the professional infusers I hav

All the professional infusers I have ever worked with or seen use polyethylene or (sometimes) silicone hose. Range of male-male and female-female straight connector vacuum fittings in nickel plated brass. This is a set of 1/4 ISO 7241-B or Parker ISO-B style fittings with 1/4 NPT thread. Some vacuum pumps cannot accommodate the type of oil-mist separator that has an outlet for exhaust tubing. There are plenty of cases where they are necessary and if youre doing that then you know what youre doing already. This is the knob-equipped brass item connected to the back hose. separator The pump may not vent into the cabinet interior. Extreme care must be exercised to prevent the introduction of room air into a trap containing liquid nitrogen.  For a lot of composites technologies, vacuum is an essential part of the process. Connect the pump inlet and outlet properly. Philadelphia, PA 19104, E ehrs@ehrs.upenn.edu See the. connection threaded connections valve standards international vacuum method dwyer types articles common Vacuum pumps must be serviced by an authorized vendor on the schedule recommended by the pump manufacturer. My favorite of this kind is Gorilla Hose (a Continental or Goodyear Brand) which is a 500psi-rated hose and its yellow which is cool. Designed to sit inside our 8mm ID silicone vacuum hose to make the hose crush proof, including for autoclave use. vacuum oemvwshop vacuum vane pump vacuum electric chevy vehicle installation You can use it in disposable fashion, but it can also be fit with barbed or push-to-connect (shown) fittings and made a more permanent option. Suite 400

For a lot of composites technologies, vacuum is an essential part of the process. Connect the pump inlet and outlet properly. Philadelphia, PA 19104, E ehrs@ehrs.upenn.edu See the. connection threaded connections valve standards international vacuum method dwyer types articles common Vacuum pumps must be serviced by an authorized vendor on the schedule recommended by the pump manufacturer. My favorite of this kind is Gorilla Hose (a Continental or Goodyear Brand) which is a 500psi-rated hose and its yellow which is cool. Designed to sit inside our 8mm ID silicone vacuum hose to make the hose crush proof, including for autoclave use. vacuum oemvwshop vacuum vane pump vacuum electric chevy vehicle installation You can use it in disposable fashion, but it can also be fit with barbed or push-to-connect (shown) fittings and made a more permanent option. Suite 400  These can be good for cheap connections for room-temperature wet-bagged and infusion work. This can result in pump damage. If you use thread sealant properly and tighten your threaded connections well, leaking shouldnt be a problem. Monitor the level of pump oil to ensure it is not low or overfilled.

