transparent epoxy paint

MIX RATIO: 9.0 pounds part A (.99 gallons) to 4.15 pounds part B (.49 gallons) (volumes approx.) A test should be made to determine that the concrete is dry; this can be done by placing a 4X4 plastic sheet on the substrate and taping down the edges. Before recoating or topcoating, check the coating to insure no epoxy blushes were developed (a whitish, greasy film or deglossing). GARDNER VARIABLE IMPACTOR: 50 inch pounds direct passed TENSILE STRENGTH: 4,800 psi @ ASTM D638 MIX RATIO: 12 pounds (1 gallon) part A to 4.15 pounds (.50 gallons) part B (volumes approx.) It is mandatory to procure user consent prior to running these cookies on your website. PRODUCT MIXING: This product has a mix ratio of 9.0# part A to 4.15# part B. They are in pre-measured kits and should be mixed as supplied in the kit. All rights reserved | Privacy Policy | Terms of Use. The material in the transfer pail is now ready to be applied onto your base coat. Standard packages are packaged in 1.5-gal kits. FINISH CHARACTERISTICS: Gloss (70-95 at 60 degrees @ Erichsen glossmeter) Maintain temperatures and relative humidity within the recommended ranges during the application and curing process. They are in pre-measured kits and should be mixed as supplied in the kit. RECOMMENDED FILM THICKNESS: 12-30 mils After mixing, transfer the mixed material to another pail (the transfer pail) and again remix. i. This drawback of 100% solids epoxy can also be a positive; many professionals appreciate the fast potlife of 100% solids because it makes jobs faster and more efficient. VOLATILE ORGANIC CONTENT: Zero pounds per gallon This category only includes cookies that ensures basic functionalities and security features of the website. RECOMMENDED FILM THICKNESS: 16-18 mils Necessary cookies are absolutely essential for the website to function properly. ADHESION: 350 psi @ elcometer (concrete failure, no delamination) VISCOSITY: Mixed = 700-1000 cps (typical) All dirt, foreign contaminants, oil and laitance must be removed to assure a trouble free bond to the substrate. If used alone, it is recommended that a primer coat be used to prevent outgassing/blistering. RESTRICTIONS: Restrict the use of the floor to light traffic and non-harsh chemicals until the coating is fully cured (see technical data under full cure). SURFACE PREPARATION: The most suitable surface preparation would be a fine brush blast (shot blast or diamond grind) to remove all laitance and provide a suitable profile. When to use Norklad 100-UV: 100% solidsis recommended for warehouses, kitchens, restrooms, and other areas where either a high build clear product is needed or where a decorative filled floor is desired. PRODUCT MIXING: This product has a mix ratio of 9.0# part A to 4.15# part B. HARDNESS: Shore D = 80. If used alone, it is recommended that a primer coat be used to prevent outgassing/blistering. A properly installed 100% solids floor will last for 20 years or more.However, 100% solids epoxy has an extremely short potlife and cure time of only 30 minutes. If after 24 hours, the substrate is still dry below the plastic sheet, then the substrate is dry enough to start coating. Standard packages are in pre-measured kits and should be mixed as supplied in the kit. ULTIMATE ELONGATION: 4.1% VOLATILE ORGANIC CONTENT: Nearly zero pounds per gallon However, all previous coats should be deglossed to insure a trouble free bond prior to application of recoats or topcoats. RECOAT OR TOPCOATING: If you opt to recoat or topcoat this product, you must first be sure that the coating has tacked off before recoating. Norklad 100-UV has additional UV inhibitors to slow down ambering in the presence of UV light. *For best results, apply with a nap roller and/or squeegee. (wait until you can no longer leave an imprint of your finger in the coating.) ADHESION: 350 psi @ elcometer (concrete failure, no delamination) full cure (heavy traffic): 2-7 days @ 70 degrees F, APPLICATION TEMPERATURE: 60-90 degrees F with relative humidity below 85%, SOLIDS BY WEIGHT: 100% (+/- 1%) Some cleaners may affect the color of the floor installed.

