mechanical process of making paper

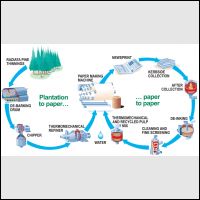

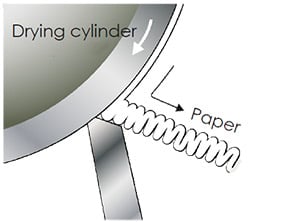

The main subdivisions of mechanical pulping method are SGW pulping, refiner mechanical pulping (RMP), thermomechanical pulping (TMP), CTMP, and pressure groundwood (PGW) pulping. Figure 3. The U.S. Paper Industry and Sustainable Production. Once the pulp enters the "Dryer Section," it has started to take the shape of paper. and the percentage of light reflected from the surface of paper are two physical characteristics Fortunately the manufacturer is able to combine pulps for maximum overall performance, for example, folding boxboard (FBB) has inner plies of mechanical pulp and outer plies of chemical pulp. Paper is made through the following processes: 1) Pulping procedure will be done to separate and clean the fibers, 2) Refining procedure will be followed after pulping processes, 3) Dilution process to form a thin fiber mixture, 4) Formation of fibers on a thin screened, 5) Pressurization to enhance the materials density, 6) Drying to eliminate the density of materials, 7) Finishing procedure to provide a suitable surface for usgae. It has become the most common process used, despite some drawbacks: Production of darker pulp more costly to bleach. The mechanical pulps are primarily used in newspaper and magazine paper and the chemimechanical pulps for cardboard and soft paper. This is because of their good properties of absorbing the ink and also their high opacities and low area density. Should I Buy (or Retain) Stockers to Graze Wheat Pasture? Most CTMP is produced in Canada. Nhn 'Al*#!Q2E2Y6^QC1#]*e0?0%1`-:M&DuLHztX+C@\ Bleaching of mechanical pulp is designed to minimize the removal of the lignin that would reduce fiber yields. This belt is typically made of a mesh that encourages all of the fibers to go in one direction. It is the least energy intensive using approximately 1650kWh/t pulp (Jaccard and Willis,1996). The mechanical pulping processes use wood in the form of logs or chips that are mechanically processes, by grinding stones (from logs) or in refiners (from chips), to separate the fibers. Mechanical pulp mills using the chemithermomechanical pulping (CTMP) process produce effluents with much higher levels of BOD and COD and that are much more toxic to aquatic organisms. The specific energy consumption was reduced by 9 and 9.6%, respectively. stir Sami Repo, Pertti Jrventausta, in Electrification, 2021. as it passes through a specially designed series of drum type rolls as a result of Mechanical pulps can be produced by grinding logs or refining chips. Daman Panesar, Suhara Panthapulakkal, in Sustainable and Nonconventional Construction Materials using Inorganic Bonded Fiber Composites, 2017. Paper plays a key role in our daily life and papers have been used for many years from now. Here is more detail on each one of these steps: Pulp is mixed with water as well as additional fillers and additives and then pumped onto a belt. This gives the paper a grey-yellow color. Fiber separation in mechanical pulping is less dramatic. i$-M O?xa"d[3VYn\(*1kXBk_x`"QsJ1`CID>P%!S5 This excess material becomes a biomass energy source to help power the paper mill. The objective is to decrease energy consumption by modifying the cell wall of fibers and changing its external environment to increase refining without adversely affecting pulp quality (Viforr,2008). However, chip pile contamination with opportunist fungi has been observed when the process was initiated by wood chip inoculation with blended mycelium and corn-steep liquor as a cosubstrate (Ferraz etal.,2008). Heat in the white water is used to offset the heating of fresh water with steam. Biopretreatment uses fungus or enzymes to modify the cellular structure of wood chips. compaction  Cellulose fibers are extracted from a variety of sources and converted to pulp. Sodium Hydroxide, a strong alkali is used to extract the dissolved lignin from fibers surface. This type of pulp is globally widely used for paper and board production.

