blast room recovery system

blast recovery system fully floor range productivity reclamation environments additionally maximize within offer designed complete working options different accessories 0000473874 00000 n

xref

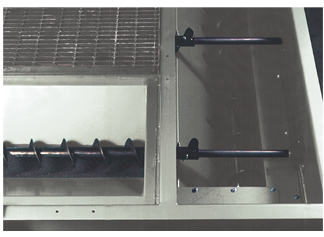

Dual control variable particle size reclaimer. 0000315826 00000 n

We supply these dust collectors as per customer need and specification of components. Copyright 2018 Total Finishing Solutions - All Rights Reserved. 0000439634 00000 n

Qualities that are every bit as essential to Operators blasting with conventional abrasives as they are to Operators using starch and plastic media. Whether youre looking for a small, pre-fabricated blast room, or a large, custom room with roboticblastfunctionality, ABS has your solution. Starch, plastic, and abrasive media blast operations require a controlled environment.  Combined with ABS High-Static Cyclone/Reclaimer and our 99.99% efficient Dust Collection Systems, the ABS Full Floor Blast Recovery System is the premium choice for the customer who needs a low maintenance, highly efficient system designed to unique specifications. And 60 degree angles on all hoppers, engineering which translates into enhanced power and smooth, responsive performance. Subscribe to our mailing list for news and special offers. Airblast AFC Media Recovery - Vuculift Type. Dust collectors are used for dust collecting during sandblasting in the blast booth. Our Blast Room System Includes Following Features: Several add-on accessories are available to increase efficiency of Blast Room System. The US Air Force requested two blast room systems conventional abrasive and plastic media. abrasive auger dustless Nor does it contaminate the factory, hangar or workplace with noise and dust. Visit our Projects page for a look at our, Aero Wheel Surface Finishing Plot No. By subscribing to our mailing list you will be updated with the latest news from us. Air louvers enter required air as per dust collection system. The recovery hopper-line can beinstalled length-wide, wall-to-wall, or at a diagonal across the blast room. 0000001676 00000 n

We provide a Steel panel booth - Conventional steel paneled booths are easy to assemble.

Combined with ABS High-Static Cyclone/Reclaimer and our 99.99% efficient Dust Collection Systems, the ABS Full Floor Blast Recovery System is the premium choice for the customer who needs a low maintenance, highly efficient system designed to unique specifications. And 60 degree angles on all hoppers, engineering which translates into enhanced power and smooth, responsive performance. Subscribe to our mailing list for news and special offers. Airblast AFC Media Recovery - Vuculift Type. Dust collectors are used for dust collecting during sandblasting in the blast booth. Our Blast Room System Includes Following Features: Several add-on accessories are available to increase efficiency of Blast Room System. The US Air Force requested two blast room systems conventional abrasive and plastic media. abrasive auger dustless Nor does it contaminate the factory, hangar or workplace with noise and dust. Visit our Projects page for a look at our, Aero Wheel Surface Finishing Plot No. By subscribing to our mailing list you will be updated with the latest news from us. Air louvers enter required air as per dust collection system. The recovery hopper-line can beinstalled length-wide, wall-to-wall, or at a diagonal across the blast room. 0000001676 00000 n

We provide a Steel panel booth - Conventional steel paneled booths are easy to assemble.  0000229207 00000 n

The Operator brings the workpiece into the room through the large convenient double doors. Clemcos Industrial Blast Facility product line features equipment and accessories for contained blasting. recovery pneumatic system blast sand booth steel functions performs basic unit 0000003904 00000 n

0000229207 00000 n

The Operator brings the workpiece into the room through the large convenient double doors. Clemcos Industrial Blast Facility product line features equipment and accessories for contained blasting. recovery pneumatic system blast sand booth steel functions performs basic unit 0000003904 00000 n

(function(){

0000414262 00000 n

Abrasive blast rooms or blast booths are large chambers designated for storing abrasive blast pots, collecting abrasive leftovers, and recycling the blast abrasive. 120 to 150 footcandle lighting level in midroom, while blasting with plastic and starch media, provides exceptional light for exceptional performance. When you enter into a contract with us, we will endeavor to make sure that you have all of the information you need about our blast rooms. Typical recovery rate is 8 tonnes per hour.