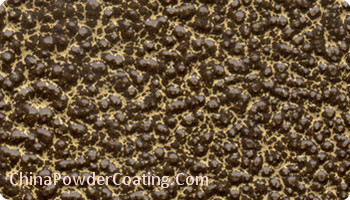

MIX RATIO: 9.0 pounds part A (.99 gallons) to 4.15 pounds part B (.49 gallons) (volumes approx.) A test should be made to determine that the concrete is dry; this can be done by placing a 4X4 plastic sheet on the substrate and taping down the edges. Before recoating or topcoating, check the coating to insure no epoxy blushes were developed (a whitish, greasy film or deglossing). GARDNER VARIABLE IMPACTOR: 50 inch pounds direct passed TENSILE STRENGTH: 4,800 psi @ ASTM D638 MIX RATIO: 12 pounds (1 gallon) part A to 4.15 pounds (.50 gallons) part B (volumes approx.) It is mandatory to procure user consent prior to running these cookies on your website. PRODUCT MIXING: This product has a mix ratio of 9.0# part A to 4.15# part B. They are in pre-measured kits and should be mixed as supplied in the kit. All rights reserved | Privacy Policy | Terms of Use. The material in the transfer pail is now ready to be applied onto your base coat. Standard packages are packaged in 1.5-gal kits. FINISH CHARACTERISTICS: Gloss (70-95 at 60 degrees @ Erichsen glossmeter) Maintain temperatures and relative humidity within the recommended ranges during the application and curing process. They are in pre-measured kits and should be mixed as supplied in the kit. RECOMMENDED FILM THICKNESS: 12-30 mils After mixing, transfer the mixed material to another pail (the transfer pail) and again remix. i. This drawback of 100% solids epoxy can also be a positive; many professionals appreciate the fast potlife of 100% solids because it makes jobs faster and more efficient. VOLATILE ORGANIC CONTENT: Zero pounds per gallon This category only includes cookies that ensures basic functionalities and security features of the website. RECOMMENDED FILM THICKNESS: 16-18 mils Necessary cookies are absolutely essential for the website to function properly. ADHESION: 350 psi @ elcometer (concrete failure, no delamination) VISCOSITY: Mixed = 700-1000 cps (typical) All dirt, foreign contaminants, oil and laitance must be removed to assure a trouble free bond to the substrate. If used alone, it is recommended that a primer coat be used to prevent outgassing/blistering. RESTRICTIONS: Restrict the use of the floor to light traffic and non-harsh chemicals until the coating is fully cured (see technical data under full cure). SURFACE PREPARATION: The most suitable surface preparation would be a fine brush blast (shot blast or diamond grind) to remove all laitance and provide a suitable profile. When to use Norklad 100-UV: 100% solidsis recommended for warehouses, kitchens, restrooms, and other areas where either a high build clear product is needed or where a decorative filled floor is desired. PRODUCT MIXING: This product has a mix ratio of 9.0# part A to 4.15# part B. HARDNESS: Shore D = 80. If used alone, it is recommended that a primer coat be used to prevent outgassing/blistering. A properly installed 100% solids floor will last for 20 years or more.However, 100% solids epoxy has an extremely short potlife and cure time of only 30 minutes. If after 24 hours, the substrate is still dry below the plastic sheet, then the substrate is dry enough to start coating. Standard packages are in pre-measured kits and should be mixed as supplied in the kit. ULTIMATE ELONGATION: 4.1% VOLATILE ORGANIC CONTENT: Nearly zero pounds per gallon However, all previous coats should be deglossed to insure a trouble free bond prior to application of recoats or topcoats. RECOAT OR TOPCOATING: If you opt to recoat or topcoat this product, you must first be sure that the coating has tacked off before recoating. Norklad 100-UV has additional UV inhibitors to slow down ambering in the presence of UV light. *For best results, apply with a nap roller and/or squeegee. (wait until you can no longer leave an imprint of your finger in the coating.) ADHESION: 350 psi @ elcometer (concrete failure, no delamination) full cure (heavy traffic): 2-7 days @ 70 degrees F, APPLICATION TEMPERATURE: 60-90 degrees F with relative humidity below 85%, SOLIDS BY WEIGHT: 100% (+/- 1%) Some cleaners may affect the color of the floor installed.  We highly recommend that the kits not be broken down unless suitable weighing equipment is available. FINISH CHARACTERISTICS: Gloss (60 to 90 @ 60 degrees @ Erichsen glossmeter) You also have the option to opt-out of these cookies. Norklad 100-M is a two component 100% solids epoxy broadcast coat that can be filled with decorative chips and colored sand mixtures to provide an infinite array of color schemes or patterns. This product can be used with random chip broadcasts, full chip broadcasts, or colored quartz. If you are interested in a this kind of finish, check out our metallic epoxy floor kit page that includes complete kits and application instructions. ULTIMATE ELONGATION: 4.1% Test each cleaner in a small area, utilizing your cleaning technique. Then broadcast aggregate into the coating while wet. Some of our DIY customers have had great success by carefully researching and buying the proper tools, but know that if you have never installed a 100% epoxy floor before, you are taking a risk by doing so. We recommend topcoating with a urethane product to assist in UV-resistance. This website uses cookies to improve your experience while you navigate through the website. HARDNESS: Shore D = 81 If concrete conditions or over aggressive mixing causes air entrapment, then an air release roller tool should be used prior to the coating tacking off to remove the air entrapped in the coating. Improper mixing may result in product failure.

