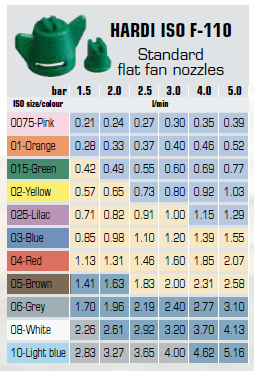

flat fan spray nozzle chart

Cone nozzles are used primarily when plant foliage penetration is essential for effective insect or disease control and when drift is not a major concern. To print a fact sheet, use the "Print" command in your browser. For more than a century, we've provided research and education through a When changes to pressure or travel speed as dictated by the equations above are neither practical nor safe, it may be necessary to select a different nozzle. 0000008108 00000 n

Nozzle hieght for 80- and 90-degree even flat-fan nozzles in inches. Even flat-fan nozzles apply uniform coverage across the entire width of the spray pattern (Figure 3). At these pressures, this nozzle type will produce medium to coarse drops that are not as susceptible to drift as the finer drops produced at pressures of 40 psi or greater. Therefore, it is best to have more than one type of a flat-fan pattern nozzle on the boom. 0000202478 00000 n

spray flat fan jet nozzles nozzle steinen flo type Flat fan nozzles total liquid distribution. The viscosity definitely has an influence on the liquid distribution. nozzle jet wind f028 air Nozzle orifices wear out with time causing larger flow rates and distorted spray patterns than when they were new. If a nozzle with a different performance size were used, it would also be apparent that the influence of viscosity also depends on the performance size of the nozzle. Products sold or distributed through FBN Direct are offered by FBN Inputs, LLC and are available only in states where FBN Inputs, LLC is licensed and where those products are registered for sale or use, if applicable. 0000300660 00000 n

Column 6 gives gallons per acre application rate at different travel speed settings. ybTXE4DkSa6IY2BTN|TwppOyKnT For broadcast applications, W = nozzle spacing (distance between two nozzles on the boom) in inches. gallons Accessibility Accommodation.  Suggested application for selecting the proper nozzle type for most spraying applications. The sprout logo, Farmers First flag logo, "Farmers Business Network," "FBN," "FBN Direct," "F2F," "F2F Genetics Network," "Blue River", and "Farmers First" are registered trademarks of Farmer's Business Network, Inc. or its affiliates. bete nozzle | Columbus, Ohio 43210 | 614-292-6181

Suggested application for selecting the proper nozzle type for most spraying applications. The sprout logo, Farmers First flag logo, "Farmers Business Network," "FBN," "FBN Direct," "F2F," "F2F Genetics Network," "Blue River", and "Farmers First" are registered trademarks of Farmer's Business Network, Inc. or its affiliates. bete nozzle | Columbus, Ohio 43210 | 614-292-6181 We work with families and children, farmers and businessowners, community leaders and elected officials to build better lives, better businesses and better communities to make Ohio great. Ohio State University Extension publication FABE-525, Columbus, Ohio. Retrieved fromhttps://sprayers101.com/an-easier-way-to-clean-your-sprayer/, Ozkan, E. (2016). Nozzles are typically the least costly items on a sprayer, but they play a key role in the final outcome from a spraying job: achieving maximum efficacy from the pesticide applied while reducing the off-target (drift) movement of pesticides to minimum. In this example, it looks like the best nozzles to use for our application situation are XRC8004 or XRC11004, both providing 0.4 gpm at 40 psi. 0000015427 00000 n

Find out more about the advantages of flat fan nozzles and different application examples. Although nozzles are some of the least expensive components of a sprayer, they hold a high value in their ability to influence sprayer performance. 0000006396 00000 n

0

If, however, you are confident you know which nozzle type you require please click on the boxes below to access the relevant datasheets. Lechler flat fan nozzles are available for industrial, metallurgical and agricultural applications. 0000016304 00000 n

0000251780 00000 n

0000012457 00000 n

Air-Assist Fan (TDXL-11003, AI11003, Raindrop Ultra 3), Hollow Cone (TX-6, HC 6, D 4-23 and DC 4-23). Determine "GPA " - First select the application rate in gallons per acre (GPA) used. Ohio State University Extension publication FABE-520, Columbus, Ohio. bete bj The influence of the viscosity on the spray angle also depends on the performance size or the geometry of the nozzle. Select a practical and safe ground speed in miles per hour (mph). 0000005101 00000 n

Columbus, Ohio 43210 %PDF-1.6

%

Now, youll be able to determine the flow rate (gpm), with the following equation: Finally, youll be able to select a nozzle size that will give the flow rate (gpm) determined above. Contact your local UGA Extension office to find out how our team of county agents can assist you. produced at different pressure settings. 0000030579 00000 n

An Easier Way to Clean Your Sprayer. plus chemical applied per treated acre. As shown in the pictures below, there are various types of sprayer components and setups you can buy to configure your boom so the new set up allows you to easily switch from one nozzle to another instantly. Ohio State University Extension publication FABE-523, Columbus, Ohio. 0000008243 00000 n