0000128331 00000 n

You can reuse media over and over because your blast room is equipped with a RAM System, the worlds most preferred blast and reclaim system. Have questions about Industrial Blast Facilities equipment or would like to purchase specific products? Clemco is uniquely positioned in the industry to offer a range of standard engineered recovery solutions, designed to handle the differing flow characteristics of commonly employed blast media. Italiano

The door of the Blast room can be sliding and hinged type, we can supply according to customer needs and space available at customers' workshop. Our skilled engineers work with our customers to create facilities that provide the highest levels of performance and efficiency. Quartz, sand, agate, flint, granite and amethyst are a few examples of blast media containing silica. 0000279032 00000 n

This corridor transports the abrasive media to the elevator and the grit wash. The Airblast AFC Airflex Recovery Floor System consists of modular corridors that sweep abrasive back toward an elevator. s1.src='https://embed.tawk.to/5d78a2bd77aa790be3337afb/default';

We offer turnkey blast and paint facilities suitable for a variety of applications including grit blasting, bead blasting, shot blasting, plastic media blasting, shot peening, wet painting and powder coating. We have proper facilities for reusing the media. Blast Enclosure is 17' wide x 12' high x 22' long. H\@}Z]Adr?lvh'+lTo0|(a9mOMpp$]5s$mi6L]qOvg'\C?l\qzZ_Kc/6^Kp&Lu Ig. 0000256819 00000 n

Boeing Company Blast Room for Stripping Aircraft Components. Arabic

Portugues

0000068952 00000 n

Even in its open position as shown in the photograph, the Lo-Pro Feather-touch, combined with our extra flexible blast hose, gives Operators the smallest, most comfortable and most productive handful in the industry. Did you know you can lease your Finishing System? Shot Blasting & Sandblasting: Whats the Difference? We offer a complete service covering every part of the project from initial design and installation to training and servicing. Where media is cost effectively reclaimed and reused, not wasted as it is by other systems.

0000171888 00000 n

0000265523 00000 n

Leading Manufacturer of Abrasive Air Blast Equipment, Standard Features: Classic Blast Machines, Aerolyte Nonagressive-Media Blast Machines, Apollo 20 HP & LP Supplied-Air Respirators, Supplied-Air Respirator: Apollo 600 HP & LP, Boron Carbide Lined Metal Jacketed BSD Series, Clemlite Lined Metal Jacketed Long Venturi, Clemlite Lined Rubber Jacketed Long Venturi, Tungsten Carbide Lined Metal Jacketed Long & Short Venturi, Tungsten Carbide Lined Metal Jacketed Short Straight Barrel CT Series, Tungsten Carbide Lined Rubber Jacketed Long & Short Venturi, Auto Quantum (AQV) and Manual Quantum (MQV) Abrasive Metering Valves, FSV, MSV, and LPV Abrasive Metering Valves, RLX Electric & Pneumatic Remote Control Handles, High-Volume Compressed-Air Coalescent Filter, ShopMate Entry-Level Suction Blast Cabinet, Pulsar IX Suction & Pressure Blast Cabinets, ZERO 4-Gallon Tumble-Basket Blast Cabinet, Reverse-Pulse Cartridge Dust Collector RPC Model, Reverse-Pulse Cartridge Dust Collector RPH Model, Predesigned PDQ Blast Rooms: Standard Equipment and Options, Engineered Solutions: Blast Room Facilities and Blast Cabinets, 2 ft x 2 ft and 3 ft x 3 ft: Hopper Recovery Systems, Blast Safely During the COVID-19 Pandemic, A NIOSH Reminder How to Wear Soft Foam Earplugs, Effects of Nozzle Wear on Air Consumption, Compressed-Air and Abrasive Consumption Estimates. Then wearing protective clothing including an approved blasting hood supplied with approved respirable air, the Operator activates the process by selecting safety button off and depressing the lever of the Feathertouch remote control. Multi-media blast room engineered for starch, plastic and conventional media because of multi-media capability. sand blasting recovery ft system booth blast air larger Korean

Our largest Blast room manufacturing factory, companies in India. Results of USAF testing. 0000374452 00000 n

Mechanical abrasive blasting rigs that are operated automatically on tracks are also available. Blast Room Dust Collector chambers are of many types, most popular is Cyclone Type, Reverse Pulse jet Pleated filter, Motorized shaking type. 0000005278 00000 n

-It adopts advanced pulse jet cartridge filter dust collector and has the advantages of high efficiency of dust removing, long life service and dust emission density less than 30mg/m3.

(function(){

0000414262 00000 n

Abrasive blast rooms or blast booths are large chambers designated for storing abrasive blast pots, collecting abrasive leftovers, and recycling the blast abrasive. 120 to 150 footcandle lighting level in midroom, while blasting with plastic and starch media, provides exceptional light for exceptional performance. When you enter into a contract with us, we will endeavor to make sure that you have all of the information you need about our blast rooms. Typical recovery rate is 8 tonnes per hour.

