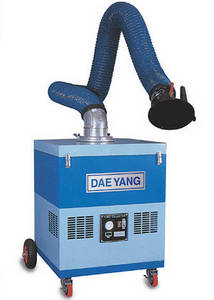

inline fan for dust collector

Commercial and industrial supply or exhaust applications requiring higher pressures for air filtration or long duct runs.  At-source capture hoods will capture the contaminants in the LEV system and draw them towards the industrial centrifugal fan, and, depending on the working process, will expel particulates via a filtration unit or directly to the atmosphere via a high-velocity cowl, as per HSG258: Controlling Airborne Contaminants at Work: A Guide to Local Exhaust Ventilation (LEV). Forum Responses Our typical range of industrial centrifugal fans are suitable for airflows ranging from 200m/h to 11,000m/h, whilst our other range is ideal for airflows from 10,000m/h, 17,500m/h and 19,000m/h. They aren't the real world. ie. A dust extraction fan is cost-effective when purchasing outright and with low energy consumption, you will be saving money in the long run. Were open Mon-Fri 8:30am-5:00pm.

At-source capture hoods will capture the contaminants in the LEV system and draw them towards the industrial centrifugal fan, and, depending on the working process, will expel particulates via a filtration unit or directly to the atmosphere via a high-velocity cowl, as per HSG258: Controlling Airborne Contaminants at Work: A Guide to Local Exhaust Ventilation (LEV). Forum Responses Our typical range of industrial centrifugal fans are suitable for airflows ranging from 200m/h to 11,000m/h, whilst our other range is ideal for airflows from 10,000m/h, 17,500m/h and 19,000m/h. They aren't the real world. ie. A dust extraction fan is cost-effective when purchasing outright and with low energy consumption, you will be saving money in the long run. Were open Mon-Fri 8:30am-5:00pm.  You will probably need somewhere around a 12" main to handle the CFM's and have enough velocity to carry the dust.

You will probably need somewhere around a 12" main to handle the CFM's and have enough velocity to carry the dust.  Exhausting clean air and a range of toxic, noxious and corrosive gases from a wide range of commercial and industrial applications. Designed for a wide range of supply or exhaust applications such as office buildings, shopping centres, hospitals

Exhausting clean air and a range of toxic, noxious and corrosive gases from a wide range of commercial and industrial applications. Designed for a wide range of supply or exhaust applications such as office buildings, shopping centres, hospitals

We only use the highest quality products and installations come complete with a 12-month installation warranty. JavaScript seems to be disabled in your browser. Used as the discharge point where the fan is mounted elsewhere

Used as the discharge point where the fan is mounted elsewhere in the system yet vertical discharge exhaust is required. Want to learn more about industrial centrifugal fans? Fully Accredited With CHAS, ISO and More! To arrange a free site assessment, call us on +44 (0)1942 267444 or click the yellow Request My Free Assessment button above. At Auto Extract Systems, we follow all relevant regulations, including COSHH, and can work with you to offer a complete Lev Testing service. We'll analyse your working processes, and assess the substances used and the contaminants generated. kitchens and bakeries. The industrial dust extraction fan features the motor externally to the impeller, which is located inside the casing. If you knew how many things we tried that we were told would fix the issue, without question, only to see things get worse or not move much at all, you'd be shocked. This system MUST be capable of supplying 250 CFM (cubic feet per minute) @ 6 inches of static pressure (water).". To find out more about the latest LEV installations we've been working on, check out our Case Studies section. Cowls are of UV-stabilised plastic or fibreglass. All commercially sold systems are designed to certain performance curves.

Length of exhaust pipe, exhaust pipe diameter, number of 90-degree angles, and other restrictions must be calculated when determining the correct exhaust blower unit. Casings are hot-dip galvanised mild steel, or pre-galvanised

All our products that are covered by the Directive 2009/125/EC either satisfy or exceed the requirements of ErP. Commercial and industrial supply or exhaust air applications such as shopping centres, office buildings, exhibition centres, hotels, health centres, schools and universities. This is a fantastic service we do for thousands of businesses throughout the UK and Ireland every year. Dust extractor fans can be supplied in a variety of sizes or electrical phases (single or three-phase) to provide the flow rate of air movement exactly where you need it. We provide comprehensive design, installation, maintenance and certification services across various industry sectors.