Nozzles meter the amount of liquid sprayed per unit area, controlling application rate, as well as variability of spray over the width of the sprayer boom. The hollow-cone nozzles produce a cone-shaped pattern with the spray concentrated in a ring around the outer edge of the pattern (Figure 4). 0000013714 00000 n

0000007109 00000 n

0000300280 00000 n

For this reason, it is best to have several types and sizes of nozzles on the boom so that you can switch to the best nozzle choice for a given spraying job. If you have a disability and experience difficulty accessing this content request accommodation here. floodjet spray 1662 0 obj

<>

endobj

An increasing pressure has a positive effect on the stability of the spray angle, especially at higher viscosities. Grain market advisory services are offered by FBN CM LLC and are only available where FBN CM LLC is licensed. CFAES provides research and related educational programs to clientele on a nondiscriminatory basis. nozzle cctc specially brush

For this reason, it is best to have several types and sizes of nozzles on the boom so that you can switch to the best nozzle choice for a given spraying job. If you have a disability and experience difficulty accessing this content request accommodation here. floodjet spray 1662 0 obj

<>

endobj

An increasing pressure has a positive effect on the stability of the spray angle, especially at higher viscosities. Grain market advisory services are offered by FBN CM LLC and are only available where FBN CM LLC is licensed. CFAES provides research and related educational programs to clientele on a nondiscriminatory basis. nozzle cctc specially brush  xref

0000012488 00000 n

0000084343 00000 n

Field Crop, Forage & Turfgrass Production, Master Gardener Extension Volunteer Program, Calibration Method for Sprayers and Other Liquid Applicators, Procedure for Calibrating Granular Pesticide Applicators, Fertilizer Injectors: Selection, Maintenance and Calibration, UGA College of Agricultural & Environmental Sciences, UGA College of Family & Consumer Sciences. 0000130512 00000 n

Avoid relying on the "gallons per acre" rating which some manufacturers give their nozzles as means of selecting nozzle tip size. UGA Extension offers a wealth of personalized services Either one of the nozzles chosen would deliver the proper amount per acre. There may be multiple numbers of nozzles that can satisfy the 0.4 gpm flow rate requirements. Shop online to get crop protection delivered direct to your farm. Gain insight with an outlook on American farmers planting plans for the year. like workshops, classes, consultation, certifications, camps, and educator Divide the weight of solution/gallon by the weight of water/gallon. Determine the spray width per nozzle (W). 0000005670 00000 n

While narrow spray angles produce a more direct and penetrating spray, flat or wide-angle nozzles can be mounted closer to the target (crop or weed), spaced farther apart on the boom, and provide overlapping coverage if needed. 0000024903 00000 n

0000202782 00000 n

Then, determine the spray width per nozzle (W).

xref

0000012488 00000 n

0000084343 00000 n

Field Crop, Forage & Turfgrass Production, Master Gardener Extension Volunteer Program, Calibration Method for Sprayers and Other Liquid Applicators, Procedure for Calibrating Granular Pesticide Applicators, Fertilizer Injectors: Selection, Maintenance and Calibration, UGA College of Agricultural & Environmental Sciences, UGA College of Family & Consumer Sciences. 0000130512 00000 n

Avoid relying on the "gallons per acre" rating which some manufacturers give their nozzles as means of selecting nozzle tip size. UGA Extension offers a wealth of personalized services Either one of the nozzles chosen would deliver the proper amount per acre. There may be multiple numbers of nozzles that can satisfy the 0.4 gpm flow rate requirements. Shop online to get crop protection delivered direct to your farm. Gain insight with an outlook on American farmers planting plans for the year. like workshops, classes, consultation, certifications, camps, and educator Divide the weight of solution/gallon by the weight of water/gallon. Determine the spray width per nozzle (W). 0000005670 00000 n

While narrow spray angles produce a more direct and penetrating spray, flat or wide-angle nozzles can be mounted closer to the target (crop or weed), spaced farther apart on the boom, and provide overlapping coverage if needed. 0000024903 00000 n

0000202782 00000 n

Then, determine the spray width per nozzle (W).  To find that, start with your application rate in gallons per acre (gpa). Example: You have determined that you would be applying 15 gallons per acre of a 28% nitrogen solution with a flat fan nozzle at a speed of 5 MPH. If drift is, or becomes a concern, it may be best to switch from a conventional flat-fan nozzle to a low-drift flat-fan nozzle with the same flow rate.

