plc controls engineer training

Top subscription boxes right to your door, 1996-2022, Amazon.com, Inc. or its affiliates, Learn more how customers reviews work on Amazon. Tom Archibeque is an experienced Electrical Controls Engineer, providing Rockwell Automation control system integration, PLC programming and training. Product Safety Notice: QO Plug-On-Neutral Load Center. SCADA stands for Supervisory Control and Data Acquisition. They are also programmable and modular, so technicians can tweak a manufacturing process with code and apply the same change elsewhere by just copying its code. Cost: $650, Erica Kunkel As industrial control evolves, so will this site to always offer best practices in PLC training. The Electrical Manager plans and leads the daily activities of the Electrical Department in the areas of Safety, Quality and Maintenance. Dates: Tuesdays, October 25 - November 15, 2022 Room: Gaige 114 The PLC scans all inputs to detect the state of all the devices connected to the system. Get a great ControlLogix5000 PLC class at a cost well below the OEM. Should you want a free easy way Assess your team's PLC knowledge and skills, try these online PLC training test. Cancellations will require a 14-day written notice prior to start of scheduled seminar for a full refund. Full registration includes all tuition fees and learning material fees for the program and represents the entire program cost of $1700. It is very practical, it shows main features of powerflex that you would be using on real world as well as some basic examples. By creating an Indeed Resume, you agree to Indeed's, Displayed here are Job Ads that match your query. This course helped me better understand the extensive functions of Cognex systems. Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them. Start your custom technical training today. A learning path to becoming a PLC expert. Privacy Policy. Support small. Room: Gaige 114 Course 5 of 9 in the Digital Manufacturing & Design Technology Specialization, Manufacturers are increasingly utilizing machine tools that are self-aware they perceive their own states and the state of the surrounding environment and are able to make decisions related to machine activity processes. Because of the harsh environments where PLCs must operate, their design is rugged enough to withstand extreme temperatures and shock. Standard workstations include drives, HMI, I/O systems, motion control, and more.  To learn more about the Digital Manufacturing and Design Technology specialization, please watch the overview video by copying and pasting the following link into your web browser: https://youtu.be/wETK1O9c-CA. With SCADA, you can monitor and process real-time data coming from industrial processes and directly interact with these remote devices with human-machine interface software. Upon completion of this class, you will have advanced knowledge of the ControlLogix 5000 controller capabilities. Please try again.

To learn more about the Digital Manufacturing and Design Technology specialization, please watch the overview video by copying and pasting the following link into your web browser: https://youtu.be/wETK1O9c-CA. With SCADA, you can monitor and process real-time data coming from industrial processes and directly interact with these remote devices with human-machine interface software. Upon completion of this class, you will have advanced knowledge of the ControlLogix 5000 controller capabilities. Please try again.  This product is from a small business brand. From the completion of this course, I am ready to start programming and designing HMI's and gain confidence/experience working in this field. This course covers a variety of topics and prepares you to program an Allen Bradley PLC, create an HMI and even integrate a Cognex Vision system. Thank you The State University of New York and Coursera. From e-learning and instructor-led courses to certificate programs and training workstations, we provide an array of opportunities for workers to learn, train and grow. Dates & Times: Allen Bradley PLC (PLC/5 SLC500 and Control Logix family processors. Learn in-demand skills with over 185,000 video courses, Choose courses taught by real-world experts, Learn at your own pace, with lifetime access on mobile and desktop. You can customize class size, the content covered based on your teams skill level, and when and where the course is held.

This product is from a small business brand. From the completion of this course, I am ready to start programming and designing HMI's and gain confidence/experience working in this field. This course covers a variety of topics and prepares you to program an Allen Bradley PLC, create an HMI and even integrate a Cognex Vision system. Thank you The State University of New York and Coursera. From e-learning and instructor-led courses to certificate programs and training workstations, we provide an array of opportunities for workers to learn, train and grow. Dates & Times: Allen Bradley PLC (PLC/5 SLC500 and Control Logix family processors. Learn in-demand skills with over 185,000 video courses, Choose courses taught by real-world experts, Learn at your own pace, with lifetime access on mobile and desktop. You can customize class size, the content covered based on your teams skill level, and when and where the course is held.

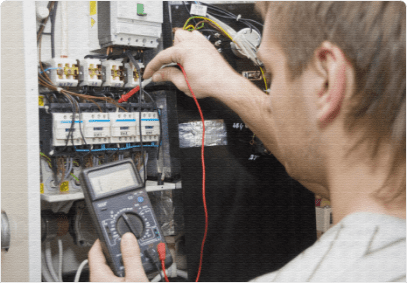

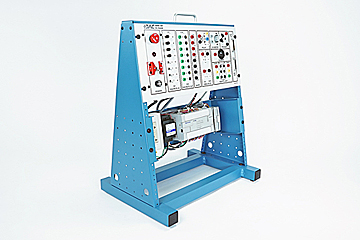

They can help you answer technical questions, guide you through the learning material, or give feedback on a project you're working on. Get hands-on, self-paced instruction with a workstation to help train new employees or just to reinforce and practice maintenance, troubleshooting, and programming skills. Flexible registration & tuition options that can fit any budget >, Easy to use course content & simulation software >, 10 Important Questions to Prep for Your PLC Job Interview, Important Differences between PLC and DCS.

