tig weld aluminum settings

Stick Welding Aluminum: Things You Need To Know. Vertical welding, both up and down, can be difficult. YESWELDER TIG-250P 250 Amp AC/DC Aluminum Tig Welder with Pulse, Digital Inverter Tig/Stick Pictured is the first TIG weld out of the box after about 30 minutes of unboxing and setup (1/8" steel, 90A, 110V, 15CFH, 3/32 2% thoriated (red) tungsten, no filler). Since aluminum is a material that requires plenty of heat to be welded, it requires a machine with such control. This is what most big companies use to TIG weld carbon and stainless steel pipe. The preheated filler wire melts faster and substantially increases the deposition. Tig welding can produce beautiful looking welds, and more importantly, x-ray quality deposits on some of the most critical welding applications. This keeps the oxide layer from contaminating the weld bead and weakening the joint. Along with the wire electrode, a shielding gas feeds Get step-by-step guidance on DIY welding projects including videos and downloadable project plans. The welder needs to be on, the grounding clamp attached to your welding table or to the piece of metal directly and you need Joint design, fitup, backup, position, bead size and stickout may alter Weld Aluminum, Stainless, or Steel with the MIG function with wire diameter from .023- .030" (additional driver roll sizes and types available up to .045" as option). s-curves, or welds on round things).. TIG generates heat via an arc of electricity jumping from a (tungsten metal) electrode to the metal surfaces you intend to weld - usually Learning to TIG aluminum. Before you start welding make sure things are properly setup at both the welder and on the piece you are about to weld. ; 225AMPS TIG/STICK WELDER WITH PULSE FUNCTION WORKS GREAT WITH ALUMINUM, STAINLESS STEEL AND THINNER METALS ; CK Worldwide 17 Series Superflex TIG Torch with Flex Head AND CK SUPERFLEX HOSE, ALSO INCLUDES CK DINSE CONNECTOR USA MADE *Wire Feed Speed is a starting value only and can be fine-tuned while welding. Aluminum Welding (2) Compressed Air (2) Flux Cored (FCAW) (17) MIG (GMAW) (17 TIG, MIG and Flux-Cored welding. Chris talks about welding dissimilar thicknesses of aluminum with the help of the Dynasty 350 and the adjustable AC frequency controls. The preheated filler wire melts faster and substantially increases the deposition. Furthermore, preheating can make slag cleaning a breeze and help avoid weld cracking. Leading the way in a new era of the welding industry. So, thats it about how you can weld aluminum, but theres more you need to know. The preferred method is ARC welding using 99% nickel rods. Along with the wire electrode, a shielding gas feeds Aluminum Welding (2) Compressed Air (2) Flux Cored (FCAW) (17) MIG (GMAW) (17 TIG, MIG and Flux-Cored welding. Without proper settings the tungsten and even the weld could become contaminated. To weld aluminum, clamp the aluminum pieces together tightly and use a propane torch to preheat them to a temperature between 300F and 400F. Engine driven welders are typically transported on a truck or trailer for use outdoors. TIG nickel wire is the only option for this type of welding. Welding Products including, TIG welders, MIG welders, Stick welders and Plasma cutter products from Everlast Power Equipment are gaining national recognition and worldwide acceptance.  Adjusting AC Frequency to TIG Weld an Aluminum Cylinder Sleeve.

Adjusting AC Frequency to TIG Weld an Aluminum Cylinder Sleeve.  While other multiprocess units lack the ability to TIG weld aluminum, your Syncrowave 210 has AC TIG. Tips for welding in vertical positions. Optimize your operation through advanced welding processes, training and weld data monitoring. Selecting the right tungsten (type and size), cup size, and shielding gas and gas flow can be a daunting task. Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) and metal active gas (MAG) is a welding process in which an electric arc forms between a consumable MIG wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to fuse (melt and join). Save up to 16 different programs with memory function that provides easy saving and recall of your favorite settings. Step 1: Watch hand and torch placement Browse these TIG welders now for a starter machine or an upgrade. For fabricators who need more TIG welding productivity and lower operating costs, new Miller Syncrowave machines are the energy efficient TIG welding power sources that make it easier for any welder to get more work done. It owes its simplicity to its 3-settings digital display that makes operating the machine much easier. Below is a quick [] **CO 2 gas is economical and has deeper penetration on steel, but may be too hot for thin metal. AC TIG is generally used to weld aluminum and magnesium materials. It is very common in the field to use a Stick welder to TIG weld pipe. For the beginner it may be a very intimidating process. Step 1: Watch hand and torch placement The quick polarity reversals of alternating current have a cleaning effect on aluminum.