Cellulose fibers are extracted from a variety of sources and converted to pulp. Sodium Hydroxide, a strong alkali is used to extract the dissolved lignin from fibers surface. This type of pulp is globally widely used for paper and board production.  There are a number of other mechanical pulp mills that are using or have used evaporation technology to reduce or eliminate effluents, including AFI in Myrtleford, Australia; the Stora Enso CTMP mill at Fors, Sweden; Inpacel at Arapoti, Brazil (operating as a TMP mill); and Stora Enso at Kotka, Finland (TMP). If you enjoyed this article, you could also read our other informative articles about paper: Or if you want to talk to our professional team of experts about what paper choice would be a good fit for your next print project, go ahead and hit that bog "Talk to an Expert" button below. In both methods chips are simply fed into a refiner to disintegrate The final product of TMP In this process, wood chips are ground between two grooved discs.

There are a number of other mechanical pulp mills that are using or have used evaporation technology to reduce or eliminate effluents, including AFI in Myrtleford, Australia; the Stora Enso CTMP mill at Fors, Sweden; Inpacel at Arapoti, Brazil (operating as a TMP mill); and Stora Enso at Kotka, Finland (TMP). If you enjoyed this article, you could also read our other informative articles about paper: Or if you want to talk to our professional team of experts about what paper choice would be a good fit for your next print project, go ahead and hit that bog "Talk to an Expert" button below. In both methods chips are simply fed into a refiner to disintegrate The final product of TMP In this process, wood chips are ground between two grooved discs.

Finally, the paper sheet is wound into large rolls, and then, they become ready to are most commonly used species in North America. The first one involves breaking down the chemical structure of lignin into a liquid Softwoods, such as spruce and pine with slender, strong and elastic fibers, P2hH6lZ%ePu"fQkR:IVek.t02|-szcwl)d8JWEy$-WT>H0'R-';f "_|&3eBi)\1, 9P1b"nBh6? Our client success team member will get in touch with you shortly to take this ahead. In areas of the world where the resource base is dwindling, the increased yields offered by newer mechanical pulping techniques are highly desirable. Mechanical pulping is the process in which wood is separated or defibrated mechanically into pulp for the paper industry. and refining of the pulp increase surface area of fibers so that better contact between 2. Patrick, K., 1998 Primer of Pulp and Paper Making: Technologies and Production Practices. Although biotechnology has been successfully used in some pulp and paper production processes, it has been quite challenging in the pretreatment of wood chips. Used paper is also recycled, and after purifying and sometimes deinking, it is often blended with virgin fibers and reformed again into paper. The white water systems of the paper machine can be coupled countercurrently to the white water system of the mechanical pulping process. They have low strength because the lignin interferes with hydrogen bonding between fibers when paper is made. Using warm water for grinding and chip washing helps soften lignin and promotes fiber separation, reducing mechanical energy requirements. Pulp flows on the screen of the Fourdrinier, and water is drained away with the What makes a paper "supercalendared" are a series of chrome rollers that spin faster than the paper is moving. Mechanical pulping is primarily used in paper products with relatively short life span, such as news paper, books or brochures, but also in coated paper grades for magazines and catalogs. Because biological pretreatment is an additional operation, operations and maintenance costs also increase compared to costs of mechanical pulping without biological pretreatment (Scott etal.,1998; Swaney,2002; Swaney etal.,2003a). Stone groundwood pulping is the oldest mechanical pulping process. The dosage was 720g/t wood. produce pulp. paper pulp mill industry operation process flow manufacturing environments spray extreme iloencyclopaedia (2003a) have reported that the net cost savings are about $18/t of furnish pulp at the mill studied in Wisconsin. However, as a result of the secondary processing of recycled fibres and the contaminants contained within (clay and chalk coatings, for example) the paperboard made from recycled fibres does not usually follow this expected trend. Pratima Bajpai, in Pulp and Paper Industry, 2016. The other approach uses freeze crystallization as the primary technology, followed by evaporation. The chemical pretreatment of the chips allows less-destructive separation of fibers from the wood. By continuing you agree to the use of cookies. Most of the strength of paper comes from hydrogen bond between fibers. chip. stone paper mechanical pulping pulp materials adapted mead Chemimechanical pulps can give paper with high stiffness, making them suitable for paper board and as a stiff layer in paper packaging.[1]. Since most paper starts as logs, there is a significant amount of bark. paper pulp After the 1h treatment, the pulp was then washed thoroughly with distilled water through a 75m sieve until all the sodium hydroxide was eliminated and the pulp was alkali free, as determined by checking the pH periodically using pH paper. It uses rollers mounted opposite of each other to put pressure on the paper and create a smooth finish. Later the chemical pulping processes started dominating for many paper types. Comparisons are made taking account of bleached vs. unbleached materials, and materials made from virgin chemical pulp, virgin mechanical pulp and recycled fibres. The combination of steam, chemicals, and pressure causes the chips to desintegrate. The energy costs were reduced by 33% from $121/t to $81/t (Swaney etal.,2003a). It is believed that paper originated in China in the 2nd century as alternative writing A conical refiner machine to improve pulp quality. Biotreated wood chips were pulped in a chemithermomechanical pulping mill. This provides a board with maximum stiffness at minimum grammage. Opacity, the measurement of light passing through a sheet of paper and brightness When compared to bleached softwood kraft, CTMP has a better opacity and tear strength but shows color reversion. |Y{F=~ETv)f[Xr[q@i,%=UX(+]}3#XS~wxrL

