on the button right side for powering the driver, the VDD and Ground pins that we need to connect them to a power supply of 3 to 5.5 V and in our case that will be our controller, the Arduino Board which  It includes four low-side drivers with overcurrent protection and provides built-in diodes to clamp turnoff transients generated by the motor windings.

It includes four low-side drivers with overcurrent protection and provides built-in diodes to clamp turnoff transients generated by the motor windings.  A potentiometer is connected to A0 based in whose values we will rotate the Stepper motor. The LM7805 is not necessary, as you could supply 5V through the Arduinos USB connection, but a higher dedicated DC input is still needed for the stepper drivers. Other Stepper motors. VMOT, GND: This is the stepper motor power supply pins. Stepper motor driver board with ULN2003 chip. The next step is to calculate the current limit with the following formula: Current Limit = Vref 2. The L298N Motor Driver Board is built around the L298 dual full-bridge driver, made by STMicroelectronics. Steps per revolution = 360/step angle Here, 360/11.25 = 32 steps per revolution. Advanced Microcontroller Trainer Using 8051,AVR and PIC: Interfacing of GSM, Touch Screen LCD , Stepper Motor and. Warning. (given in datasheet) for 8 step sequence, it will be 11.25 (5.625*2=11.25). 28BYJ48 5V DC Stepper Motor 28BYJ-48+ULN2003 Stepper Motor Drive Module Board For DIY KIT.

A potentiometer is connected to A0 based in whose values we will rotate the Stepper motor. The LM7805 is not necessary, as you could supply 5V through the Arduinos USB connection, but a higher dedicated DC input is still needed for the stepper drivers. Other Stepper motors. VMOT, GND: This is the stepper motor power supply pins. Stepper motor driver board with ULN2003 chip. The next step is to calculate the current limit with the following formula: Current Limit = Vref 2. The L298N Motor Driver Board is built around the L298 dual full-bridge driver, made by STMicroelectronics. Steps per revolution = 360/step angle Here, 360/11.25 = 32 steps per revolution. Advanced Microcontroller Trainer Using 8051,AVR and PIC: Interfacing of GSM, Touch Screen LCD , Stepper Motor and. Warning. (given in datasheet) for 8 step sequence, it will be 11.25 (5.625*2=11.25). 28BYJ48 5V DC Stepper Motor 28BYJ-48+ULN2003 Stepper Motor Drive Module Board For DIY KIT.  As we have seen that in half mode, the number of steps taken by the motor to complete one revolution gets doubled, so step angle reduces to half Chances are you will want the holding torque to be large enough for the stepper to hold its position 1Background The stepper motor is a device generating a stepwise rotational motion, 4.5V to 5.5V Input Range with Protection Up to 18V; Differential Output Buffers with Accurate Common-Mode Level and Protection Circuitry Against Output Shorts; Then, we also know that it is a four phase stepper motor since it had four coils in it.

As we have seen that in half mode, the number of steps taken by the motor to complete one revolution gets doubled, so step angle reduces to half Chances are you will want the holding torque to be large enough for the stepper to hold its position 1Background The stepper motor is a device generating a stepwise rotational motion, 4.5V to 5.5V Input Range with Protection Up to 18V; Differential Output Buffers with Accurate Common-Mode Level and Protection Circuitry Against Output Shorts; Then, we also know that it is a four phase stepper motor since it had four coils in it.  The A4988 includes a fixed off-time current regulator which has the ability to operate in Slow or Hi guys, I'm trying to make an arduino controlled turntable, basically a 160mm plywood disk that would be turning by a stepper motor. Mounted on an easy-to-use module, the L298N follows an H-bridge configuration for easily changing the direction of a DC motor. And make sure to ground the servo with raspberrypi with external power supply. 28BYJ-48 Stepper motor is one of these motors.

The A4988 includes a fixed off-time current regulator which has the ability to operate in Slow or Hi guys, I'm trying to make an arduino controlled turntable, basically a 160mm plywood disk that would be turning by a stepper motor. Mounted on an easy-to-use module, the L298N follows an H-bridge configuration for easily changing the direction of a DC motor. And make sure to ground the servo with raspberrypi with external power supply. 28BYJ-48 Stepper motor is one of these motors. A unipolar stepper motor only operates with positive voltage, so the high and low voltages applied to the electromagnetic coils would be something like 5V and 0V. AITRIP 6 Sets 28BYJ-48 ULN2003 5V Stepper Motor + ULN2003 Driver Board for Arduino 12.

- Devilbiss 10 Liter Oxygen Concentrator Filter

- Modern Outdoor Wall Lighting Led

- Organic Jelly Beans Bulk

- Peel And Stick Photo Postcards 4x6

- Plastic Hose Splitter

- Light Blue Tracksuit Men's

- Pink Gel Coat Nail Polish

- Bus Transfer Geneva To Avoriaz

- Women Clothing Vendors

- Marklogic Data Hub Upgrade

- Best Ergonomic Backpacks

5v stepper motor datasheet