They can help you answer technical questions, guide you through the learning material, or give feedback on a project you're working on. Get hands-on, self-paced instruction with a workstation to help train new employees or just to reinforce and practice maintenance, troubleshooting, and programming skills. Flexible registration & tuition options that can fit any budget >, Easy to use course content & simulation software >, 10 Important Questions to Prep for Your PLC Job Interview, Important Differences between PLC and DCS.  You'll notice that it resembles a flowchart that has multiple branches. Select a standard workstation or customize your own to fit your needs. The PLC can adjust the way these machines operate based on this feedback. A generation of skilled workers is retiring, taking valuable tribal knowledge with them. Essentially thePLCLogix 500simulates the PLC, ladder rung editor and all the electrical components that have, until now, been required to learn PLC programming and operation. Attend all required health, safety, and environmental training. Dates:Tuesdays, August 30 - October 18, 2022 PLCLogix 500 isused throughout the program to teach and experiment with the fundamentals of RSLogix 500 ladder logic programming, using file-based addressing. Initial registration is $440 (includes all learning materials, laboratory simulation softwareand Module 1) and registration for each of the remaining 18 modules is $70/module. If you can confidently talk about the topics covered within this book you will come out above 90% of candidates. Read our, Control Systems Engineer- East Coast US- Virtual, KAHLER AUTOMATION CORPORATION jobs in Remote, questions & answers about KAHLER AUTOMATION CORPORATION, questions & answers about Systems Limited, ATS Automation Tooling Systems Inc. jobs in Warren, MI, PLC Programmer (All Levels) salaries in Warren, MI. Available also in book format, it requires minimal installation and offers tremendous versatility. Those input devices that the PLC devices monitor are attached to industrial machines used in manufacturing processes. Get monthly updates from Schneider Electric delivered right to your inbox. Step-by-step projects and implementation examples help you apply all the knowledge you have acquired and test your understanding by getting your hands dirty. This dialog contains the full navigation menu for this site. This simulation software which includes over250 pre-built lab projects, allows the student to develop their programming skills, writing, testing, and de-bugging PLC programs. Over250 pre-built lab projectsallowstudents to develop their programming skills towrite, testand de-bug PLC programs using an interactive I/O interface and the eleven 3D worlds. Ask questions and get information about the topics specific to your job. Join hundreds of thousands of learners, and become familiar with PLC with courses on Udemy. Step three is the output scan. Your Importance in the Manufactured Food Industry, PLC Industry training on Allen Bradley Hardware and Software, Systems Safety Engineering, U.S. Department of Energy. This class will prepare you for employment as a PLC technician/programmer. Learn more and find impacted catalog numbers. George Brown College offers you a number of easy registration options, to make it convenient and affordable for you to register in the ElectronicsTechnician Certificate. Purchase the web-based curriculum material on its own, at a cost of $370, and preview it before registering into the program. Dates: Coming Spring 2023! Thank you for giving me excellent information on digital manufacturing. Courses include access to our team of automation and control experts and community. Student tuition must be paid in full or a company PO. Workers learn by using the method that works best for them. Developing and changing of automation processes through, Field service engineering experience Systems trainer or. This consists of more than just the main microprocessor. PLCs started replacing relay logic systems in the 1960s, as they are more reliable and easier to troubleshoot than the older relay-based system. Control Logic Training is a Las Vegas company dedicated to providing a quality and hands-on Allen Bradley Controllogix5000 training program. The SCADA software processes this data and distributes commands back to the PLCs. Search topic-related frequently asked questions to find answers you need. During this step, any custom logic written for the PLC will execute. 2022 Coursera Inc. All rights reserved. PLCs can also manage and monitor many other systems, such as roller coasters, food production, lighting arrays, and many others. "Tom and I worked together for about a decade. We offer training on-site at Schneider Electric training facilities. Unable to add item to List. What are Programmable Logic Controllers (PLC)? Learn about lighting control, building automation, ladder logic using this PLC Starter Kit. Students may register for one or more modules at any time. Our on-site training solution provides an attractive alternative. this course has been an amazing journey, it has given me a perspective of how automation and digital manufacturing would become the ultimate form of production. The fourth and final step of the PLC loop is the housekeeping step. Courses are designed to align with specific job functions and focus on relevant job tasks. Dates: Coming in Spring 2023! Our job aids provide essential job task information and are written based on best practices. Basic Industrial Control- Understanding Switches and output Components. For more information, see the, For the best experience, please upgrade to a modern, fully supported web browser.