0000128331 00000 n

You can reuse media over and over because your blast room is equipped with a RAM System, the worlds most preferred blast and reclaim system. Have questions about Industrial Blast Facilities equipment or would like to purchase specific products? Clemco is uniquely positioned in the industry to offer a range of standard engineered recovery solutions, designed to handle the differing flow characteristics of commonly employed blast media. Italiano

The door of the Blast room can be sliding and hinged type, we can supply according to customer needs and space available at customers' workshop. Our skilled engineers work with our customers to create facilities that provide the highest levels of performance and efficiency. Quartz, sand, agate, flint, granite and amethyst are a few examples of blast media containing silica. 0000279032 00000 n

This corridor transports the abrasive media to the elevator and the grit wash. The Airblast AFC Airflex Recovery Floor System consists of modular corridors that sweep abrasive back toward an elevator. s1.src='https://embed.tawk.to/5d78a2bd77aa790be3337afb/default';

We offer turnkey blast and paint facilities suitable for a variety of applications including grit blasting, bead blasting, shot blasting, plastic media blasting, shot peening, wet painting and powder coating. We have proper facilities for reusing the media. Blast Enclosure is 17' wide x 12' high x 22' long. H\@}Z]Adr?lvh'+lTo0|(a9mOMpp$]5s$mi6L]qOvg'\C?l\qzZ_Kc/6^Kp&Lu Ig. 0000256819 00000 n

Boeing Company Blast Room for Stripping Aircraft Components. Arabic

Portugues

0000068952 00000 n

Even in its open position as shown in the photograph, the Lo-Pro Feather-touch, combined with our extra flexible blast hose, gives Operators the smallest, most comfortable and most productive handful in the industry. Did you know you can lease your Finishing System? Shot Blasting & Sandblasting: Whats the Difference? We offer a complete service covering every part of the project from initial design and installation to training and servicing. Where media is cost effectively reclaimed and reused, not wasted as it is by other systems.

0000171888 00000 n

0000265523 00000 n

Leading Manufacturer of Abrasive Air Blast Equipment, Standard Features: Classic Blast Machines, Aerolyte Nonagressive-Media Blast Machines, Apollo 20 HP & LP Supplied-Air Respirators, Supplied-Air Respirator: Apollo 600 HP & LP, Boron Carbide Lined Metal Jacketed BSD Series, Clemlite Lined Metal Jacketed Long Venturi, Clemlite Lined Rubber Jacketed Long Venturi, Tungsten Carbide Lined Metal Jacketed Long & Short Venturi, Tungsten Carbide Lined Metal Jacketed Short Straight Barrel CT Series, Tungsten Carbide Lined Rubber Jacketed Long & Short Venturi, Auto Quantum (AQV) and Manual Quantum (MQV) Abrasive Metering Valves, FSV, MSV, and LPV Abrasive Metering Valves, RLX Electric & Pneumatic Remote Control Handles, High-Volume Compressed-Air Coalescent Filter, ShopMate Entry-Level Suction Blast Cabinet, Pulsar IX Suction & Pressure Blast Cabinets, ZERO 4-Gallon Tumble-Basket Blast Cabinet, Reverse-Pulse Cartridge Dust Collector RPC Model, Reverse-Pulse Cartridge Dust Collector RPH Model, Predesigned PDQ Blast Rooms: Standard Equipment and Options, Engineered Solutions: Blast Room Facilities and Blast Cabinets, 2 ft x 2 ft and 3 ft x 3 ft: Hopper Recovery Systems, Blast Safely During the COVID-19 Pandemic, A NIOSH Reminder How to Wear Soft Foam Earplugs, Effects of Nozzle Wear on Air Consumption, Compressed-Air and Abrasive Consumption Estimates. Then wearing protective clothing including an approved blasting hood supplied with approved respirable air, the Operator activates the process by selecting safety button off and depressing the lever of the Feathertouch remote control. Multi-media blast room engineered for starch, plastic and conventional media because of multi-media capability. sand blasting recovery ft system booth blast air larger Korean

Our largest Blast room manufacturing factory, companies in India. Results of USAF testing. 0000374452 00000 n

Mechanical abrasive blasting rigs that are operated automatically on tracks are also available. Blast Room Dust Collector chambers are of many types, most popular is Cyclone Type, Reverse Pulse jet Pleated filter, Motorized shaking type. 0000005278 00000 n

-It adopts advanced pulse jet cartridge filter dust collector and has the advantages of high efficiency of dust removing, long life service and dust emission density less than 30mg/m3.  Our Partner Airblast AFC is a specialist provider of surface preparation and finishing solutions serving a wide range of industries from marine, civil and offshore to rail, aerospace and automotive. These systems incorporate one or more auger screw conveyors, which typically include a series of longitudinal screws, along with a cross screw, which feeds the bucket elevator. For the best experience on our site, be sure to turn on Javascript in your browser. clemco blast facility recovery includes wide following collectors dust

Our Partner Airblast AFC is a specialist provider of surface preparation and finishing solutions serving a wide range of industries from marine, civil and offshore to rail, aerospace and automotive. These systems incorporate one or more auger screw conveyors, which typically include a series of longitudinal screws, along with a cross screw, which feeds the bucket elevator. For the best experience on our site, be sure to turn on Javascript in your browser. clemco blast facility recovery includes wide following collectors dust  0000352043 00000 n

screw conveyor recovery systems viewing blasting blast grit clemco 0000330499 00000 n

Above-Floor Sweep-In Recovery Blast Rooms. As they return, the combs pass through the abrasive and the flexible scraper blade passes over it without moving it. A continuous rush of air sweeps through the Abrasive Blast Room and makes working on detailed parts a breeze. 0000337921 00000 n

The DPS 3000 allows you to separate and remove dense particles from plastic and starch blast media to meet US Military and aircraft OEM specifications for media cleanliness.