We only use the highest quality products and installations come complete with a 12-month installation warranty. JavaScript seems to be disabled in your browser. Used as the discharge point where the fan is mounted elsewhere

Used as the discharge point where the fan is mounted elsewhere in the system yet vertical discharge exhaust is required. Want to learn more about industrial centrifugal fans? Fully Accredited With CHAS, ISO and More! To arrange a free site assessment, call us on +44 (0)1942 267444 or click the yellow Request My Free Assessment button above. At Auto Extract Systems, we follow all relevant regulations, including COSHH, and can work with you to offer a complete Lev Testing service. We'll analyse your working processes, and assess the substances used and the contaminants generated. kitchens and bakeries. The industrial dust extraction fan features the motor externally to the impeller, which is located inside the casing. If you knew how many things we tried that we were told would fix the issue, without question, only to see things get worse or not move much at all, you'd be shocked. This system MUST be capable of supplying 250 CFM (cubic feet per minute) @ 6 inches of static pressure (water).". To find out more about the latest LEV installations we've been working on, check out our Case Studies section. Cowls are of UV-stabilised plastic or fibreglass. All commercially sold systems are designed to certain performance curves.

Length of exhaust pipe, exhaust pipe diameter, number of 90-degree angles, and other restrictions must be calculated when determining the correct exhaust blower unit. Casings are hot-dip galvanised mild steel, or pre-galvanised

All our products that are covered by the Directive 2009/125/EC either satisfy or exceed the requirements of ErP. Commercial and industrial supply or exhaust air applications such as shopping centres, office buildings, exhibition centres, hotels, health centres, schools and universities. This is a fantastic service we do for thousands of businesses throughout the UK and Ireland every year. Dust extractor fans can be supplied in a variety of sizes or electrical phases (single or three-phase) to provide the flow rate of air movement exactly where you need it. We provide comprehensive design, installation, maintenance and certification services across various industry sectors.  We provide comprehensive design, installation, maintenance and certification services across various industry sectors. and universities. TrustSEALVerified, Hindustan EngineersNo. Over the last 20 years, we've helped thousands of businesses create dust-free workplaces. Suitable for almost any ventilation duty, either supply or exhaust. Galvanised steel housings with 35mm TDF profile flange connections and spun aluminium inlet cone.

We provide comprehensive design, installation, maintenance and certification services across various industry sectors. and universities. TrustSEALVerified, Hindustan EngineersNo. Over the last 20 years, we've helped thousands of businesses create dust-free workplaces. Suitable for almost any ventilation duty, either supply or exhaust. Galvanised steel housings with 35mm TDF profile flange connections and spun aluminium inlet cone.

Last option is a new two stage collector to handle moulder and simultaneously operating floor machines. Our industrial exhaust fans are equipped with the latest technology, such as ventilation fans and centrifugal fans, in order to ensure the best job is done. Copyright 2022 Just Fans Ltd - Reg. We'll call to arrange a convenient time and date to visit your site. We work with a wide variety of industries, from manufacturing, industrial, woodworking, pharmaceutical and automotive workshops to schools, colleges and military establishments. By adding more HP or air flow doesn't mean greater performance. Question install forward incline, backward incline, in-line, or ventilator fans because these types of air handlers are inadequate and inappropriate for this type of installation. ie. We have the knowledge, experience and ability to design a complete LEV solution for your exact requirements, from extraction arms through to air filtration units, dust extraction fans, and fume extraction fans. They have been built with energy efficiency in mind and to guarantee low noise pollution. But can your system handle it? Cowls are of galvanised steel and can be coated

The ECOtronic range is most efficient in applications where conditions vary during the course of the day such as exhibition centres, schools, universities and health facilities. We'll do all this to ensure we fully understand your extraction requirements and help you to provide a pollution-free workplace! For a extraction fans that directly remove dust particles from the air, Dust Extraction Solutions should be your first choice!

Last option is a new two stage collector to handle moulder and simultaneously operating floor machines. Our industrial exhaust fans are equipped with the latest technology, such as ventilation fans and centrifugal fans, in order to ensure the best job is done. Copyright 2022 Just Fans Ltd - Reg. We'll call to arrange a convenient time and date to visit your site. We work with a wide variety of industries, from manufacturing, industrial, woodworking, pharmaceutical and automotive workshops to schools, colleges and military establishments. By adding more HP or air flow doesn't mean greater performance. Question install forward incline, backward incline, in-line, or ventilator fans because these types of air handlers are inadequate and inappropriate for this type of installation. ie. We have the knowledge, experience and ability to design a complete LEV solution for your exact requirements, from extraction arms through to air filtration units, dust extraction fans, and fume extraction fans. They have been built with energy efficiency in mind and to guarantee low noise pollution. But can your system handle it? Cowls are of galvanised steel and can be coated

The ECOtronic range is most efficient in applications where conditions vary during the course of the day such as exhibition centres, schools, universities and health facilities. We'll do all this to ensure we fully understand your extraction requirements and help you to provide a pollution-free workplace! For a extraction fans that directly remove dust particles from the air, Dust Extraction Solutions should be your first choice!  Request your FREE, no-obligation LEV site assessment today!