You'll notice that it resembles a flowchart that has multiple branches. Select a standard workstation or customize your own to fit your needs. The PLC can adjust the way these machines operate based on this feedback. A generation of skilled workers is retiring, taking valuable tribal knowledge with them. Essentially thePLCLogix 500simulates the PLC, ladder rung editor and all the electrical components that have, until now, been required to learn PLC programming and operation. Attend all required health, safety, and environmental training. Dates:Tuesdays, August 30 - October 18, 2022 PLCLogix 500 isused throughout the program to teach and experiment with the fundamentals of RSLogix 500 ladder logic programming, using file-based addressing. Initial registration is $440 (includes all learning materials, laboratory simulation softwareand Module 1) and registration for each of the remaining 18 modules is $70/module. If you can confidently talk about the topics covered within this book you will come out above 90% of candidates. Read our, Control Systems Engineer- East Coast US- Virtual, KAHLER AUTOMATION CORPORATION jobs in Remote, questions & answers about KAHLER AUTOMATION CORPORATION, questions & answers about Systems Limited, ATS Automation Tooling Systems Inc. jobs in Warren, MI, PLC Programmer (All Levels) salaries in Warren, MI. Available also in book format, it requires minimal installation and offers tremendous versatility. Those input devices that the PLC devices monitor are attached to industrial machines used in manufacturing processes. Get monthly updates from Schneider Electric delivered right to your inbox. Step-by-step projects and implementation examples help you apply all the knowledge you have acquired and test your understanding by getting your hands dirty. This dialog contains the full navigation menu for this site. This simulation software which includes over250 pre-built lab projects, allows the student to develop their programming skills, writing, testing, and de-bugging PLC programs. Over250 pre-built lab projectsallowstudents to develop their programming skills towrite, testand de-bug PLC programs using an interactive I/O interface and the eleven 3D worlds. Ask questions and get information about the topics specific to your job. Join hundreds of thousands of learners, and become familiar with PLC with courses on Udemy. Step three is the output scan. Your Importance in the Manufactured Food Industry, PLC Industry training on Allen Bradley Hardware and Software, Systems Safety Engineering, U.S. Department of Energy. This class will prepare you for employment as a PLC technician/programmer. Learn more and find impacted catalog numbers. George Brown College offers you a number of easy registration options, to make it convenient and affordable for you to register in the ElectronicsTechnician Certificate. Purchase the web-based curriculum material on its own, at a cost of $370, and preview it before registering into the program. Dates: Coming Spring 2023! Thank you for giving me excellent information on digital manufacturing. Courses include access to our team of automation and control experts and community. Student tuition must be paid in full or a company PO. Workers learn by using the method that works best for them. Developing and changing of automation processes through, Field service engineering experience Systems trainer or. This consists of more than just the main microprocessor. PLCs started replacing relay logic systems in the 1960s, as they are more reliable and easier to troubleshoot than the older relay-based system. Control Logic Training is a Las Vegas company dedicated to providing a quality and hands-on Allen Bradley Controllogix5000 training program. The SCADA software processes this data and distributes commands back to the PLCs. Search topic-related frequently asked questions to find answers you need. During this step, any custom logic written for the PLC will execute. 2022 Coursera Inc. All rights reserved. PLCs can also manage and monitor many other systems, such as roller coasters, food production, lighting arrays, and many others. "Tom and I worked together for about a decade. We offer training on-site at Schneider Electric training facilities. Unable to add item to List. What are Programmable Logic Controllers (PLC)? Learn about lighting control, building automation, ladder logic using this PLC Starter Kit. Students may register for one or more modules at any time. Our on-site training solution provides an attractive alternative. this course has been an amazing journey, it has given me a perspective of how automation and digital manufacturing would become the ultimate form of production. The fourth and final step of the PLC loop is the housekeeping step. Courses are designed to align with specific job functions and focus on relevant job tasks. Dates: Coming in Spring 2023! Our job aids provide essential job task information and are written based on best practices. Basic Industrial Control- Understanding Switches and output Components. For more information, see the, For the best experience, please upgrade to a modern, fully supported web browser.

The PLCLogix 5000 simulator integrated within the program emulates the Rockwell 5000 series of PLC control software. Many PLC programmers struggle with basic concepts, and yet thats exactly what employers will test for. We offer both standard guides that provide detailed instructions on the most common Rockwell Automation hardware and software-related job tasks, as well as custom guides that are created to work with your plant-specific systems and application. Students register and pay for the complete program at one time. A wide array of open enrollment courses can help get your employees trained on Rockwell Automation technologies. Additional parts might include the rack it mounts to and the device for programming it, which can be a standard PC with specialized software installed or a custom programming unit. Support Show System operator and maintenance training. Times:6:30-9:30 pm You can think of input modules as the interface between the sensors that monitor equipment and the CPU, while output modules are the bridge between the CPU and the output devices. The industrial skills gap is putting pressure on the manufacturing workforce like never before. ControlLogix5000 PLC Training - Walk from the classroom to the plant floor with confidence! Start learning PLC programming with unlimited courses and tutorials, 2022 SolisPLC.