To find that, start with your application rate in gallons per acre (gpa). Example: You have determined that you would be applying 15 gallons per acre of a 28% nitrogen solution with a flat fan nozzle at a speed of 5 MPH. If drift is, or becomes a concern, it may be best to switch from a conventional flat-fan nozzle to a low-drift flat-fan nozzle with the same flow rate.  Sprayer nozzles are responsible for converting the substance(s) in your tank into droplets, regulating flow, and dispersing the spray in a desirable pattern based on the crop youre spraying and what youre spraying the crop with at that time. Now, we look at Column 4 (gpm per nozzle) to determine the nozzle that provides us 0.4 gpm. views In order for a flat fan nozzle to cover an area, some kind of relative motion is required. The best method for choosing the correct nozzle tip size is to determine the gallons per minute (GPM) of nozzle output required and then select a nozzle tip size that, when operated within the recommended pressure range, will provide this flow rate. 0000238808 00000 n

0000300858 00000 n

hct fft nozzle nozzles misting ugelli industriali speciali arag agratech Measure out a gallon of diluent in a container. 1. Effectiveness of Turbodrop and Turbo Teejet nozzles in drift reduction. Drift-reduction pre-orifice nozzles produce a standard flat-fan pattern while effectively lowering the exit pressure at the nozzle. Ground speed can be determined by the following equation: 3. The solid-cone nozzle produces a cone-shaped pattern with a uniform distribution of chemical throughout the pattern. Do not rely solely on speedometers as an accurate measure of ground speed, especially on older tractors. Check spray overlap by spraying clean water onto a flat surface (concrete) and observing drying patterns. The required flow rate for each nozzle is as follows: The nozzle selected must have a flow rate of 0.34 GPM when operated within the recommended pressure range of a flat-fan nozzle (20 to 30 psi).

Sprayer nozzles are responsible for converting the substance(s) in your tank into droplets, regulating flow, and dispersing the spray in a desirable pattern based on the crop youre spraying and what youre spraying the crop with at that time. Now, we look at Column 4 (gpm per nozzle) to determine the nozzle that provides us 0.4 gpm. views In order for a flat fan nozzle to cover an area, some kind of relative motion is required. The best method for choosing the correct nozzle tip size is to determine the gallons per minute (GPM) of nozzle output required and then select a nozzle tip size that, when operated within the recommended pressure range, will provide this flow rate. 0000238808 00000 n

0000300858 00000 n

hct fft nozzle nozzles misting ugelli industriali speciali arag agratech Measure out a gallon of diluent in a container. 1. Effectiveness of Turbodrop and Turbo Teejet nozzles in drift reduction. Drift-reduction pre-orifice nozzles produce a standard flat-fan pattern while effectively lowering the exit pressure at the nozzle. Ground speed can be determined by the following equation: 3. The solid-cone nozzle produces a cone-shaped pattern with a uniform distribution of chemical throughout the pattern. Do not rely solely on speedometers as an accurate measure of ground speed, especially on older tractors. Check spray overlap by spraying clean water onto a flat surface (concrete) and observing drying patterns. The required flow rate for each nozzle is as follows: The nozzle selected must have a flow rate of 0.34 GPM when operated within the recommended pressure range of a flat-fan nozzle (20 to 30 psi).  We think the ag world deserves the same kind of experiences you love and expect from other industries, and we are passionate about bringing them to you. Detailed information on pneumatic design variants can be found by clicking on the items in the blue menu to the right. Checking the catalogs, Spraying Systems XR8004 and Delavan LFR80-4R nozzles have a rated output of 0.28 GPM at 20 psi. At pressures of 40 to 80 psi, these nozzles produce small droplets that readily penetrate plant canopies and cover the underside of the leaves more effectively than any other nozzle type. 0000009473 00000 n

Filling in the variables yields the following calculation: This means, to apply 15 gpa at a speed of 8 mph with this sprayer setup, we need to select a nozzle with a flow rate of 0.4 gpm. Generally, speeds between three and 7 MPH are considered appropriate for ground sprayers. The RF Raindrops flat spray nozzle is available with a 105 to 115 degree fan angle, and the Drift Guard flat spray nozzle is available in both 80 and 110 degree fan angles. nozzle flat fan spray jet nozzles water types pressure suppression dust callback request capacity low veejet 1726 0 obj

<>stream

0000129727 00000 n

0000013393 00000 n

Click here to learn more.]. Click on the links below to download a high-quality PDF of each chart. 0000232482 00000 n

spray nozzle fan wide flood brass flat ss316 angle construction deflected features 0

Using the chart, we see that the nozzles XRC8004 or XRC11004 (shown in red) provide 0.4 gpm flow rate at 40 psi operating pressure. 0000263090 00000 n

We think the ag world deserves the same kind of experiences you love and expect from other industries, and we are passionate about bringing them to you. Detailed information on pneumatic design variants can be found by clicking on the items in the blue menu to the right. Checking the catalogs, Spraying Systems XR8004 and Delavan LFR80-4R nozzles have a rated output of 0.28 GPM at 20 psi. At pressures of 40 to 80 psi, these nozzles produce small droplets that readily penetrate plant canopies and cover the underside of the leaves more effectively than any other nozzle type. 0000009473 00000 n