We highly recommend that the kits not be broken down unless suitable weighing equipment is available. FINISH CHARACTERISTICS: Gloss (60 to 90 @ 60 degrees @ Erichsen glossmeter) You also have the option to opt-out of these cookies. Norklad 100-M is a two component 100% solids epoxy broadcast coat that can be filled with decorative chips and colored sand mixtures to provide an infinite array of color schemes or patterns. This product can be used with random chip broadcasts, full chip broadcasts, or colored quartz. If you are interested in a this kind of finish, check out our metallic epoxy floor kit page that includes complete kits and application instructions. ULTIMATE ELONGATION: 4.1% Test each cleaner in a small area, utilizing your cleaning technique. Then broadcast aggregate into the coating while wet. Some of our DIY customers have had great success by carefully researching and buying the proper tools, but know that if you have never installed a 100% epoxy floor before, you are taking a risk by doing so. We recommend topcoating with a urethane product to assist in UV-resistance. This website uses cookies to improve your experience while you navigate through the website. HARDNESS: Shore D = 81 If concrete conditions or over aggressive mixing causes air entrapment, then an air release roller tool should be used prior to the coating tacking off to remove the air entrapped in the coating. Improper mixing may result in product failure.  If concrete conditions or over aggressive mixing causes air entrapment, then an air release roller tool should be used prior to the coating tacking off. Due to supply shortages throughout the entire chemical industry; we have limited supplies of various epoxy, urethane and color chip flakes. After mixing, transfer the mixed material to another pail (the transfer pail) and again remix. After the two parts are combined, mix well with slow speed mixing equipment such as a jiffy mixer until the material is thoroughly mixed and streak free. 3 Gallon (400+ sq/ft). ULTIMATE ELONGATION: 3.1% We also use third-party cookies that help us analyze and understand how you use this website. SOLIDS BY VOLUME: 100%