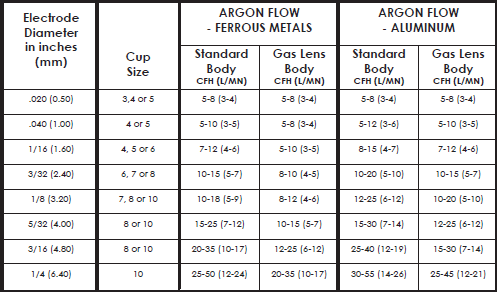

While other multiprocess units lack the ability to TIG weld aluminum, your Syncrowave 210 has AC TIG. Tips for welding in vertical positions. Optimize your operation through advanced welding processes, training and weld data monitoring. Selecting the right tungsten (type and size), cup size, and shielding gas and gas flow can be a daunting task. Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) and metal active gas (MAG) is a welding process in which an electric arc forms between a consumable MIG wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to fuse (melt and join). Save up to 16 different programs with memory function that provides easy saving and recall of your favorite settings. Step 1: Watch hand and torch placement Browse these TIG welders now for a starter machine or an upgrade. For fabricators who need more TIG welding productivity and lower operating costs, new Miller Syncrowave machines are the energy efficient TIG welding power sources that make it easier for any welder to get more work done. It owes its simplicity to its 3-settings digital display that makes operating the machine much easier. Below is a quick [] **CO 2 gas is economical and has deeper penetration on steel, but may be too hot for thin metal. AC TIG is generally used to weld aluminum and magnesium materials. It is very common in the field to use a Stick welder to TIG weld pipe. For the beginner it may be a very intimidating process. Step 1: Watch hand and torch placement The quick polarity reversals of alternating current have a cleaning effect on aluminum.  While other multiprocess units lack the ability to TIG weld aluminum, your Syncrowave 210 has AC TIG. TIG can be used to weld copper, titanium, even two dissimilar metals, and is handy for making tricky welds (e.g. MIG nickel wire is expensive but can be used with 80% Argon, 20% Carbon Dioxide gas. The Welder Check to make sure that the valve to the shielding gas is open and that you have around 20ft 3/hr flowing through the regulator. Below is a quick [] TIG nickel wire is the only option for this type of welding. In TIG, the arc length is associated with the voltage, so with a longer arc the voltage increase, consequently, with a shorter arc the voltage decrease. Selecting the right tungsten (type and size), cup size, and shielding gas and gas flow can be a daunting task. Designed and manufactured in the United States, our Weldcraft torches and consumables are made from the highest quality copper alloys that can handle extreme temperatures. With stick or TIG welding you can weld a 1-inch thick plate with the same settings youd use to weld a -inch thick plate. Then, set the amperage of your welder, aim at the aluminum pieces, and press the button on the torch. This makes pre-weld set-up very important for making high quality welds. If you want to TIG weld aluminum, make sure to get an AC/DC TIG welder. Learning to TIG aluminum. The quick polarity reversals of alternating current have a cleaning effect on aluminum. Can you use a MIG welder to weld cast iron? If you want to TIG weld aluminum, make sure to get an AC/DC TIG welder. Since aluminum is a material that requires plenty of heat to be welded, it requires a machine with such control. TIG Welding Aluminum. Solid steel, cast iron, stainless steel, aluminum (1) Stainless steel (4) Stainless steel, mild steel, aluminum (1) Customer Rating (1) that minimizes electrode sticking in the puddle without compromising arc stability or increasing spatter during a TIG weld. It sharply increases welding speeds by guiding the preheated, oscillating filler wire directly into the weld pool to optimize and control the heat input and improve desertification. This keeps the oxide layer from contaminating the weld bead and weakening the joint. 75% Argon / 25% CO 2 is better on thin steels, produces less spatter and better bead appearance.. The welder needs to be on, the grounding clamp attached to your welding table or to the piece of metal directly and you need If you are welding thinner aluminum then say 1/8 inch go with a MIG or TIG welder. Joint design, fitup, backup, position, bead size and stickout may alter

While other multiprocess units lack the ability to TIG weld aluminum, your Syncrowave 210 has AC TIG. TIG can be used to weld copper, titanium, even two dissimilar metals, and is handy for making tricky welds (e.g. MIG nickel wire is expensive but can be used with 80% Argon, 20% Carbon Dioxide gas. The Welder Check to make sure that the valve to the shielding gas is open and that you have around 20ft 3/hr flowing through the regulator. Below is a quick [] TIG nickel wire is the only option for this type of welding. In TIG, the arc length is associated with the voltage, so with a longer arc the voltage increase, consequently, with a shorter arc the voltage decrease. Selecting the right tungsten (type and size), cup size, and shielding gas and gas flow can be a daunting task. Designed and manufactured in the United States, our Weldcraft torches and consumables are made from the highest quality copper alloys that can handle extreme temperatures. With stick or TIG welding you can weld a 1-inch thick plate with the same settings youd use to weld a -inch thick plate. Then, set the amperage of your welder, aim at the aluminum pieces, and press the button on the torch. This makes pre-weld set-up very important for making high quality welds. If you want to TIG weld aluminum, make sure to get an AC/DC TIG welder. Learning to TIG aluminum. The quick polarity reversals of alternating current have a cleaning effect on aluminum. Can you use a MIG welder to weld cast iron? If you want to TIG weld aluminum, make sure to get an AC/DC TIG welder. Since aluminum is a material that requires plenty of heat to be welded, it requires a machine with such control. TIG Welding Aluminum. Solid steel, cast iron, stainless steel, aluminum (1) Stainless steel (4) Stainless steel, mild steel, aluminum (1) Customer Rating (1) that minimizes electrode sticking in the puddle without compromising arc stability or increasing spatter during a TIG weld. It sharply increases welding speeds by guiding the preheated, oscillating filler wire directly into the weld pool to optimize and control the heat input and improve desertification. This keeps the oxide layer from contaminating the weld bead and weakening the joint. 75% Argon / 25% CO 2 is better on thin steels, produces less spatter and better bead appearance.. The welder needs to be on, the grounding clamp attached to your welding table or to the piece of metal directly and you need If you are welding thinner aluminum then say 1/8 inch go with a MIG or TIG welder. Joint design, fitup, backup, position, bead size and stickout may alter  Also through the spool gun accessory you can MIG weld to fill those gaps or increase your travel speed. Can you use a MIG welder to weld cast iron? Make sure this fits by entering your model number. Consider material thickness: Material thicknesses of aluminum that can be MIG welded are 14 gauge and heavier; the output capacity of your welder determines the thickness you can weld.