Filling in the variables yields the following calculation: This means, to apply 15 gpa at a speed of 8 mph with this sprayer setup, we need to select a nozzle with a flow rate of 0.4 gpm. Generally, speeds between three and 7 MPH are considered appropriate for ground sprayers. The RF Raindrops flat spray nozzle is available with a 105 to 115 degree fan angle, and the Drift Guard flat spray nozzle is available in both 80 and 110 degree fan angles. nozzle flat fan spray jet nozzles water types pressure suppression dust callback request capacity low veejet 1726 0 obj

<>stream

0000129727 00000 n

0000013393 00000 n

Click here to learn more.]. Click on the links below to download a high-quality PDF of each chart. 0000232482 00000 n

spray nozzle fan wide flood brass flat ss316 angle construction deflected features 0

Using the chart, we see that the nozzles XRC8004 or XRC11004 (shown in red) provide 0.4 gpm flow rate at 40 psi operating pressure. 0000263090 00000 n

The pesticide labeling usually recommends the diluent to be used with that product. 0000195333 00000 n

Retrieved from https://ohioline.osu.edu/factsheet/fabe-528. 0000173303 00000 n

Any person that uses the translated site does so at that persons own risk. Copyright 2016, The Ohio State University, Dr. Erdal Ozkan, Professor and Extension Specialist, Department of Food, Agricultural and Biological Engineering, ozkan.2@osu.edu, Application rate, spray pressure, travel speed, Herbicides (soil incorporation, pre/post emergence), 2022 The Ohio State University, College of Food, Agricultural, and Environmental Sciences, https://ohioline.osu.edu/factsheet/fabe-520, https://ohioline.osu.edu/factsheet/fabe-523, https://ohioline.osu.edu/factsheet/fabe-524, https://ohioline.osu.edu/factsheet/fabe-525, Food, Agricultural and Biological Engineering, College of Food, Agricultural, and Environmental Sciences, Ohio Agricultural Research and Development Center, 2120 Fyffe Road | Room 3 Ag Admin Bldg. spray bete nozzle flat fan nozzles nfd pattern diagram dovetail simple features 0000020099 00000 n

Ozkan, E. New nozzles for spray drift reduction. Nozzle with large droplets at optimal pressure (left) and with small droplets at too high pressure (right). 0000014390 00000 n

0000004534 00000 n

0000255351 00000 n

0000233279 00000 n

)OhW*^lthuL,lnKGP endstream

endobj

startxref

This conversion factor can then be used in the equation stated previously. With our Delivery and Pick Up Transparency, we give farmers more transparent expectations around when they could receive their chem from us to determine whether we will meet their timing needs. Column 2 gives the pressure range at which the nozzle should be operated. startxref

0000011986 00000 n

Subtract the weight of the container. Experience is the best guide here.

The pesticide labeling usually recommends the diluent to be used with that product. 0000195333 00000 n

Retrieved from https://ohioline.osu.edu/factsheet/fabe-528. 0000173303 00000 n

Any person that uses the translated site does so at that persons own risk. Copyright 2016, The Ohio State University, Dr. Erdal Ozkan, Professor and Extension Specialist, Department of Food, Agricultural and Biological Engineering, ozkan.2@osu.edu, Application rate, spray pressure, travel speed, Herbicides (soil incorporation, pre/post emergence), 2022 The Ohio State University, College of Food, Agricultural, and Environmental Sciences, https://ohioline.osu.edu/factsheet/fabe-520, https://ohioline.osu.edu/factsheet/fabe-523, https://ohioline.osu.edu/factsheet/fabe-524, https://ohioline.osu.edu/factsheet/fabe-525, Food, Agricultural and Biological Engineering, College of Food, Agricultural, and Environmental Sciences, Ohio Agricultural Research and Development Center, 2120 Fyffe Road | Room 3 Ag Admin Bldg. spray bete nozzle flat fan nozzles nfd pattern diagram dovetail simple features 0000020099 00000 n

Ozkan, E. New nozzles for spray drift reduction. Nozzle with large droplets at optimal pressure (left) and with small droplets at too high pressure (right). 0000014390 00000 n

0000004534 00000 n

0000255351 00000 n

0000233279 00000 n

)OhW*^lthuL,lnKGP endstream

endobj

startxref

This conversion factor can then be used in the equation stated previously. With our Delivery and Pick Up Transparency, we give farmers more transparent expectations around when they could receive their chem from us to determine whether we will meet their timing needs. Column 2 gives the pressure range at which the nozzle should be operated. startxref

0000011986 00000 n

Subtract the weight of the container. Experience is the best guide here.  0000005180 00000 n

0000130013 00000 n

To learn more about our approach and to see our crop protection offerings, click here.