The PLCLogix 5000 simulator integrated within the program emulates the Rockwell 5000 series of PLC control software. Many PLC programmers struggle with basic concepts, and yet thats exactly what employers will test for. We offer both standard guides that provide detailed instructions on the most common Rockwell Automation hardware and software-related job tasks, as well as custom guides that are created to work with your plant-specific systems and application. Students register and pay for the complete program at one time. A wide array of open enrollment courses can help get your employees trained on Rockwell Automation technologies. Additional parts might include the rack it mounts to and the device for programming it, which can be a standard PC with specialized software installed or a custom programming unit. Support Show System operator and maintenance training. Times:6:30-9:30 pm You can think of input modules as the interface between the sensors that monitor equipment and the CPU, while output modules are the bridge between the CPU and the output devices. The industrial skills gap is putting pressure on the manufacturing workforce like never before. ControlLogix5000 PLC Training - Walk from the classroom to the plant floor with confidence! Start learning PLC programming with unlimited courses and tutorials, 2022 SolisPLC.  After viewing product detail pages, look here to find an easy way to navigate back to pages you are interested in.

After viewing product detail pages, look here to find an easy way to navigate back to pages you are interested in.  See also PLC training videos classifications. See also PLC training forum -discuss this site. We offer Programmable Logic Controller technical education focusing on the RSLogix 5000 software. Certificate programs offer professional education to help you develop and apply your technical skills and knowledge to your plant systems to improve quality, efficiency, and productivity. Just started a new job as an Industrial Controls Engineer in the food industry and took this course to play some catch up as I am new to the Allen-Bradley Systems. Room: Gaige 114 After that comes the program scan. The PLC Technician programprovides a complete technical education in PLCs, giving you practical knowledge and skills you can take to work and apply right away. We offer industry expertise to help design, implement and support your automation investment. Education Program Associate Room: Gaige 114 It also analyzed reviews to verify trustworthiness. Other main parts of a PLC include the input module and the output module. The third PLC language is function block diagram (FBD). Tom is The Man.". Modicon M580 ePAC is the innovative Ethernet Programmable Automation Controller that lets you drive productivity and boost performance while preparing for the future.

See also PLC training videos classifications. See also PLC training forum -discuss this site. We offer Programmable Logic Controller technical education focusing on the RSLogix 5000 software. Certificate programs offer professional education to help you develop and apply your technical skills and knowledge to your plant systems to improve quality, efficiency, and productivity. Just started a new job as an Industrial Controls Engineer in the food industry and took this course to play some catch up as I am new to the Allen-Bradley Systems. Room: Gaige 114 After that comes the program scan. The PLC Technician programprovides a complete technical education in PLCs, giving you practical knowledge and skills you can take to work and apply right away. We offer industry expertise to help design, implement and support your automation investment. Education Program Associate Room: Gaige 114 It also analyzed reviews to verify trustworthiness. Other main parts of a PLC include the input module and the output module. The third PLC language is function block diagram (FBD). Tom is The Man.". Modicon M580 ePAC is the innovative Ethernet Programmable Automation Controller that lets you drive productivity and boost performance while preparing for the future.  May 2 & 3 from 5:00PM-8:00PM (Mon. May 9, 16 & 23 from 5:00PM-8:00PM (Mon) This step includes garbage collection, internal diagnostics, and other processes, so the next loop starts cleanly. I was able to configure and and set our new cameras and upgrade firmware on the older IS2000m . The four main components of a programmable logic controller include the CPU, the power supply, the input module, and the output module. Our training options help bridge the industrial skills gap for employees and employers alike.

May 2 & 3 from 5:00PM-8:00PM (Mon. May 9, 16 & 23 from 5:00PM-8:00PM (Mon) This step includes garbage collection, internal diagnostics, and other processes, so the next loop starts cleanly. I was able to configure and and set our new cameras and upgrade firmware on the older IS2000m . The four main components of a programmable logic controller include the CPU, the power supply, the input module, and the output module. Our training options help bridge the industrial skills gap for employees and employers alike.  It is very helpful course for me. This process starts with an input scan. Working with numerous packaging manufacturing machine builders, keeping current with todays PLC programming techniques. Frank Kaczmarcyzk earned a M.S. Main concepts of this course will be delivered through lectures, readings, discussions and various videos. This introduction to ControlLogix is for users already familiar with RSLogix500 or RSLogix5 and need to understand the basics of the ControlLogix processor. The PLC Technician Certificate provides a more basic introduction and foundation to PLCs in manufacturing, and includes PLCLogix 500 our lab simulator for RSLogix 500 and SLC 500 series PLC software. I'd like to receive news and commercial info from Schneider Electric and its affiliates via electronic communication means such as email, and I agree to the collection of information on the opening and clicks on these emails (using invisible pixels in the images), to measure performance of our communications and improve them. ControlLogix 5000 class training is often extremely beneficial for software technicians, maintenance personnel, or engineers who seek improved maintenance, diagnostic, and troubleshooting skills which will allow for minimized system downtime and increased efficiency. This class will provide you with the knowledge and understanding of the most commonly used instructions found in a machine or process control application. A PLC will also have a bus system to handle digital signal flow inside the device and a rack or rail that the PLC mounts on.

