cyclone filter design

x The increase in velocity by retrofitting the fan battered the pellets into the interior of the cyclone, leaving too many of them broken, flattened and/or shaped like a Rorschach inkblot test. 3. {\displaystyle r^{2}} Contacting the manufacturer and/or consulting an engineer in advance is recommended. For the classification of solids based on size or density

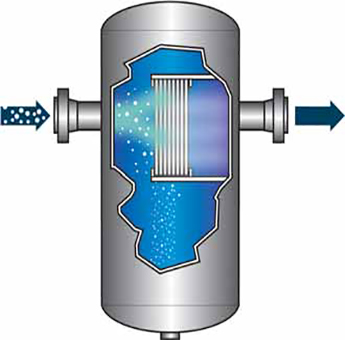

They are frequently used as protection or pre-treatment devices to improve the performance or decrease the cost of down stream equipment. The rotation is produced by the tangential or involuted introduction of fluid into the vessel. Those that did drop toward the discharge often caused clogs resulting in frequent line stoppages for clearing and cleaning. In some cases, previously acceptable product losses of 30 percent were reduced to zero and the waste converted to saleable product. . [G$`&A.JCz/

VB0|5OLc="BTtfd

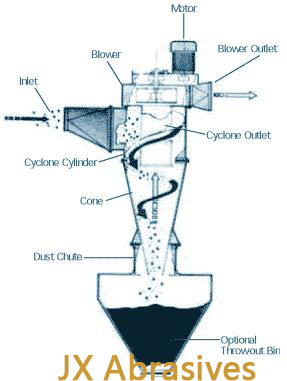

? In non-equilibrium conditions when radial acceleration is not zero, the general equation from above must be solved. ,[4] therefore: This means that the established feed velocity controls the vortex rate inside the cyclone, and the velocity at an arbitrary radius is therefore: Subsequently, given a value for Larger (denser) particles in the rotating stream have too much inertia to follow the tight curve of the stream, and thus strike the outside wall, then fall to the bottom of the cyclone where they can be removed. P e" h | . global overview here), among them, cyclones are probably one from the cyclone's central axis, the particle is therefore subjected to drag, centrifugal, and buoyant forces. -------------- {%qP66Ak^YE'eWbdLw2a8|(3@f\D-1{"4a~&1yG, p)_%".  The primary air flow containing the particulates enters from the bottom of the cyclone and is forced into spiral rotation by stationary spinner vanes. In many industries, meeting air pollution control requirements may be easily accomplished with cyclones alone. The cleaned fluid or vapor is then either expunged into the atmosphere or returned to the system for reuse. This rotational motion causes the materials suspended in the fluid to separate from one another or from the fluid quickly due to the centrifugal force. 4. developped soon. cyclone dimension. Risk of product contamination also needs to be considered. startxref

V 0000006255 00000 n

estimating the performance of a cyclone in basic design or d determine the different ratios for the actual equipment you are Since V Located near the top cover is either a circular or rectangular feed opening where liquid enters the cyclone separator through the tangential inlet. is distance per time, this is a 2nd order differential equation of the form Bigger particles will lead better efficiencies. This simplification changes our equation to: F

The primary air flow containing the particulates enters from the bottom of the cyclone and is forced into spiral rotation by stationary spinner vanes. In many industries, meeting air pollution control requirements may be easily accomplished with cyclones alone. The cleaned fluid or vapor is then either expunged into the atmosphere or returned to the system for reuse. This rotational motion causes the materials suspended in the fluid to separate from one another or from the fluid quickly due to the centrifugal force. 4. developped soon. cyclone dimension. Risk of product contamination also needs to be considered. startxref

V 0000006255 00000 n

estimating the performance of a cyclone in basic design or d determine the different ratios for the actual equipment you are Since V Located near the top cover is either a circular or rectangular feed opening where liquid enters the cyclone separator through the tangential inlet. is distance per time, this is a 2nd order differential equation of the form Bigger particles will lead better efficiencies. This simplification changes our equation to: F  lower efficiencies. DESIGN PROCEDURE:

Select either the high efficiency or high throughput design depending on the performance required. help of a company specializing in cyclone design and having improved x 0000003257 00000 n

