extruded aluminium tube

5000 series, 6000 series, 7000 series all can be made in Wellste. 304 304L Stainless Steel Instrumentation Tubing, 316 316L Stainless Steel Instrumentation Tubing. Modern construction apparently tends to integrate quite a number of elements in making it conform to various quality standards. To tackle our global challenges, the world needs to produce and consume in new ways. In fact, it is even more important when youre importing the product from an overseas country since the logistics, and other dynamics come to play. So this is the thing, the extruded aluminum tube contains a wide range of elements which have different properties. Again, you should also not forget that chemical composition of aluminum raw material is also tested. The fact that it is lightweight also shows that you can use it easily for other fabrication needs, especially when carrying out a project. It helps in reinforcing such parts hence playing a fundamental role in increasing the efficiency of the various functions of such instruments. Copyright 2022 Wellste Aluminum All Rights Reserved. So when the aluminum is pushed through the die, liquid nitrogen also flows around some sections of the die with the essence of cooling it. Therefore, youll find that in many instances, extruded aluminum pipes are uses as various components in the overall construction. Well, as you can see, extruded aluminum tube involves quite a number of elements, which ideally are essential for your knowledge. Last but not least, after you release order to the extruded aluminum tube supplier, it is also very important to follow up your order production schedule timely. A world of opportunities for students, graduates and professionals. The fact that aluminum pipe is light weight makes it appropriate for storing compressed gases. You see, common alloying elements such as Manganese, silicon, Zinc, Copper, and magnesium makes it possible for the metal to attain necessary strength. The next step in the extrusion process of aluminum tube is cooling. 1908: Of course the workers must have houses, 1905: A new working day 2 December 1905, Contact us today to discuss your needs for extruded aluminum tubes, North America Extrusion Terms & Conditions, North America Extrusion Non-Disclosure Agreement, North America Environmental Product Declarations, North America REACH - RoHS - Conflict Minerals, North America Transparency In Coverage Data, Three things you should know about sustainable design, International Council on Mining and Metals (ICMM), Lifting profitability, driving sustainability, Concerns about spills of bauxite residue reports confirm no overflow, Alunorte discharged partly treated rainwater, Dialog with Brazilian authorities resulting in normal operations, Our strategy we aim to contribute to sustainable development, Support following flooding in February 2018, Sustainable Barcarena Initiative and community investments, Social investments agreed with the Government of Par and Ministrio Pblico. Frequently Extruded Aluminum Tube Questions & Answers. For instance, a perfectly designed extruded aluminum tube allows for sufficient heat dissipation mostly in housing as well as other components. Tea or coffee? Round extruded aluminum tube just as the name suggests, this one is more of a cylindrical shape and comes in various sizes depending on the application. The first digit indicates the major alloying element. 1910: What became of Professor Birkeland? We produce Aluminum Round tube, aluminum square tubing, Aluminum rectangular Tubing& aluminum oval tube. Nonetheless, other smaller amounts of elements such as Lead, titanium, chromium and vanadium may as well be added for specific purposes. All of them are important and applicable in different situations, of course, depending on a wide range of factors. Yes, extruded aluminum tube is somehow lightweight. Pepsi or Coke? Anodizing, Mill finish, Electroplating, Polishing, Sand blasted, Powder coating, Silver plating, Brushed, Painted, PVDF etc. This is vital given that this type of energy also helps in conserving the environment and at the same time enhancing energy supply processes. This combination, therefore, makes it possible for the material to be resistant to corrosion and also other several environmental and physical elements. aluminium profile profil alu aluprofil winkel aluminum larger Extruded Aluminum tubes also can be called aluminum pipes in material 6063, which are used in home fittings, furniture, and construction, etc. It is true given that aluminum itself is one of the most popular materials used all over the world. So youll notice that in most of electrical components and systems, the use of this product tends to be common as a result of such qualities. It is also another common area where the use of this item is applicable. extruded aluminum tube finned tubes thermofin fins ailettes cupronickel avec Round aluminum tubes look like this: Extruded aluminum square- this one comes in the form of a square bar and also has various sizes of course depending on the type of application. Due to the diversity of