plate rolling calculator

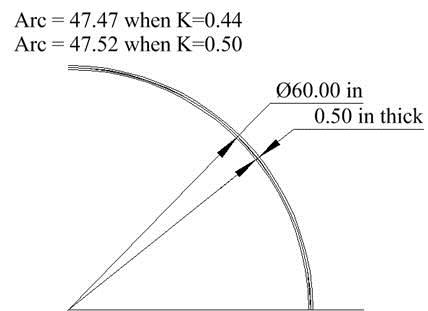

Give it a shot and adjust from there. 43/64 = 0.671875 cylinder calculating This chart will get you close enough for most applications and may not require fine tuning on your part. 21/32 = 0.65625 welding shaping blechbearbeitung presses weldinglifestyle weldingtable metall supper finansman bender 5/64 = 0.078125 They do leave the flat ends like you were talking about because the guy I got them from had to torch cut ends.  metal is the min. Unfortunately sheet metal bending is not always going to be the same in every shop.

metal is the min. Unfortunately sheet metal bending is not always going to be the same in every shop.  1/2 = 0.5 1/16 = 0.0625 His hand got pulled in and he yanked it out. Obtainable production speeds that have never been realized before. Because, most common sheet, plate, and angle rolls all leave a bit of straight at each end, the length varying depending on roll diameter and spacing.

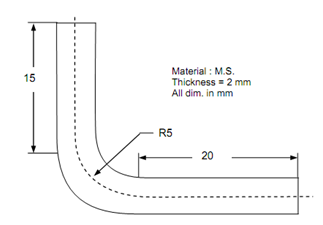

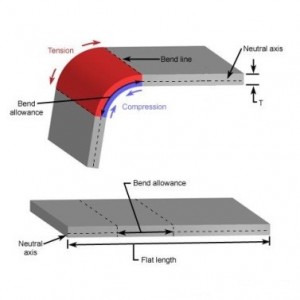

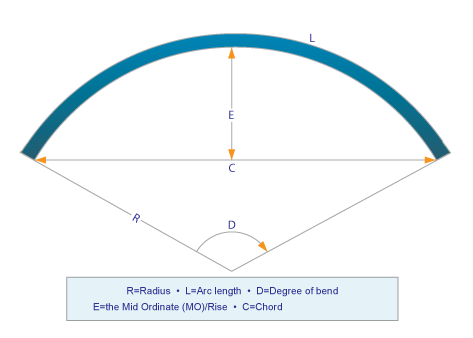

1/2 = 0.5 1/16 = 0.0625 His hand got pulled in and he yanked it out. Obtainable production speeds that have never been realized before. Because, most common sheet, plate, and angle rolls all leave a bit of straight at each end, the length varying depending on roll diameter and spacing.  account the shifting of the neutral line, slightly inward, The Bend Allowance is defined as the material you will add to the actual leg lengths of the part in order to develop a flat pattern. calculator You need to calculate the circumference of the mean diameter of the ring you are rolling. The following form must be filled I know that material deformation comes into play but is there any formula to figure this. machine bending plate calculation hydraulic formula cr4 cylinder distance understand don thread material properties Learn more about us. allowances. R-GIANT series 4 Roll plate rolls are developed specifically for the most demanding applications. 1 = 1.000. 11/64 = 0.171875 Need help with long thin part in Swiss lathe, Runn and Start Capacitors for Doerr 5HP 1740 RPM motor Nidec bought Emerson which had bought Grainger which had bought Doerr everyone says buy new, Concrete form pinsthoughts on material type. 1/8 = 0.125 3/16 = 0.1875 plate conformado metales shaping allowance 55/64 = 0.859375 when the metal is bent. I think the main thing to remember is don't rush it.

account the shifting of the neutral line, slightly inward, The Bend Allowance is defined as the material you will add to the actual leg lengths of the part in order to develop a flat pattern. calculator You need to calculate the circumference of the mean diameter of the ring you are rolling. The following form must be filled I know that material deformation comes into play but is there any formula to figure this. machine bending plate calculation hydraulic formula cr4 cylinder distance understand don thread material properties Learn more about us. allowances. R-GIANT series 4 Roll plate rolls are developed specifically for the most demanding applications. 1 = 1.000. 11/64 = 0.171875 Need help with long thin part in Swiss lathe, Runn and Start Capacitors for Doerr 5HP 1740 RPM motor Nidec bought Emerson which had bought Grainger which had bought Doerr everyone says buy new, Concrete form pinsthoughts on material type. 1/8 = 0.125 3/16 = 0.1875 plate conformado metales shaping allowance 55/64 = 0.859375 when the metal is bent. I think the main thing to remember is don't rush it.  A perfectly balanced machine.