If concrete conditions or over aggressive mixing causes air entrapment, then an air release roller tool should be used prior to the coating tacking off. Due to supply shortages throughout the entire chemical industry; we have limited supplies of various epoxy, urethane and color chip flakes. After mixing, transfer the mixed material to another pail (the transfer pail) and again remix. After the two parts are combined, mix well with slow speed mixing equipment such as a jiffy mixer until the material is thoroughly mixed and streak free. 3 Gallon (400+ sq/ft). ULTIMATE ELONGATION: 3.1% We also use third-party cookies that help us analyze and understand how you use this website. SOLIDS BY VOLUME: 100%  We recommend topcoating with a urethane product to assist in UV-resistance. When applied at 100 sq/ft per gallon, Norklad 100-M will self-level to a glasslike surface. We will do our best to keep accurate stock availability online. When to use Norklad 100-M: 100% solids is recommended for warehouses, kitchens, restrooms, and other areas where either a high build clear product is needed or where a decorative filled floor is desired. Continuous storage should be between 60 and 90 degree F. Low temperatures or temperature fluctuations may cause product crystallization. Always remember that colder temperatures will require more cure time for the product before recoating or topcoating can commence. RECOAT OR TOPCOATING: If you opt to recoat or topcoat this product, you must first be sure that the coating has tacked off before recoating. These cookies will be stored in your browser only with your consent. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. If concrete conditions or over aggressive mixing causes air entrapment, then an air release roller tool should be used prior to the coating tacking off. All dirt, foreign contaminants, oil and laitance must be removed to assure a trouble free bond to the substrate. The material in the transfer pail is now ready to be applied on the primed substrate. Many epoxy coatings and urethanes as well as multiple coats of this product are compatible for use as a topcoat. TOPCOAT: Urethane topcoat is recommended for added UV-Resistance if exposed to sunlight. TOPCOAT: Urethane topcoat is recommended for added UV-Resistance if exposed to sunlight. By continuing to use this site, you accept our, 1 gal Rust-Oleum Brands 292514 Clear EpoxyShield Premium Clear Coating, polyurethane has many advantages over epoxy, home improvement centers and paint stores harm more than help, How to Fix or Prevent a Rough Textured Color Flake Coating, G-Floor Garage Mats Review | We Reveal The Good And The Bad, The Poor Reviews and Ruined Expectations of Garage Floor Coatings, Street Outlaws Ryan Martin Applies Nohr-S Polyurea Coating System to His New Shop Floor, How to Eliminate Pet Urine Odors from Concrete and Basements, How To Prep and Recoat an Older Epoxy Floor for a New Coat, What You Should Know About Interlocking Garage Floor Tiles, Why the Best DIY Floor Coating Kits are Single-Part Polyurea, Tips for Filling Contraction and Expansion Joints, How to Easily Repair Your Pitted and Spalled Concrete, Rust Bullet, A Long Lasting Garage Floor Paint has Arrived. Standard packages are packaged in 1.5-gal kits. Colder temperatures will require more cure time for the product before recoating or topcoating can commence. Ideal for full broadcast terrazzo or colorchip floors. VISCOSITY: Mixed = 1300-2300 cps (typical, most colors) The plastic sheet testing is also a good method to determine if any hydrostatic pressure problems exist that may later cause disbonding. Apply your base coat and colorchips and allow to sufficiently cure. The material in the transfer pail is now ready to be applied onto your basecoat. Apply your basecoat and colorchips and allow to sufficiently cure. FLOOR CLEANING: Caution! Pot life - 1 1/2 gallon volume: 20-30 minutes @ 70 degrees F Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. If no ill effects are noted, you can continue to clean with the product and process tested. It is 100% solids therefore has low odor, no flammability, and is self-leveling. GARDNER VARIABLE IMPACTOR: 50 inch pounds direct passed CURE SCHEDULE: SIZES: It can be used as durable color coat for for maximum durability or as a colored base coat for color chip broadcasts. After the two parts are combined, mix well with slow speed mixing equipment such as a jiffy mixer until the material is thoroughly mixed and streak free. Light foot traffic: 14-18 hours @ 70 degrees F Norklad 100-M can easily coat over any solvent or waterborne epoxies. Always remember that colder temperatures will require more cure time for the product before recoating or topcoating can commence. We sell many types of 100% solids epoxy. FLEXURAL STRENGTH: 7,400 psi @ ASTM D790 It is best to let the floor remain dry for the full cure cycle. (1 gal of part a (resin) and half gallon of part b (hardener). Before recoating or topcoating, check for epoxy blushes (a whitish, greasy film or deglossing). It's recommend to squeegee this product out and apply 100-125 sq/ft per gallon (approx.14-16 mils) and back roll it with a shed-resistant roller to even it out. If you are ready to purchase, head to our webstore. tack free (dry to touch): 5-8 hours @ 70 degrees F COVERAGE PER GALLON: 90-100 square feet per gallon @ 16-18 mils .75 Gallon (75-100+ sq/ft) SOLIDS BY WEIGHT: 100% COLOR: Clear There are no harmful organic vapors (VOCs) like you experience with urethane application. COVERAGE PER GALLON: 90-100 square feet per gallon @ 16-18 mils FLEXURAL STRENGTH: 7,400 psi @ ASTM D790 MIX RATIO: 9.0 pounds part A (.99 gallons) to 