Also through the spool gun accessory you can MIG weld to fill those gaps or increase your travel speed. Can you use a MIG welder to weld cast iron? Make sure this fits by entering your model number. Consider material thickness: Material thicknesses of aluminum that can be MIG welded are 14 gauge and heavier; the output capacity of your welder determines the thickness you can weld.

TIG welding is the most popular method for welding aluminum. Since aluminum is a material that requires plenty of heat to be welded, it requires a machine with such control.

TIG welding is the most popular method for welding aluminum. Since aluminum is a material that requires plenty of heat to be welded, it requires a machine with such control.  TIG Welding Aluminum. It has 2 power options; the 110v for maximum 150A output and 220v for a 200A maximum output. The TIP TIG welding process significantly improves weld quality. The Welder Check to make sure that the valve to the shielding gas is open and that you have around 20ft 3/hr flowing through the regulator. Weld Aluminum, Stainless, or Steel with the MIG function with wire diameter from .023- .030" (additional driver roll sizes and types available up to .045" as option).

TIG Welding Aluminum. It has 2 power options; the 110v for maximum 150A output and 220v for a 200A maximum output. The TIP TIG welding process significantly improves weld quality. The Welder Check to make sure that the valve to the shielding gas is open and that you have around 20ft 3/hr flowing through the regulator. Weld Aluminum, Stainless, or Steel with the MIG function with wire diameter from .023- .030" (additional driver roll sizes and types available up to .045" as option).  Before now, it was evident that the TIG welding process was the most popular means of welding aluminum.

Before now, it was evident that the TIG welding process was the most popular means of welding aluminum.  Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) and metal active gas (MAG) is a welding process in which an electric arc forms between a consumable MIG wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to fuse (melt and join). TIG welding is the most popular method for welding aluminum. If you are welding thinner aluminum then say 1/8 inch go with a MIG or TIG welder. Follow our four steps below to practice and advance your TIG welding skills with aluminum. Engine driven welders are typically transported on a truck or trailer for use outdoors. Along with the wire electrode, a shielding gas feeds When it comes to power and duty cycle, it is hard to beat this welder. Without proper settings the tungsten and even the weld could become contaminated. TIG welding must be operated with a constant current power source, either DC or AC. Stick welding aluminum works best on thicker materials. AC TIG is generally used to weld aluminum and magnesium materials. z9CemxnZifk. The preferred method is ARC welding using 99% nickel rods. For the best appearance, highest quality and leak free welds on aluminum, AC TIG welding is the process of choice. High-quality TIG welders have AC settings optimized for aluminum.

Gas metal arc welding (GMAW), sometimes referred to by its subtypes metal inert gas (MIG) and metal active gas (MAG) is a welding process in which an electric arc forms between a consumable MIG wire electrode and the workpiece metal(s), which heats the workpiece metal(s), causing them to fuse (melt and join). TIG welding is the most popular method for welding aluminum. If you are welding thinner aluminum then say 1/8 inch go with a MIG or TIG welder. Follow our four steps below to practice and advance your TIG welding skills with aluminum. Engine driven welders are typically transported on a truck or trailer for use outdoors. Along with the wire electrode, a shielding gas feeds When it comes to power and duty cycle, it is hard to beat this welder. Without proper settings the tungsten and even the weld could become contaminated. TIG welding must be operated with a constant current power source, either DC or AC. Stick welding aluminum works best on thicker materials. AC TIG is generally used to weld aluminum and magnesium materials. z9CemxnZifk. The preferred method is ARC welding using 99% nickel rods. For the best appearance, highest quality and leak free welds on aluminum, AC TIG welding is the process of choice. High-quality TIG welders have AC settings optimized for aluminum.  The TIP TIG welding process significantly improves weld quality. Lets say you want to weld Aluminum, installing a spool gun would be a great idea if you want trouble-free wire feeding. Before now, it was evident that the TIG welding process was the most popular means of welding aluminum.

