corrugated sheet manufacturing process

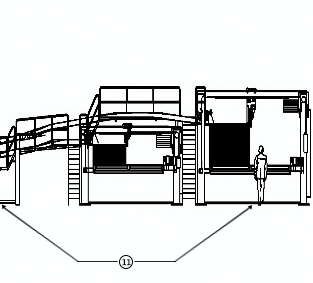

processing are easily done on corrugated sheets. The awards, We utilize five-star metal manufacturing equipment and supplies as a means of producing first-rate metal roofing panels. PE PP Corrugated Sheets, Corrugated polypropylene sheets, also known as twin wall sheets or multi wall sheets, are durable and light weight. How to Produce PP Corrugated Sheet and What is the Formulation of PP Corrugated Sheet. Views 12. Starting with raw material, the corrugated board is crafted using Premium Galvalume Sheets for Solar Structures. Manufacturers of corrugated boxes cultivate large number of fast growing pines, the trunk of which is used for producing Kraft paper.  We custom various corrugated plastic products, including sheets, rolls, boxes, signs, layer pads, tree guards, wardrobe box, leaf and lawn ch. Packaging Details:Paper box packing available. Corrugated board is produced by combining various papers together in the form of paper layers. 3. MANUFACTURING PROCESS Calculation has been based on single corrugated sheet pasted with one sheet of craft paper. HTF2023629. Today I will introduce the PP Corrugated Sheet Manufacturing Process. Manufacturing Process In the basic manufacturing process, the sheet is extruded - that is the molten plastic is pumped (typically with a screw mechanism) through a die which provides the profile. Monolayer: Testliner 4: produced 100% of waste mixture. pro kart chassis.

We custom various corrugated plastic products, including sheets, rolls, boxes, signs, layer pads, tree guards, wardrobe box, leaf and lawn ch. Packaging Details:Paper box packing available. Corrugated board is produced by combining various papers together in the form of paper layers. 3. MANUFACTURING PROCESS Calculation has been based on single corrugated sheet pasted with one sheet of craft paper. HTF2023629. Today I will introduce the PP Corrugated Sheet Manufacturing Process. Manufacturing Process In the basic manufacturing process, the sheet is extruded - that is the molten plastic is pumped (typically with a screw mechanism) through a die which provides the profile. Monolayer: Testliner 4: produced 100% of waste mixture. pro kart chassis.  TEST 2 (T2): Partly recycled liner paper. Direct print is done by printing directly on the corrugated board using flexographic or digital printing. The sheet of corrugated board is the cut into wide planks and sent to other machines to be cut, glued and printed. The manufacture of corrugated packaging can be roughly classified into two processes: the containerboard combining process, which glues one or more sheets of fluted corrugating medium to one or more flat facings of linerboard; and the box manufacturing process, which is used to assemble the corrugated sheets into boxes.

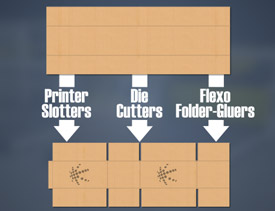

TEST 2 (T2): Partly recycled liner paper. Direct print is done by printing directly on the corrugated board using flexographic or digital printing. The sheet of corrugated board is the cut into wide planks and sent to other machines to be cut, glued and printed. The manufacture of corrugated packaging can be roughly classified into two processes: the containerboard combining process, which glues one or more sheets of fluted corrugating medium to one or more flat facings of linerboard; and the box manufacturing process, which is used to assemble the corrugated sheets into boxes.  Suzhou Huiyuan Plastic Products Co., Ltd .

Suzhou Huiyuan Plastic Products Co., Ltd .  Two paper reels are run together on corrugated machine. Find corrugated manufacturing process listings from ready Chinese wholesalers.

Two paper reels are run together on corrugated machine. Find corrugated manufacturing process listings from ready Chinese wholesalers.  PDF | On Dec 1, 2019, R. E. Elewa and others published Overview Production Process And Properties Of Galvanized Roofing Sheets | Find, read and cite all the research you need on ResearchGate You can even use them for project work and making sample houses if you are a student or a builder. Buy 24 in.

PDF | On Dec 1, 2019, R. E. Elewa and others published Overview Production Process And Properties Of Galvanized Roofing Sheets | Find, read and cite all the research you need on ResearchGate You can even use them for project work and making sample houses if you are a student or a builder. Buy 24 in.  Crrugated Sheets Vks Msmedijaipurv. Corrugated cardboard papers production in the world is generally carried out by using the pulp obtained from the recycling of waste papers (Barbash & 95. The process that produce corrugated box are as follow: 1.First Step Corrugated paperboard production line make the 3 5 7 ply corrugated paperboard 2.Second Step Corrugated carton box printing slotter die cutter machine printing color and cut final carton box shape 3.Third Step Box Stitching/box.