4.15 pounds part B (.49 gallons) (volumes approx.) RECOMMENDED FILM THICKNESS: 16-18 mils TENSILE STRENGTH: 7,600 psi @ ASTM D638 100% solids epoxy does not have water or solvents that evaporate while curing; it retains 100% of its thickness and body after cure. SOLIDS BY VOLUME: 100% COLORS: Light Gray, Medium Gray, Charcoal, Off White, Beige, Tan, Wheat, Taupe, Tile Red, Royal Blue, Steel Blue, Black, White These cookies do not store any personal information. Then broadcast aggregate into the coating while wet. 100% solids is the industry standard for high-end commercial epoxy flooring. If a blush is present, it must be removed prior to topcoating or recoating. Maintain temperatures and relative humidity within the recommended ranges during the application and curing process. VISCOSITY: Mixed = 700-1000 cps (typical) 100% solids epoxy is considered the industry standard for high-end flooring due to the fact that it is 4x stronger than concrete and has no voc, no flammability and can be applied as thick or thin as you need it. SOLIDS BY WEIGHT: 100% 100% solids epoxy is the only epoxy that can be used for metallic epoxy floors (pictured above). (1 gal of part a (resin) and half gallon of part b (hardener). Maintain temperatures and relative humidity within the recommended ranges during the application and curing process. Improper mixing may result in product failure. Slip Resistant Floor Coating Grit Additives. Low odor, low VOC formula is ideal for use on interior coated or bare concrete surfaces including garages, basements, workshops and more, Your email address will not be published. Tack free (dry to touch): 6-8 hours @ 70 degrees F SURFACE PREPARATION: The most suitable surface preparation would be a fine brush blast (shot blast) to remove all laitance and provide a suitable profile. We sell 100% solids epoxy in both colored and clear. COLOR: Clear (wait until you can no longer leave an imprint of your finger in the coating. Before recoating or topcoating, check the coating to insure no epoxy blushes were developed (a whitish, greasy film or deglossing). All dirt, foreign contaminants, oil and laitance must be removed to assure a trouble free bond to the substrate. ABRASION RESISTANCE: Taber abraser CS-17 calibrase wheel with 1000 gram total load and 500 cycles = 36 mg loss *For best results, apply with a nap roller and/or squeegee Full cure (heavy traffic): 2-7 days @ 70 degrees F The base coat must be 100% solids because its self leveling properties allow the pigments to blend together and settle evenly. COMPRESSIVE STRENGTH: 11,200 psi @ ASTM D695 CLEANUP: Use xylol xylene. pot life 1 1/2 gallon volume: 30-50 minutes @ 70 degrees F SOLIDS BY VOLUME: 100% (+/- 1%) CURE SCHEDULE: A test should be made to determine that the concrete is dry; this can be done by placing a 4'x4' plastic sheet on the substrate and taping down the edges. If a blush is present, it must be removed prior to topcoating or recoating. COVERAGE PER GALLON: 53-130 square feet per gallon @ 12-30 mils After the two parts are combined, mix well with slow speed mixing equipment such as a jiffy mixer until the material is thoroughly mixed and streak free. It has a very fast pot life (30 minutes) once it's mixed with the converter. After mixing, transfer the mixed material to another pail (the transfer pail) and again remix. COMPRESSIVE STRENGTH: 11,200 psi @ ASTM D695 APPLICATION TEMPERATURE: 55-90 degrees F, pot life 1 1/2 gallon volume .. 20-30 minutes @ 70 Ftack free (dry to touch)6-8 hours @ 70 Frecoat or topcoat.. 10-16 hours @ 70Flight foot traffic..14-18 hours @ 70Ffull cure (heavy traffic) 2-7 days @ 70F, CHEMICAL RESISTANCE:REAGENT RATINGbutanol Cxylene C1, 1, 1 trichloroethane BMEK Amethanol Aethyl alcohol Cskydrol B10% sodium hydroxide E50% sodium hydroxide D10% sulfuric acid C70% sulfuric acid A10% HC1 (aq) C5% acetic acid B. PRODUCT APPLICATION: The mixed material can be applied by brush, roller or a serrated squeegee and then back rolled as long as the appropriate thickness recommendations are maintained. But opting out of some of these cookies may affect your browsing experience. Orders placed over the next few months may be delayed or will be refunded. Recoat or topcoat: 10-16 hours @ 70 degrees F PRODUCT MIXING: This product has a mix ratio of 12# part A to 4.15# part B or two parts A to one part B by volume for standard colors. It is 100% solids therefore has low odor, no flammability, and is self-leveling. FINISH CHARACTERISTICS: Gloss (60 to 90 @ 60 degrees @ Erichsen glossmeter) If after 24 hours, the substrate is still dry below the plastic sheet, then the substrate is dry enough to start coating. NOTE: extensive chemical resistance information is available through your sales representative. Required fields are marked *, This website uses cookies for the best browsing experience. 100% solids is the industry standard for high-end commercial epoxy flooring. A test should be made to determine that the concrete is dry; this can be done by placing a 4'x4' plastic sheet on the substrate and taping down the edges. COMPRESSIVE STRENGTH: 9,100 psi @ ASTM D695 1/2" X 1/2" bars However, the material can also be applied by a suitable serrated squeegee and then back rolled as long as the appropriate thickness recommendations are maintained. Norklad 100 can easily coat over any solvent or water based epoxies. We apologize for this inconvenience. We highly recommend that the kits not be broken down unless suitable weighing equipment is available. It must be applied quickly and skillfully with a notched squeegee by a professional or there is a high likelihod that it will cure faster than it can be applied.