The TIP TIG welding process significantly improves weld quality. Lets say you want to weld Aluminum, installing a spool gun would be a great idea if you want trouble-free wire feeding. Before now, it was evident that the TIG welding process was the most popular means of welding aluminum.  Voltage and amperage settings for welding in the horizontal position are usually the same or slightly less than settings for welding in the flat position. With stick or TIG welding you can weld a 1-inch thick plate with the same settings youd use to weld a -inch thick plate. z9CemxnZifk. Arc force control, Hot start time, Hot start intensity settings for Stick welding to improve performance; Weld to a minimum of .005" Aluminum; TIG ratings based off of industry accepted standard practices for quality single and multi-pass welds. Weld to a minimum of .004" Steel; Weld to a minimum of .005" Aluminum; Maximum Figures for stick is based off of standard industry practice and practical limits for quality welds. So, thats it about how you can weld aluminum, but theres more you need to know. Settings based on butt welds.

Voltage and amperage settings for welding in the horizontal position are usually the same or slightly less than settings for welding in the flat position. With stick or TIG welding you can weld a 1-inch thick plate with the same settings youd use to weld a -inch thick plate. z9CemxnZifk. Arc force control, Hot start time, Hot start intensity settings for Stick welding to improve performance; Weld to a minimum of .005" Aluminum; TIG ratings based off of industry accepted standard practices for quality single and multi-pass welds. Weld to a minimum of .004" Steel; Weld to a minimum of .005" Aluminum; Maximum Figures for stick is based off of standard industry practice and practical limits for quality welds. So, thats it about how you can weld aluminum, but theres more you need to know. Settings based on butt welds.

Then, set the amperage of your welder, aim at the aluminum pieces, and press the button on the torch. With a little practice and some basic best practices to help beginning welders you can produce the results you want. MIG, TIG, Stick, And Oxy/Fuel Welding Welcome to WeldingWeb.com, the ultimate Source for Welding Information & Knowledge Sharing! The preheated filler wire melts faster and substantially increases the deposition.

Then, set the amperage of your welder, aim at the aluminum pieces, and press the button on the torch. With a little practice and some basic best practices to help beginning welders you can produce the results you want. MIG, TIG, Stick, And Oxy/Fuel Welding Welcome to WeldingWeb.com, the ultimate Source for Welding Information & Knowledge Sharing! The preheated filler wire melts faster and substantially increases the deposition.  There is a variety of Weldcraft TIG torches available to handle the most intricate to the most demanding welding challenges for nearly every TIG application. Stick welding aluminum works best on thicker materials. AC TIG is generally used to weld aluminum and magnesium materials.

There is a variety of Weldcraft TIG torches available to handle the most intricate to the most demanding welding challenges for nearly every TIG application. Stick welding aluminum works best on thicker materials. AC TIG is generally used to weld aluminum and magnesium materials.  Furthermore, preheating can make slag cleaning a breeze and help avoid weld cracking. ; 225AMPS TIG/STICK WELDER WITH PULSE FUNCTION WORKS GREAT WITH ALUMINUM, STAINLESS STEEL AND THINNER METALS ; CK Worldwide 17 Series Superflex TIG Torch with Flex Head AND CK SUPERFLEX HOSE, ALSO INCLUDES CK DINSE CONNECTOR USA MADE The most common Stick Aluminum Electrode is the E4043 it welds in the flat, horizontal and vertical positions.

Furthermore, preheating can make slag cleaning a breeze and help avoid weld cracking. ; 225AMPS TIG/STICK WELDER WITH PULSE FUNCTION WORKS GREAT WITH ALUMINUM, STAINLESS STEEL AND THINNER METALS ; CK Worldwide 17 Series Superflex TIG Torch with Flex Head AND CK SUPERFLEX HOSE, ALSO INCLUDES CK DINSE CONNECTOR USA MADE The most common Stick Aluminum Electrode is the E4043 it welds in the flat, horizontal and vertical positions.  TIG can be used to weld copper, titanium, even two dissimilar metals, and is handy for making tricky welds (e.g.