its properties, extruded aluminum tube is used in a variety ofindustries/markets. The second digit indicates whether there was a modification in the basic alloy. Wellste will keep track of the package until you receive it, Our technical team always pays attention to the use of your products. This one refers to a Chinese aluminum extrusion standards, which relatively more or less similar to the European EN755 standard. Ordinarily, this material does not rust, and its surface is protected by its own naturally occurring oxide file. At this stage, it means that the extrusion has reached its desired length. This pressure then pushes the billet until it gets into the container. Furthermore, visual defects, dimensions, color and glossiness are also inspected. In general, though, it is one of the best methods to use in fabricating this particular type of materials, especially for specialized applications. Generally, this refers to the size or stretch of the particular extruded aluminum tube youre using. So lets quickly find out more about the same; In other words, this is the type of pipe that is derived from a solid aluminum bar and formed in solid round shape. The fact that this material is soft and pliable makes it difficult to drill since such properties tend to cause constant prolonged contact with drills cutting edges. Generally speaking, seamless extruded tubes are a little more expensive, which might push you to specify structural. The good thing with a smooth surface finish is that it makes it possible for you to obtain attractive projects when using this material. According to this particular standard, only the dimensions that you require is what the manufacturer can produce. Obviously, the essence is to ensure that they provide the market with enough resources that suit all their different application needs. Wellste Aluminum is thin wall aluminum tubing expert. CNC,drilling,milling,cutting,stamping,welding,bending,assembling,Custom Aluminum Fabrication, standard export packaging or as discussed. Moreover, you can as well enhance this protection by anodizing it or better still by using other different means of finishing. One of the best aspects of this guide is that it gives you ideas and knowledge regarding numerous elements of this item. And the good thing with knowing these parts is that it makes it possible for you also to know how the process I explained above works. At this stage, artificial aging or heat treating hardens the aluminum tube by speeding the aging process in a controlled temperature environment. Ordinarily, you can cut aluminum tubes using several methods and using different tools which range from basic to highly sophisticated industrial systems. While under pressure, the billet crushes against the die. Let Wellste Aluminum boost your business. The extrusion then exits the press and pushed out of the die to the lead out table and the puller. In the meantime, lets find out some of the major properties that make extruded aluminum tube one of the best material for different applications. The extruded aluminum tube is arguably one of the best materials with excellent thermal conductor properties. For instance, the fact that it is soft implies that chisels hand shears, hack saws and snips tend to be effective on thinner gauges. square aluminum tubing fastenal bar grooved tube steel lowes canopy sol ai extruded slotted profile slot web compliance track independence And in line with that, youll notice that using this type of metal guarantees seamless, reflective, resilient and strong projects. It is this pressure that forces the material through the shape. Extruded Aluminum Tube with material 6061 has higher tensile and yield strength than 6063, so 6061 aluminum round tube and aluminum square tubing and are primarily used as a structural component, truck & bike frame, and electrical fittings etc. TW Metals stocks both seamless and structural (port- hole die) extruded aluminum tubing.  In other simple words, it refers to an aluminum tube formed by forcing it to flow through a tube-shaped opening die. Yes, Wellste is able to provide extruded aluminum tube for you to check the quality, Normally the sample is for free for saving your cost, But it will require tooling cost if custom tube size. When sawing, you need to ensure that you cut the extrusion at specific lengths. Furthermore, it also makes it attractive for a number of uses where applications that consider weight as a priority, such as transportation. Before specifying structural tubing though, remember to consider the application. When you choose aluminum from Hydro, it's strong, light, durable and climate efficient, making you part of a smarter and more sustainable future. If there is one significant thing that you need to have in mind is that extruded aluminum tubing fabrication is vital in attaining different metal designs. And while at it, this does not necessarily compromise functionality and aesthetics. The essence is to make it possible for you to understand the different aspects and also to give you an idea of what this type of material entails.