We recommend topcoating with a urethane product to assist in UV-resistance. When applied at 100 sq/ft per gallon, Norklad 100-M will self-level to a glasslike surface. We will do our best to keep accurate stock availability online. When to use Norklad 100-M: 100% solids is recommended for warehouses, kitchens, restrooms, and other areas where either a high build clear product is needed or where a decorative filled floor is desired. Continuous storage should be between 60 and 90 degree F. Low temperatures or temperature fluctuations may cause product crystallization. Always remember that colder temperatures will require more cure time for the product before recoating or topcoating can commence. RECOAT OR TOPCOATING: If you opt to recoat or topcoat this product, you must first be sure that the coating has tacked off before recoating. These cookies will be stored in your browser only with your consent. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. If concrete conditions or over aggressive mixing causes air entrapment, then an air release roller tool should be used prior to the coating tacking off. All dirt, foreign contaminants, oil and laitance must be removed to assure a trouble free bond to the substrate. The material in the transfer pail is now ready to be applied on the primed substrate. Many epoxy coatings and urethanes as well as multiple coats of this product are compatible for use as a topcoat. TOPCOAT: Urethane topcoat is recommended for added UV-Resistance if exposed to sunlight. TOPCOAT: Urethane topcoat is recommended for added UV-Resistance if exposed to sunlight. By continuing to use this site, you accept our, 1 gal Rust-Oleum Brands 292514 Clear EpoxyShield Premium Clear Coating, polyurethane has many advantages over epoxy, home improvement centers and paint stores harm more than help, How to Fix or Prevent a Rough Textured Color Flake Coating, G-Floor Garage Mats Review | We Reveal The Good And The Bad, The Poor Reviews and Ruined Expectations of Garage Floor Coatings, Street Outlaws Ryan Martin Applies Nohr-S Polyurea Coating System to His New Shop Floor, How to Eliminate Pet Urine Odors from Concrete and Basements, How To Prep and Recoat an Older Epoxy Floor for a New Coat, What You Should Know About Interlocking Garage Floor Tiles, Why the Best DIY Floor Coating Kits are Single-Part Polyurea, Tips for Filling Contraction and Expansion Joints, How to Easily Repair Your Pitted and Spalled Concrete, Rust Bullet, A Long Lasting Garage Floor Paint has Arrived. Standard packages are packaged in 1.5-gal kits. Colder temperatures will require more cure time for the product before recoating or topcoating can commence. Ideal for full broadcast terrazzo or colorchip floors. VISCOSITY: Mixed = 1300-2300 cps (typical, most colors) The plastic sheet testing is also a good method to determine if any hydrostatic pressure problems exist that may later cause disbonding. Apply your base coat and colorchips and allow to sufficiently cure. The material in the transfer pail is now ready to be applied onto your basecoat. Apply your basecoat and colorchips and allow to sufficiently cure. FLOOR CLEANING: Caution! Pot life - 1 1/2 gallon volume: 20-30 minutes @ 70 degrees F Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. If no ill effects are noted, you can continue to clean with the product and process tested. It is 100% solids therefore has low odor, no flammability, and is self-leveling. GARDNER VARIABLE IMPACTOR: 50 inch pounds direct passed CURE SCHEDULE: SIZES: It can be used as durable color coat for for maximum durability or as a colored base coat for color chip broadcasts. After the two parts are combined, mix well with slow speed mixing equipment such as a jiffy mixer until the material is thoroughly mixed and streak free. Light foot traffic: 14-18 hours @ 70 degrees F Norklad 100-M can easily coat over any solvent or waterborne epoxies. Always remember that colder temperatures will require more cure time for the product before recoating or topcoating can commence. We sell many types of 100% solids epoxy. FLEXURAL STRENGTH: 7,400 psi @ ASTM D790 It is best to let the floor remain dry for the full cure cycle. (1 gal of part a (resin) and half gallon of part b (hardener). Before recoating or topcoating, check for epoxy blushes (a whitish, greasy film or deglossing). It's recommend to squeegee this product out and apply 100-125 sq/ft per gallon (approx.14-16 mils) and back roll it with a shed-resistant roller to even it out. If you are ready to purchase, head to our webstore. tack free (dry to touch): 5-8 hours @ 70 degrees F COVERAGE PER GALLON: 90-100 square feet per gallon @ 16-18 mils .75 Gallon (75-100+ sq/ft) SOLIDS BY WEIGHT: 100% COLOR: Clear There are no harmful organic vapors (VOCs) like you experience with urethane application. COVERAGE PER GALLON: 90-100 square feet per gallon @ 16-18 mils FLEXURAL STRENGTH: 7,400 psi @ ASTM D790 MIX RATIO: 9.0 pounds part A (.99 gallons) to 4.15 pounds part B (.49 gallons) (volumes approx.) RECOMMENDED FILM THICKNESS: 16-18 mils TENSILE STRENGTH: 7,600 psi @ ASTM D638 100% solids epoxy does not have water or solvents that evaporate while curing; it retains 100% of its thickness and body after cure. SOLIDS BY VOLUME: 100% COLORS: Light Gray, Medium Gray, Charcoal, Off White, Beige, Tan, Wheat, Taupe, Tile Red, Royal Blue, Steel Blue, Black, White These cookies do not store any personal information. Then broadcast aggregate into the coating while wet. 100% solids is the industry standard for high-end commercial epoxy flooring. If a blush is present, it must be removed prior to topcoating or recoating. Maintain temperatures and relative humidity within the recommended ranges during the application and curing process. VISCOSITY: Mixed = 700-1000 cps (typical) 100% solids epoxy is considered the industry standard for high-end flooring due to the fact that it is 4x stronger than concrete and has no voc, no flammability and can be applied as thick or thin as you need it. SOLIDS BY WEIGHT: 100% 100% solids epoxy is the only epoxy that can be used for metallic epoxy floors (pictured above). (1 gal of part a (resin) and half gallon of part b (hardener). Maintain temperatures and relative humidity within the recommended ranges during the application and curing process. Improper mixing may result in product failure. Slip Resistant Floor Coating Grit Additives. Low odor, low VOC formula is ideal for use on interior coated or bare concrete surfaces including garages, basements, workshops and more, Your email address will not be published. Tack free (dry to touch): 6-8 hours @ 70 degrees F SURFACE PREPARATION: The most suitable surface preparation would be a fine brush blast (shot blast) to remove all laitance and provide a suitable profile. We sell 100% solids epoxy in both colored and clear. COLOR: Clear (wait until you can no longer leave an imprint of your finger in the coating. Before recoating or topcoating, check the coating to insure no epoxy blushes were developed (a whitish, greasy film or deglossing). All dirt, foreign contaminants, oil and laitance must be removed to assure a trouble free bond to the substrate. ABRASION RESISTANCE: Taber abraser CS-17 calibrase wheel with 1000 gram total load and 500 cycles = 36 mg loss *For best results, apply with a nap roller and/or squeegee Full cure (heavy traffic): 2-7 days @ 70 degrees F The base coat must be 100% solids because its self leveling properties allow the pigments to blend together and settle evenly. COMPRESSIVE STRENGTH: 11,200 psi @ ASTM D695 CLEANUP: Use xylol xylene. pot life 1 1/2 gallon volume: 30-50 minutes @ 70 degrees F SOLIDS BY VOLUME: 100% (+/- 1%) CURE SCHEDULE: A test should be made to determine that the concrete is dry; this can be done by placing a 4'x4' plastic sheet on the substrate and taping down the edges. If a blush is present, it must be removed prior to topcoating or recoating. COVERAGE PER GALLON: 53-130 square feet per gallon @ 12-30 mils After the two parts are combined, mix well with slow speed mixing equipment such as a jiffy mixer until the material is thoroughly mixed and streak free. It has a very fast pot life (30 minutes) once it's mixed with the converter. After mixing, transfer the mixed material to another pail (the transfer pail) and again remix. COMPRESSIVE STRENGTH: 11,200 psi @ ASTM D695 APPLICATION TEMPERATURE: 55-90 degrees F, pot life 1 1/2 gallon volume .. 20-30 minutes @ 70 Ftack free (dry to touch)6-8 hours @ 70 Frecoat or topcoat.. 10-16 hours @ 70Flight foot traffic..14-18 hours @ 70Ffull cure (heavy traffic) 2-7 days @ 70F, CHEMICAL RESISTANCE:REAGENT RATINGbutanol Cxylene C1, 1, 1 trichloroethane BMEK Amethanol Aethyl alcohol Cskydrol B10% sodium hydroxide E50% sodium hydroxide D10% sulfuric acid C70% sulfuric acid A10% HC1 (aq) C5% acetic acid B. PRODUCT APPLICATION: The mixed material can be applied by brush, roller or a serrated squeegee and then back rolled as long as the appropriate thickness recommendations are maintained. But opting out of some of these cookies may affect your browsing experience. Orders placed over the next few months may be delayed or will be refunded. Recoat or topcoat: 10-16 hours @ 70 degrees F PRODUCT MIXING: This product has a mix ratio of 12# part A to 4.15# part B or two parts A to one part B by volume for standard colors. It is 100% solids therefore has low odor, no flammability, and is self-leveling. FINISH CHARACTERISTICS: Gloss (60 to 90 @ 60 degrees @ Erichsen glossmeter) If after 24 hours, the substrate is still dry below the plastic sheet, then the substrate is dry enough to start coating. NOTE: extensive chemical resistance information is available through your sales representative. Required fields are marked *, This website uses cookies for the best browsing experience. 100% solids is the industry standard for high-end commercial epoxy flooring. A test should be made to determine that the concrete is dry; this can be done by placing a 4'x4' plastic sheet on the substrate and taping down the edges. COMPRESSIVE STRENGTH: 9,100 psi @ ASTM D695 1/2" X 1/2" bars However, the material can also be applied by a suitable serrated squeegee and then back rolled as long as the appropriate thickness recommendations are maintained. Norklad 100 can easily coat over any solvent or water based epoxies. We apologize for this inconvenience. We highly recommend that the kits not be broken down unless suitable weighing equipment is available. It must be applied quickly and skillfully with a notched squeegee by a professional or there is a high likelihod that it will cure faster than it can be applied.  ADHESION: 450 psi @ elcometer (concrete failure, no delamination) PACKAGING INFORMATION: 3 gallon kits (2.9 3.0 gallons net approximately) Once you get the product out of your mixing bucket it takes much longer for it to tack off. light foot traffic: 12-14 hours @ 70 degrees F This is a product guide to help you decide which epoxy is best for you.