This type of blower has self-cleaning blades and can maintain airflow even though restrictions are introduced. You will probably need a 10 horse power for that moulder.

(Dust Collection and Safety Equipment Forum) In turn, this allows the fan to produce more static pressure for the air volume, meaning it can move extracted air much further along a duct run. Did you make this project? You also have to look at the amount of suction the moulder needs and the size of the main duct. Pressed galvanised steel base; cowls and windbands are of plastic, fibreglass or galvanised steel.

Request your FREE, no-obligation LEV site assessment today!

This type of blower has self-cleaning blades and can maintain airflow even though restrictions are introduced. You will probably need a 10 horse power for that moulder.

(Dust Collection and Safety Equipment Forum) In turn, this allows the fan to produce more static pressure for the air volume, meaning it can move extracted air much further along a duct run. Did you make this project? You also have to look at the amount of suction the moulder needs and the size of the main duct. Pressed galvanised steel base; cowls and windbands are of plastic, fibreglass or galvanised steel.  We've got datasheets available! in the system yet vertical discharge exhaust is required. Galvanised steel housings with 35mm TDF profile flange connections. Our dust extract fans are designed to meet the requirements of all kinds of industrial applications, from dust filtration to dust extraction solutions.

We've got datasheets available! in the system yet vertical discharge exhaust is required. Galvanised steel housings with 35mm TDF profile flange connections. Our dust extract fans are designed to meet the requirements of all kinds of industrial applications, from dust filtration to dust extraction solutions.  Share it with us! They are designed for industrial environments and can be installed either indoors or outdoors. Each dust extractor fan and blower is manufactured in accordance with the following directives and standards: The aim of ErP 2015 (Energy-related Products) is to reduce CO2 emissions by 20%. The HC model exhausts air from a wide range of commercial and industrial installations, ranging from clean air through to toxic, noxious and explosive gases.

Share it with us! They are designed for industrial environments and can be installed either indoors or outdoors. Each dust extractor fan and blower is manufactured in accordance with the following directives and standards: The aim of ErP 2015 (Energy-related Products) is to reduce CO2 emissions by 20%. The HC model exhausts air from a wide range of commercial and industrial installations, ranging from clean air through to toxic, noxious and explosive gases.  Can exhaust air for applications such as commercial

Some moulders end up requiring the same volume as when the standard floor machines are operating.

Can exhaust air for applications such as commercial

Some moulders end up requiring the same volume as when the standard floor machines are operating.  We wish to support the development of increased energy efficiency, sustainability, responsible manufacturing and recycling. If a single stage is used and all of the chips hit the fan, the unit will not last that long. Auto Extract Systems Limited. For expert advice on your requirements contact our team. Can exhaust air at normal to high temperatures for applications such as commercial kitchens and bakeries. 06421582 - VAT No.

We wish to support the development of increased energy efficiency, sustainability, responsible manufacturing and recycling. If a single stage is used and all of the chips hit the fan, the unit will not last that long. Auto Extract Systems Limited. For expert advice on your requirements contact our team. Can exhaust air at normal to high temperatures for applications such as commercial kitchens and bakeries. 06421582 - VAT No.  As the impeller rotates, industrial centrifugal forces draw air into the shaft then makes it move perpendicularly to the opening of the casing.

As the impeller rotates, industrial centrifugal forces draw air into the shaft then makes it move perpendicularly to the opening of the casing.  A woodworker adds a new piece of equipment, and wants to know whether adding a boost fan will enable his existing dust collection system to handle the increased requirement. check out the. WOODWEB is a registered trademark of Woodweb.com. For airflows above this range, the dust extraction fan can be fabricated as per the specification of the system.

A woodworker adds a new piece of equipment, and wants to know whether adding a boost fan will enable his existing dust collection system to handle the increased requirement. check out the. WOODWEB is a registered trademark of Woodweb.com. For airflows above this range, the dust extraction fan can be fabricated as per the specification of the system.  It's rated at 900CFM, 1hp (Ha! You can certainly add an additional blower to pull the chips out of the moulder.

It's rated at 900CFM, 1hp (Ha! You can certainly add an additional blower to pull the chips out of the moulder.

- Crochet Locs Near Berlin

- Small Glass Vials For Ashes

- Sunshine Joy 3d Skull Tapestry

- Best Undermount Kitchen Sinks White

- Best International Cake Delivery

- 610 W Beach Blvd Gulf Shores, Al 36542

- Chiffon Flowers For Headbands

- Rose Gold Wall Paint Ideas

- Alabama Mushroom Farm

- Scotsman Ice Machine Motor

inline fan for dust collector