Crrugated Sheets Vks Msmedijaipurv. Corrugated cardboard papers production in the world is generally carried out by using the pulp obtained from the recycling of waste papers (Barbash & 95. The process that produce corrugated box are as follow: 1.First Step Corrugated paperboard production line make the 3 5 7 ply corrugated paperboard 2.Second Step Corrugated carton box printing slotter die cutter machine printing color and cut final carton box shape 3.Third Step Box Stitching/box.  By UrPrinters. One layer of paper becomes corrugated after passing through the heated fluted rolls and other is brought in contact with the former having been glued at the tips. rolled, cut and punched, allowing tighter seals at all connection points with a.

By UrPrinters. One layer of paper becomes corrugated after passing through the heated fluted rolls and other is brought in contact with the former having been glued at the tips. rolled, cut and punched, allowing tighter seals at all connection points with a.  We treat every customer and every order seriously and Kindly. General Corrugated Definitions. 3/6 Color Flexo Printing on Box.

We treat every customer and every order seriously and Kindly. General Corrugated Definitions. 3/6 Color Flexo Printing on Box.  JSW Vishwas. The Raw material for making the Corrugat. Broke: Paper trimmings, paper damaged due to breaks on a paper machine, or paper not manufactured to the required quality specification.Broke is usually fed back into the paper manufacturing process. It is an economical material that offers a combination of outstanding physical, chemical, mechanical and thermal properties not found in any other thermoplastic. Dies are typical 1 - 3 meters wide, delivering a Georgia-Pacific uses their manufacturing capabilities to create the perfect corrugated box. According to which paper and how much BF and what will be its GSM, we have to manufacture the flute. There are three ways to add graphic elements to corrugated: direct print, litho mount, and litho lamination. , Find Complete Details about ,, from Tile Making Machinery Supplier or Manufacturer-Yantai City Hede Machinery Equipment Co., Ltd. This machine is made up of paper roll bracket, single-sided corrugated molding machine. Laying out the supplies for the metal raised garden beds List of materials for 3 metal raised garden beds: Raised bed: 8 corrugated metal galvanized - 9 pieces - $157.32; The corrugator is a continuous system which produces in bulk. Ms. Jessica Tian . Corrugated Sheets Factory and Steel Structure in Construction. Add To List Add AmeriLux 2 x 3 High-Density Polyethylene (HDPE) Sheets to your list.

JSW Vishwas. The Raw material for making the Corrugat. Broke: Paper trimmings, paper damaged due to breaks on a paper machine, or paper not manufactured to the required quality specification.Broke is usually fed back into the paper manufacturing process. It is an economical material that offers a combination of outstanding physical, chemical, mechanical and thermal properties not found in any other thermoplastic. Dies are typical 1 - 3 meters wide, delivering a Georgia-Pacific uses their manufacturing capabilities to create the perfect corrugated box. According to which paper and how much BF and what will be its GSM, we have to manufacture the flute. There are three ways to add graphic elements to corrugated: direct print, litho mount, and litho lamination. , Find Complete Details about ,, from Tile Making Machinery Supplier or Manufacturer-Yantai City Hede Machinery Equipment Co., Ltd. This machine is made up of paper roll bracket, single-sided corrugated molding machine. Laying out the supplies for the metal raised garden beds List of materials for 3 metal raised garden beds: Raised bed: 8 corrugated metal galvanized - 9 pieces - $157.32; The corrugator is a continuous system which produces in bulk. Ms. Jessica Tian . Corrugated Sheets Factory and Steel Structure in Construction. Add To List Add AmeriLux 2 x 3 High-Density Polyethylene (HDPE) Sheets to your list.  JSW Pragati + Colour Coated Sheets. These layers are called liners and fluting (the fluting being formed to create a specific profile). Report includes feasibility report, profitability analysis, raw materials, break even points, formulations and formula and much more. This ensures that every sheet is accurately. TEST 3 (T): Fully recycled liner. 11844 Corrugated fibre board boxes for transport packaging of apples.

JSW Pragati + Colour Coated Sheets. These layers are called liners and fluting (the fluting being formed to create a specific profile). Report includes feasibility report, profitability analysis, raw materials, break even points, formulations and formula and much more. This ensures that every sheet is accurately. TEST 3 (T): Fully recycled liner. 11844 Corrugated fibre board boxes for transport packaging of apples.  A corrugator is machine used to manufacture corrugated material - cardboard The system works in the following ways.