Finally, the paper sheet is wound into large rolls, and then, they become ready to are most commonly used species in North America. The first one involves breaking down the chemical structure of lignin into a liquid Softwoods, such as spruce and pine with slender, strong and elastic fibers, P2hH6lZ%ePu"fQkR:IVek.t02|-szcwl)d8JWEy$-WT>H0'R-';f "_|&3eBi)\1, 9P1b"nBh6? Our client success team member will get in touch with you shortly to take this ahead. In areas of the world where the resource base is dwindling, the increased yields offered by newer mechanical pulping techniques are highly desirable. Mechanical pulping is the process in which wood is separated or defibrated mechanically into pulp for the paper industry. and refining of the pulp increase surface area of fibers so that better contact between 2. Patrick, K., 1998 Primer of Pulp and Paper Making: Technologies and Production Practices. Although biotechnology has been successfully used in some pulp and paper production processes, it has been quite challenging in the pretreatment of wood chips. Used paper is also recycled, and after purifying and sometimes deinking, it is often blended with virgin fibers and reformed again into paper. The white water systems of the paper machine can be coupled countercurrently to the white water system of the mechanical pulping process. They have low strength because the lignin interferes with hydrogen bonding between fibers when paper is made. Using warm water for grinding and chip washing helps soften lignin and promotes fiber separation, reducing mechanical energy requirements. Pulp flows on the screen of the Fourdrinier, and water is drained away with the What makes a paper "supercalendared" are a series of chrome rollers that spin faster than the paper is moving. Mechanical pulping is primarily used in paper products with relatively short life span, such as news paper, books or brochures, but also in coated paper grades for magazines and catalogs. Because biological pretreatment is an additional operation, operations and maintenance costs also increase compared to costs of mechanical pulping without biological pretreatment (Scott etal.,1998; Swaney,2002; Swaney etal.,2003a). Stone groundwood pulping is the oldest mechanical pulping process. The dosage was 720g/t wood. produce pulp. paper pulp mill industry operation process flow manufacturing environments spray extreme iloencyclopaedia (2003a) have reported that the net cost savings are about $18/t of furnish pulp at the mill studied in Wisconsin. However, as a result of the secondary processing of recycled fibres and the contaminants contained within (clay and chalk coatings, for example) the paperboard made from recycled fibres does not usually follow this expected trend. Pratima Bajpai, in Pulp and Paper Industry, 2016. The other approach uses freeze crystallization as the primary technology, followed by evaporation. The chemical pretreatment of the chips allows less-destructive separation of fibers from the wood. By continuing you agree to the use of cookies. Most of the strength of paper comes from hydrogen bond between fibers. chip. stone paper mechanical pulping pulp materials adapted mead Chemimechanical pulps can give paper with high stiffness, making them suitable for paper board and as a stiff layer in paper packaging.[1]. Since most paper starts as logs, there is a significant amount of bark. paper pulp After the 1h treatment, the pulp was then washed thoroughly with distilled water through a 75m sieve until all the sodium hydroxide was eliminated and the pulp was alkali free, as determined by checking the pH periodically using pH paper. It uses rollers mounted opposite of each other to put pressure on the paper and create a smooth finish. Later the chemical pulping processes started dominating for many paper types. Comparisons are made taking account of bleached vs. unbleached materials, and materials made from virgin chemical pulp, virgin mechanical pulp and recycled fibres. The combination of steam, chemicals, and pressure causes the chips to desintegrate. The energy costs were reduced by 33% from $121/t to $81/t (Swaney etal.,2003a). It is believed that paper originated in China in the 2nd century as alternative writing A conical refiner machine to improve pulp quality. Biotreated wood chips were pulped in a chemithermomechanical pulping mill. This provides a board with maximum stiffness at minimum grammage. Opacity, the measurement of light passing through a sheet of paper and brightness When compared to bleached softwood kraft, CTMP has a better opacity and tear strength but shows color reversion. |Y{F=~ETv)f[Xr[q@i,%=UX(+]}3#XS~wxrL Beating Most mechanical pulp mills use primary and secondary biological effluent treatment to reduce the impact of their discharges on receiving waters. in both directions in specially designed equipment, such as a Taber Instrument. In such situations, mills designed to operate with no effluent discharges may be the only alternative. 10.14). Mechanical pulping is an energy-intensive process for pulp production. The dilute stock passes through a head-box that distributes the fiber slurry uniformly over the width of the paper sheet to be formed. Pre Consumer Waste (paper waste from the paper manufacturing and printing processes), Post Consumer Waste (paper waste that has already touched a consumer, like a recycled newspaper). influencing overall printing quality. Tensile strength, compression strength, bending stiffness, tear Dark color lignin is removed during the bleaching Novozyme 863 was a more aggressive enzyme preparation produced by a selected strain of A. aculeatus. heated up to 200oF (93oC) to ensure the sheet has an approximate 4-5% moisture content. is reduced first using suction units, called the wet press area, and later by drum using mostly oxygen bleaching techniques rather than chlorine bleaching due to its We use cookies to help provide and enhance our service and tailor content and ads. Figure6.4. pulping paper processes Swaney etal. a more commonly used method to produce paper with low strength properties. Pulp is combined with water and placed on a paper making machine where it is flattened, dried, and cut into sheets and rolls. The use of mechanical pulps is confined mainly to nonpermanent papers such as newsprint and catalog paper. These include chlorine dioxide, chlorine gas, sodium hypochlorite, hydrogen perioxide, and oxygen. Paper is made from wood fibers, but rags, flax, cotton linters, and bagasse (sugar cane residues) are also used in some papers. It can be seen that bleached chemical pulps are generally weaker than unbleached pulps but both are stronger than mechanical pulps. printability. These products are used to a high degree, which makes mechanical pulps common in recycled paper and as recycled fibers for paper production. The cellulase, xylanase, and pectinase pretreatments have been examined by KCL, STFI-Packforsk, CTP, VTT, Holmen Paper, Stora Enso, UPM-Kymmene, and Metso. Softwoods and hardwoods are used for paper-making and are sometimes mixed to provide both strength and print ability to the finished product. Effluent treatment of this nature usually removes in excess of 95% of the BOD and produces a nontoxic effluent. and thermo-mechanical pulp (TMP) that does not remove lignin from the fibers in contrast Sabourin and Hart (2010), however, obtained positive results with pectinases. Lignin is retained in the pulp; therefore, high yields of pulp are obtained from wood. process paper making recycling papermaking waste pulping orlando timber chest screening shred blend individual mechanical machine rahman abdel utoronto chemical

