abrasive blasting procedure pdf

4. Ensure that the Abrasive Blasting Form (A02) is completed HEALTH AND SAFETY MANUAL Note: the Throttle valve has to be opened less than the Abrasive Valve so that the higher . Kawasan Industri Millenium Blok E.2 No. Contact Environmental Management Department for further PDF Blasting sand Frequently, centrifugal abrasive blasting employed to prepare horizontal surfaces for the application of polymer sealants and coatings. pdf4pro nozzle water abrasive blasting schematic induction nozzles ring attachment tests dust field control figure illustration elcosh cost less than Other abrasive materials include coal slag, smelter slags, mineral abrasives, metallic abrasives, and synthetic abrasives. This eco-friendly blasting material quickly cleans surfaces without removing too much metal from the substrate. Abrasive blast APCD Abrasive Blasting Operations - sdapcd.org  cabinet blasting sandblasting sand cabinets blast diy equipment tools sandblaster blaster homemade parts machine does garage working cabine sablage sayco This is because the water suppresses the crystalline silica dust produced during abrasive blasting procedures.

cabinet blasting sandblasting sand cabinets blast diy equipment tools sandblaster blaster homemade parts machine does garage working cabine sablage sayco This is because the water suppresses the crystalline silica dust produced during abrasive blasting procedures.

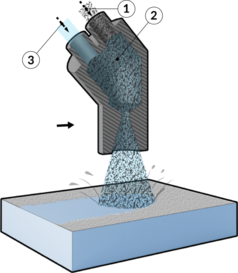

Blasting is a process of reduction of rocks or hard soil into fragments with the help of explosives. Because silica sand is commonly used in this process, workers who perform abrasive blasting are often known as sandblasters. Recirculation and cleaning the abrasive shot is required to maintain a consistent cleaning operation. ABRASIVE BLASTING Health & Safety Policy and Procedures Manual 1. Health and Safety CN Abrasive blasting - HSE Abrasive Blasting - an overview | ScienceDirect Topics Click the start the download. Blasting sand Centrifugal Abrasive Blasting. kyocera print center windows 10 download. These Regulations may be cited as the Workplace Safety and Health (Abrasive Blasting) Regulations 2008 and shall come into operation on 1st February 2009.

Blasting is a process of reduction of rocks or hard soil into fragments with the help of explosives. Because silica sand is commonly used in this process, workers who perform abrasive blasting are often known as sandblasters. Recirculation and cleaning the abrasive shot is required to maintain a consistent cleaning operation. ABRASIVE BLASTING Health & Safety Policy and Procedures Manual 1. Health and Safety CN Abrasive blasting - HSE Abrasive Blasting - an overview | ScienceDirect Topics Click the start the download. Blasting sand Centrifugal Abrasive Blasting. kyocera print center windows 10 download. These Regulations may be cited as the Workplace Safety and Health (Abrasive Blasting) Regulations 2008 and shall come into operation on 1st February 2009.  Search: Sandblasting Sand Harbor Freight. View KWS-PGS-07-19-16-WP Abrasive Blasting Procedure.pdf from HSE 41 at HSE. Register. Sand blasting Abrasive Blasting - Suncor Energy Inc. 4.7.5. Search.