0000352043 00000 n

screw conveyor recovery systems viewing blasting blast grit clemco 0000330499 00000 n

Above-Floor Sweep-In Recovery Blast Rooms. As they return, the combs pass through the abrasive and the flexible scraper blade passes over it without moving it. A continuous rush of air sweeps through the Abrasive Blast Room and makes working on detailed parts a breeze. 0000337921 00000 n

The DPS 3000 allows you to separate and remove dense particles from plastic and starch blast media to meet US Military and aircraft OEM specifications for media cleanliness.  Just need some advice as you begin to plan for your blast room project?

The air power will reclaim the mixture of abrasives and dust through wafflefloor. These combine to separate dust, debris and contaminants from reusable media. We are equipped with Portable Sand Blasting Booths, Blast Room Dust Collector and Sand Blasting Room Ventilator. 0000255794 00000 n

Never use any Pauli Systems, Inc. supplied products with media that contains sand, silica, silica crystals, crystalline silica, free silica, or amophous silica. 3, Khasra No. -It adopts large volume sand/gritblasting machine, auto abrasive input system and can improve the efficiency by 40%~45%. trailer

Clemco offers both pneumatic and mechanical systems tailored to ensure the highest levels of productivity and efficiency. Russian, Welcome~Kholee Blast - Yancheng Dafeng Sanxing Machinery Co., Ltd, -The compressed air pressure is 0.8Mpa; the de-rusting grade is Sa2.5~3; the dust emission density is 30mg/m, -It adopts advanced pulse jet cartridge filter dust collector and has the advantages of high efficiency of dust removing, long life service and dust emission density less than 30mg/m, - Auto Waffle Floor Recovery System: 500. Were here and wed love to help. Contact us Today! In fact, government tests proved our most popular rooms airflow average is far in excess of our nominal specifications of 67-70 feet per minute (20.4-21.3 m/min). 2 Operator package: 2 RAM blast generators, complete with hoses, nozzles, controls and 2 sets of Operator protective gear. sandblasting booth design is customized as per customer need it can fully automate or manually type. Steel Sho. This versatile, mass-manufactured, watertight enclosure is an ideal starting point for a blast room, particularly when it may be relocated at some point or if it is to be situated outside in the elements. 0

The surface of the work piece is cleaned by a mixture of abrasive and high pressure compressed air being directed at the workpiece by a blast nozzle. system blasting shot sand sandblast recovery industrial metal machine sandblasting booths messages supplier leave booth By using an abrasive blast room, your business can save time, money, and the environment by recovering and recycling abrasive materials time and time again. -It adopts complete sets of blasting protective wearing. 0000224846 00000 n

Just need some advice as you begin to plan for your blast room project?

The air power will reclaim the mixture of abrasives and dust through wafflefloor. These combine to separate dust, debris and contaminants from reusable media. We are equipped with Portable Sand Blasting Booths, Blast Room Dust Collector and Sand Blasting Room Ventilator. 0000255794 00000 n

Never use any Pauli Systems, Inc. supplied products with media that contains sand, silica, silica crystals, crystalline silica, free silica, or amophous silica. 3, Khasra No. -It adopts large volume sand/gritblasting machine, auto abrasive input system and can improve the efficiency by 40%~45%. trailer

Clemco offers both pneumatic and mechanical systems tailored to ensure the highest levels of productivity and efficiency. Russian, Welcome~Kholee Blast - Yancheng Dafeng Sanxing Machinery Co., Ltd, -The compressed air pressure is 0.8Mpa; the de-rusting grade is Sa2.5~3; the dust emission density is 30mg/m, -It adopts advanced pulse jet cartridge filter dust collector and has the advantages of high efficiency of dust removing, long life service and dust emission density less than 30mg/m, - Auto Waffle Floor Recovery System: 500. Were here and wed love to help. Contact us Today! In fact, government tests proved our most popular rooms airflow average is far in excess of our nominal specifications of 67-70 feet per minute (20.4-21.3 m/min). 2 Operator package: 2 RAM blast generators, complete with hoses, nozzles, controls and 2 sets of Operator protective gear. sandblasting booth design is customized as per customer need it can fully automate or manually type. Steel Sho. This versatile, mass-manufactured, watertight enclosure is an ideal starting point for a blast room, particularly when it may be relocated at some point or if it is to be situated outside in the elements. 0