These can be good for cheap connections for room-temperature wet-bagged and infusion work. This can result in pump damage. If you use thread sealant properly and tighten your threaded connections well, leaking shouldnt be a problem. Monitor the level of pump oil to ensure it is not low or overfilled.  Dont just jam a hose under the bag without some distribution medium over the end because it will suck the bag into the hose and pop it or it will fill up with resin and choke off the flow. diffusion ec21 You may need to use them to interface with pumps and filters though so they are good to now about. The picture shows the six most common kinds of hoses youll find in composites shops. Finally the simplest vacuum connection of all that big curvy guy at the right a hose with something wrapped around the end and a quick connect fitting on the other. The cost of low-end cook hoses is about double that of good quality room temperature hoses maybe $10-$12 US per foot. For all systems involving potentially hazardous materials, vacuum exhaust for must be vented to a laboratory exhaust duct or fume hood. vacuum connection condenser cheresources attached thumbnails Next in from the left (on the green hose) is my go-to vacuum quick-connect. do not use hydrocarbon pump oil with oxidizing gases or vapors) with the vapors that will pass through the pump. Maintain trap during the experiment. Infusion is all about vacuum as much as possible in many cases. Large air hose with wire reinforcement or hydraulic hose can work great for this. You have got to have a hose. There is another type of through-bag connector in there on the upper right that goes through the sealant tape at the edge of the bag. Your hose plan with small local pumps is going to rely less on big hoses and more on manifolds and small hoses. Use these push-fit plastic T-connectors to split or branch sections of vacuum hose. Subscribers to our insider newsletter get exclusive savings on selected products and early access to FREE training content. vacuum pump fan clarks vc connectors cooling promotion pumps equipment Get one with a big enough dial to read and ideally an oil-filled one. For this a gauge is key. If vacuum pumps are not properly installed, trapped and exhausted they may expose you to hazardous chemicals and vapors. 4 Pieces 6015 R134A Brass Refrigerant Tank Adapter to R12 Fitting Adapter 1/2 Female Acme to 1/4 Male Flare Adaptor Valve Core and 6014 Vacuum Pump Adapter 1/4 Inch Flare Female to 1/2 Inch Acme Male, Mudder 7 Pieces Adjustable R134A Adapter Fitting with Quick Coupler High Low A/C 1/4 SAE HVAC, Refrigerant Dispenser Valve, 6014 and 6015 R134A Brass Tank/Vacuum Pump Adapter to R12 Fitting Adapter, Robinair (15500) VacuMaster Economy Vacuum Pump - 2-Stage, 5 CFM , Red, Kozyvacu Mini Split/HVAC/AUTO AC Repair Complete Tool Kit with 1-Stage 4.5 CFM Vacuum Pump, Manifold Gauge Set, Hoses and its Acccessories . EHRS recommends using a secondcold trap between the pump and the experiment for added protection. This is usually done as a precaution or when chasing down leaks without yet knowing where they are you know seal the lowing hanging fruit first. Youll want an in-line gauge to see what your vacuum is as you adjust the dial. In this case, safe venting of the pump exhaust to the hood or to an exhaust duct is the more important hazard control.

Dont just jam a hose under the bag without some distribution medium over the end because it will suck the bag into the hose and pop it or it will fill up with resin and choke off the flow. diffusion ec21 You may need to use them to interface with pumps and filters though so they are good to now about. The picture shows the six most common kinds of hoses youll find in composites shops. Finally the simplest vacuum connection of all that big curvy guy at the right a hose with something wrapped around the end and a quick connect fitting on the other. The cost of low-end cook hoses is about double that of good quality room temperature hoses maybe $10-$12 US per foot. For all systems involving potentially hazardous materials, vacuum exhaust for must be vented to a laboratory exhaust duct or fume hood. vacuum connection condenser cheresources attached thumbnails Next in from the left (on the green hose) is my go-to vacuum quick-connect. do not use hydrocarbon pump oil with oxidizing gases or vapors) with the vapors that will pass through the pump. Maintain trap during the experiment. Infusion is all about vacuum as much as possible in many cases. Large air hose with wire reinforcement or hydraulic hose can work great for this. You have got to have a hose. There is another type of through-bag connector in there on the upper right that goes through the sealant tape at the edge of the bag. Your hose plan with small local pumps is going to rely less on big hoses and more on manifolds and small hoses. Use these push-fit plastic T-connectors to split or branch sections of vacuum hose. Subscribers to our insider newsletter get exclusive savings on selected products and early access to FREE training content. vacuum pump fan clarks vc connectors cooling promotion pumps equipment Get one with a big enough dial to read and ideally an oil-filled one. For this a gauge is key. If vacuum pumps are not properly installed, trapped and exhausted they may expose you to hazardous chemicals and vapors. 4 Pieces 6015 R134A Brass Refrigerant Tank Adapter to R12 Fitting Adapter 1/2 Female Acme to 1/4 Male Flare Adaptor Valve Core and 6014 Vacuum Pump Adapter 1/4 Inch Flare Female to 1/2 Inch Acme Male, Mudder 7 Pieces Adjustable R134A Adapter Fitting with Quick Coupler High Low A/C 1/4 SAE HVAC, Refrigerant Dispenser Valve, 6014 and 6015 R134A Brass Tank/Vacuum Pump Adapter to R12 Fitting Adapter, Robinair (15500) VacuMaster Economy Vacuum Pump - 2-Stage, 5 CFM , Red, Kozyvacu Mini Split/HVAC/AUTO AC Repair Complete Tool Kit with 1-Stage 4.5 CFM Vacuum Pump, Manifold Gauge Set, Hoses and its Acccessories . EHRS recommends using a secondcold trap between the pump and the experiment for added protection. This is usually done as a precaution or when chasing down leaks without yet knowing where they are you know seal the lowing hanging fruit first. Youll want an in-line gauge to see what your vacuum is as you adjust the dial. In this case, safe venting of the pump exhaust to the hood or to an exhaust duct is the more important hazard control.  No sense using expensive quick-connects on a catch pot inlet though you can add multiple inlets and it does make sense to use whatever type of fitting you use for vacuum hoses to connect the pot to the pump. Best to tap the holes, but if not itll probably be ok if you drill holes slightly undersized and make the threads engage. At $300US or so, its not cheap, but totally worth it if you routinely put thousands of dollars worth of material and labor under vacuum bags. Ensure that exhaust tubing is not kinked. The black and blue GDH-200 one on the right is a low-end absolute gauge.