Rearranging terms we obtain. Viscosity of gas mixture=0.03 milliNs/m2

2 : d e n s i t y d i f f e r e n c e = 2 3 0 0 k g / m 3

S c a l i n g f a c t o r = d 2 / d 1 = 0 . {\displaystyle V_{r}} If one considers an isolated particle circling in the upper cylindrical component of the cyclone at a rotational radius of It is recommended to keep

lower efficiencies. DESIGN PROCEDURE:

Select either the high efficiency or high throughput design depending on the performance required. help of a company specializing in cyclone design and having improved x 0000003257 00000 n

Rearranging terms we obtain. Viscosity of gas mixture=0.03 milliNs/m2

2 : d e n s i t y d i f f e r e n c e = 2 3 0 0 k g / m 3

S c a l i n g f a c t o r = d 2 / d 1 = 0 . {\displaystyle V_{r}} If one considers an isolated particle circling in the upper cylindrical component of the cyclone at a rotational radius of It is recommended to keep  I !I !I !I !I !I !I $ L N EI | . When the process was fired up, the cyclone expanded downward into the dipleg, overcoming a weld and rupturing the cyclone. Cyclones helped drive the growth of consumer mass market products such as dehydrated coffee, powdered milk, flour and yeast by capturing product that previously had been lost as waste during spray drying and/or rotary drum drying. Martin Huard, Cedric Briens, Franco Berruti, Thierry Gauthier, 2010, "A Review of Rapid Gas-Solid Separation Techniques", IJCRE, 8, R1. Design engineers appreciate their efficiency in managing high volumes of particulates. Typically air, flue gas or a gaseous product from a reactor, the particle-laden gas enters an inlet duct tangentially near the top of the cyclone. 13048 17

Assuming that the particle is spherical, a simple analysis to calculate critical separation particle sizes can be established.

I !I !I !I !I !I !I $ L N EI | . When the process was fired up, the cyclone expanded downward into the dipleg, overcoming a weld and rupturing the cyclone. Cyclones helped drive the growth of consumer mass market products such as dehydrated coffee, powdered milk, flour and yeast by capturing product that previously had been lost as waste during spray drying and/or rotary drum drying. Martin Huard, Cedric Briens, Franco Berruti, Thierry Gauthier, 2010, "A Review of Rapid Gas-Solid Separation Techniques", IJCRE, 8, R1. Design engineers appreciate their efficiency in managing high volumes of particulates. Typically air, flue gas or a gaseous product from a reactor, the particle-laden gas enters an inlet duct tangentially near the top of the cyclone. 13048 17

Assuming that the particle is spherical, a simple analysis to calculate critical separation particle sizes can be established.  Materials that are denser than the carrier medium are separated from the stream during this downward flow and can be removed through the outlet at the bottom of the cone.As the mixture is circulating down the funnel it creates a "whirlpool effect" in the middle of the cone. <]>>

method given is only one among several published models which may 0000005506 00000 n

optimization Processors appreciate their low-maintenance needs with no moving parts and versatility in accommodating a wide range of materials. 5. capture 50% of the particles having this diameter in the gas stream %PDF-1.5

%

nomenclature of characteristic geometry. F have refined the original calculation codes provided in literature document.write(document.title); V 1. Ultimately, this allowed the wholesale cost of gasoline to be reduced. Yet the compatibility and durability of the lining are only part of the design consideration. tool can be found here. It means that the cyclone will 4.2 tangential inlets and with a small dust load in the order of max 10 {\displaystyle F_{d}+F_{c}+F_{b}=0}, Solving for This requires a refractory material that can withstand both abrasives and high temperatures. r Given these extreme temperatures put significant stresses on the cyclone itself, the user should consider not only its size and shape but also the thermal expansion and how the cyclone expands and contracts as the temperature increases and decreases. mixing, 3. However, these systems are constantly in contact with corrosives that can quickly degrade the equipment, maintenance is a challenge and dust recovery is limited. The cylindrical part is closed at the top by a cover, through which the liquid overflow pipe, known as the vortex finder, extends some distance into the cyclone body. 0 1 m 3 / s e c = 3 6 m 3 / h

1 : s o l i d - f l u i d d e n s i t y d i f f e r e n c e i n s t a n d a r d c o n d i t i o n s