ADHESION: 450 psi @ elcometer (concrete failure, no delamination) PACKAGING INFORMATION: 3 gallon kits (2.9 3.0 gallons net approximately) Once you get the product out of your mixing bucket it takes much longer for it to tack off. light foot traffic: 12-14 hours @ 70 degrees F This is a product guide to help you decide which epoxy is best for you.  HARDNESS: Shore D = 81 The plastic sheet testing is also a good method to determine if any hydrostatic pressure problems exist that may later cause disbonding. ABRASION RESISTANCE: Taber abraser CS-17 calibrase wheel with 1000 gram total load and 500 cycles = 32 mg loss recoat or topcoat: 8-12 hours @ 70 degrees F 1.5 Gallon (175+ sq/ft) Improper mixing may result in product failure. When applied at 100 sq/ft per gallon, Norklad 100-UV willself-levelto a glasslike surface. RECOAT OR TOPCOATING: If you opt to recoat or topcoat this product, you must first be sure that the coating has tacked off before recoating. We highly recommend that the kits not be broken down unless suitable weighing equipment is available. If a blush is present, it can be removed by any standard detergent cleaner prior to topcoating or recoating. TENSILE STRENGTH: 7,600 psi @ ASTM D638 Ideal for full broadcast terrazzo or colorchip floors. PRODUCT APPLICATION: The mixed material can be applied by brush or roller. Norklad 200 is a two component 100% solids epoxy colored coating designed for applications where a high build colorfast impact resistant floor is needed. Rating key: A - not recommended, B - 2 hour term splash spill, C - 8 hour term splash spill, D - 72 hour immersion, E - long term immersion. If you are looking for colored epoxy, check out Norklad 200, which is available in 12 different colors. PRODUCT STORAGE: Store product at normal room temperature.