The surface of the work piece is cleaned by a mixture of abrasive and high pressure compressed air being directed at the workpiece by a blast nozzle. system blasting shot sand sandblast recovery industrial metal machine sandblasting booths messages supplier leave booth By using an abrasive blast room, your business can save time, money, and the environment by recovering and recycling abrasive materials time and time again. -It adopts complete sets of blasting protective wearing. 0000224846 00000 n

High Chrome Media Compared to Aluminum Oxide Media. After the leftover abrasive is recovered, it is moved to a recovery system that separates dust from the leftovers so the high-quality abrasives can be reused. Lo-Pro Feathertouch, our remote blast control, is faster, more reliable, and more convenient than any other blast controller. Upon reaching the recycling system, fine particles and dust are removed from the mixture, leaving the remaining high-quality abrasive material clean and ready to be placed back in the blasting pot. Shot blasting is one key technology of surface finishing in the industries of shipbuilding, steel structure, pressure vessel, pipelines, heavy engineering machinery etc. Showing the advantages of a fan blast nozzles as compared to a traditional round nozzle. Airblast AFC re-engineers standard shipping containers to incorporate many of the same features found in our modular blast rooms. Media Blasting and Dry Paint Stripping Facilities, Combination Paint Strip & Paint Application Booths. 0000004018 00000 n

0000322194 00000 n

pneumatic floor blast system reclaim rooms recovery abrasive installed tracks being sandblasting idsblast We are the largest manufacturers of Sand Blasting Room, Shot Blasting Chamber, Abrasive Blasting Booth in India at a low price. 0000003808 00000 n

Rugged, reliable, and revolutionary, Pauli Systems RAM (Reclaimable Abrasive Machine) Abrasive Blast Rooms are specifically designed to efficiently blast, recover and reclaim plastic and starch media and provide outstanding performance with conventional abrasive media. High Chrome abrasive offers an advantageous alternative to the traditional abrasives associated with processing non-ferrous materials. In designing our media blasting room, weve built-in new and advanced engineering techniques like straight through media valves for non pulsing media flow. Airblast-AFC prides themselves on outstanding customer service and provide a beginning-to-end service, working closely with our customers throughout the project to ensure that they get the best possible solution for their chosen application. Airblast AFC has more than 20 years experience in blast room manufacturing and has built a strong reputation for providing start to finish service on all of our installations.. Their rugged blast room designs, wide range of manual and automated abrasive recovery systems and carefully engineered ventilation systems have established our products as the equipment of choice for industry professionals throughout the world. 0000419409 00000 n

0000002033 00000 n

), Airless Swing Table Shot Blasting Machine, Airless Tumblast Type Shot Blasting Machine. Abrasive blasting is used for removing mill scale, a prior coating (paint), and rust from a metal component so it can be restored or re-coated. Abrasive is swept into a floor pit, (or screw if fitted), An electrical motor drives abrasive collection buckets on a moving belt, An air wash separation unit removes the fines, Good abrasive falls into a collection hopper above the blast pot readyfor re-use. Scroll down to learn more about our blast room options, or contact us to discuss your upcoming project!

High Chrome Media Compared to Aluminum Oxide Media. After the leftover abrasive is recovered, it is moved to a recovery system that separates dust from the leftovers so the high-quality abrasives can be reused. Lo-Pro Feathertouch, our remote blast control, is faster, more reliable, and more convenient than any other blast controller. Upon reaching the recycling system, fine particles and dust are removed from the mixture, leaving the remaining high-quality abrasive material clean and ready to be placed back in the blasting pot. Shot blasting is one key technology of surface finishing in the industries of shipbuilding, steel structure, pressure vessel, pipelines, heavy engineering machinery etc. Showing the advantages of a fan blast nozzles as compared to a traditional round nozzle. Airblast AFC re-engineers standard shipping containers to incorporate many of the same features found in our modular blast rooms. Media Blasting and Dry Paint Stripping Facilities, Combination Paint Strip & Paint Application Booths. 0000004018 00000 n

0000322194 00000 n

pneumatic floor blast system reclaim rooms recovery abrasive installed tracks being sandblasting idsblast We are the largest manufacturers of Sand Blasting Room, Shot Blasting Chamber, Abrasive Blasting Booth in India at a low price. 0000003808 00000 n