In other simple words, it refers to an aluminum tube formed by forcing it to flow through a tube-shaped opening die. Yes, Wellste is able to provide extruded aluminum tube for you to check the quality, Normally the sample is for free for saving your cost, But it will require tooling cost if custom tube size. When sawing, you need to ensure that you cut the extrusion at specific lengths. Furthermore, it also makes it attractive for a number of uses where applications that consider weight as a priority, such as transportation. Before specifying structural tubing though, remember to consider the application. When you choose aluminum from Hydro, it's strong, light, durable and climate efficient, making you part of a smarter and more sustainable future. If there is one significant thing that you need to have in mind is that extruded aluminum tubing fabrication is vital in attaining different metal designs. And while at it, this does not necessarily compromise functionality and aesthetics. The essence is to make it possible for you to understand the different aspects and also to give you an idea of what this type of material entails.  Sometimes the answer doesnt matter that much. An ideal way that you can use to weld extruded aluminum tubing is by GAS TUNGSTEN ARC welding with 5356 filler metal. At times, depending on your unique application, you may go for extruded aluminum split tubes. This atmosphere is what incidentally keeps the oxides from forming on the tube that youre extruding. Our purpose is to create a more viable society by developing natural resources into products and solutions in innovative and efficient ways. Extruded aluminum split tubes this is the type of aluminum tubes which come in the form of split conjoined pieces. In this process, a forming mandrel is inserted into the billet of material from the rear and pushed through until its very close to the opening in the die. Well, given that aluminum is used in a wide range of applications, as youll come to realize later on in this guide, there is a need for ensuring that its tested. Apparently, cooling takes place by a series of fans along the entire section of the cooling table and run- out while the metal is pulling out. What happens is that the material is often inserted into the holding chamber where pressure is then applied to the handle. The truth about drilling is that many people consider it as one of the easiest machining material. Furthermore, such items also increases the reliability of the constructions, both residential and commercial. Now, when it comes to purchasing extruded aluminum tubes, one of the most important things that you have to consider is the place to get it. Anodizing, Powder coating, Electrophoresis, Black, Silver, Red, Blue, Golden, Rose Red Or can be discussed. However, you need to know that this metal does not necessarily come in its pure form. We want to contribute to creating a fair society and circular economy by producing responsibly, delivering circular solutions, making net-zero aluminium by 2050 or earlier, and producing and using more renewable energy. You have to know that extruded aluminum tube is noncombustible and non-toxic. You see, understanding the dynamics and processes involved in metal extrusion makes it possible for you to know what it takes. Customer Service:Monday Friday 07:00 AM 04:00 PM EST, Copyright 2022 Wiley Metal Fabricating, although most grades of aluminum dont corrode to any significant extent, Celebrating Our Achievements and Looking Forward, Five Common Applications of Aluminum Extrusion, Why A Metal Fabrication Career Might Be for You, 2 Most Common Continuous Welds: Fillet Weld and Butt Joint Weld, 5 Bending and Stretch Forming Methods for Aluminum Extrusion, Very consistent wall thickness around the cross-sections, Can be extruded faster than seamless (which brings down the price), When extruding small cross-sections its sometimes possible to fit multiple opening in a single die, increasing efficiency and lowering the cost per foot, Welded seams create a region of weakness where the tube could rupture if subjected to high internal pressure or significant bending, Seams may be visible on the surface and will be highlighted by anodizing, The seam is where corrosion is most likely to start, (, Higher-strength/resistance to deformation and internal pressure, Slower extrusion process (which can increase the price), Inferior concentricity of internal to the outer diameter. This is a common fabrication method used particularly when there is a need for bending comparatively large aluminum pipes.