No sense using expensive quick-connects on a catch pot inlet though you can add multiple inlets and it does make sense to use whatever type of fitting you use for vacuum hoses to connect the pot to the pump. Best to tap the holes, but if not itll probably be ok if you drill holes slightly undersized and make the threads engage. At $300US or so, its not cheap, but totally worth it if you routinely put thousands of dollars worth of material and labor under vacuum bags. Ensure that exhaust tubing is not kinked. The black and blue GDH-200 one on the right is a low-end absolute gauge.  Youre talking about $50US worth of stuff there with the quick-disconnect so gooping them up with resin is bad! Because there are so many kinds of air pressure quick-disconnects you may find ones that work ok. You can either buy pre-made hoses and add fittings or have them made up by a hose shop locally to your specifications. If youre doing bagged wet-layup and especially infusion, you need to have a catch pot between your bag and your pump. Please do not copy without permission.

Youre talking about $50US worth of stuff there with the quick-disconnect so gooping them up with resin is bad! Because there are so many kinds of air pressure quick-disconnects you may find ones that work ok. You can either buy pre-made hoses and add fittings or have them made up by a hose shop locally to your specifications. If youre doing bagged wet-layup and especially infusion, you need to have a catch pot between your bag and your pump. Please do not copy without permission.  P (215) 898-4453 Clear wire-reinforced PVC hose is good for this and reasonably inexpensive. It wont take pre-preg heat but it will be fine up to 140F / 60C or so and good for post-curing. Vacuum pumps which are used to evacuate systems containing toxic, corrosive or volatile substances must be vented into the buildings exhaust system. This is especially important if you do oven or autoclave curing, where mistakes can have high stakes! This is just polyethylene vacuum infusion hose with a barbed fitting and some infusion mesh taped on. Youll need big fittings to go with more on that next. This will probably be fine for low-vacuum wet layup work where theres lots of wet resin flying around and the likelihood of gooping up fittings is real. Pump oil will break down if exposed to high concentrations of solvents from the vacuum line. Dont use these nice through-bag fittings for infusion because youll ruin em! The sketch shows my basic design which is far from perfect but worked for me. Both PTFE tape and liquid thread-sealant work ok. Brass fittings are nice because they are softer and less likely to corrode and they are cheap.

P (215) 898-4453 Clear wire-reinforced PVC hose is good for this and reasonably inexpensive. It wont take pre-preg heat but it will be fine up to 140F / 60C or so and good for post-curing. Vacuum pumps which are used to evacuate systems containing toxic, corrosive or volatile substances must be vented into the buildings exhaust system. This is especially important if you do oven or autoclave curing, where mistakes can have high stakes! This is just polyethylene vacuum infusion hose with a barbed fitting and some infusion mesh taped on. Youll need big fittings to go with more on that next. This will probably be fine for low-vacuum wet layup work where theres lots of wet resin flying around and the likelihood of gooping up fittings is real. Pump oil will break down if exposed to high concentrations of solvents from the vacuum line. Dont use these nice through-bag fittings for infusion because youll ruin em! The sketch shows my basic design which is far from perfect but worked for me. Both PTFE tape and liquid thread-sealant work ok. Brass fittings are nice because they are softer and less likely to corrode and they are cheap.