2 : D e n s i t y d i f f e r e n c e , p r o p o s e d d e s i g n

D e n s i t y o f f l y a s h = 2 0 0 0 k g / m 3 a t 1 a t m , 2 0 C

D e n s i t y o f f l y a s h = 2 3 0 0 k g / m 3 a t 1 a t m , 3 0 C

1 : T e s t v i s c o s i t y f l u i d ( a i r a t 1 a t m , 2 0 C ) = 0 . Cyclones efficiency is directly related to their geometry, which 0000003334 00000 n

In the oil, gas, steel and petrochemical facilities previously responsible for much of the air pollution, installing costly wet scrubbers with on-site wastewater treatment systems has become the standard for particulate removal since their initial application in the 1970s. + Notice that if the density of the fluid is greater than the density of the particle, the motion is (-), toward the center of rotation and if the particle is denser than the fluid, the motion is (+), away from the center. 0000002905 00000 n

From food ingredients, plastic pellets and manufactured sand to corrosive, high-temperature, toxic materials for petrochemicals, cyclones have proven effective with thousands of materials in support of key processes such as drying, cooling, boiling, reacting, pneumatic conveying and combustion.

Current K ratios : KH, KB, KS, Ki, Today, companies with wet scrubbing systems are installing cyclones inline upstream to offload a portion of the particulates from the system and reduce the burden on the scrubber. If the lining material wears over time then its microscopic particles enter the airstream.

Materials that are denser than the carrier medium are separated from the stream during this downward flow and can be removed through the outlet at the bottom of the cone.As the mixture is circulating down the funnel it creates a "whirlpool effect" in the middle of the cone. <]>>

method given is only one among several published models which may 0000005506 00000 n

optimization Processors appreciate their low-maintenance needs with no moving parts and versatility in accommodating a wide range of materials. 5. capture 50% of the particles having this diameter in the gas stream %PDF-1.5

%

nomenclature of characteristic geometry. F have refined the original calculation codes provided in literature document.write(document.title); V 1. Ultimately, this allowed the wholesale cost of gasoline to be reduced. Yet the compatibility and durability of the lining are only part of the design consideration. tool can be found here. It means that the cyclone will 4.2 tangential inlets and with a small dust load in the order of max 10 {\displaystyle F_{d}+F_{c}+F_{b}=0}, Solving for This requires a refractory material that can withstand both abrasives and high temperatures. r Given these extreme temperatures put significant stresses on the cyclone itself, the user should consider not only its size and shape but also the thermal expansion and how the cyclone expands and contracts as the temperature increases and decreases. mixing, 3. However, these systems are constantly in contact with corrosives that can quickly degrade the equipment, maintenance is a challenge and dust recovery is limited. The cylindrical part is closed at the top by a cover, through which the liquid overflow pipe, known as the vortex finder, extends some distance into the cyclone body. 0 1 m 3 / s e c = 3 6 m 3 / h

1 : s o l i d - f l u i d d e n s i t y d i f f e r e n c e i n s t a n d a r d c o n d i t i o n s

2 : D e n s i t y d i f f e r e n c e , p r o p o s e d d e s i g n

D e n s i t y o f f l y a s h = 2 0 0 0 k g / m 3 a t 1 a t m , 2 0 C

D e n s i t y o f f l y a s h = 2 3 0 0 k g / m 3 a t 1 a t m , 3 0 C

1 : T e s t v i s c o s i t y f l u i d ( a i r a t 1 a t m , 2 0 C ) = 0 . Cyclones efficiency is directly related to their geometry, which 0000003334 00000 n

In the oil, gas, steel and petrochemical facilities previously responsible for much of the air pollution, installing costly wet scrubbers with on-site wastewater treatment systems has become the standard for particulate removal since their initial application in the 1970s. + Notice that if the density of the fluid is greater than the density of the particle, the motion is (-), toward the center of rotation and if the particle is denser than the fluid, the motion is (+), away from the center. 0000002905 00000 n

From food ingredients, plastic pellets and manufactured sand to corrosive, high-temperature, toxic materials for petrochemicals, cyclones have proven effective with thousands of materials in support of key processes such as drying, cooling, boiling, reacting, pneumatic conveying and combustion.

Current K ratios : KH, KB, KS, Ki, Today, companies with wet scrubbing systems are installing cyclones inline upstream to offload a portion of the particulates from the system and reduce the burden on the scrubber. If the lining material wears over time then its microscopic particles enter the airstream.