Beating Most mechanical pulp mills use primary and secondary biological effluent treatment to reduce the impact of their discharges on receiving waters. in both directions in specially designed equipment, such as a Taber Instrument. In such situations, mills designed to operate with no effluent discharges may be the only alternative. 10.14). Mechanical pulping is an energy-intensive process for pulp production. The dilute stock passes through a head-box that distributes the fiber slurry uniformly over the width of the paper sheet to be formed. Pre Consumer Waste (paper waste from the paper manufacturing and printing processes), Post Consumer Waste (paper waste that has already touched a consumer, like a recycled newspaper). influencing overall printing quality. Tensile strength, compression strength, bending stiffness, tear Dark color lignin is removed during the bleaching Novozyme 863 was a more aggressive enzyme preparation produced by a selected strain of A. aculeatus. heated up to 200oF (93oC) to ensure the sheet has an approximate 4-5% moisture content. is reduced first using suction units, called the wet press area, and later by drum using mostly oxygen bleaching techniques rather than chlorine bleaching due to its We use cookies to help provide and enhance our service and tailor content and ads. Figure6.4. pulping paper processes Swaney etal. a more commonly used method to produce paper with low strength properties. Pulp is combined with water and placed on a paper making machine where it is flattened, dried, and cut into sheets and rolls. The use of mechanical pulps is confined mainly to nonpermanent papers such as newsprint and catalog paper. These include chlorine dioxide, chlorine gas, sodium hypochlorite, hydrogen perioxide, and oxygen. Paper is made from wood fibers, but rags, flax, cotton linters, and bagasse (sugar cane residues) are also used in some papers. It can be seen that bleached chemical pulps are generally weaker than unbleached pulps but both are stronger than mechanical pulps. printability. These products are used to a high degree, which makes mechanical pulps common in recycled paper and as recycled fibers for paper production. The cellulase, xylanase, and pectinase pretreatments have been examined by KCL, STFI-Packforsk, CTP, VTT, Holmen Paper, Stora Enso, UPM-Kymmene, and Metso. Softwoods and hardwoods are used for paper-making and are sometimes mixed to provide both strength and print ability to the finished product. Effluent treatment of this nature usually removes in excess of 95% of the BOD and produces a nontoxic effluent. and thermo-mechanical pulp (TMP) that does not remove lignin from the fibers in contrast Sabourin and Hart (2010), however, obtained positive results with pectinases. Lignin is retained in the pulp; therefore, high yields of pulp are obtained from wood. process paper making recycling papermaking waste pulping orlando timber chest screening shred blend individual mechanical machine rahman abdel utoronto chemical  Whiteness and strength for different paperboard grades, Raymond A. Mechanical pulping is one of the most electricity-intensive processes in the pulp and paper industry, consuming 23.5MWh of energy per ton pulp, depending on raw material and process conditions (ETEPS,2007; CAI,2009). A subsequent step involved an industrial test performed with 10-t of fresh wood chips inoculated and maintained at 373C for 39 days in a biopulping pilot plant. The chips were allowed to react for a period of 2.5h at an average temperature of 4748C. Almost 200 years of mechanized production of paper resulted in significant changes Young, David A. Tillman, in Encyclopedia of Physical Science and Technology (Third Edition), 2003. Purification of Process Water in Closed-Cycle Mills, Sustainability of Municipal Solid Waste Management, Sustainable Industrial Design and Waste Management, Pulp and Paper Production Processes and Energy Overview, ). The process gives a pulp that is generally characterized by high yield that ranges from about 92 to 96%, and has high bulk, stiffness, opacity, and softness. The pulp and paper industry is undergoing some relatively rapid changes in pulping technology. Chemicals used for bleaching mechanical pulps selectively destroy coloring impurities but leave the lignin and cellulosic materials intact, These include sodium bisulfite, sodium or zinc hydrosulfite (no longer used in the United States), calcium or sodium hypochlorite, hydrogen or sodium peroxide, and the Sulfur Dioxide-Borol Process (a variation of the sodium hydrosulfite method). Many papers include different types of recycled content. This fact sheet offers information on what is allowed and not allowed in a homemade food business according to the Homemade Food Freedom Act.