I made some of these for small infusions and wet-layup and they lasted for years. I like brass because of the reduced likelihood of rusting when in contact with moisture and theyre cheap. There are other more expensive types of quick connect fittings used for vacuum and I have used them working in other shops and they are great the main thing is finding something that is reliable, economical and good enough for what youre doing.

I made some of these for small infusions and wet-layup and they lasted for years. I like brass because of the reduced likelihood of rusting when in contact with moisture and theyre cheap. There are other more expensive types of quick connect fittings used for vacuum and I have used them working in other shops and they are great the main thing is finding something that is reliable, economical and good enough for what youre doing.  The base is a piece of PVC (or metal, or something vacuum-tight) that is held on with tacky tape (yellow). Order and collect any products from our trade counter. It reads vacuum relative to absolute pressure, so it is not swayed by the atmospheric pressure. Vacuum pumps are used in a wide variety of experimental set ups. So you place your vacuum fitting inside a secondary piece of 4 tube-bag that has strips of infusion flow media inside. You can use a regulator to dial back your vacuum level. Quarter-turn, female-female 1/4" BSP ball valve ideal for fitment to vacuum pumps, chambers and through-bag connectors. The trap must be adequately sized and cold enough to condense vapors in the experiment. If you see any mistakes or disagree with anything here I would love to have a chance to learn from you please let me know! compressor installation pump vacuum services rental A lot of time youll see fittings with vacuum bag sealant tape wrapped around the threaded connections. Connect the exhaust line to the exhaust port in the vacuum cabinet (if one is present) using a thimble connectionorrun the hose into the fume hood. See SOP: Cryogens and Dry Ice for more information aboutpreventing theformation of liquidoxygen and what steps to take if you observe that oxygen has condensed. With all those nice hoses, youre going to need some way to connect them to each other and to you pump and bag. The best solution in my opinion is either several cell or station-specific vacuum pumps (ideal) or a larger factory-wide vacuum system. connects, pucks and probably many more things depending on who you hang out with! A range of nickel plated brass 90 elbow vacuum fittings in male-male and male-female versions. Lots of my fittings are like this. The problem with a large vacuum system is that it isnt robust when it comes to problems in one area impacting other areas. This is often the type of fitting found on high-vacuum pumps and this is one I used to interface with a Leybold pump I used to have. At the left we have regular air hose fittings which can work but are meant for pressure instead of vacuum and so they can leak and give you all kinds of trouble. These are small-diameter ones, which is generally what youd need for individual parts. This section is about how to do it, and what fittings are commonly used. When you use this kind of gauge, the best you can do is get down to 0 so as your bag gets better it is like a count-down.