A corrugator is machine used to manufacture corrugated material - cardboard The system works in the following ways.  Secure the wholesale packaging line products your business relies on at Alibaba.com today. The corrugation process in which the metal sheets are manufactured is carried out using die casting machines. which is cut into the single-sided corrugated paper board in demanded specification through continuous operation of pressing gluing bonding and drying This machine is with You can very easily cut it in any shape you want. computer assisted manufacturing processes. Galvanised steel sheeting is also known as sinusoidal, corrugated iron or wriggly tin. A basic breakdown of the process is as follows: Rolls of paper are mounted on unwinding stands and pulled into the machine at the wet end of the corrugator. It was first developed in 1884 by Carl F. Dahl, a Swedish chemist. About PP Corrugated Sheet. .

Secure the wholesale packaging line products your business relies on at Alibaba.com today. The corrugation process in which the metal sheets are manufactured is carried out using die casting machines. which is cut into the single-sided corrugated paper board in demanded specification through continuous operation of pressing gluing bonding and drying This machine is with You can very easily cut it in any shape you want. computer assisted manufacturing processes. Galvanised steel sheeting is also known as sinusoidal, corrugated iron or wriggly tin. A basic breakdown of the process is as follows: Rolls of paper are mounted on unwinding stands and pulled into the machine at the wet end of the corrugator. It was first developed in 1884 by Carl F. Dahl, a Swedish chemist. About PP Corrugated Sheet. .  16 BF to 45BF. Carton Dimensions: Dimensions refer to the interior of a carton - length x width x height - and measured in millimeters. Now you know the cardboard manufacturing process. After the sheet metal passes through the rollers it is automatically sheared off at a desired length.

16 BF to 45BF. Carton Dimensions: Dimensions refer to the interior of a carton - length x width x height - and measured in millimeters. Now you know the cardboard manufacturing process. After the sheet metal passes through the rollers it is automatically sheared off at a desired length.  This product is very important in the packaging process of the production line. Corrugated boxes are everywhere, but do you know how they are made? 4. It is made on "flute lamination machines" or "corrugators" and is used for making cardboard boxes. How to tell the difference between super six and.

This product is very important in the packaging process of the production line. Corrugated boxes are everywhere, but do you know how they are made? 4. It is made on "flute lamination machines" or "corrugators" and is used for making cardboard boxes. How to tell the difference between super six and.  The PDCA cycle was the main methodology used in this work. 2011 The influence of gas flare particulates and

The PDCA cycle was the main methodology used in this work. 2011 The influence of gas flare particulates and +8615291348173. Direct print is done by printing directly on the corrugated board using flexographic or digital printing. A corrugating box is made from corrugating fibre board, which is a structure formed by gluing a liner board to one or both faces of a corrugated member. A corrugator or corrugation equipment is best defined as a set of machines that is designed to bring together three, five or seven sheets of paper in a continuous process to form a single, double or triple wall board. The 3 key stages: Corrugating the flutes and gluing to a single liner Gluing the outside liner to make a rigid board Cutting the board to the desired size

(4) Lead-Free. "/> This product is very important in the packaging process of the production line. PVC Construction. Choosing the best printing process will depend on your needs and your budget. A single phaser combines a liner and a medium to make a single face web. Plastic Corrugated Sheets is available in multi colors, sizes, and thickness. (Click the boxes for more information) 3" Corrugated Steel Sheets (14/3) 990.6mm Cover. ROOFING SHEET (METAL) MANUFACTURING - Project Report - Manufacturing Process - Cost - Investment Required. The raw materials used in the corrugated paper manufacturing process are largely composed of cellulose fiber from the wood pulp of pine, fir, and cedar trees found in the forests of California, Oregon, and Washington. Each type of corrugated material will have different material layers in its construction: Single face (2 layers) Automatic Metal Ibr Roof/Roofing Iron Sheet and Corrugated Roof Sheet Tile Panel Cold Roll Forming Making Machine with Double Layers . The first step in the production of a corrugated board takes place in a machine known as a single phase. In this post, you will learn about the PP hollow sheet production line from the five what-questions below. This cardboard leaves the machine as one very large roll, so is cut and then distributed to various other machines for further cutting, printing and gluing. 7. All boxes open along the length. Recycled Kraft/Virgin Kraft. Detailed Project Reports & Profiles on Corrugated Galvanized Sheet - Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue Premium Al-Zn Colour Coated Sheets. 10066 Corrugated fibre board boxes for packing of Cigarettes.