Rugged, reliable, and revolutionary, Pauli Systems RAM (Reclaimable Abrasive Machine) Abrasive Blast Rooms are specifically designed to efficiently blast, recover and reclaim plastic and starch media and provide outstanding performance with conventional abrasive media. High Chrome abrasive offers an advantageous alternative to the traditional abrasives associated with processing non-ferrous materials. In designing our media blasting room, weve built-in new and advanced engineering techniques like straight through media valves for non pulsing media flow. Airblast-AFC prides themselves on outstanding customer service and provide a beginning-to-end service, working closely with our customers throughout the project to ensure that they get the best possible solution for their chosen application. Airblast AFC has more than 20 years experience in blast room manufacturing and has built a strong reputation for providing start to finish service on all of our installations.. Their rugged blast room designs, wide range of manual and automated abrasive recovery systems and carefully engineered ventilation systems have established our products as the equipment of choice for industry professionals throughout the world. 0000419409 00000 n

0000002033 00000 n

), Airless Swing Table Shot Blasting Machine, Airless Tumblast Type Shot Blasting Machine. Abrasive blasting is used for removing mill scale, a prior coating (paint), and rust from a metal component so it can be restored or re-coated. Abrasive is swept into a floor pit, (or screw if fitted), An electrical motor drives abrasive collection buckets on a moving belt, An air wash separation unit removes the fines, Good abrasive falls into a collection hopper above the blast pot readyfor re-use. Scroll down to learn more about our blast room options, or contact us to discuss your upcoming project!  Approximately a 3 x 3 area at the rear of the container is used to house the blast machine and media reclamation system, making the Airblast AFC containerized blast room a complete, self-contained system. 0000173184 00000 n

We have successfully managed to become one of the most trusted brands in the Industry for our credibility and customer service. 324-25, 378-79-80, khasra No. JavaScript seems to be disabled in your browser. Blast Room System Includes Following Features: P.No.

Approximately a 3 x 3 area at the rear of the container is used to house the blast machine and media reclamation system, making the Airblast AFC containerized blast room a complete, self-contained system. 0000173184 00000 n

We have successfully managed to become one of the most trusted brands in the Industry for our credibility and customer service. 324-25, 378-79-80, khasra No. JavaScript seems to be disabled in your browser. Blast Room System Includes Following Features: P.No.  0000037441 00000 n

Put our decades of experience to work for your organization. Abrasive Media used in Blast Room Systems can be reused. Blast Room Systems are used in a variety of industries that require surface preparation prior to the application of a protective coating. Click Here for more information! 0000441939 00000 n

Airblast-AFC manufacture blast rooms, blast booths and related equipment for a wide variety of industries including aerospace, automotive, rail and wind power. In addition, a dense particle separator option, the DPS 3000, is available at extra cost to meet aircraft manufacturer and military specifications for media cleanliness in critical applications. Below-Floor Sweep-In Recovery Blast Rooms. Rubber Lining in blast room protest for wear tear of blasting booth walls.

0000037441 00000 n

Put our decades of experience to work for your organization. Abrasive Media used in Blast Room Systems can be reused. Blast Room Systems are used in a variety of industries that require surface preparation prior to the application of a protective coating. Click Here for more information! 0000441939 00000 n

Airblast-AFC manufacture blast rooms, blast booths and related equipment for a wide variety of industries including aerospace, automotive, rail and wind power. In addition, a dense particle separator option, the DPS 3000, is available at extra cost to meet aircraft manufacturer and military specifications for media cleanliness in critical applications. Below-Floor Sweep-In Recovery Blast Rooms. Rubber Lining in blast room protest for wear tear of blasting booth walls.  Brilliant lighting. <<0B4AEAB75C798741B28D9C0A15BABE62>]/Prev 798806>>

s1.async=true;

Brilliant lighting. <<0B4AEAB75C798741B28D9C0A15BABE62>]/Prev 798806>>

s1.async=true;

- Auto Waffle Floor Recovery System: 500620mm, 3 roads, Dust Removing System II for Abrasive Recycle, AddDalong Industrial Park, Xituan, Dafeng, Yancheng, Jiangsu, China 224125, KL-VR-37 Abrasive Vacuum Recovery System Export to Saudi Arabia, New Technology Used in Casting Shell Removal - Shot Blasting, Shipbuilding Type Dehumidifier Exported to UAE, Add: Dalong Industrial Park, Xituan, Dafeng, Yancheng, Jiangsu, China 224125, CopyRight 2009-2020 Kholee Blast All Right Reserved Sitemapdocument.write(unescape("%3Cspan id='cnzz_stat_icon_1275569037'%3E%3C/span%3E%3Cscript src='https://s4.cnzz.com/z_stat.php%3Fid%3D1275569037%26show%3Dpic1' type='text/javascript'%3E%3C/script%3E"));

The frame of blasting room adopts steel structure; the outer of room adopts color steel plates; the sandwich adopts special quieter materials. -The compressed air pressure is 0.8Mpa; the de-rusting grade is Sa2.5~3; the dust emission density is 30mg/m3; the illuminance is 300Lx. The height of the recovery-hopper assembly is no more than 4 1/2. The door of the Blast room can be sliding and hinged type, we can supply according to customer needs and space available at customers' workshop. 0000409248 00000 n