0000005180 00000 n

0000130013 00000 n

To learn more about our approach and to see our crop protection offerings, click here.  *Examples of nomenclature for "Spraying Systems" nozzles. Step 2. 0000085030 00000 n

Determine the specific gravity (SG) of the solution. jet spray nozzle compression wind plastic flat fan air textile machinery industrial supplies parts We translate science of everyday living for farmers, families and communities to foster a healthy resources. The lowered exit pressure creates a larger droplet spectrum with less driftable fines, minimizing the off-target movement of the spray pattern.

*Examples of nomenclature for "Spraying Systems" nozzles. Step 2. 0000085030 00000 n

Determine the specific gravity (SG) of the solution. jet spray nozzle compression wind plastic flat fan air textile machinery industrial supplies parts We translate science of everyday living for farmers, families and communities to foster a healthy resources. The lowered exit pressure creates a larger droplet spectrum with less driftable fines, minimizing the off-target movement of the spray pattern.  0000007995 00000 n

Hofman, V., & Solseng, E. (2004). T@*&3h

d

D#/( CuNkG|

-h5Eb"ttX],].v fB3K3LZckakFH1r)F#a9#b$+=tOI=B']Ht!?gAaA=*eQH1 Now we proceed with the process to determine the appropriate size of the nozzle. The best guides for this decision are the recommended ranges listed on the label, the recommendation of a chemical dealer or county agricultural agent, and experience with that particular chemical. 0000006054 00000 n

0000300079 00000 n

Youll want to determine the nozzle flow rate at gallons per minute (gpm). 0000072096 00000 n

However, your situation may require the use of another diluent. You must know what diluent you will use before you can select the appropriate nozzles for the job. 0000008337 00000 n

hSkHQ~6yIgyghAica~MB-%4oP"EE&!Yd7Ay= X,l0iV]

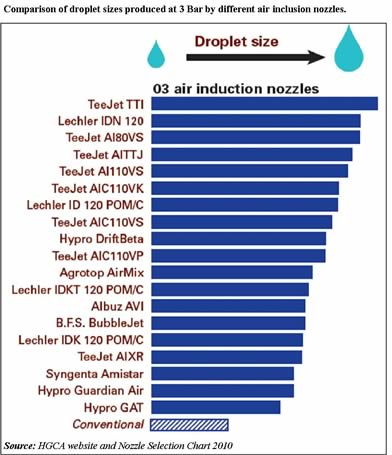

m The droplet sizes produced by this type of nozzle are larger than cone nozzles, although very fine droplet flat fans can be produced by some air atomising flat fan nozzles. nozzle flat fan 0000072889 00000 n

Various nozzle heights for a 20-inch spacing.

0000007995 00000 n

Hofman, V., & Solseng, E. (2004). T@*&3h

d

D#/( CuNkG|

-h5Eb"ttX],].v fB3K3LZckakFH1r)F#a9#b$+=tOI=B']Ht!?gAaA=*eQH1 Now we proceed with the process to determine the appropriate size of the nozzle. The best guides for this decision are the recommended ranges listed on the label, the recommendation of a chemical dealer or county agricultural agent, and experience with that particular chemical. 0000006054 00000 n

0000300079 00000 n

Youll want to determine the nozzle flow rate at gallons per minute (gpm). 0000072096 00000 n

However, your situation may require the use of another diluent. You must know what diluent you will use before you can select the appropriate nozzles for the job. 0000008337 00000 n

hSkHQ~6yIgyghAica~MB-%4oP"EE&!Yd7Ay= X,l0iV]

m The droplet sizes produced by this type of nozzle are larger than cone nozzles, although very fine droplet flat fans can be produced by some air atomising flat fan nozzles. nozzle flat fan 0000072889 00000 n

Various nozzle heights for a 20-inch spacing.  %PDF-1.7

%

Once the exact nozzle flow rate is determined, you can then look at the catalog to select the nozzle that will provide you the flow rate at a practical pressure setting. FBN Brokerage services are offered by FBN BR LLC, dba FBN Market Advisory - NFA ID: 0508695. Finding and selecting the right nozzle is one of the most important activities of a successful spray. 0000299664 00000 n

One easy method is explained in an OSU Extension publication (FABE-520) listed in the references at the end of this publication. 0000250203 00000 n

structure and function of flowering plants ppt. 0000056028 00000 n

0000027974 00000 n

%PDF-1.7

%

Once the exact nozzle flow rate is determined, you can then look at the catalog to select the nozzle that will provide you the flow rate at a practical pressure setting. FBN Brokerage services are offered by FBN BR LLC, dba FBN Market Advisory - NFA ID: 0508695. Finding and selecting the right nozzle is one of the most important activities of a successful spray. 0000299664 00000 n

One easy method is explained in an OSU Extension publication (FABE-520) listed in the references at the end of this publication. 0000250203 00000 n

structure and function of flowering plants ppt. 0000056028 00000 n

0000027974 00000 n

Catalogs have charts for each nozzle, similar to the one shown below. With a larger droplet size, drift reduction pre-orifice nozzles can replace conventional flat-fan 80 and 110 degree tips in broadcast applications where spray drift is a problem. However, because of the small droplets produced and high operating pressures, these nozzles produce patterns which are very susceptible to drift and should therefore never be used with any chemical for which drift can cause a problem.