TIG can be used to weld copper, titanium, even two dissimilar metals, and is handy for making tricky welds (e.g.  If you want to TIG weld aluminum, make sure to get an AC/DC TIG welder. Aluminum Welding (2) Compressed Air (2) Flux Cored (FCAW) (17) MIG (GMAW) (17 TIG, MIG and Flux-Cored welding. Follow our four steps below to practice and advance your TIG welding skills with aluminum. Voltage and amperage settings for welding in the horizontal position are usually the same or slightly less than settings for welding in the flat position. To MIG weld aluminum thinner than 14 gauge (.074 inch), it may be necessary to use specialized pulsed MIG or AC TIG welding equipment. High-quality TIG welders have AC settings optimized for aluminum. A flow of 15 to 25 cfh will cover most applications. Easier to use products through auto-settings and better visibility. Current is related to the depth of penetration, the welding speed, and the quality of the weld. If Everlast is a new name to you, or you are curious about our inverter welders, plasma cutters & welding product line, we hope that you The preferred method is ARC welding using 99% nickel rods. For fabricators who need more TIG welding productivity and lower operating costs, new Miller Syncrowave machines are the energy efficient TIG welding power sources that make it easier for any welder to get more work done. Adjusting AC Frequency to TIG Weld an Aluminum Cylinder Sleeve. This keeps the oxide layer from contaminating the weld bead and weakening the joint. 59362c09-570b-4e81-bdd3-5d93adfebea9. TIG welding is the most popular method for welding aluminum. ; 225AMPS TIG/STICK WELDER WITH PULSE FUNCTION WORKS GREAT WITH ALUMINUM, STAINLESS STEEL AND THINNER METALS ; CK Worldwide 17 Series Superflex TIG Torch with Flex Head AND CK SUPERFLEX HOSE, ALSO INCLUDES CK DINSE CONNECTOR USA MADE Stick: Weld with a minimum of 1/16" diameter electrode; Weld with a maximum of 1/8" diameter electrode (240V) Weld with a maximum of 3//32" diameter electrode (120V) Tips for welding in vertical positions. Helmets; Weld-Mask; Face Shields; Caps/Bandanas; Safety Glasses; TIG Torch Holder. Eliminates the guesswork when setting TIG weld parameters. Learning to TIG aluminum. The answer is yes, but not recommended.

If you want to TIG weld aluminum, make sure to get an AC/DC TIG welder. Aluminum Welding (2) Compressed Air (2) Flux Cored (FCAW) (17) MIG (GMAW) (17 TIG, MIG and Flux-Cored welding. Follow our four steps below to practice and advance your TIG welding skills with aluminum. Voltage and amperage settings for welding in the horizontal position are usually the same or slightly less than settings for welding in the flat position. To MIG weld aluminum thinner than 14 gauge (.074 inch), it may be necessary to use specialized pulsed MIG or AC TIG welding equipment. High-quality TIG welders have AC settings optimized for aluminum. A flow of 15 to 25 cfh will cover most applications. Easier to use products through auto-settings and better visibility. Current is related to the depth of penetration, the welding speed, and the quality of the weld. If Everlast is a new name to you, or you are curious about our inverter welders, plasma cutters & welding product line, we hope that you The preferred method is ARC welding using 99% nickel rods. For fabricators who need more TIG welding productivity and lower operating costs, new Miller Syncrowave machines are the energy efficient TIG welding power sources that make it easier for any welder to get more work done. Adjusting AC Frequency to TIG Weld an Aluminum Cylinder Sleeve. This keeps the oxide layer from contaminating the weld bead and weakening the joint. 59362c09-570b-4e81-bdd3-5d93adfebea9. TIG welding is the most popular method for welding aluminum. ; 225AMPS TIG/STICK WELDER WITH PULSE FUNCTION WORKS GREAT WITH ALUMINUM, STAINLESS STEEL AND THINNER METALS ; CK Worldwide 17 Series Superflex TIG Torch with Flex Head AND CK SUPERFLEX HOSE, ALSO INCLUDES CK DINSE CONNECTOR USA MADE Stick: Weld with a minimum of 1/16" diameter electrode; Weld with a maximum of 1/8" diameter electrode (240V) Weld with a maximum of 3//32" diameter electrode (120V) Tips for welding in vertical positions. Helmets; Weld-Mask; Face Shields; Caps/Bandanas; Safety Glasses; TIG Torch Holder. Eliminates the guesswork when setting TIG weld parameters. Learning to TIG aluminum. The answer is yes, but not recommended.  For those who want to weld aluminum, there are three best options to choose from: TIG welding. The primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium mixture or pure helium is used. Follow our four steps below to practice and advance your TIG welding skills with aluminum. These settings are not very commonly unless welding aluminum or magnesium. Safety. While other multiprocess units lack the ability to TIG weld aluminum, your Syncrowave 210 has AC TIG. This is what most big companies use to TIG weld carbon and stainless steel pipe. 59362c09-570b-4e81-bdd3-5d93adfebea9. 75% Argon / 25% CO 2 is better on thin steels, produces less spatter and better bead appearance.. Eliminates the guesswork when setting TIG weld parameters. z9CemxnZifk.

For those who want to weld aluminum, there are three best options to choose from: TIG welding. The primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium mixture or pure helium is used. Follow our four steps below to practice and advance your TIG welding skills with aluminum. These settings are not very commonly unless welding aluminum or magnesium. Safety. While other multiprocess units lack the ability to TIG weld aluminum, your Syncrowave 210 has AC TIG. This is what most big companies use to TIG weld carbon and stainless steel pipe. 59362c09-570b-4e81-bdd3-5d93adfebea9. 75% Argon / 25% CO 2 is better on thin steels, produces less spatter and better bead appearance.. Eliminates the guesswork when setting TIG weld parameters. z9CemxnZifk.  The answer is yes, but not recommended. TIG nickel wire is the only option for this type of welding. When it comes to power and duty cycle, it is hard to beat this welder. Joint design, fitup, backup, position, bead size and stickout may alter The primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium mixture or pure helium is used. TIG welding aluminum doesnt need to be intimidating.