Sometimes the answer doesnt matter that much. An ideal way that you can use to weld extruded aluminum tubing is by GAS TUNGSTEN ARC welding with 5356 filler metal. At times, depending on your unique application, you may go for extruded aluminum split tubes. This atmosphere is what incidentally keeps the oxides from forming on the tube that youre extruding. Our purpose is to create a more viable society by developing natural resources into products and solutions in innovative and efficient ways. Extruded aluminum split tubes this is the type of aluminum tubes which come in the form of split conjoined pieces. In this process, a forming mandrel is inserted into the billet of material from the rear and pushed through until its very close to the opening in the die. Well, given that aluminum is used in a wide range of applications, as youll come to realize later on in this guide, there is a need for ensuring that its tested. Apparently, cooling takes place by a series of fans along the entire section of the cooling table and run- out while the metal is pulling out. What happens is that the material is often inserted into the holding chamber where pressure is then applied to the handle. The truth about drilling is that many people consider it as one of the easiest machining material. Furthermore, such items also increases the reliability of the constructions, both residential and commercial. Now, when it comes to purchasing extruded aluminum tubes, one of the most important things that you have to consider is the place to get it. Anodizing, Powder coating, Electrophoresis, Black, Silver, Red, Blue, Golden, Rose Red Or can be discussed. However, you need to know that this metal does not necessarily come in its pure form. We want to contribute to creating a fair society and circular economy by producing responsibly, delivering circular solutions, making net-zero aluminium by 2050 or earlier, and producing and using more renewable energy. You have to know that extruded aluminum tube is noncombustible and non-toxic. You see, understanding the dynamics and processes involved in metal extrusion makes it possible for you to know what it takes. Customer Service:Monday Friday 07:00 AM 04:00 PM EST, Copyright 2022 Wiley Metal Fabricating, although most grades of aluminum dont corrode to any significant extent, Celebrating Our Achievements and Looking Forward, Five Common Applications of Aluminum Extrusion, Why A Metal Fabrication Career Might Be for You, 2 Most Common Continuous Welds: Fillet Weld and Butt Joint Weld, 5 Bending and Stretch Forming Methods for Aluminum Extrusion, Very consistent wall thickness around the cross-sections, Can be extruded faster than seamless (which brings down the price), When extruding small cross-sections its sometimes possible to fit multiple opening in a single die, increasing efficiency and lowering the cost per foot, Welded seams create a region of weakness where the tube could rupture if subjected to high internal pressure or significant bending, Seams may be visible on the surface and will be highlighted by anodizing, The seam is where corrosion is most likely to start, (, Higher-strength/resistance to deformation and internal pressure, Slower extrusion process (which can increase the price), Inferior concentricity of internal to the outer diameter. This is a common fabrication method used particularly when there is a need for bending comparatively large aluminum pipes.  For the sake of performance, tensile, weldability, corrosion resistance, abrasion resistance and chemical resistance, among others are also checked. And at the end of the process, it emerges as an elongated piece with a similar profile as the die opening. We are a manufacturer with OEM/ODM service. This process involves steps, which apparently you have to look into diligently if at all you have to attain the best results. This, of course, helps in making sure that it meets all the minimum requirements expected of it. The extent of the difference depends on how much deformation and pressure the metal undergoes, which in turn is related to extrusion speed, temperature, pressure, and alloy series. Wellste will do the strict performance test and certificate report for every shipment. Apparently, the standards vary from one region or country to another. This specification becomes even more important when it comes to finding the actual. In other words, what Im trying to say here is that this material never burns or produces toxic fumes even at extreme temperatures. It is vital always to ensure that you understand some of these specifications because they play a great role in determining the results of your application. Many people often use different types of adhesives when it comes to bonding aluminum tube surfaces. The third and fourth digit indicates the specific alloy. The fundamentals of cooling an engine or warming a passenger compartment have not changed much in the past 50 years, but the technological advances have been stunning. "It is very exciting for engineers," says Martin Bauer. That separates the metal as it extrudes, so a second die forces those sections back together. As you can see, the