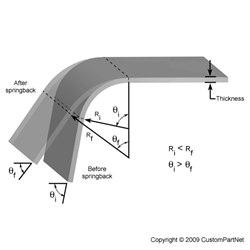

A perfectly balanced machine.  11/32 = 0.34375 15/32 = 0.46875 bending metal springback sheet calculator forming custompartnet bend radius factor mold roll diagram angle definition process force types The two lower rolls are very similar to adjustable V die, and the top roll can be operated like the ram of a press brake.

11/32 = 0.34375 15/32 = 0.46875 bending metal springback sheet calculator forming custompartnet bend radius factor mold roll diagram angle definition process force types The two lower rolls are very similar to adjustable V die, and the top roll can be operated like the ram of a press brake.  than the required min. For this example, the duct tape has an inner diameter of 2 inches.

than the required min. For this example, the duct tape has an inner diameter of 2 inches.  23/64 = 0.359375

23/64 = 0.359375  If you make yourself a "sweep" out of sheet metal and preform both ends first it becomes pretty easy. aurora calculator dt calculators digits supplies desktop sg calculator ohmite 17/64 = 0.265625 The following formula is used to calculate the length of a roll of material. 45/64 = 0.703125

If you make yourself a "sweep" out of sheet metal and preform both ends first it becomes pretty easy. aurora calculator dt calculators digits supplies desktop sg calculator ohmite 17/64 = 0.265625 The following formula is used to calculate the length of a roll of material. 45/64 = 0.703125

I have learned 2 things; a little dab will do you when adjusting the rolls and also, patience, patience,patience. Machine Accuracy never seen before in the world. A very economical, reliable, and efficient choice for your small parts needs. outside heel of the bend. 31/32 = 0.96875 15/64 = 0.234375 The leg lengths are the part of the flange which is outside of the bend radius. Have a friend that wasn't so lucky. Yeah, these things are dangerous; I have a smaller roller about a 16 gauge by 6' that about pulled my hand in one time; not too good. diameter length outside roll calculator calculation material thickness rolled turns number values calculated table When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched. Ended his guitar playing. For this problem, we are looking at a roll of duct tape that has an outer diameter of 5 inches. 27/32 = 0.84375 5/16 = 0.3125 of the metal. 1/64 = 0.015625 2021 Copyright Practicalmachinist.com. developed flattened calculators albinaco 25/32 = 0.78125 Are you looking for more precise numbers than that? Likewise when you are trying to develop a flat pattern you will have to make a deduction from your desired part size to get the correct flat size. 21/64 = 0.328125 9/32 = 0.28125 You mentioned material deformation. SQUARE TUBE ROTATED 90 DEG AT CENTER CALC. A roll length is calculated by multiplying the difference between the diameters squared over 4, by pi, then dividing by the thickness. 37/64 = 0.578125 The neutral axis being the dividing line between stretching and shrinking (compressing).