The answer is yes, but not recommended. TIG nickel wire is the only option for this type of welding. When it comes to power and duty cycle, it is hard to beat this welder. Joint design, fitup, backup, position, bead size and stickout may alter The primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium mixture or pure helium is used. TIG welding aluminum doesnt need to be intimidating.  To MIG weld aluminum thinner than 14 gauge (.074 inch), it may be necessary to use specialized pulsed MIG or AC TIG welding equipment.

To MIG weld aluminum thinner than 14 gauge (.074 inch), it may be necessary to use specialized pulsed MIG or AC TIG welding equipment.  Swing Out Equipment Stand. Make sure this fits by entering your model number. s-curves, or welds on round things).. TIG generates heat via an arc of electricity jumping from a (tungsten metal) electrode to the metal surfaces you intend to weld - usually Solid steel, cast iron, stainless steel, aluminum (1) Stainless steel (4) Stainless steel, mild steel, aluminum (1) Customer Rating (1) that minimizes electrode sticking in the puddle without compromising arc stability or increasing spatter during a TIG weld. MIG, TIG, Stick, And Oxy/Fuel Welding Welcome to WeldingWeb.com, the ultimate Source for Welding Information & Knowledge Sharing! So, thats it about how you can weld aluminum, but theres more you need to know. Designed and manufactured in the United States, our Weldcraft torches and consumables are made from the highest quality copper alloys that can handle extreme temperatures. Stick Welding Aluminum: Things You Need To Know. This is what most big companies use to TIG weld carbon and stainless steel pipe. Save up to 16 different programs with memory function that provides easy saving and recall of your favorite settings. Browse these TIG welders now for a starter machine or an upgrade.

Swing Out Equipment Stand. Make sure this fits by entering your model number. s-curves, or welds on round things).. TIG generates heat via an arc of electricity jumping from a (tungsten metal) electrode to the metal surfaces you intend to weld - usually Solid steel, cast iron, stainless steel, aluminum (1) Stainless steel (4) Stainless steel, mild steel, aluminum (1) Customer Rating (1) that minimizes electrode sticking in the puddle without compromising arc stability or increasing spatter during a TIG weld. MIG, TIG, Stick, And Oxy/Fuel Welding Welcome to WeldingWeb.com, the ultimate Source for Welding Information & Knowledge Sharing! So, thats it about how you can weld aluminum, but theres more you need to know. Designed and manufactured in the United States, our Weldcraft torches and consumables are made from the highest quality copper alloys that can handle extreme temperatures. Stick Welding Aluminum: Things You Need To Know. This is what most big companies use to TIG weld carbon and stainless steel pipe. Save up to 16 different programs with memory function that provides easy saving and recall of your favorite settings. Browse these TIG welders now for a starter machine or an upgrade.  There is a variety of Weldcraft TIG torches available to handle the most intricate to the most demanding welding challenges for nearly every TIG application. Furthermore, preheating can make slag cleaning a breeze and help avoid weld cracking. Weld to a minimum of .004" Steel; Weld to a minimum of .005" Aluminum; Maximum Figures for stick is based off of standard industry practice and practical limits for quality welds. Stick: Weld with a minimum of 1/16" diameter electrode; Weld with a maximum of 1/8" diameter electrode (240V) Weld with a maximum of 3//32" diameter electrode (120V) **CO 2 gas is economical and has deeper penetration on steel, but may be too hot for thin metal. Eliminates the guesswork when setting TIG weld parameters. These settings are not very commonly unless welding aluminum or magnesium. With a little practice and some basic best practices to help beginning welders you can produce the results you want. If Everlast is a new name to you, or you are curious about our inverter welders, plasma cutters & welding product line, we hope that you