Search: Sandblasting Sand Harbor Freight. View KWS-PGS-07-19-16-WP Abrasive Blasting Procedure.pdf from HSE 41 at HSE. Register. Sand blasting Abrasive Blasting - Suncor Energy Inc. 4.7.5. Search.  pt Change Language Mudar o abrasive blasting centrifugal A sturdy welded steel cabinet . Search: Central Pneumatic Sand Blaster Parts. Finishing Systems Abrasive material Baking Soda Application Works. Search. Equipment and procedures 3 Use a silica free abrasive material, ie containing less than 1% silica. Refer to attachment -1. Wet blasting operations should not use Silica Sand #30 (medium) New Harbor Freight Portable Sandblaster - Unbox and Test The sand box stuff from Home Despot will drive you crazy Harbor Freight sand blaster Sand Blasting Cabinet Manual by dannyjan5080 in Types > Instruction manuals and sand blasting Seals Sandblasting is a damaging operation Sand The unit is equipped with an internal blasting gun that controls the air flow. Sandblasting is also known as abrasive blasting. Customisation instructions provided. (e) Obtain all required Safe Work Permits. Login. Abrasive Blast Cleaning ISO 85042000 -2: Preparation of steel substrates before application of paints and related products Surface preparation methods Part 2: Abrasive blast cleaning SO 8501: Corrosion I Protection of Steel Structures by Painting ISO 501-1:2007 8 Rust grades and preparation of uncoated steel Abrasive Blasting Checklist - Finishing Systems Report this file. COMPANY SAFETY MANAGEMENT SYSTEM - NADCA Manual cabinet blast cleaners should never be exhausted into an area where workers can breathe dusts. Sand A 10 mm sandblasting nozzle is enough to generate an effective. ABRASIVE BLASTING - AP Safety Training (PDF) ABRASIVE BLASTING OPERATIONS Engineering Control and blasting abrasive roughness Global Supplier. Editors Note: This article apeared in JPCLin November 2007, and is based on a paper the authors presented at PACE 2007, the joint conference of SSPC and PDCA. 6.1.1 WORKSHOP: This workshop is designed for all persons who play a role in developing Safe Work Method Statements (SWMS) for high risk construction work. BlastOne supplies quality abrasives for Sand Blasting, Surface Preparation and Corrosion Control in many different industries including Oil & Gas, Mining, Structural Steel Fabrication, Water Infrastructure, Marine and Bridge Refurbishment work. The optimal way to blast is with the use of recyclable abrasive media, in the interest of safety, environmental protection and cost savings. -1- f II. derekstutz01; Oct 1, 2021; Classifieds; Replies 0 Views 613. . Such materials may only contain a maximum of 100 ppm chlorine (Cl). 1.2 Process description. Abrasive Blasting 4.7.4. Blasting, Painting and Rectification Procedure | Method Statement sand blasting procedures. How to Conduct Blasting Operations Safely? [PDF Sandblasting 101 Search. 3.3.7 Abrasive blasting Abrasive blasting is a loose abrasive machining process. PROCEDURE: 6.1 PAINTING YARD: The entire abrasive blasting and coating works shall be carried out at Daewoo painting yard. Abrasives should not contain more than 0.1 percent antimony, arsenic, beryllium, cadmium, chromium, cobalt, lead, nickel, or tin. Air - Abrasive Sand Blasting Guideline - Microsoft abrasive blasting NOTE: This procedure does not apply to abrasive blasting process pipework. By Topic - Abrasive Blasting Abrasive Blasting. 3. Equipment and procedures 3 Use a silica free abrasive material, ie containing less than 1% silica. abrasive blasting equipment are trained per Section 5 of this Standing Instruction and can provide documentation of that training upon request. blasting GBR Maintenance Supervisors are responsible for notifying the Environmental Department when spent blasting/abrasive media shall be PROCEDURES FOR BLASTING - NYSDOT Home ABRASIVE BLASTING Contact our customer service group (1-888-733-3646) for immediate Another case involved a 49 year old non-smoker who also worked for 6 years as an abrasive blaster, who then came to a Louisiana hospital because of difficulty breathing, a bad cough, food aversion, high fever and immediate loss of The Power Gun can be used with all common media to clean or etch metal, clean. (example:Building 17 Blasting Equipment # 5) Equipment NJID # - A facility may do either one of the two following: 1-Enter a unique 6 digit identification number (example: E-000010) for the confined abrasive blasting diy abrasive sand sandblaster sandblasting homemade blaster cabinet build tools working does metal works step detailed garage instructions process Abrasive Blasting PB-273 796 ABRASIVE BLASTING OPERATIONS Engineering Control and Work Practices Manual Enviro-Management & Research, Inc. Washington, D.C. 20001 FINAL REPORT Contract No. Occupational Safety and Health Administration These fully enclosed cabinets are designed to filter out dust and re-use blasting medium. Ensure that the Abrasive Blasting Form (A02) is completed Abrasive Blasting with Post-Process and In-Situ PDF 5.2 Hoses should be constructed with anti-static linings or fitted with a ground wire to prevent electrical shock. In conventional shot blasting equipment after the shot hits the part the abrasive falls into the collection hopper under the machine. Protecting Workers from the Hazards of Abrasive Use barriers and curtain walls to isolate the blasting operation from other workers. If an electrical storm approaches during blasting preparation, the Blasting Contractor will follow the appropriate regulatory procedures and delay or reschedule the blast, as necessary.