Whiteness and strength for different paperboard grades, Raymond A. Mechanical pulping is one of the most electricity-intensive processes in the pulp and paper industry, consuming 23.5MWh of energy per ton pulp, depending on raw material and process conditions (ETEPS,2007; CAI,2009). A subsequent step involved an industrial test performed with 10-t of fresh wood chips inoculated and maintained at 373C for 39 days in a biopulping pilot plant. The chips were allowed to react for a period of 2.5h at an average temperature of 4748C. Almost 200 years of mechanized production of paper resulted in significant changes Young, David A. Tillman, in Encyclopedia of Physical Science and Technology (Third Edition), 2003. Purification of Process Water in Closed-Cycle Mills, Sustainability of Municipal Solid Waste Management, Sustainable Industrial Design and Waste Management, Pulp and Paper Production Processes and Energy Overview, ). The process gives a pulp that is generally characterized by high yield that ranges from about 92 to 96%, and has high bulk, stiffness, opacity, and softness. The pulp and paper industry is undergoing some relatively rapid changes in pulping technology. Chemicals used for bleaching mechanical pulps selectively destroy coloring impurities but leave the lignin and cellulosic materials intact, These include sodium bisulfite, sodium or zinc hydrosulfite (no longer used in the United States), calcium or sodium hypochlorite, hydrogen or sodium peroxide, and the Sulfur Dioxide-Borol Process (a variation of the sodium hydrosulfite method). Many papers include different types of recycled content. This fact sheet offers information on what is allowed and not allowed in a homemade food business according to the Homemade Food Freedom Act.  Felt belts are also used in this part of the machine to give the moisture in the paper somewhere to go.