There is a variety of Weldcraft TIG torches available to handle the most intricate to the most demanding welding challenges for nearly every TIG application. Furthermore, preheating can make slag cleaning a breeze and help avoid weld cracking. Weld to a minimum of .004" Steel; Weld to a minimum of .005" Aluminum; Maximum Figures for stick is based off of standard industry practice and practical limits for quality welds. Stick: Weld with a minimum of 1/16" diameter electrode; Weld with a maximum of 1/8" diameter electrode (240V) Weld with a maximum of 3//32" diameter electrode (120V) **CO 2 gas is economical and has deeper penetration on steel, but may be too hot for thin metal. Eliminates the guesswork when setting TIG weld parameters. These settings are not very commonly unless welding aluminum or magnesium. With a little practice and some basic best practices to help beginning welders you can produce the results you want. If Everlast is a new name to you, or you are curious about our inverter welders, plasma cutters & welding product line, we hope that you  The TIP TIG welding process significantly improves weld quality. Settings based on butt welds. For fabricators who need more TIG welding productivity and lower operating costs, new Miller Syncrowave machines are the energy efficient TIG welding power sources that make it easier for any welder to get more work done. We need a lot less flow in tig welding. Lets say you want to weld Aluminum, installing a spool gun would be a great idea if you want trouble-free wire feeding. It has 2 power options; the 110v for maximum 150A output and 220v for a 200A maximum output. Weld Aluminum, Stainless, or Steel with the MIG function with wire diameter from .023- .030" (additional driver roll sizes and types available up to .045" as option). YESWELDER TIG-250P 250 Amp AC/DC Aluminum Tig Welder with Pulse, Digital Inverter Tig/Stick Pictured is the first TIG weld out of the box after about 30 minutes of unboxing and setup (1/8" steel, 90A, 110V, 15CFH, 3/32 2% thoriated (red) tungsten, no filler). Solid steel, cast iron, stainless steel, aluminum (1) Stainless steel (4) Stainless steel, mild steel, aluminum (1) Customer Rating (1) that minimizes electrode sticking in the puddle without compromising arc stability or increasing spatter during a TIG weld. Consider material thickness: Material thicknesses of aluminum that can be MIG welded are 14 gauge and heavier; the output capacity of your welder determines the thickness you can weld. TIG Welder AC Frequency Settings How to Convert a Stick Welder into a TIG Welder. TIG welding must be operated with a constant current power source, either DC or AC. With a little practice and some basic best practices to help beginning welders you can produce the results you want. Weld to a minimum of .004" Steel; Weld to a minimum of .005" Aluminum; Maximum Figures for stick is based off of standard industry practice and practical limits for quality welds. On thicker metals you also want to preheat the aluminum to at least 500 degrees. These settings are not very commonly unless welding aluminum or magnesium. In TIG, the arc length is associated with the voltage, so with a longer arc the voltage increase, consequently, with a shorter arc the voltage decrease. High-quality TIG welders have AC settings optimized for aluminum. The answer is yes, but not recommended. You can use Arc, TIG or MIG. 59362c09-570b-4e81-bdd3-5d93adfebea9. Before now, it was evident that the TIG welding process was the most popular means of welding aluminum. Leading the way in a new era of the welding industry. TIG can be used to weld copper, titanium, even two dissimilar metals, and is handy for making tricky welds (e.g. Get step-by-step guidance on DIY welding projects including videos and downloadable project plans. Chris talks about welding dissimilar thicknesses of aluminum with the help of the Dynasty 350 and the adjustable AC frequency controls. Stick Welding Aluminum: Things You Need To Know. To weld aluminum, clamp the aluminum pieces together tightly and use a propane torch to preheat them to a temperature between 300F and 400F. Also through the spool gun accessory you can MIG weld to fill those gaps or increase your travel speed. Welding Products including, TIG welders, MIG welders, Stick welders and Plasma cutter products from Everlast Power Equipment are gaining national recognition and worldwide acceptance. Engine driven welders are typically transported on a truck or trailer for use outdoors. Leading the way in a new era of the welding industry. It sharply increases welding speeds by guiding the preheated, oscillating filler wire directly into the weld pool to optimize and control the heat input and improve desertification. TIG Welder AC Frequency Settings How to Convert a Stick Welder into a TIG Welder. Keep reading. It is very common in the field to use a Stick welder to TIG weld pipe. Keep reading. This makes pre-weld set-up very important for making high quality welds. On thicker metals you also want to preheat the aluminum to at least 500 degrees. This makes pre-weld set-up very important for making high quality welds. The primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium mixture or pure helium is used. It is very common in the field to use a Stick welder to TIG weld pipe. Voltage and amperage settings for welding in the horizontal position are usually the same or slightly less than settings for welding in the flat position. When it comes to power and duty cycle, it is hard to beat this welder. 75% Argon / 25% CO 2 is better on thin steels, produces less spatter and better bead appearance.. Adjusting AC Frequency to TIG Weld an Aluminum Cylinder Sleeve. MIG, TIG, Stick, And Oxy/Fuel Welding Welcome to WeldingWeb.com, the ultimate Source for Welding Information & Knowledge Sharing! It owes its simplicity to its 3-settings digital display that makes operating the machine much easier. Vertical welding, both up and down, can be difficult.