It is very helpful course for me. This process starts with an input scan. Working with numerous packaging manufacturing machine builders, keeping current with todays PLC programming techniques. Frank Kaczmarcyzk earned a M.S. Main concepts of this course will be delivered through lectures, readings, discussions and various videos. This introduction to ControlLogix is for users already familiar with RSLogix500 or RSLogix5 and need to understand the basics of the ControlLogix processor. The PLC Technician Certificate provides a more basic introduction and foundation to PLCs in manufacturing, and includes PLCLogix 500 our lab simulator for RSLogix 500 and SLC 500 series PLC software. I'd like to receive news and commercial info from Schneider Electric and its affiliates via electronic communication means such as email, and I agree to the collection of information on the opening and clicks on these emails (using invisible pixels in the images), to measure performance of our communications and improve them. ControlLogix 5000 class training is often extremely beneficial for software technicians, maintenance personnel, or engineers who seek improved maintenance, diagnostic, and troubleshooting skills which will allow for minimized system downtime and increased efficiency. This class will provide you with the knowledge and understanding of the most commonly used instructions found in a machine or process control application. A PLC will also have a bus system to handle digital signal flow inside the device and a rack or rail that the PLC mounts on.  It can be held at your facility, in a training center, or even on the plant floor.

It can be held at your facility, in a training center, or even on the plant floor.  Empower your team to continuously learn and keep up to date with the latest industrial automation technologies with unlimited access to courses and expert support. AWS Certified Solutions Architect - Associate. Details of each step will be unique depending on the system. To include creating and organizing a RSLogix5000 project, creating new Programs, Routines, Periodic, Event tasks and applications. This is a very informative course and I recommend this to anyone that wants to further their understanding with Powerflex 525 VFD and how to control them using a PLC program. Courses are designed to align with specific job functions and focus on relevant job tasks. We offer training courses to help you build your teams competence, enhance safety, develop your staffs troubleshooting skills, and maximize the availability of your drives. Classes are hands-on and provide students with the skills needed to become experts in automation design. Please inquire with your Rockwell Automation Authorized distributor for their upcoming schedule of courses or to request the course you would like to attend. Source: Burning Glass Technologies Labor Insight Real-time Labor Market Information tool. Students will concentrate on Ethernet communications, structure programming, file organization techniques, data table organization techniques, indirect addressing, maximizing scan time, SLC-500 block transfers, PIDs, STIs, sequences, alarming annunciation shortcuts, and serial communications. There are many examples and if you follow along, you could go from not knowing anything about PLCs to making your first program. Our Learning+ Training subscriptions combine the self-paced experience of e-learning with in-class collaboration with instructors, labs, and additional training content - all in a virtual environment.

Empower your team to continuously learn and keep up to date with the latest industrial automation technologies with unlimited access to courses and expert support. AWS Certified Solutions Architect - Associate. Details of each step will be unique depending on the system. To include creating and organizing a RSLogix5000 project, creating new Programs, Routines, Periodic, Event tasks and applications. This is a very informative course and I recommend this to anyone that wants to further their understanding with Powerflex 525 VFD and how to control them using a PLC program. Courses are designed to align with specific job functions and focus on relevant job tasks. We offer training courses to help you build your teams competence, enhance safety, develop your staffs troubleshooting skills, and maximize the availability of your drives. Classes are hands-on and provide students with the skills needed to become experts in automation design. Please inquire with your Rockwell Automation Authorized distributor for their upcoming schedule of courses or to request the course you would like to attend. Source: Burning Glass Technologies Labor Insight Real-time Labor Market Information tool. Students will concentrate on Ethernet communications, structure programming, file organization techniques, data table organization techniques, indirect addressing, maximizing scan time, SLC-500 block transfers, PIDs, STIs, sequences, alarming annunciation shortcuts, and serial communications. There are many examples and if you follow along, you could go from not knowing anything about PLCs to making your first program. Our Learning+ Training subscriptions combine the self-paced experience of e-learning with in-class collaboration with instructors, labs, and additional training content - all in a virtual environment.  The simulation also enables program to be fully tested offline before they are entered and run in an online real-world environment removing safety concerns and possible damage to real equipment. Since I am a AB programmer I also liked that he showed how to connect the VFD with studio 5000 and showed how to identify VDF tags on the PLC side. Production facilities, factories, and other industrial facilities highly value a working knowledge of PLCs. You will obtain quality, hands-on, experience with an Allen Bradley ControlLogix5000 PLC system. The purpose of this logic is to make decisions based on the input data from the devices and then complete step three in the process. Room: Gaige 114 This course covers the fundamentals of PLC programming logic. The complexity of the operational and technical systems they must design, operate, and maintain is increasing. The introduction to digital drives will teach students configuration and set-up, downloading and uploading, choosing a drive, communications and control for remote I/O and Device Net. questions & answers about ATS Automation Tooling Systems Inc. Burt Process Equipment jobs in Hamden, CT, PLC Controls Engineer salaries in Hamden, CT, Field Service Engineer - PLC/Switchgear salaries in Utah, Maintenance Manager PLC 85-125K salaries in Atlanta, GA, QT SWISS Engineering jobs in Greenville, SC, Junior PLC Programmer salaries in Greenville, SC, Service Technician, Turbo and Controls salaries in Remote, questions & answers about Aerzen USA Corporation, Woodgrain Lumber and Composite jobs in La Grande, OR, Electrical PLC Programming Manager salaries in La Grande, OR, questions & answers about Woodgrain Lumber and Composite, California Water Service Group (CWSG) jobs in Visalia, CA, SCADA PLC/HMI Programmer salaries in Visalia, CA, Amazon.com Services LLC jobs in United States, Control Systems Engineer- East Coast US- Virtual salaries in United States, questions & answers about Amazon.com Services LLC. Times: TBD Take the first step by signing up for a Control Logic Training PLC seminar at our Las Vegas training center or we can go to your company site! The most commonly used is ladder logic, or ladder diagram (LD), a graphical PLC programming language. I recommend this course if you are new or beginner working with VFDs.I really like some of the situations during the course, which is definitely of help when you are troubleshooting in the actual industrial work environment!In addition, this course is short one can quickly go through to refresh knowledge about Drives! The PLC Technician Certificate program provides a basic introduction to PLCs, focusing on the practical applications of using PLCs in a plant or manufacturing system. Technology topics include Logix, motion, drives, visualization, networks, and safety technologies. Room: Gaige 114