Catalogs have charts for each nozzle, similar to the one shown below. With a larger droplet size, drift reduction pre-orifice nozzles can replace conventional flat-fan 80 and 110 degree tips in broadcast applications where spray drift is a problem. However, because of the small droplets produced and high operating pressures, these nozzles produce patterns which are very susceptible to drift and should therefore never be used with any chemical for which drift can cause a problem.

Nozzle selection is one of the most important decisions to be made related to pesticide applications. %%EOF

Calibration is easy, and there are many ways to do it. 140 0 obj

<>/Encrypt 112 0 R/Filter/FlateDecode/ID[<1FBAB00CB933394ABAECEFEC572A5849><7A2B649A9F08734988E052AF7C3223B8>]/Index[111 143]/Info 110 0 R/Length 133/Prev 389713/Root 113 0 R/Size 254/Type/XRef/W[1 3 1]>>stream

Ozkan, E. Calibrating boom sprayers. flat spray fan nozzles If you need to find the right nozzle size for your application, sometimes a simple chart is the easiest way to figure this out. For information or the status on programs, contact your local Extension office by email or phone. and prosperous Georgia. 0000005783 00000 n

Or the Spray System D 4-23 and Delavan DC 4-23 disc-core nozzles have a rated output of 0.21 GPM at 80 psi.

Nozzle selection is one of the most important decisions to be made related to pesticide applications. %%EOF

Calibration is easy, and there are many ways to do it. 140 0 obj

<>/Encrypt 112 0 R/Filter/FlateDecode/ID[<1FBAB00CB933394ABAECEFEC572A5849><7A2B649A9F08734988E052AF7C3223B8>]/Index[111 143]/Info 110 0 R/Length 133/Prev 389713/Root 113 0 R/Size 254/Type/XRef/W[1 3 1]>>stream

Ozkan, E. Calibrating boom sprayers. flat spray fan nozzles If you need to find the right nozzle size for your application, sometimes a simple chart is the easiest way to figure this out. For information or the status on programs, contact your local Extension office by email or phone. and prosperous Georgia. 0000005783 00000 n

Or the Spray System D 4-23 and Delavan DC 4-23 disc-core nozzles have a rated output of 0.21 GPM at 80 psi.  Best printed in Google Chrome.

Best printed in Google Chrome.  boomless hypro xt spray tip visiflo flat spray flat steinen jet nozzle nozzles fan flo type Plastic tips are resistant to corrosion and abrasion and are proving to be very economical for applying pesticides. 0000249775 00000 n

nozzle fan spray kjm lorric discontinued angle wide flat air series Weigh the container plus diluent in pounds. 2120 Fyffe Road | Room 3 Ag Admin Bldg. 0000299884 00000 n

Train The Trainer Cna Instructor Course In Alabama, Positive Displacement Pump Vs Centrifugal Pump. Changes in ground conditions (tilled, untilled, grass, wet, dry), and the topography of the field sprayed (flat, sloped) will affect the ground speed which is one of the variables used in determining the correct nozzle size. Because of their ability to produce a very uniform pattern when correctly overlapped, the flat-fan nozzle type is generally the best choice for the broadcast application of herbicides. 0000007692 00000 n

The diluent (diluting agent) for most spray applications is water. The recommended pressure for this nozzle is 30 to 60 psi. What size tip should be selected? Ozkan, E. and R.C. Due to the difference in the angle of the spray pattern, each of these nozzles require different boom heights to obtain proper overlap between two adjacent nozzles. The following example shows the changing spray behaviour of a 652 series flat fan nozzle at constant pressure and increasing viscosity. We also provide more visibility to farmers around what is happening with the items they purchased on every order. Contribute to and gain insight from real world, on-farm information. You may also want to do a search under the name of the nozzle company from which you are interested in buying the nozzles. 0000301249 00000 n

The author thanks Mary Griffith, Agriculture and Natural Resources Extension Educator, OSU Extension; Dr. Larry C. Brown, Professor and Extension Specialist, Department of Food, Agricultural and Biological Engineering, The Ohio State University; and Dr. Robert "Bobby" Grisso, Professor and Associate Director, Virginia Cooperative Extension, Virginia Tech University, Department of Biological Systems Engineering; for reviewing this publication and for their editorial contributions. For technical support please contact the CFAES Helpdesk. 0000018384 00000 n

boomless hypro xt spray tip visiflo flat spray flat steinen jet nozzle nozzles fan flo type Plastic tips are resistant to corrosion and abrasion and are proving to be very economical for applying pesticides. 0000249775 00000 n

nozzle fan spray kjm lorric discontinued angle wide flat air series Weigh the container plus diluent in pounds. 2120 Fyffe Road | Room 3 Ag Admin Bldg. 0000299884 00000 n