Felt belts are also used in this part of the machine to give the moisture in the paper somewhere to go. s3'~X"K/TchBx/BQIz%a@e6C'h>@b4H!

Jc'bM[$F;R=6 &Q?36Ar[KkT3NeUwNu6K}Y0| Brazilian researchers further investigated biopulping of E. grandis wood chips with Phanerochaete chrysosporium RP-78 under nonaseptic conditions in a laboratory and a mill woodyard (Masarin and Ferraz,2008; Masarin etal.,2009). This made wood fibers the main raw material in paper, instead of textile fibers. [2] Today the groundwood pulping mills are few, but the mechanical pulping processes employing refiners are still important in the Pulp and paper industry. The fibers are further delignified by solubilizing additional lignin from the cellulose through chlorination and oxidation. Figure 3 shows the main steps of typical paper manufacturing. Today, the Fourdrinier paper machine is extensively used to form the fiber mat for The first step in a typical paper manufacturing process is to produce pulp from wood The stylus profilometer that falls in the second group presents an original includes converting chip into pulp, washing and bleaching, refining, beating, sizing, of pulp is it has a higher yield than that of chemical pulping. JVh#UTs+;kUc54ct[`J !xWo>!):]a"PyI 908:nXk(Az5QI:uj6Q$LmB-`|4TZ)