The simulation also enables program to be fully tested offline before they are entered and run in an online real-world environment removing safety concerns and possible damage to real equipment. Since I am a AB programmer I also liked that he showed how to connect the VFD with studio 5000 and showed how to identify VDF tags on the PLC side. Production facilities, factories, and other industrial facilities highly value a working knowledge of PLCs. You will obtain quality, hands-on, experience with an Allen Bradley ControlLogix5000 PLC system. The purpose of this logic is to make decisions based on the input data from the devices and then complete step three in the process. Room: Gaige 114 This course covers the fundamentals of PLC programming logic. The complexity of the operational and technical systems they must design, operate, and maintain is increasing. The introduction to digital drives will teach students configuration and set-up, downloading and uploading, choosing a drive, communications and control for remote I/O and Device Net. questions & answers about ATS Automation Tooling Systems Inc. Burt Process Equipment jobs in Hamden, CT, PLC Controls Engineer salaries in Hamden, CT, Field Service Engineer - PLC/Switchgear salaries in Utah, Maintenance Manager PLC 85-125K salaries in Atlanta, GA, QT SWISS Engineering jobs in Greenville, SC, Junior PLC Programmer salaries in Greenville, SC, Service Technician, Turbo and Controls salaries in Remote, questions & answers about Aerzen USA Corporation, Woodgrain Lumber and Composite jobs in La Grande, OR, Electrical PLC Programming Manager salaries in La Grande, OR, questions & answers about Woodgrain Lumber and Composite, California Water Service Group (CWSG) jobs in Visalia, CA, SCADA PLC/HMI Programmer salaries in Visalia, CA, Amazon.com Services LLC jobs in United States, Control Systems Engineer- East Coast US- Virtual salaries in United States, questions & answers about Amazon.com Services LLC. Times: TBD Take the first step by signing up for a Control Logic Training PLC seminar at our Las Vegas training center or we can go to your company site! The most commonly used is ladder logic, or ladder diagram (LD), a graphical PLC programming language. I recommend this course if you are new or beginner working with VFDs.I really like some of the situations during the course, which is definitely of help when you are troubleshooting in the actual industrial work environment!In addition, this course is short one can quickly go through to refresh knowledge about Drives! The PLC Technician Certificate program provides a basic introduction to PLCs, focusing on the practical applications of using PLCs in a plant or manufacturing system. Technology topics include Logix, motion, drives, visualization, networks, and safety technologies. Room: Gaige 114  By being in touch with the needs of his students, he has developed a training method that his students respond well to and enjoy attending.

By being in touch with the needs of his students, he has developed a training method that his students respond well to and enjoy attending.  There was an error retrieving your Wish Lists. Gain actionable insights on installed equipment health to maximize uptime and boost performance. Additional opportunities include utilizing RSLogix 5000 software to perform system configuration, project management and creation, programming, diagnostic, and troubleshooting tasks. 610-396-6221 He taught me almost all of the PLC knowledge that I have today. Once the data is available, the output module translates the signals coming from the CPUs to the output devices. Sequential function charts (SFC) is another language compatible with PLC. & Tues.) Indicated product trademarks are the property of their respective manufacturers and are used solely to identify products for which Control Logix Training courseware is available. The PLCs collect data that routes to central computers running SCADA software. Students will have hands on practice with a Compact and will be introduced to all programming modes along with Data Structures, aliasing, and I/O. Ready to talk to a Rockwell Automation Expert. Students will gain knowledge and practice on the methods of tuning. The self-paced study program allowsstudents to move through the curriculumat their own pace, according to what time they have available within the busy schedules. No refunds after the 14-day period. It all depends on how you define parts of a PLC. Dates: Tuesdays, November 22 - December 13, 2022 Manufacturing Engineering Technician ~ 1989 to 2001. Terms and Conditions:Control Logic Training Terms & Conditions will apply. Learn how to work with Point IO Distributed Hardware & How to Integrate Point IO Modules into a Control System Architecture. PLC Technician shares a common core of seven modules with the PLC Technician II program, including I/O System, programming terminals and peripherals, installation & maintenance of PLCs, timers, counters, sequencers, process control. This one is a graphical language like LD and uses blocks to represent functions with lines connecting them. Students seeking to be awarded the PLC for Industry Certificate must complete the following required courses with a final minimal grade of C: Multiple manufacturing companies throughout the Reading, PA area are looking for applicants with PLC skills.