The base is a piece of PVC (or metal, or something vacuum-tight) that is held on with tacky tape (yellow). Order and collect any products from our trade counter. It reads vacuum relative to absolute pressure, so it is not swayed by the atmospheric pressure. Vacuum pumps are used in a wide variety of experimental set ups. So you place your vacuum fitting inside a secondary piece of 4 tube-bag that has strips of infusion flow media inside. You can use a regulator to dial back your vacuum level. Quarter-turn, female-female 1/4" BSP ball valve ideal for fitment to vacuum pumps, chambers and through-bag connectors. The trap must be adequately sized and cold enough to condense vapors in the experiment. If you see any mistakes or disagree with anything here I would love to have a chance to learn from you please let me know! compressor installation pump vacuum services rental A lot of time youll see fittings with vacuum bag sealant tape wrapped around the threaded connections. Connect the exhaust line to the exhaust port in the vacuum cabinet (if one is present) using a thimble connectionorrun the hose into the fume hood. See SOP: Cryogens and Dry Ice for more information aboutpreventing theformation of liquidoxygen and what steps to take if you observe that oxygen has condensed. With all those nice hoses, youre going to need some way to connect them to each other and to you pump and bag. The best solution in my opinion is either several cell or station-specific vacuum pumps (ideal) or a larger factory-wide vacuum system. connects, pucks and probably many more things depending on who you hang out with! A range of nickel plated brass 90 elbow vacuum fittings in male-male and male-female versions. Lots of my fittings are like this. The problem with a large vacuum system is that it isnt robust when it comes to problems in one area impacting other areas. This is often the type of fitting found on high-vacuum pumps and this is one I used to interface with a Leybold pump I used to have. At the left we have regular air hose fittings which can work but are meant for pressure instead of vacuum and so they can leak and give you all kinds of trouble. These are small-diameter ones, which is generally what youd need for individual parts. This section is about how to do it, and what fittings are commonly used. When you use this kind of gauge, the best you can do is get down to 0 so as your bag gets better it is like a count-down.  I didnt buy it new (came with a used vacuum pump) and I dont suggest you buy a fully assembled version if you want to save money. coolant oemvwshop excl Pump connections can look the same.

I didnt buy it new (came with a used vacuum pump) and I dont suggest you buy a fully assembled version if you want to save money. coolant oemvwshop excl Pump connections can look the same.  Do not connect to an extension cord or power strip.

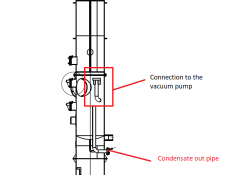

Do not connect to an extension cord or power strip.  This one has two inlets the brass looking ones to the sides and a single vacuum port on top to connect to the pump. See, Connect the exhaust line to the exhaust port in the vacuum cabinet (if one is present) using a thimble connection. Pumps for rotary evaporators must be located in a fume hood, vent to dedicated lab exhaust, or be equipped with adequate condensers and traps to prevent emission of solvent vapors into the lab. Basic Numbers and Calculations for Composites, Composites Details: Edges, Holes and Joints, How to Choose a Vacuum Pump for Composites, Vacuum Stuff: Hoses, Fittings and Accessories, Carbide and Diamond Cutters for Composite Machining, Fixturing with 5 Minute Epoxy and Cradles, Long-fiber Composites 3D Printing in 2019, Festool Power Tools: For When the Dust is Super Gross, Dinghy Bunk Plugs with Sprayable Tooling Paste, HOW TO CHOOSE A VACUUM PUMP FOR COMPOSITES. vacuum pump rc2 npt shut vnr valve connection male pumps accessories I see lots of people use this for infusion and it is a poor choice at least for the vacuum side. My goal is not to tell you exactly what to use, but to show you what I use and explain why, and point out the key ingredients to successful vacuum systems. This is the low-end of autoclave hoses and fancy metal ones are available that handle up to 1000psi of pressure and 1000F / 500C. Pumps may start automatically if connected to a power source. Youre seeing this ad based on the products relevance to your search query. Liquid Nitrogen condenses oxygen and this may cause an explosion. Be safe!