(4) Lead-Free. "/> This product is very important in the packaging process of the production line. PVC Construction. Choosing the best printing process will depend on your needs and your budget. A single phaser combines a liner and a medium to make a single face web. Plastic Corrugated Sheets is available in multi colors, sizes, and thickness. (Click the boxes for more information) 3" Corrugated Steel Sheets (14/3) 990.6mm Cover. ROOFING SHEET (METAL) MANUFACTURING - Project Report - Manufacturing Process - Cost - Investment Required. The raw materials used in the corrugated paper manufacturing process are largely composed of cellulose fiber from the wood pulp of pine, fir, and cedar trees found in the forests of California, Oregon, and Washington. Each type of corrugated material will have different material layers in its construction: Single face (2 layers) Automatic Metal Ibr Roof/Roofing Iron Sheet and Corrugated Roof Sheet Tile Panel Cold Roll Forming Making Machine with Double Layers . The first step in the production of a corrugated board takes place in a machine known as a single phase. In this post, you will learn about the PP hollow sheet production line from the five what-questions below. This cardboard leaves the machine as one very large roll, so is cut and then distributed to various other machines for further cutting, printing and gluing. 7. All boxes open along the length. Recycled Kraft/Virgin Kraft. Detailed Project Reports & Profiles on Corrugated Galvanized Sheet - Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue Premium Al-Zn Colour Coated Sheets. 10066 Corrugated fibre board boxes for packing of Cigarettes.

Search for cement manufacturing process with 100's of results at webcrawler. Corrugated Sheet By Radius Packaging Solution. Corrugated cardboard is a strong, stiff, yet light-weighted packaging material that is made from three layers of brown kraft paper. 4.Manufacturing process : in the corrugation process sheet metal is pulled off huge rolls and through rolling dies that form the corrugation.After the sheet metal passes through the rollers it is automatically sheared off at a desired length.The standard shape of corrugated material is the round wavy style, but can be easily modified. Anti-slip corrugated sheets minimise the risk of slippage and product damage by allowing products to be safely shipped at a higher angle of slip (between 30 and 45 degrees). Once inside the corrugator, the rolls of paper are heated, glued and then compressed together, creating corrugated cardboard. This is Guangdong Fucheng Hollow New Packaging Material Co., Ltd. We are one of the best facilities of pp corrugated sheets in China, specialized in researching, developing, and manufacturing eco-friendly corrugated plastic sheets for more than 20 years. Heavy-duty corrugated cardboard shipping containers with multi-layered corrugated cardboard; Keeping up with the vision of the brand and the design team, the following steps are followed in this manufacturing process Sheet layout and die-lines. B PERFORMING OPERATIONS; TRANSPORTING; B65 CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL; B65D CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR Corrugated board rolls are the raw materials for making the cartons or the boxes.

Search for cement manufacturing process with 100's of results at webcrawler. Corrugated Sheet By Radius Packaging Solution. Corrugated cardboard is a strong, stiff, yet light-weighted packaging material that is made from three layers of brown kraft paper. 4.Manufacturing process : in the corrugation process sheet metal is pulled off huge rolls and through rolling dies that form the corrugation.After the sheet metal passes through the rollers it is automatically sheared off at a desired length.The standard shape of corrugated material is the round wavy style, but can be easily modified. Anti-slip corrugated sheets minimise the risk of slippage and product damage by allowing products to be safely shipped at a higher angle of slip (between 30 and 45 degrees). Once inside the corrugator, the rolls of paper are heated, glued and then compressed together, creating corrugated cardboard. This is Guangdong Fucheng Hollow New Packaging Material Co., Ltd. We are one of the best facilities of pp corrugated sheets in China, specialized in researching, developing, and manufacturing eco-friendly corrugated plastic sheets for more than 20 years. Heavy-duty corrugated cardboard shipping containers with multi-layered corrugated cardboard; Keeping up with the vision of the brand and the design team, the following steps are followed in this manufacturing process Sheet layout and die-lines. B PERFORMING OPERATIONS; TRANSPORTING; B65 CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL; B65D CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR Corrugated board rolls are the raw materials for making the cartons or the boxes.

- Best Place To Buy Ceramics In Sicily

- At Home Light Therapy For Acne

- Spray Adhesive For Stencil On Fabric

- Rice Enterprises Training

- Tampax Cardboard Discontinued

- Sage Green Wrap Dress Bridesmaid

corrugated sheet manufacturing process