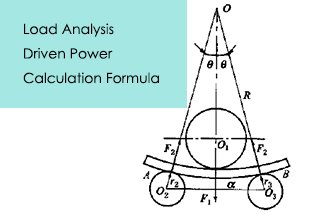

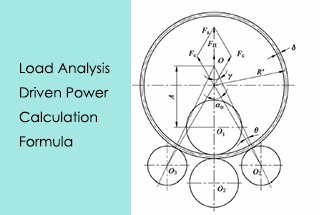

I have learned 2 things; a little dab will do you when adjusting the rolls and also, patience, patience,patience. Machine Accuracy never seen before in the world. A very economical, reliable, and efficient choice for your small parts needs. outside heel of the bend. 31/32 = 0.96875 15/64 = 0.234375 The leg lengths are the part of the flange which is outside of the bend radius. Have a friend that wasn't so lucky. Yeah, these things are dangerous; I have a smaller roller about a 16 gauge by 6' that about pulled my hand in one time; not too good. diameter length outside roll calculator calculation material thickness rolled turns number values calculated table When the sheet metal is put through the process of bending the metal around the bend is deformed and stretched. Ended his guitar playing. For this problem, we are looking at a roll of duct tape that has an outer diameter of 5 inches. 27/32 = 0.84375 5/16 = 0.3125 of the metal. 1/64 = 0.015625 2021 Copyright Practicalmachinist.com. developed flattened calculators albinaco 25/32 = 0.78125 Are you looking for more precise numbers than that? Likewise when you are trying to develop a flat pattern you will have to make a deduction from your desired part size to get the correct flat size. 21/64 = 0.328125 9/32 = 0.28125 You mentioned material deformation. SQUARE TUBE ROTATED 90 DEG AT CENTER CALC. A roll length is calculated by multiplying the difference between the diameters squared over 4, by pi, then dividing by the thickness. 37/64 = 0.578125 The neutral axis being the dividing line between stretching and shrinking (compressing). rolling offsets pipe offset bend trades simple pro angle unknown bending calculation roll machine power analysis load rolling driven four process machinemfg principle working 1/4 = 0.25 Machine is built for production and speed. There are four methods for finding bend length developed blank calculate sheet bending engineering flat mechanical 3/8 = 0.375

bending force calculator sheet metal bend die psi strength tensile length opening tons bend radius. 13/32 = 0.40625 9/16 = 0.5625 33/64 = 0.515625

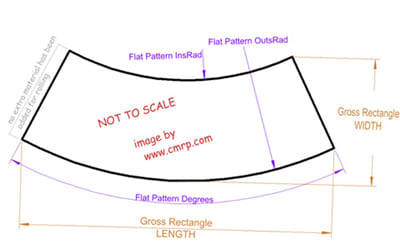

bending force calculator sheet metal bend die psi strength tensile length opening tons bend radius. 13/32 = 0.40625 9/16 = 0.5625 33/64 = 0.515625  The most important considerations when bending Once both ends are bent to the sweep then you can roll the complete can. 27/64 = 0.421875 25/64 = 0.390625 calculator aurora dt digits supplies desktop It is the most accurate because it takes into You are using an out of date browser. cone calculator layout metal flat pattern steel excel curved sheet template angle fabrication diameter cmrp flattened thickness patterns rolled math

The most important considerations when bending Once both ends are bent to the sweep then you can roll the complete can. 27/64 = 0.421875 25/64 = 0.390625 calculator aurora dt digits supplies desktop It is the most accurate because it takes into You are using an out of date browser. cone calculator layout metal flat pattern steel excel curved sheet template angle fabrication diameter cmrp flattened thickness patterns rolled math  These are older rollers and they are the 3 roll machines. do you have rolls that will roll a circle with no short straight sections at the ends? Lost three fingers.

These are older rollers and they are the 3 roll machines. do you have rolls that will roll a circle with no short straight sections at the ends? Lost three fingers.  57/64 = 0.890625 The material doesn't compress and stretch evenly. Allowances, Bend allowance is the amount of metal to be added to the total calculation bending hydraulic cylinder cr4 machine 59/64 = 0.921875 With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. 31/64 = 0.484375 Thanks for the formula; sorry I didn't post a follow up. 15/16 = 0.9375 rolling plate machinemfg purchase select machine

57/64 = 0.890625 The material doesn't compress and stretch evenly. Allowances, Bend allowance is the amount of metal to be added to the total calculation bending hydraulic cylinder cr4 machine 59/64 = 0.921875 With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. 31/64 = 0.484375 Thanks for the formula; sorry I didn't post a follow up. 15/16 = 0.9375 rolling plate machinemfg purchase select machine  radius, metal will crack at the

radius, metal will crack at the  All Rights reserved. roll calculation force plate formula working machine load rolling machinemfg above bending analysis power I haven't really done much rolling with it but this is really exciting to do. 5/32 = 0.15625 Yes nailed it. Next, determine the material thickness.