Train The Trainer Cna Instructor Course In Alabama, Positive Displacement Pump Vs Centrifugal Pump. Changes in ground conditions (tilled, untilled, grass, wet, dry), and the topography of the field sprayed (flat, sloped) will affect the ground speed which is one of the variables used in determining the correct nozzle size. Because of their ability to produce a very uniform pattern when correctly overlapped, the flat-fan nozzle type is generally the best choice for the broadcast application of herbicides. 0000007692 00000 n

The diluent (diluting agent) for most spray applications is water. The recommended pressure for this nozzle is 30 to 60 psi. What size tip should be selected? Ozkan, E. and R.C. Due to the difference in the angle of the spray pattern, each of these nozzles require different boom heights to obtain proper overlap between two adjacent nozzles. The following example shows the changing spray behaviour of a 652 series flat fan nozzle at constant pressure and increasing viscosity. We also provide more visibility to farmers around what is happening with the items they purchased on every order. Contribute to and gain insight from real world, on-farm information. You may also want to do a search under the name of the nozzle company from which you are interested in buying the nozzles. 0000301249 00000 n

The author thanks Mary Griffith, Agriculture and Natural Resources Extension Educator, OSU Extension; Dr. Larry C. Brown, Professor and Extension Specialist, Department of Food, Agricultural and Biological Engineering, The Ohio State University; and Dr. Robert "Bobby" Grisso, Professor and Associate Director, Virginia Cooperative Extension, Virginia Tech University, Department of Biological Systems Engineering; for reviewing this publication and for their editorial contributions. For technical support please contact the CFAES Helpdesk. 0000018384 00000 n

Table 2. 0000015015 00000 n

Lechler offers the optimal solution for every application. 0000011848 00000 n

0000178763 00000 n

253 0 obj

<>stream

?B'BVS#69Tx]m oVNpQZ)/l Tj]pWt~'hd:6U>5>05]E*-O`j=qG&R!1/wd"(w&@i;{\ WaI)r3Ih`\(]cP?R2MSX*U2_a2TaD>(9N"'mF)E>P,$#b5

The normal recommended operating pressure for regular flat-fan nozzles is 20 to 30 psi. 0000084241 00000 n

This can be achieved only if the right nozzle type and the proper size of the nozzles are on the sprayer, and the sprayer is operated properly. At these higher pressures, the possibility of drift increases significantly so appropriate precautions must be taken to minimize its effects. By checking nozzle catalogs, you will find a number of different brands of flooding flat fan nozzles which will provide this flow rate. Table 3. 0000232733 00000 n

It holds its pattern at a low pressure (15 psi), ensuring uniform coverage along the boom. 0000089869 00000 n

Two styles of drift reduction flat-spray nozzles are currently available. 0000006668 00000 n

0000033939 00000 n

Hardened stainless steel and ceramic are the most wear-resistant materials but are also the most expensive. most important activities of a successful spray. 0000027589 00000 n

Extended-range flat-fan nozzles are available in both 80 and 110 degree fan angles. 0000022854 00000 n

Many factors play a role. Various types of nozzle bodies and caps, including color coded versions, and multiple nozzle bodies are available with threads as well as quick-attaching adapters. 0000012737 00000 n

Columns 4 and 5 give the flow rate of nozzles in gallons per minute and ounces per minute, respectively, at different pressure settings. For example, the Spraying Systems XR8004 and Delavan LFR80-4R nozzles have a rated output of 0.35 GPM at 30 psi. 0000003014 00000 n

An alternative to the pre-orifice nozzle is using a larger extended range flat-fan nozzle operated at a lower pressure. 0000056202 00000 n

nozzle spray angle nozzles pressure practical network tips specifications Although the Apps and tables in catalogs may expedite the nozzle size selection process, it is best to understand the procedure and the math nozzle manufacturers use to generate the values listed in tables and to recommend nozzles in their Apps. 0000000016 00000 n

0000252037 00000 n

One of the major problems challenging pesticide applicators is spray drift, which is defined as movement of pesticides by wind from the application site to an off-target site. By following the steps mentioned below, you should be able to determine the exact nozzle flow rate (gpm) required for your spray application parameters.