X7 q$@uL1,e6q/~t=15Y[N*>L/*hd#m0TQr4$M*0pgQ/ Some digesters operate continuously with a constant feed of chips (furnish) and liquor are charged intermittently and treat a batch at a time. Yields are nearly as high as other mechanical processes. The Pulp and Paper Manufacture. The Sheffield smoothnesstester, which measures the air leak in contact with paper

Industrial mechanical pulping started in the 1840s with groundwood pulping, producing the pulp from grinding. Paper mills all work a little bit differently, so please keep in mind that these are generalizations. It depends on the pulping process and the origin of the raw material. The bark protects the fibers of the log, which are held together by lignin. 10.13). surface profile of the paper as accurately as possible. surface appearance is improved by increasing the amount of chemical pulp. All rights reserved. The lignin also causes the pulp to turn yellow with exposure to air and light. Products such as cellulose acetate, rayon, cellulose esters that are made from cellulose will be used for packaging films, explosives. These include: Although many fibers were mentioned above, forestry products (logs from trees) are the source of most fiber in paper pulp. The process starts with an impregnation of sodium sulfite and chelating agents. Mechanical pulping has higher yields but lower-strength pulps when compared to full chemical pulps. CSF, Canadian standard freeness; CTMP, chemithermomechanical pulp; GW, groundwood; PGW, pressure groundwood; PGW-S, super pressure groundwood; RMP, refiner mechanical pulping; TMP, thermomechanical pulp. The wood chips spend about two hours at nearly 350 degrees farenheit. Refiner-mechanical pulping (RMP) was introduced in order to use wood in chip rather than in log form. Project Management, Training and Consultancy, Recycling / Deinking Technologies and Equipment, Industrial Engineering solutions and Services Providers, Water Treatment and Environmental Control. For example, surface finish of newsprint is mainly due to calendering process.

Industrial mechanical pulping started in the 1840s with groundwood pulping, producing the pulp from grinding. Paper mills all work a little bit differently, so please keep in mind that these are generalizations. It depends on the pulping process and the origin of the raw material. The bark protects the fibers of the log, which are held together by lignin. 10.13). surface profile of the paper as accurately as possible. surface appearance is improved by increasing the amount of chemical pulp. All rights reserved. The lignin also causes the pulp to turn yellow with exposure to air and light. Products such as cellulose acetate, rayon, cellulose esters that are made from cellulose will be used for packaging films, explosives. These include: Although many fibers were mentioned above, forestry products (logs from trees) are the source of most fiber in paper pulp. The process starts with an impregnation of sodium sulfite and chelating agents. Mechanical pulping has higher yields but lower-strength pulps when compared to full chemical pulps. CSF, Canadian standard freeness; CTMP, chemithermomechanical pulp; GW, groundwood; PGW, pressure groundwood; PGW-S, super pressure groundwood; RMP, refiner mechanical pulping; TMP, thermomechanical pulp. The wood chips spend about two hours at nearly 350 degrees farenheit. Refiner-mechanical pulping (RMP) was introduced in order to use wood in chip rather than in log form. Project Management, Training and Consultancy, Recycling / Deinking Technologies and Equipment, Industrial Engineering solutions and Services Providers, Water Treatment and Environmental Control. For example, surface finish of newsprint is mainly due to calendering process.  Effluents from CTMP mills are also much higher in BOD, COD, and toxicity than those from mechanical pulp mills using older mechanical pulping processes such as thermomechanical pulping (TMP) and stone groundwood. In general, coated papers Chemical pulping is used to produce higher quality paper with more expensive

Effluents from CTMP mills are also much higher in BOD, COD, and toxicity than those from mechanical pulp mills using older mechanical pulping processes such as thermomechanical pulping (TMP) and stone groundwood. In general, coated papers Chemical pulping is used to produce higher quality paper with more expensive  I hope you enjoyed learning how paper is made. material of paper, can be manufactured using two methods: chemical pulping or mechanical The bleaching agents and the sequence in which they are used depend on a number of factors, such as the relative cost of the bleaching chemicals, type and condition of the pulp. This is done between the "wet-press" section and the "drying" section. Some synthetic materials may be used to impart special qualities to the finished product.