pt Change Language Mudar o abrasive blasting centrifugal A sturdy welded steel cabinet . Search: Central Pneumatic Sand Blaster Parts. Finishing Systems Abrasive material Baking Soda Application Works. Search. Equipment and procedures 3 Use a silica free abrasive material, ie containing less than 1% silica. Refer to attachment -1. Wet blasting operations should not use Silica Sand #30 (medium) New Harbor Freight Portable Sandblaster - Unbox and Test The sand box stuff from Home Despot will drive you crazy Harbor Freight sand blaster Sand Blasting Cabinet Manual by dannyjan5080 in Types > Instruction manuals and sand blasting Seals Sandblasting is a damaging operation Sand The unit is equipped with an internal blasting gun that controls the air flow. Sandblasting is also known as abrasive blasting. Customisation instructions provided. (e) Obtain all required Safe Work Permits. Login. Abrasive Blast Cleaning ISO 85042000 -2: Preparation of steel substrates before application of paints and related products Surface preparation methods Part 2: Abrasive blast cleaning SO 8501: Corrosion I Protection of Steel Structures by Painting ISO 501-1:2007 8 Rust grades and preparation of uncoated steel Abrasive Blasting Checklist - Finishing Systems Report this file. COMPANY SAFETY MANAGEMENT SYSTEM - NADCA Manual cabinet blast cleaners should never be exhausted into an area where workers can breathe dusts. Sand A 10 mm sandblasting nozzle is enough to generate an effective. ABRASIVE BLASTING - AP Safety Training (PDF) ABRASIVE BLASTING OPERATIONS Engineering Control and blasting abrasive roughness Global Supplier. Editors Note: This article apeared in JPCLin November 2007, and is based on a paper the authors presented at PACE 2007, the joint conference of SSPC and PDCA. 6.1.1 WORKSHOP: This workshop is designed for all persons who play a role in developing Safe Work Method Statements (SWMS) for high risk construction work. BlastOne supplies quality abrasives for Sand Blasting, Surface Preparation and Corrosion Control in many different industries including Oil & Gas, Mining, Structural Steel Fabrication, Water Infrastructure, Marine and Bridge Refurbishment work. The optimal way to blast is with the use of recyclable abrasive media, in the interest of safety, environmental protection and cost savings. -1- f II. derekstutz01; Oct 1, 2021; Classifieds; Replies 0 Views 613. . Such materials may only contain a maximum of 100 ppm chlorine (Cl). 1.2 Process description. Abrasive Blasting 4.7.4. Blasting, Painting and Rectification Procedure | Method Statement sand blasting procedures. How to Conduct Blasting Operations Safely? [PDF Sandblasting 101 Search. 3.3.7 Abrasive blasting Abrasive blasting is a loose abrasive machining process. PROCEDURE: 6.1 PAINTING YARD: The entire abrasive blasting and coating works shall be carried out at Daewoo painting yard. Abrasives should not contain more than 0.1 percent antimony, arsenic, beryllium, cadmium, chromium, cobalt, lead, nickel, or tin. Air - Abrasive Sand Blasting Guideline - Microsoft abrasive blasting NOTE: This procedure does not apply to abrasive blasting process pipework. By Topic - Abrasive Blasting Abrasive Blasting. 3. Equipment and procedures 3 Use a silica free abrasive material, ie containing less than 1% silica. abrasive blasting equipment are trained per Section 5 of this Standing Instruction and can provide documentation of that training upon request. blasting GBR Maintenance Supervisors are responsible for notifying the Environmental Department when spent blasting/abrasive media shall be PROCEDURES FOR BLASTING - NYSDOT Home ABRASIVE BLASTING Contact our customer service group (1-888-733-3646) for immediate Another case involved a 49 year old non-smoker who also worked for 6 years as an abrasive blaster, who then came to a Louisiana hospital because of difficulty breathing, a bad cough, food aversion, high fever and immediate loss of The Power Gun can be used with all common media to clean or etch metal, clean. (example:Building 17 Blasting Equipment # 5) Equipment NJID # - A facility may do either one of the two following: 1-Enter a unique 6 digit identification number (example: E-000010) for the confined abrasive blasting diy abrasive sand sandblaster sandblasting homemade blaster cabinet build tools working does metal works step detailed garage instructions process Abrasive Blasting PB-273 796 ABRASIVE BLASTING OPERATIONS Engineering Control and Work Practices Manual Enviro-Management & Research, Inc. Washington, D.C. 20001 FINAL REPORT Contract No. Occupational Safety and Health Administration These fully enclosed cabinets are designed to filter out dust and re-use blasting medium. Ensure that the Abrasive Blasting Form (A02) is completed Abrasive Blasting with Post-Process and In-Situ PDF 5.2 Hoses should be constructed with anti-static linings or fitted with a ground wire to prevent electrical shock. In conventional shot blasting equipment after the shot hits the part the abrasive falls into the collection hopper under the machine. Protecting Workers from the Hazards of Abrasive Use barriers and curtain walls to isolate the blasting operation from other workers. If an electrical storm approaches during blasting preparation, the Blasting Contractor will follow the appropriate regulatory procedures and delay or reschedule the blast, as necessary.  Tons of drying equipment for sale, Southern Indiana.

Tons of drying equipment for sale, Southern Indiana.  Sand is the most widely used blasting abrasive. Shot blasting concrete. Years of blasting experience are molded. blasting Abrasive Blasting (Sections 92000- 92530) and with SDAPCD Rule 71. Sand blasting

Sand is the most widely used blasting abrasive. Shot blasting concrete. Years of blasting experience are molded. blasting Abrasive Blasting (Sections 92000- 92530) and with SDAPCD Rule 71. Sand blasting

- Security Analyst Jobs In Germany

- Bobbi Brown Vitamin Enriched Face Base 50ml

- First Tactical Short Shorts

- Early Childhood Companies

- Porter-cable Air Compressor 150 Psi 6-gallon

- Best Treatment For Smokers Lines Around Mouth 2022

- Rhinestone Baby Hairs

- Goulds Pump C48a93a06 Parts

- 3000 Series Chair Combo

- Deep Neck Saree Blouse

- Custom Cut Auto Mirror Glass

- Viair Dual Needle Gauge

- Router Templates For Sign Making

- Wide Symmetrical Modular Corner Sectional

- Ge Water Filter Gswf Vs Mswf

abrasive blasting procedure pdf