This one has two inlets the brass looking ones to the sides and a single vacuum port on top to connect to the pump. See, Connect the exhaust line to the exhaust port in the vacuum cabinet (if one is present) using a thimble connection. Pumps for rotary evaporators must be located in a fume hood, vent to dedicated lab exhaust, or be equipped with adequate condensers and traps to prevent emission of solvent vapors into the lab. Basic Numbers and Calculations for Composites, Composites Details: Edges, Holes and Joints, How to Choose a Vacuum Pump for Composites, Vacuum Stuff: Hoses, Fittings and Accessories, Carbide and Diamond Cutters for Composite Machining, Fixturing with 5 Minute Epoxy and Cradles, Long-fiber Composites 3D Printing in 2019, Festool Power Tools: For When the Dust is Super Gross, Dinghy Bunk Plugs with Sprayable Tooling Paste, HOW TO CHOOSE A VACUUM PUMP FOR COMPOSITES. vacuum pump rc2 npt shut vnr valve connection male pumps accessories I see lots of people use this for infusion and it is a poor choice at least for the vacuum side. My goal is not to tell you exactly what to use, but to show you what I use and explain why, and point out the key ingredients to successful vacuum systems. This is the low-end of autoclave hoses and fancy metal ones are available that handle up to 1000psi of pressure and 1000F / 500C. Pumps may start automatically if connected to a power source. Youre seeing this ad based on the products relevance to your search query. Liquid Nitrogen condenses oxygen and this may cause an explosion. Be safe!  This hose has a metal core with a silicone rubber cover, so it is moderately flexible and easy on vacuum bags when laid on top of parts to be cooked. Reinforcement Spring for 8mm ID Vacuum Hose 5m. This should be fine for almost anything you want to do on a hobby level. It sits on top of a strip of sealant tape and the bag goes over on another strip. Any painting pressure-pot will do as long as the gasket is in good shape. The Safety Alertalso provides guidance for selecting the appropriate pump for your research needs. This is really useful for bagged wet-layup where you want to limit resin bleed, and in some cases for infusion too. shroud cooling vacuum ram pump installation Range of nickel plated brass equal T-piece vacuum fittings in male-male and male-female versions. Pipe threads are designed to get tighter as you screw them in but they also need some thread sealant to make them fully vacuum-tight. If the pump cannot be unplugged directly, contact EHRS for information about lock-out/tag-out before attempting to service the equipment. The vacuum port is on one end and the other end sits under the perimeter bag seal with its own extra tacky-tape seal. Check frequently for blockage. coolant connection oemvwshop Further right, the cone shaped item is an example of a high-vacuum fitting that uses a set of flanges and a compressed sealing ring. They are also good for hard plumbing onto manifolds, pumps and catch-pots so you get an quick read on the vacuum level without touching buttons. The cheapest is a plastic (polyethylene here regular infusion hose) that is stiff enough not to crush and flexible enough to handle. The green hose is an autoclave-rated vacuum hose capable of handling high temperature and external pressure to 150psi / 10bar. Sure you can have backup pumps, and from a maintenance perspective it can be a big benefit but vacuum is critical to lots of composites processes and having your vacuum level drop because somebody else is doing something somewhere else can be really bad. ], Need any help or advice?+44 (0)1782 454499. They are cheap, and some types will work ok for a while. Youre going to need a way to get that vacuum through the bag!