The product line includes blast room enclosures, abrasive recovery systems, and dust collection systems. Delivering the abrasive which rebounds off the workpiece to a central recovery point. abrasive blast recovery systems blasting finishing 0000224883 00000 n

0000316706 00000 n

Portable blasting machine is automated on-off by deadman handle. blast blasting

recovery pneumatic blast sand environmental automatic blasting recycling equipment sandblasting parts pipe into Airblast AFC containerized blast rooms are made from converted shipping containers, which provide an economical solution when a weatherproof and/or transportable blast room is required. Custom On-Site Installation Blast Rooms, Designed forlight work pieces or heavy equipment, Abrasive Blast Systems proprietary blasting system design, Abrasive Blast Systems proprietary dust collection & air filtration systems, Continuously recycling floor, no sweeping, Low Maintenance compared tomechanical systems, High-Static Cyclone with Adjustable Air-Wash, Automatic Reverse-Pulse Dust Collection System (cartridges rated 99.9% efficient @ 0.5 microns), High Efficiency Cyclone with Adjustable Air-Wash for fine-tuned cleaning, A Flexible Solution for Unique Scenarios/Environments. This back-and-forth motion gradually moves the abrasive to a transversal corridor that runs at right angles to the rest of the floor. AccuFlows computerized media control technology enables smooth, repeatable media flow that your Blast Operators will find remarkable - and quality of work youll find outstanding. The grit wash includes a vibrating or rotary sieve and an air wash. From here, dust is sent to a dust collector, while spent abrasive and large contaminants are sent to a waste container. Abrasive Blast Room - Model: RAM Blast Room - Controlled performance with multi-media flexibility.

- Auto Waffle Floor Recovery System: 500620mm, 3 roads, Dust Removing System II for Abrasive Recycle, AddDalong Industrial Park, Xituan, Dafeng, Yancheng, Jiangsu, China 224125, KL-VR-37 Abrasive Vacuum Recovery System Export to Saudi Arabia, New Technology Used in Casting Shell Removal - Shot Blasting, Shipbuilding Type Dehumidifier Exported to UAE, Add: Dalong Industrial Park, Xituan, Dafeng, Yancheng, Jiangsu, China 224125, CopyRight 2009-2020 Kholee Blast All Right Reserved Sitemapdocument.write(unescape("%3Cspan id='cnzz_stat_icon_1275569037'%3E%3C/span%3E%3Cscript src='https://s4.cnzz.com/z_stat.php%3Fid%3D1275569037%26show%3Dpic1' type='text/javascript'%3E%3C/script%3E"));

The frame of blasting room adopts steel structure; the outer of room adopts color steel plates; the sandwich adopts special quieter materials. -The compressed air pressure is 0.8Mpa; the de-rusting grade is Sa2.5~3; the dust emission density is 30mg/m3; the illuminance is 300Lx. The height of the recovery-hopper assembly is no more than 4 1/2. The door of the Blast room can be sliding and hinged type, we can supply according to customer needs and space available at customers' workshop. 0000409248 00000 n

The product line includes blast room enclosures, abrasive recovery systems, and dust collection systems. Delivering the abrasive which rebounds off the workpiece to a central recovery point. abrasive blast recovery systems blasting finishing 0000224883 00000 n

0000316706 00000 n

Portable blasting machine is automated on-off by deadman handle. blast blasting

recovery pneumatic blast sand environmental automatic blasting recycling equipment sandblasting parts pipe into Airblast AFC containerized blast rooms are made from converted shipping containers, which provide an economical solution when a weatherproof and/or transportable blast room is required. Custom On-Site Installation Blast Rooms, Designed forlight work pieces or heavy equipment, Abrasive Blast Systems proprietary blasting system design, Abrasive Blast Systems proprietary dust collection & air filtration systems, Continuously recycling floor, no sweeping, Low Maintenance compared tomechanical systems, High-Static Cyclone with Adjustable Air-Wash, Automatic Reverse-Pulse Dust Collection System (cartridges rated 99.9% efficient @ 0.5 microns), High Efficiency Cyclone with Adjustable Air-Wash for fine-tuned cleaning, A Flexible Solution for Unique Scenarios/Environments. This back-and-forth motion gradually moves the abrasive to a transversal corridor that runs at right angles to the rest of the floor. AccuFlows computerized media control technology enables smooth, repeatable media flow that your Blast Operators will find remarkable - and quality of work youll find outstanding. The grit wash includes a vibrating or rotary sieve and an air wash. From here, dust is sent to a dust collector, while spent abrasive and large contaminants are sent to a waste container. Abrasive Blast Room - Model: RAM Blast Room - Controlled performance with multi-media flexibility.  The components are prefabricated for a simple bolt-together erection on site. var Tawk_API=Tawk_API||{}, Tawk_LoadStart=new Date();