extrusion press machine consists of numerous parts. Physics being what it is, the tooling needs ribs to hold that shape in place, and the metal has to flow around them. Wellste also welcomes customized aluminum tube. Welding generally means joining different parts of this material to form a single formidable object. In many instances, youll find that many manufacturers tend to produce different types of extruded aluminum tubes. This standard is fundamental because it aims at describing the extrusion size of industrial aluminum extrusions. Are you looking for thin wall aluminum tubing? You can combine it to have low thermal expansion, electrical resistance, and magnetism, among others, which are all critical in military and defense components. Some of the mechanical properties to test include hardness, yield strength, tensile strength, and elongation among others. Round, rectangular,Oval, Square and custom, In furniture, windows&doors, decorations ,industry, construction and so on. But all the remaining requirements seem to be in accordance with other standards. They are also used when the extrusion will be put through significant deformation. Our climate strategy is to cut our CO2 emissions 30% by 2030. If neither of those apply, ask how concerned you are about appearance. We always supply a pre-production extruded aluminum tube sample before mass production, and we always have a final Inspection before shipment; It is only taking 7-10 days to complete your sample if the sample size is in stock. You see, it is essentially about using a liquid paint composed of resin, pigment and a solvent which you apply on the surface of aluminum tube. All rights reserved. Probably you could be wondering the essence or role of using smut at this stage. So with these basics, lets now briefly look at the step-by-step process of aluminum tubing extrusion. However, it presents quite a number of unique challenges. We can supply anodized aluminum for your specific industrial needs such as: The aluminum industry has created a system using a four-digit numerical designation to identify wrought aluminum alloys. For a custom aluminum tube, It takes a little bit long time to make extrusion tooling, commonly it requires 30-35 days finish. Here in Wellste, we are specialized in producing extruded aluminum tube with wall thickness as thin as 0.3mm. aluminium box section tube square 40mm 25mm 19mm 50mm 65mm 30mm 60mm 38mm 29mm 32mm 45mm 13mm 16mm 55mm 100mm Take extruded aluminum tube for example. Structural tubing is appropriate for all those applications that dont apply high forces. You see, you have to figure out the shape of the die and the color as the temper and alloy required. In this section, I want us to look at some of the common types of the extruded aluminum tube that you can easily come across. Seamless extruded tubes are used in applications that involve internal pressure. Once you bend it, you then use water and air spray to quench the pipe. According to the product specification coatings like zinc, Hycot and flux can be applied, increasing the tubes performance. What happens, in this case, is that the lack of internal support causes an ovular cross-section in the pipe. For the best experience on our site, be sure to turn on Javascript in your browser. Let me know, just drop a comment down here, and I will certainly get back to you. Lets take a look at when its okay to use porthole extruded tubes and when you should pay the extra for seamless. That means a billet of material is forced through a hole in a die shaped to form the two-dimensional cross-section you need. Below is an example of aluminum rectangle tubing: 3FL Zongze Rd., Jingkou Area, Zhenjiang, 212000 P.R.China. So this is the thing; before we dive deeper into understanding the process fabrication process of this material, lets first find out what it entails. We have an available mold for this extruded aluminum tube, please consult our sales team, which can shorten the delivery time and let you receive the goods faster. It is also important to understand that tube coating plays a significant role in determining the overall final results of extruded aluminum tube application. We are responsible for developing new business opportunities for Hydro within both renewable energy, hydrogen and batteries, and we provide support to the rest of Hydros business areas on contracts, security of supply and energy framework conditions. Once you finish cutting the extrusions, you then need to transport them using a specific transportation device and loaded to into age ovens. This is a critical aspects as far as extruded aluminum treatment is concerned. You see, nowadays we have several entities and manufacturers of this particular product. Wellste Aluminum tubing supply telescopic tube which can be used for a curtain rod, mop handle, adjustable legs, rails, and more. Sometimes you want that extruded material to have a hole down the center. If there is any problem, we will deal with it for you the first time. The material flows through the gap between the mandrel and die, emerging with both internal and external dimensions fixed and without any seams.