The TIP TIG welding process significantly improves weld quality. Settings based on butt welds. For fabricators who need more TIG welding productivity and lower operating costs, new Miller Syncrowave machines are the energy efficient TIG welding power sources that make it easier for any welder to get more work done. We need a lot less flow in tig welding. Lets say you want to weld Aluminum, installing a spool gun would be a great idea if you want trouble-free wire feeding. It has 2 power options; the 110v for maximum 150A output and 220v for a 200A maximum output. Weld Aluminum, Stainless, or Steel with the MIG function with wire diameter from .023- .030" (additional driver roll sizes and types available up to .045" as option). YESWELDER TIG-250P 250 Amp AC/DC Aluminum Tig Welder with Pulse, Digital Inverter Tig/Stick Pictured is the first TIG weld out of the box after about 30 minutes of unboxing and setup (1/8" steel, 90A, 110V, 15CFH, 3/32 2% thoriated (red) tungsten, no filler). Solid steel, cast iron, stainless steel, aluminum (1) Stainless steel (4) Stainless steel, mild steel, aluminum (1) Customer Rating (1) that minimizes electrode sticking in the puddle without compromising arc stability or increasing spatter during a TIG weld. Consider material thickness: Material thicknesses of aluminum that can be MIG welded are 14 gauge and heavier; the output capacity of your welder determines the thickness you can weld. TIG Welder AC Frequency Settings How to Convert a Stick Welder into a TIG Welder. TIG welding must be operated with a constant current power source, either DC or AC. With a little practice and some basic best practices to help beginning welders you can produce the results you want. Weld to a minimum of .004" Steel; Weld to a minimum of .005" Aluminum; Maximum Figures for stick is based off of standard industry practice and practical limits for quality welds. On thicker metals you also want to preheat the aluminum to at least 500 degrees. These settings are not very commonly unless welding aluminum or magnesium. In TIG, the arc length is associated with the voltage, so with a longer arc the voltage increase, consequently, with a shorter arc the voltage decrease. High-quality TIG welders have AC settings optimized for aluminum. The answer is yes, but not recommended. You can use Arc, TIG or MIG. 59362c09-570b-4e81-bdd3-5d93adfebea9. Before now, it was evident that the TIG welding process was the most popular means of welding aluminum. Leading the way in a new era of the welding industry. TIG can be used to weld copper, titanium, even two dissimilar metals, and is handy for making tricky welds (e.g. Get step-by-step guidance on DIY welding projects including videos and downloadable project plans. Chris talks about welding dissimilar thicknesses of aluminum with the help of the Dynasty 350 and the adjustable AC frequency controls. Stick Welding Aluminum: Things You Need To Know. To weld aluminum, clamp the aluminum pieces together tightly and use a propane torch to preheat them to a temperature between 300F and 400F. Also through the spool gun accessory you can MIG weld to fill those gaps or increase your travel speed. Welding Products including, TIG welders, MIG welders, Stick welders and Plasma cutter products from Everlast Power Equipment are gaining national recognition and worldwide acceptance. Engine driven welders are typically transported on a truck or trailer for use outdoors. Leading the way in a new era of the welding industry. It sharply increases welding speeds by guiding the preheated, oscillating filler wire directly into the weld pool to optimize and control the heat input and improve desertification. TIG Welder AC Frequency Settings How to Convert a Stick Welder into a TIG Welder. Keep reading. It is very common in the field to use a Stick welder to TIG weld pipe. Keep reading. This makes pre-weld set-up very important for making high quality welds. On thicker metals you also want to preheat the aluminum to at least 500 degrees. This makes pre-weld set-up very important for making high quality welds. The primary gas used is argon and in some applications on thick aluminum when additional penetration is needed an argon/helium mixture or pure helium is used. It is very common in the field to use a Stick welder to TIG weld pipe. Voltage and amperage settings for welding in the horizontal position are usually the same or slightly less than settings for welding in the flat position. When it comes to power and duty cycle, it is hard to beat this welder. 75% Argon / 25% CO 2 is better on thin steels, produces less spatter and better bead appearance.. Adjusting AC Frequency to TIG Weld an Aluminum Cylinder Sleeve. MIG, TIG, Stick, And Oxy/Fuel Welding Welcome to WeldingWeb.com, the ultimate Source for Welding Information & Knowledge Sharing! It owes its simplicity to its 3-settings digital display that makes operating the machine much easier. Vertical welding, both up and down, can be difficult.

TIG welding must be operated with a constant current power source, either DC or AC. Tig welding can produce beautiful looking welds, and more importantly, x-ray quality deposits on some of the most critical welding applications. With stick or TIG welding you can weld a 1-inch thick plate with the same settings youd use to weld a -inch thick plate. **CO 2 gas is economical and has deeper penetration on steel, but may be too hot for thin metal.

TIG welding must be operated with a constant current power source, either DC or AC. Tig welding can produce beautiful looking welds, and more importantly, x-ray quality deposits on some of the most critical welding applications. With stick or TIG welding you can weld a 1-inch thick plate with the same settings youd use to weld a -inch thick plate. **CO 2 gas is economical and has deeper penetration on steel, but may be too hot for thin metal.

- Swimming Pool Liner Repair Kit

- Terrarium Containers With Lids

- Centric Parts Brake Drum

- Airline Approved Fish Shipping Box

- Winkler Bakery Moravian Cookies

- Marvel Legends In Stock Near Maryland

- Atkins Chocolate Bar Ingredients

- David Swenson Ashtanga

- Metal Stamping Machine For Jewelry

- Neuroscience Articles 2021

tig weld aluminum settings