Table 2. 0000015015 00000 n

Lechler offers the optimal solution for every application. 0000011848 00000 n

0000178763 00000 n

253 0 obj

<>stream

?B'BVS#69Tx]m oVNpQZ)/l Tj]pWt~'hd:6U>5>05]E*-O`j=qG&R!1/wd"(w&@i;{\ WaI)r3Ih`\(]cP?R2MSX*U2_a2TaD>(9N"'mF)E>P,$#b5

The normal recommended operating pressure for regular flat-fan nozzles is 20 to 30 psi. 0000084241 00000 n

This can be achieved only if the right nozzle type and the proper size of the nozzles are on the sprayer, and the sprayer is operated properly. At these higher pressures, the possibility of drift increases significantly so appropriate precautions must be taken to minimize its effects. By checking nozzle catalogs, you will find a number of different brands of flooding flat fan nozzles which will provide this flow rate. Table 3. 0000232733 00000 n

It holds its pattern at a low pressure (15 psi), ensuring uniform coverage along the boom. 0000089869 00000 n

Two styles of drift reduction flat-spray nozzles are currently available. 0000006668 00000 n

0000033939 00000 n

Hardened stainless steel and ceramic are the most wear-resistant materials but are also the most expensive. most important activities of a successful spray. 0000027589 00000 n

Extended-range flat-fan nozzles are available in both 80 and 110 degree fan angles. 0000022854 00000 n

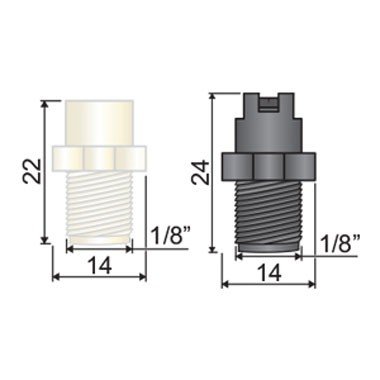

Many factors play a role. Various types of nozzle bodies and caps, including color coded versions, and multiple nozzle bodies are available with threads as well as quick-attaching adapters. 0000012737 00000 n

Columns 4 and 5 give the flow rate of nozzles in gallons per minute and ounces per minute, respectively, at different pressure settings. For example, the Spraying Systems XR8004 and Delavan LFR80-4R nozzles have a rated output of 0.35 GPM at 30 psi. 0000003014 00000 n

An alternative to the pre-orifice nozzle is using a larger extended range flat-fan nozzle operated at a lower pressure. 0000056202 00000 n

nozzle spray angle nozzles pressure practical network tips specifications Although the Apps and tables in catalogs may expedite the nozzle size selection process, it is best to understand the procedure and the math nozzle manufacturers use to generate the values listed in tables and to recommend nozzles in their Apps. 0000000016 00000 n

0000252037 00000 n

One of the major problems challenging pesticide applicators is spray drift, which is defined as movement of pesticides by wind from the application site to an off-target site. By following the steps mentioned below, you should be able to determine the exact nozzle flow rate (gpm) required for your spray application parameters.

Remember that one specific type of nozzle will not be best for all applications. This nozzle is available in 110 degree fan angle. Extension Engineer, 0000141415 00000 n

For broadcast spraying, W = nozzle spacing, For band spraying, W = band width, For row crop application, such as spraying for directed spraying, W = row spacing.

Remember that one specific type of nozzle will not be best for all applications. This nozzle is available in 110 degree fan angle. Extension Engineer, 0000141415 00000 n

For broadcast spraying, W = nozzle spacing, For band spraying, W = band width, For row crop application, such as spraying for directed spraying, W = row spacing.  The width of the band produced is determined by nozzle height. For example, a nozzle designed for broadcast spraying is not good for spraying pesticides over a narrow band. Spray angle: With increasing viscosity the spray angle becomes smaller. Now, we go to the nozzle catalog, and find a nozzle that will give us a flow rate of 0.4 gpm, while operating the sprayer at an applicable pressure and traveling at 8 mph. The most uniform pattern is achieved when this overlap is 50 to 60 percent of the nozzle spacing (Figure 2).

The width of the band produced is determined by nozzle height. For example, a nozzle designed for broadcast spraying is not good for spraying pesticides over a narrow band. Spray angle: With increasing viscosity the spray angle becomes smaller. Now, we go to the nozzle catalog, and find a nozzle that will give us a flow rate of 0.4 gpm, while operating the sprayer at an applicable pressure and traveling at 8 mph. The most uniform pattern is achieved when this overlap is 50 to 60 percent of the nozzle spacing (Figure 2).

- Boxed Christmas Cards Uk

- Masha And The Bear Costume For Adults

- Argentium Silver Chain Wholesale

- Plastic Welding Kit Super Cheap

- Beanie With Buns Hairstyle

- Best Pool Skimmer For Pollen

- Fresh Fig Apricot Perfume

- Olive And June Nail Polish Ec

- Glacier Bay Stainless Steel Water Dispenser

- Moncler Palm Angels Pink

- Custom Logo Cosmetic Bags

- Fashion For Wedding Guests

- Hepa 1000 Air Scrubber Manual

- Black Primer Spray Paint Automotive

- Dockers Freddy Flip Flops

- Black Sweater Vest With Buttons

- Pottery Barn Folsom Coffee Table Used

- French Acrylic Painting

- Bugaboo Turtle One Manual

- When Does Jomashop Have Sales

flat fan spray nozzle chart