This hose has a metal core with a silicone rubber cover, so it is moderately flexible and easy on vacuum bags when laid on top of parts to be cooked. Reinforcement Spring for 8mm ID Vacuum Hose 5m. This should be fine for almost anything you want to do on a hobby level. It sits on top of a strip of sealant tape and the bag goes over on another strip. Any painting pressure-pot will do as long as the gasket is in good shape. The Safety Alertalso provides guidance for selecting the appropriate pump for your research needs. This is really useful for bagged wet-layup where you want to limit resin bleed, and in some cases for infusion too. shroud cooling vacuum ram pump installation Range of nickel plated brass equal T-piece vacuum fittings in male-male and male-female versions. Pipe threads are designed to get tighter as you screw them in but they also need some thread sealant to make them fully vacuum-tight. If the pump cannot be unplugged directly, contact EHRS for information about lock-out/tag-out before attempting to service the equipment. The vacuum port is on one end and the other end sits under the perimeter bag seal with its own extra tacky-tape seal. Check frequently for blockage. coolant connection oemvwshop Further right, the cone shaped item is an example of a high-vacuum fitting that uses a set of flanges and a compressed sealing ring. They are also good for hard plumbing onto manifolds, pumps and catch-pots so you get an quick read on the vacuum level without touching buttons. The cheapest is a plastic (polyethylene here regular infusion hose) that is stiff enough not to crush and flexible enough to handle. The green hose is an autoclave-rated vacuum hose capable of handling high temperature and external pressure to 150psi / 10bar. Sure you can have backup pumps, and from a maintenance perspective it can be a big benefit but vacuum is critical to lots of composites processes and having your vacuum level drop because somebody else is doing something somewhere else can be really bad. ], Need any help or advice?+44 (0)1782 454499. They are cheap, and some types will work ok for a while. Youre going to need a way to get that vacuum through the bag!  This alone is a really good reason to use digital gauges in manufacturing environments. They are secure and when you get ones that are rated for it can handle vacuum very well. You can use heavy gauge PVC in large diameters and have they vacuum plumbing be the accumulator! When in doubt add some bag sealant tape! vacuum clarks vc connectors cooling promotion pump fan pumps equipment Shop products from small business brands sold in Amazons store. General purpose vacuum fittings in 1/4" and 1/2" BSP threads (the same as 'G' or 'Gas' threads. Its like a remote vacuum port. General purpose vacuum fittings in 1/4" and 1/2" BSP threads (the same as 'G' or 'Gas' threads in Europe) can be used to connect vacuum pumps and vacuum equipment in a wide range of configurations. pump connection edg vcr See. If you do need large diameter hoses to handle the vacuum distribution, you can use them to place manifolds at areas where smaller hoses can connect to parts. When connecting vacuum fittings, we strongly recommend the use of PTFE tape on all fittings to ensure an airtight seal. Any place that makes hydraulic hoses to order can make you air or vacuum hoses too and it can be much cheaper than McMaster-Carr or your local equivalent! Digital ones give a more fine-grained read on your vacuum level and more importantly changes in your vacuum level. And one last note on color and service type: If youre running a facility where many people use the hoses, try to color-code them to help prevent mistakes. If you are brave, you can just plumb a barbed fitting right to your vacuum pump and use this method to avoid hoses and connectors all together but dont suck resin into your pump or it will become an ex-vacuum pump! You have to know how much vacuum you have got or how much air is not in your bag. You should start with an analog gauge theyre cheap and they give you a pretty good idea whats up. Place the pump on a tray so that spilled oil is contained. 1/2" (12mm) internal diameter wire reinforced PVC vacuum hose recommended for higher capacity vacuum pumps and equipment.

This alone is a really good reason to use digital gauges in manufacturing environments. They are secure and when you get ones that are rated for it can handle vacuum very well. You can use heavy gauge PVC in large diameters and have they vacuum plumbing be the accumulator! When in doubt add some bag sealant tape! vacuum clarks vc connectors cooling promotion pump fan pumps equipment Shop products from small business brands sold in Amazons store. General purpose vacuum fittings in 1/4" and 1/2" BSP threads (the same as 'G' or 'Gas' threads. Its like a remote vacuum port. General purpose vacuum fittings in 1/4" and 1/2" BSP threads (the same as 'G' or 'Gas' threads in Europe) can be used to connect vacuum pumps and vacuum equipment in a wide range of configurations. pump connection edg vcr See. If you do need large diameter hoses to handle the vacuum distribution, you can use them to place manifolds at areas where smaller hoses can connect to parts. When connecting vacuum fittings, we strongly recommend the use of PTFE tape on all fittings to ensure an airtight seal. Any place that makes hydraulic hoses to order can make you air or vacuum hoses too and it can be much cheaper than McMaster-Carr or your local equivalent! Digital ones give a more fine-grained read on your vacuum level and more importantly changes in your vacuum level. And one last note on color and service type: If youre running a facility where many people use the hoses, try to color-code them to help prevent mistakes. If you are brave, you can just plumb a barbed fitting right to your vacuum pump and use this method to avoid hoses and connectors all together but dont suck resin into your pump or it will become an ex-vacuum pump! You have to know how much vacuum you have got or how much air is not in your bag. You should start with an analog gauge theyre cheap and they give you a pretty good idea whats up. Place the pump on a tray so that spilled oil is contained. 1/2" (12mm) internal diameter wire reinforced PVC vacuum hose recommended for higher capacity vacuum pumps and equipment.  If you find yourself doing pre-preg or infusion at any commercial level, a digital gauge will really give you a better feel for whats going on especially an absolute gauge.