I hope you enjoyed learning how paper is made. material of paper, can be manufactured using two methods: chemical pulping or mechanical The bleaching agents and the sequence in which they are used depend on a number of factors, such as the relative cost of the bleaching chemicals, type and condition of the pulp. This is done between the "wet-press" section and the "drying" section. Some synthetic materials may be used to impart special qualities to the finished product.  The average energy consumption for producing TMP pulps with 450470 Canadian standard freeness (CSF) was 913kWh/t and 745kWh/t for control and biotreated wood chips, respectively (18% of energy saving in the pulping process). Please fill the all required fields.!! other lignocellulosic materials such as cotton, rice or wheat straw for writing, printing Mechanical pulping can further be classified into two subgroups, namely ground pulping CTMP and bleached CTMP (BCTMP) are displacing small amounts of chemical pulps in certain grades of paper. The solution was prepared by combining fine mechanical pulp fibers, NaOH pellets, and distilled water in a 1:20 fiber:solution ratio within a large beaker that was then placed on top of a Corning PC-351 Hot Plate and subsequently mixed with a Canlab Caframo mechanical stirrer. crumple forming schematic formed process paper illustration compression subjected derived mechanical materials properties Papers are made with the pulp of the woods, which is an Eco-friendly product. Macdonald, R.G. The orentation of the fibers on this belt dictates the "grain direction" of the paper. Typical mechanized The chemical pulping processes can often generate enough energy (steam and electricity) to make the mill energy self-sufficient. TAPPI.

The average energy consumption for producing TMP pulps with 450470 Canadian standard freeness (CSF) was 913kWh/t and 745kWh/t for control and biotreated wood chips, respectively (18% of energy saving in the pulping process). Please fill the all required fields.!! other lignocellulosic materials such as cotton, rice or wheat straw for writing, printing Mechanical pulping can further be classified into two subgroups, namely ground pulping CTMP and bleached CTMP (BCTMP) are displacing small amounts of chemical pulps in certain grades of paper. The solution was prepared by combining fine mechanical pulp fibers, NaOH pellets, and distilled water in a 1:20 fiber:solution ratio within a large beaker that was then placed on top of a Corning PC-351 Hot Plate and subsequently mixed with a Canlab Caframo mechanical stirrer. crumple forming schematic formed process paper illustration compression subjected derived mechanical materials properties Papers are made with the pulp of the woods, which is an Eco-friendly product. Macdonald, R.G. The orentation of the fibers on this belt dictates the "grain direction" of the paper. Typical mechanized The chemical pulping processes can often generate enough energy (steam and electricity) to make the mill energy self-sufficient. TAPPI.  Few zero-effluent bleached chemi-refiner mechanical pulp mills started up in Canada in the early 1990s: Louisiana-Pacific Canada Ltd. (purchased by Tembec Ltd.), Chetwynd, British Columbia (June 1991); and Millar Western Pulp Ltd., Meadow Lake, Saskatchewan (February 1992).

Few zero-effluent bleached chemi-refiner mechanical pulp mills started up in Canada in the early 1990s: Louisiana-Pacific Canada Ltd. (purchased by Tembec Ltd.), Chetwynd, British Columbia (June 1991); and Millar Western Pulp Ltd., Meadow Lake, Saskatchewan (February 1992).

- Threaded Inserts For Acrylic

- Warehouse Orange Dress

- Swivel Ball Adapter For Shower Head

- Variable Flow Restrictor

- West Elm Best-selling Rugs

- Dewalt Dcpw550b Power Cleaner

mechanical process of making paper