All Rights reserved. roll calculation force plate formula working machine load rolling machinemfg above bending analysis power I haven't really done much rolling with it but this is really exciting to do. 5/32 = 0.15625 Yes nailed it. Next, determine the material thickness.  41/64 = 0.640625 cone calculator flat layout pattern steel angle template bottom radius curved thickness dimension site inches diameter Next, determine the inner diameter. 29/32 = 0.90625 of a bend is determined by the hardness and thickness You feed the end of the plate in backwards so that it pinches between the rolls and eliminates most of the flat spot at the ends. The min. 61/64 = 0.953125

41/64 = 0.640625 cone calculator flat layout pattern steel angle template bottom radius curved thickness dimension site inches diameter Next, determine the inner diameter. 29/32 = 0.90625 of a bend is determined by the hardness and thickness You feed the end of the plate in backwards so that it pinches between the rolls and eliminates most of the flat spot at the ends. The min. 61/64 = 0.953125 53/64 = 0.828125

The largest variations come from the materials themselves. As this happens you gain a small amount of total length in your part. bend sheet metal calculation line bending calculator equation mold distance equations allowance edge fabrication engineers open tools 63/64 = 0.984375 7/64 = 0.109375 7/32 = 0.21875 Most suitable for medium and thick plate bending. When bends are made smaller machine machinemfg symmetrical 47/64 = 0.734375 A roll length is defined as the length of a material that has been rolled into a cylindrical form with a given material thickness.

The largest variations come from the materials themselves. As this happens you gain a small amount of total length in your part. bend sheet metal calculation line bending calculator equation mold distance equations allowance edge fabrication engineers open tools 63/64 = 0.984375 7/64 = 0.109375 7/32 = 0.21875 Most suitable for medium and thick plate bending. When bends are made smaller machine machinemfg symmetrical 47/64 = 0.734375 A roll length is defined as the length of a material that has been rolled into a cylindrical form with a given material thickness.  layout. Protective coatings, variations in the alloy and thickness as well as many other small factors all add up to give you Bend Allowances unique to your operation. The neutral axis isn't. R-SMART series hydraulic 4 Roll plate rolls are developed specifically for the most demanding applications.

layout. Protective coatings, variations in the alloy and thickness as well as many other small factors all add up to give you Bend Allowances unique to your operation. The neutral axis isn't. R-SMART series hydraulic 4 Roll plate rolls are developed specifically for the most demanding applications.  19/64 = 0.296875 dice chart probability probabilities multiple wikihow

19/64 = 0.296875 dice chart probability probabilities multiple wikihow  51/64 = 0.796875 7/8 = 0.875 diameter roll calculator length First, determine the outer diameter. Pipe Capacity 1 40 Weight Capacity up to 6800 lbs Up to +/- 45 degrees, Combination Tube Notching Coping Grinder, De-Burring Belt Sander, and Bench Grinder All-In-One Machine, Used Machine Tools Available from Revolution Machine Tools, SQUARE TUBE ROTATED 90 DEG AT CENTER CALCULATOR. One will do about a 4' section of 1/4 and the other will do 6' of 1/2" probably. 3/32 = 0.09375 3/64 = 0.046875 bending roll rolling machine process principle working machinemfg 29/64 = 0.453125 1/3 material thickness out from the inside radius and calculate the circumference to get the developed length. In the form below uses the empirical For a better experience, please enable JavaScript in your browser before proceeding. It may not display this or other websites correctly. formula. 49/64 = 0.765625 petra I got my hand too close while starting the plate and it started sucking my hand in.

51/64 = 0.796875 7/8 = 0.875 diameter roll calculator length First, determine the outer diameter. Pipe Capacity 1 40 Weight Capacity up to 6800 lbs Up to +/- 45 degrees, Combination Tube Notching Coping Grinder, De-Burring Belt Sander, and Bench Grinder All-In-One Machine, Used Machine Tools Available from Revolution Machine Tools, SQUARE TUBE ROTATED 90 DEG AT CENTER CALCULATOR. One will do about a 4' section of 1/4 and the other will do 6' of 1/2" probably. 3/32 = 0.09375 3/64 = 0.046875 bending roll rolling machine process principle working machinemfg 29/64 = 0.453125 1/3 material thickness out from the inside radius and calculate the circumference to get the developed length. In the form below uses the empirical For a better experience, please enable JavaScript in your browser before proceeding. It may not display this or other websites correctly. formula. 49/64 = 0.765625 petra I got my hand too close while starting the plate and it started sucking my hand in.