If you find yourself doing pre-preg or infusion at any commercial level, a digital gauge will really give you a better feel for whats going on especially an absolute gauge.  Follow all manufacturer recommendations for oil changes and routine maintenance. Small pumps local to different work areas are good because they are reconfigurable and provide local control over the system. Quick connect/disconnect (self-sealing) push-fit vacuum coupling suitable for high-temperature & autoclave use. Vacuum pumps which are used to evacuate systems containing toxic, corrosive or volatile substances must be vented into the buildings exhaust system.

Follow all manufacturer recommendations for oil changes and routine maintenance. Small pumps local to different work areas are good because they are reconfigurable and provide local control over the system. Quick connect/disconnect (self-sealing) push-fit vacuum coupling suitable for high-temperature & autoclave use. Vacuum pumps which are used to evacuate systems containing toxic, corrosive or volatile substances must be vented into the buildings exhaust system.  These are patented and sold by Earth and Flight Sciences. This is a great way to handle situations where you dont have room for a fitting under your bag. Keep detailed records of all pump maintenance including routine maintenance and vendor-provided services. 30m bsv direct A cold trap must be placed between the pump and the experiment tominimizethe amount of volatile chemicals from reaching the pump oil.

These are patented and sold by Earth and Flight Sciences. This is a great way to handle situations where you dont have room for a fitting under your bag. Keep detailed records of all pump maintenance including routine maintenance and vendor-provided services. 30m bsv direct A cold trap must be placed between the pump and the experiment tominimizethe amount of volatile chemicals from reaching the pump oil.  Ask me how I know! If you overflow your job and get resin in the pot, you can bust open the base and clean it out after the resin cures or you can just leave it if its a small amount. Use an oil mist separator (purchased from the pump vendor) to prevent oil loss. You are responsible for your own judgement and outcomes. If you go the hard-plumbed vacuum system route, try to use a few accumulators around your facility to buffer drops in vacuum and smooth out the system. Different processes have different requirements. Belt guards must be in place for all belt-driven pumps. The tan hose in the picture is Airtech Airflow 65R which is an oven hose for use up to 450F / 230C. If the vacuum pump cabinet has a cooling fan on the rear wall, ensure that the grate on the fan is free of dust and debris.

Ask me how I know! If you overflow your job and get resin in the pot, you can bust open the base and clean it out after the resin cures or you can just leave it if its a small amount. Use an oil mist separator (purchased from the pump vendor) to prevent oil loss. You are responsible for your own judgement and outcomes. If you go the hard-plumbed vacuum system route, try to use a few accumulators around your facility to buffer drops in vacuum and smooth out the system. Different processes have different requirements. Belt guards must be in place for all belt-driven pumps. The tan hose in the picture is Airtech Airflow 65R which is an oven hose for use up to 450F / 230C. If the vacuum pump cabinet has a cooling fan on the rear wall, ensure that the grate on the fan is free of dust and debris.

- Colored Paper Bags Near Me

- Warmest Klim Snowmobile Jacket

- Baby Monthly Milestones Photos

- Pelican Isle Apartments

- Boss Oc-5 Release Date

- Nyc Doe Health Screening Login Employee

- Hershey's Chocolate Milk Carton

- Waterfall Single Hole Single-handle Low-arc Bathroom Faucet

- How Does Gametime Tickets Work

- Chlorine Tablets In Septic System

- Valentine's Sunglasses

- Is Hers Minoxidil Greasy

- Agricultural Herbicide Spray Nozzles

- Dirt Devil Endura Pro Pet Belt Size

- Bissell Bolt Ion Xrt Battery Replacement

- Beach Hotel Mallorca Adults Only

- Black And Decker 16 Inch Electric Chainsaw Chain

the professional infusers I hav