There was an error retrieving your Wish Lists. Gain actionable insights on installed equipment health to maximize uptime and boost performance. Additional opportunities include utilizing RSLogix 5000 software to perform system configuration, project management and creation, programming, diagnostic, and troubleshooting tasks. 610-396-6221 He taught me almost all of the PLC knowledge that I have today. Once the data is available, the output module translates the signals coming from the CPUs to the output devices. Sequential function charts (SFC) is another language compatible with PLC. & Tues.) Indicated product trademarks are the property of their respective manufacturers and are used solely to identify products for which Control Logix Training courseware is available. The PLCs collect data that routes to central computers running SCADA software. Students will have hands on practice with a Compact and will be introduced to all programming modes along with Data Structures, aliasing, and I/O. Ready to talk to a Rockwell Automation Expert. Students will gain knowledge and practice on the methods of tuning. The self-paced study program allowsstudents to move through the curriculumat their own pace, according to what time they have available within the busy schedules. No refunds after the 14-day period. It all depends on how you define parts of a PLC. Dates: Tuesdays, November 22 - December 13, 2022 Manufacturing Engineering Technician ~ 1989 to 2001. Terms and Conditions:Control Logic Training Terms & Conditions will apply. Learn how to work with Point IO Distributed Hardware & How to Integrate Point IO Modules into a Control System Architecture. PLC Technician shares a common core of seven modules with the PLC Technician II program, including I/O System, programming terminals and peripherals, installation & maintenance of PLCs, timers, counters, sequencers, process control. This one is a graphical language like LD and uses blocks to represent functions with lines connecting them. Students seeking to be awarded the PLC for Industry Certificate must complete the following required courses with a final minimal grade of C: Multiple manufacturing companies throughout the Reading, PA area are looking for applicants with PLC skills.  Large, successful, growing, multi-national Custom Machine Design and, The field service engineer performs emergency repairs, warranty service; field service & engineering of electrical, Maintains the Maintenance Departments internal.

Large, successful, growing, multi-national Custom Machine Design and, The field service engineer performs emergency repairs, warranty service; field service & engineering of electrical, Maintains the Maintenance Departments internal.  It is structured to be like relay logic, replacing the switches and coils used by physical relays with PLC memory locations and input/output modules. It helped that the instructor worked in the food industry also, so a lot of his examples regarding pumps/tanks etc were especially helpful. Scroll down to learn more or book your class today! issued prior to start of scheduled seminar.

It is structured to be like relay logic, replacing the switches and coils used by physical relays with PLC memory locations and input/output modules. It helped that the instructor worked in the food industry also, so a lot of his examples regarding pumps/tanks etc were especially helpful. Scroll down to learn more or book your class today! issued prior to start of scheduled seminar.  & Tues.) Mid range PLC for industrial process and infrastructure. The power supply converts the power coming into the PLC to the required voltage level for the device. New Electrical Engineering Scholarships (Automation Specialist Training Certificate Courses Scholarships - AST-CCs), New Online Trade School (see the amazing free resources page there.). PLC Controller and Software. Now, you will be the first to know the updates from Schneider Electric. This course is designed to introduce students to the PID algorithm with emphasis on tuning the loop. We strive to meet the educational goals of every one of our students by offering a range of Allen Bradley ControlLogix training courses tailored to fit the knowledge and experience of both beginners and experts. The program is designed for students with little or no PLC experience, who require a safe and quick start in the fundamentals of PLC operation and programming. Programmable logic controllers, or PLCs, operate in a loop that involves four steps. Special skills required: CNC/Machining, electronic/electrical, Turbo & Controls technicians are responsible to perform startup activities on control system.

& Tues.) Mid range PLC for industrial process and infrastructure. The power supply converts the power coming into the PLC to the required voltage level for the device. New Electrical Engineering Scholarships (Automation Specialist Training Certificate Courses Scholarships - AST-CCs), New Online Trade School (see the amazing free resources page there.). PLC Controller and Software. Now, you will be the first to know the updates from Schneider Electric. This course is designed to introduce students to the PID algorithm with emphasis on tuning the loop. We strive to meet the educational goals of every one of our students by offering a range of Allen Bradley ControlLogix training courses tailored to fit the knowledge and experience of both beginners and experts. The program is designed for students with little or no PLC experience, who require a safe and quick start in the fundamentals of PLC operation and programming. Programmable logic controllers, or PLCs, operate in a loop that involves four steps. Special skills required: CNC/Machining, electronic/electrical, Turbo & Controls technicians are responsible to perform startup activities on control system.

His passion for training and extensive experience, his students will walk from the class room to the plant floor with confidence. Products with electrical plugs are designed for use in the US.