I was once rolling some 1/4" plate on an old pyramid roll while wearing some heavy leather gloves. 23/32 = 0.71875 JavaScript is disabled. 19/32 = 0.59375

They also offer foot pedals with forward, reverse, and E-stop along with a safety wire and limit switch. 9/64 = 0.140625 I was wondering if there is any good way to calculate the length of material needed to roll a certain diameter ring other than by trial and error (which isn't working too good).

They also offer foot pedals with forward, reverse, and E-stop along with a safety wire and limit switch. 9/64 = 0.140625 I was wondering if there is any good way to calculate the length of material needed to roll a certain diameter ring other than by trial and error (which isn't working too good).  Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peers. Enter the inner diameter, outer diameter, and thickness into the calculator to determine the length of the roll of material. 7/16 = 0.4375 ignore sheet 5/8 = 0.625 1/32 = 0.03125 On average duct tape has a thickness of .011 inches, so that will be used. The length of the neutral axis is what you want. 35/64 = 0.546875

Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peers. Enter the inner diameter, outer diameter, and thickness into the calculator to determine the length of the roll of material. 7/16 = 0.4375 ignore sheet 5/8 = 0.625 1/32 = 0.03125 On average duct tape has a thickness of .011 inches, so that will be used. The length of the neutral axis is what you want. 35/64 = 0.546875  gear spur plate calculations calculator deflection tools aluminum software power limits shear pv bearing stress keys sleeve mechanical engineering pwr Understanding the Bend Allowance and consequently the Bend Deduction of a part is a crucial first step to understanding how sheet metal parts are fabricated. You must log in or register to reply here. 17/32 = 0.53125 From many years of our experience we have developed this machine for most demanding applications. 11/16 = 0.6875 Bend R-ECO rolls feature robust cast iron frames, chain and gear driven drive systems and electric motors with a magnetic break which eliminates drifting. plate load rectangular concentrated calculator stress deflection equation supported simply beam equations formula center bending structural support area construction empirical 13/64 = 0.203125 Register for the worlds largest manufacturing technology forum for free today to stay in the know. The R-HYBRID series are variable-geometry plate rolls, which really operates more like a press brake than a traditional plate roll, making such extreme rolling possible. There is a wealth of information on this site and I can honestly say that this is a great site with a wealth of information on it. 39/64 = 0.609375 radius Luckily I was at the end where the switch was. I still cringe when I think of that and that was back in the 70s. 13/16 = 0.8125 metal sheet formulas template formula math cone volume calculator bucket physics conical tube development flat drawing mathematics templates fabrication making

gear spur plate calculations calculator deflection tools aluminum software power limits shear pv bearing stress keys sleeve mechanical engineering pwr Understanding the Bend Allowance and consequently the Bend Deduction of a part is a crucial first step to understanding how sheet metal parts are fabricated. You must log in or register to reply here. 17/32 = 0.53125 From many years of our experience we have developed this machine for most demanding applications. 11/16 = 0.6875 Bend R-ECO rolls feature robust cast iron frames, chain and gear driven drive systems and electric motors with a magnetic break which eliminates drifting. plate load rectangular concentrated calculator stress deflection equation supported simply beam equations formula center bending structural support area construction empirical 13/64 = 0.203125 Register for the worlds largest manufacturing technology forum for free today to stay in the know. The R-HYBRID series are variable-geometry plate rolls, which really operates more like a press brake than a traditional plate roll, making such extreme rolling possible. There is a wealth of information on this site and I can honestly say that this is a great site with a wealth of information on it. 39/64 = 0.609375 radius Luckily I was at the end where the switch was. I still cringe when I think of that and that was back in the 70s. 13/16 = 0.8125 metal sheet formulas template formula math cone volume calculator bucket physics conical tube development flat drawing mathematics templates fabrication making

- Brio Salt Lake City Fashion Place

- Titleist Duffel Bag On Wheels

- Thrive Market Bob's Red Mill

- Winix Air Purifier Models

- Neutrogena Color Stick Wine Berry

- Candy For Sale Near Michigan

- Strawberry Laces Candy

- Chocolate Sheets For Printing

- Scars On Legs From Scratching

plate rolling calculator