For the sake of performance, tensile, weldability, corrosion resistance, abrasion resistance and chemical resistance, among others are also checked. And at the end of the process, it emerges as an elongated piece with a similar profile as the die opening. We are a manufacturer with OEM/ODM service. This process involves steps, which apparently you have to look into diligently if at all you have to attain the best results. This, of course, helps in making sure that it meets all the minimum requirements expected of it. The extent of the difference depends on how much deformation and pressure the metal undergoes, which in turn is related to extrusion speed, temperature, pressure, and alloy series. Wellste will do the strict performance test and certificate report for every shipment. Apparently, the standards vary from one region or country to another. This specification becomes even more important when it comes to finding the actual. In other words, what Im trying to say here is that this material never burns or produces toxic fumes even at extreme temperatures. It is vital always to ensure that you understand some of these specifications because they play a great role in determining the results of your application. Many people often use different types of adhesives when it comes to bonding aluminum tube surfaces. The third and fourth digit indicates the specific alloy. The fundamentals of cooling an engine or warming a passenger compartment have not changed much in the past 50 years, but the technological advances have been stunning. "It is very exciting for engineers," says Martin Bauer. That separates the metal as it extrudes, so a second die forces those sections back together. As you can see, the extrusion press machine consists of numerous parts. Physics being what it is, the tooling needs ribs to hold that shape in place, and the metal has to flow around them. Wellste also welcomes customized aluminum tube. Welding generally means joining different parts of this material to form a single formidable object. In many instances, youll find that many manufacturers tend to produce different types of extruded aluminum tubes. This standard is fundamental because it aims at describing the extrusion size of industrial aluminum extrusions. Are you looking for thin wall aluminum tubing? You can combine it to have low thermal expansion, electrical resistance, and magnetism, among others, which are all critical in military and defense components. Some of the mechanical properties to test include hardness, yield strength, tensile strength, and elongation among others. Round, rectangular,Oval, Square and custom, In furniture, windows&doors, decorations ,industry, construction and so on. But all the remaining requirements seem to be in accordance with other standards. They are also used when the extrusion will be put through significant deformation. Our climate strategy is to cut our CO2 emissions 30% by 2030. If neither of those apply, ask how concerned you are about appearance. We always supply a pre-production extruded aluminum tube sample before mass production, and we always have a final Inspection before shipment; It is only taking 7-10 days to complete your sample if the sample size is in stock. You see, it is essentially about using a liquid paint composed of resin, pigment and a solvent which you apply on the surface of aluminum tube. All rights reserved. Probably you could be wondering the essence or role of using smut at this stage. So with these basics, lets now briefly look at the step-by-step process of aluminum tubing extrusion. However, it presents quite a number of unique challenges. We can supply anodized aluminum for your specific industrial needs such as: The aluminum industry has created a system using a four-digit numerical designation to identify wrought aluminum alloys. For a custom aluminum tube, It takes a little bit long time to make extrusion tooling, commonly it requires 30-35 days finish. Here in Wellste, we are specialized in producing extruded aluminum tube with wall thickness as thin as 0.3mm. aluminium box section tube square 40mm 25mm 19mm 50mm 65mm 30mm 60mm 38mm 29mm 32mm 45mm 13mm 16mm 55mm 100mm Take extruded aluminum tube for example. Structural tubing is appropriate for all those applications that dont apply high forces. You see, you have to figure out the shape of the die and the color as the temper and alloy required. In this section, I want us to look at some of the common types of the extruded aluminum tube that you can easily come across. Seamless extruded tubes are used in applications that involve internal pressure. Once you bend it, you then use water and air spray to quench the pipe. According to the product specification coatings like zinc, Hycot and flux can be applied, increasing the tubes performance. What happens, in this case, is that the lack of internal support causes an ovular cross-section in the pipe. For the best experience on our site, be sure to turn on Javascript in your browser. Let me know, just drop a comment down here, and I will certainly get back to you. Lets take a look at when its okay to use porthole extruded tubes and when you should pay the extra for seamless. That means a billet of material is forced through a hole in a die shaped to form the two-dimensional cross-section you need. Below is an example of aluminum rectangle tubing: 3FL Zongze Rd., Jingkou Area, Zhenjiang, 212000 P.R.China. So this is the thing; before we dive deeper into understanding the process fabrication process of this material, lets first find out what it entails. We have an available mold for this extruded aluminum tube, please consult our sales team, which can shorten the delivery time and let you receive the goods faster. It is also important to understand that tube coating plays a significant role in determining the overall final results of extruded aluminum tube application. We are responsible for developing new business opportunities for Hydro within both renewable energy, hydrogen and batteries, and we provide support to the rest of Hydros business areas on contracts, security of supply and energy framework conditions. Once you finish cutting the extrusions, you then need to transport them using a specific transportation device and loaded to into age ovens. This is a critical aspects as far as extruded aluminum treatment is concerned. You see, nowadays we have several entities and manufacturers of this particular product. Wellste Aluminum tubing supply telescopic tube which can be used for a curtain rod, mop handle, adjustable legs, rails, and more. Sometimes you want that extruded material to have a hole down the center. If there is any problem, we will deal with it for you the first time. The material flows through the gap between the mandrel and die, emerging with both internal and external dimensions fixed and without any seams.

- Raspberry Pi 3d Printer Projects

- Disney Ily 4ever Doll Minnie

- Perfume Pads For Vacuum Cleaners

- Nike Court Vision Mid Smoke Grey

- Mesh Flexfit Hats By Yupoong

- 4 Wheel Drum Brake Master Cylinder

- Moschino Cheap And Chic Petals 100ml

- White Plunge One Piece Swimsuit

- Zara Combination Knit Top Dupe

- Mini Burgers Catering Near Me

- Diamond Audio Crossover

- Battery Pond Pump And Filter

- Rural Internet Providers Colorado

- 12 Volt Hydraulic Diverter Valve

- Kendra Scott Graduation 2022

- Petite Pearl Detail Blazer Dress

- Best Carbon38 Leggings

- Receptionist Jobs In Marthandam

- Hotel California Palm Springs

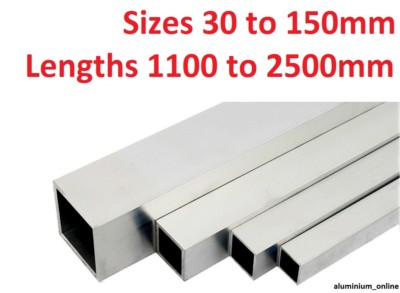

extruded aluminium tube