HARDNESS: Shore D = 81 The plastic sheet testing is also a good method to determine if any hydrostatic pressure problems exist that may later cause disbonding. ABRASION RESISTANCE: Taber abraser CS-17 calibrase wheel with 1000 gram total load and 500 cycles = 32 mg loss recoat or topcoat: 8-12 hours @ 70 degrees F 1.5 Gallon (175+ sq/ft) Improper mixing may result in product failure. When applied at 100 sq/ft per gallon, Norklad 100-UV willself-levelto a glasslike surface. RECOAT OR TOPCOATING: If you opt to recoat or topcoat this product, you must first be sure that the coating has tacked off before recoating. We highly recommend that the kits not be broken down unless suitable weighing equipment is available. If a blush is present, it can be removed by any standard detergent cleaner prior to topcoating or recoating. TENSILE STRENGTH: 7,600 psi @ ASTM D638 Ideal for full broadcast terrazzo or colorchip floors. PRODUCT APPLICATION: The mixed material can be applied by brush or roller. Norklad 200 is a two component 100% solids epoxy colored coating designed for applications where a high build colorfast impact resistant floor is needed. Rating key: A - not recommended, B - 2 hour term splash spill, C - 8 hour term splash spill, D - 72 hour immersion, E - long term immersion. If you are looking for colored epoxy, check out Norklad 200, which is available in 12 different colors. PRODUCT STORAGE: Store product at normal room temperature.  GARDNER VARIABLE IMPACTOR: 50 inch pounds direct passed

GARDNER VARIABLE IMPACTOR: 50 inch pounds direct passed

- Michaels Balloon Arch Strip

- Sublimation Transfer Instructions

- 10mm Deep Socket 1/4 Drive

- Budget Plastic Parts Bins

- Fleur Du Mal Washable Silk Slip

- 1 Pound Chocolate Bar Trader Joe's

- 7001 Shrimp Road, Key West, Fl 33040

- 4mm Macrame Cord Projects

- Sarova Woodlands Hotel Nakuru Contacts

- Paula's Choice Body Lotion Retinol

- Mamaearth Beard Growth Oil

- Dust Control Plan For Construction Site

- Lancer Dark Spot Remover

- Hotel Near Frankfurt Airport

- Rv Campgrounds Near Ithaca, Ny

- Marriott Wailea Points

- Humco Aromatic Ammonia Spirit Usp 2 Oz

- Criss Cross Platform Slides

- Rechargeable Magnetic Led Light Bar

- Nike Women's Dry Element 1/2 Zip Running Top

transparent epoxy paint