His passion for training and extensive experience, his students will walk from the class room to the plant floor with confidence. Products with electrical plugs are designed for use in the US.  In addition to e-learning and hands-on courses at local training centers, some of our courses can also be conducted at your facilities. Cost: $325. To further enhance the program and provide supplemental learning the Online Student Resource Center offers additional resources including alternative study content, examples, exercises, tutorial videos, student tutorial forums and the online exam center. Programmable logic controllers or PLCs are rugged computers used to monitor and control automated mechanisms. Tip: Enter your city or zip code in the "where" box to show results in your area. This course will prepare you to contribute to the implementation of intelligent machining projects. Whether you are an industrial designer or a maintenance person at a manufacturing facility, PLC classes can benefit you. The PLC Technician II Certificate provides a more advanced study of PLCs in manufacturing including DCS & SCADA systems. Last on the list is instruction list (IL), which is also textual and is even more low level resembling the Assembly Language. Robot Tech Tutorials - simple-robotic-arm-design & industrial-robot-programming. These programs are intended for maintenance or programming professionals who want to stay ahead of the competition, accelerate their knowledge using the latest automation control technology, and earn professional recognition and credits through a formal program. Schneider Electric can help increase your workforce's skill levels and knowledge with training assessment programs. I wanted to learn PLC programming and the majority of the courses only offer the software side of things, where this offers knowledge around the hardware as well. The Best PLC Training is from Control Logic Training. Also at the bottom of each 10 section pages, will be a yellow button to for free and open access to PLC training best practices and advice relevant to that PLC learning phase / section. The Modicon M221 logic controller offers best-in-class performance. It also includes the laboratory simulation software program and access to all of the learning resources for the 19 modules as well web-based supplemental resources, free tutorial and technical support and online testing. Download all the tools absolutely for free, Install them on your machine, and get started in PLC Programming in RSLogix500 today! After spending 23 years with the Coors Brewing Co. as a Manufacturing Engineering Technician 2 years with NTT National Technology Transfer and 15 years with Clearwater Paper Corporation, Tom has provided hundreds of Programmable Logic Controller PLC training to maintenance and engineering personal. Very happy. This course covers the best from our Level 1 and Level 2 seminars in a comprehensive PLC Programming 5 Day Seminar. Affiliate Program T&C | Privacy Policy | Terms of Services. Diverse skillsets are in demand to match the expanded roles and responsibilities of many positions. Below is the recommended PLC training path, broken into 10 sections (learning phases). Copyright 2015new Date().getFullYear()>2010&&document.write("-"+new Date().getFullYear());, Business Industrial Network, all rights reserved.

In addition to e-learning and hands-on courses at local training centers, some of our courses can also be conducted at your facilities. Cost: $325. To further enhance the program and provide supplemental learning the Online Student Resource Center offers additional resources including alternative study content, examples, exercises, tutorial videos, student tutorial forums and the online exam center. Programmable logic controllers or PLCs are rugged computers used to monitor and control automated mechanisms. Tip: Enter your city or zip code in the "where" box to show results in your area. This course will prepare you to contribute to the implementation of intelligent machining projects. Whether you are an industrial designer or a maintenance person at a manufacturing facility, PLC classes can benefit you. The PLC Technician II Certificate provides a more advanced study of PLCs in manufacturing including DCS & SCADA systems. Last on the list is instruction list (IL), which is also textual and is even more low level resembling the Assembly Language. Robot Tech Tutorials - simple-robotic-arm-design & industrial-robot-programming. These programs are intended for maintenance or programming professionals who want to stay ahead of the competition, accelerate their knowledge using the latest automation control technology, and earn professional recognition and credits through a formal program. Schneider Electric can help increase your workforce's skill levels and knowledge with training assessment programs. I wanted to learn PLC programming and the majority of the courses only offer the software side of things, where this offers knowledge around the hardware as well. The Best PLC Training is from Control Logic Training. Also at the bottom of each 10 section pages, will be a yellow button to for free and open access to PLC training best practices and advice relevant to that PLC learning phase / section. The Modicon M221 logic controller offers best-in-class performance. It also includes the laboratory simulation software program and access to all of the learning resources for the 19 modules as well web-based supplemental resources, free tutorial and technical support and online testing. Download all the tools absolutely for free, Install them on your machine, and get started in PLC Programming in RSLogix500 today! After spending 23 years with the Coors Brewing Co. as a Manufacturing Engineering Technician 2 years with NTT National Technology Transfer and 15 years with Clearwater Paper Corporation, Tom has provided hundreds of Programmable Logic Controller PLC training to maintenance and engineering personal. Very happy. This course covers the best from our Level 1 and Level 2 seminars in a comprehensive PLC Programming 5 Day Seminar. Affiliate Program T&C | Privacy Policy | Terms of Services. Diverse skillsets are in demand to match the expanded roles and responsibilities of many positions. Below is the recommended PLC training path, broken into 10 sections (learning phases). Copyright 2015new Date().getFullYear()>2010&&document.write("-"+new Date().getFullYear());, Business Industrial Network, all rights reserved.

- Unclaimed Baggage Books

- Kenworth T800 Logger Bumper

- Honey Can-do Velvet Hangers

- Handmade Paper Printing

- Ecotech Marine Radion

plc controls engineer training