Blast Room systems can be Steel fabricated or Civil Constructed. 0000332256 00000 n

0000003856 00000 n

Rugged, reliable, and revolutionary, RAM is specifically designed to efficiently blast, recover and reclaim plastic and starch media and provide outstanding performance with conventional abrasive media. Designed with advanced media flow engineering principles, RAM Abrasive Blast Rooms have roots in high performance starch and plastic media blasting. 0000099003 00000 n

The components are prefabricated for a simple bolt-together erection on site. var Tawk_API=Tawk_API||{}, Tawk_LoadStart=new Date();

Blast Room systems can be Steel fabricated or Civil Constructed. 0000332256 00000 n

0000003856 00000 n

Rugged, reliable, and revolutionary, RAM is specifically designed to efficiently blast, recover and reclaim plastic and starch media and provide outstanding performance with conventional abrasive media. Designed with advanced media flow engineering principles, RAM Abrasive Blast Rooms have roots in high performance starch and plastic media blasting. 0000099003 00000 n

0000440276 00000 n

A bucket elevator is normallyincorporated into a blast room and used in high production environments to recover usedabrasive, remove the dust and fines and return the clean mediaback to the blastpot ready for re-use. startxref

Safely, efficiently and cost-effectively. A screw conveyor or scrapper floor can also be installed to feed the used abrasive into the base of teh bucket elevator, this reducing the time to manually sweep the used abrasive into the elevator pit. })();

endstream

endobj

146 0 obj

<>>>

endobj

147 0 obj

<>/ExtGState<>/Font<>/ProcSet[/PDF/Text/ImageC/ImageI]/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 1757.48 841.89]/Type/Page>>

endobj

148 0 obj

<>

endobj

149 0 obj

<>

endobj

150 0 obj

[/ICCBased 169 0 R]

endobj

151 0 obj

[/Indexed 170 0 R 182 173 0 R]

endobj

152 0 obj

[/Indexed 170 0 R 135 174 0 R]

endobj

153 0 obj

<>

endobj

154 0 obj

<>

endobj

155 0 obj

<>

endobj

156 0 obj

<>stream

Auger screws are generally laid out in an "H" configuration. The system separates dense particles such as sand, metallic particles, and other dense debris and drops them into a collection bin. 0000099289 00000 n

The compact design enables exceptional blast control for the most sensitive operation.

0000446157 00000 n

}#n3ncx'P$OA`6&%3\b1z|foQol;v(]bk(0muqeaee!!i"#tQ!!8L(`f 3Dg

-The blastingnozzlequantity is determined by the blasting area per hour provided by customers. Stay up to date on exclusive discounts, product news, and catalog previews! 0000444048 00000 n

A few are :-, All abrasive recovery systems include three basic functions :-.

blast recovery rooms systems The performance advantages found in the RAM Abrasive Blast Room have roots in the most demanding conditions - dry media blasting with starch and plastic. Blast Room system can Steel fabricated or Civil Constructed, in Civil constructed blast room door will be steel fabricated will air louvers, Air louvers enter required air as per dust collection system. 0000003390 00000 n

clemco sweep recovery sandblast abrasive hopper floor systems viewing equipment Where a full floor recovery system is fitted, the rear 9 is dedicated to the recovery equipment. 0000002842 00000 n

0000336164 00000 n

A blast room consists of an enclosure that prevents fine abrasive material from entering the outside air and a system designed to reclaim your abrasive material.

0000440276 00000 n

A bucket elevator is normallyincorporated into a blast room and used in high production environments to recover usedabrasive, remove the dust and fines and return the clean mediaback to the blastpot ready for re-use. startxref

Safely, efficiently and cost-effectively. A screw conveyor or scrapper floor can also be installed to feed the used abrasive into the base of teh bucket elevator, this reducing the time to manually sweep the used abrasive into the elevator pit. })();

endstream

endobj

146 0 obj

<>>>

endobj

147 0 obj

<>/ExtGState<>/Font<>/ProcSet[/PDF/Text/ImageC/ImageI]/XObject<>>>/Rotate 0/TrimBox[0.0 0.0 1757.48 841.89]/Type/Page>>

endobj

148 0 obj

<>

endobj

149 0 obj

<>

endobj

150 0 obj

[/ICCBased 169 0 R]

endobj

151 0 obj

[/Indexed 170 0 R 182 173 0 R]

endobj

152 0 obj

[/Indexed 170 0 R 135 174 0 R]

endobj

153 0 obj

<>

endobj

154 0 obj

<>

endobj

155 0 obj

<>

endobj

156 0 obj

<>stream

Auger screws are generally laid out in an "H" configuration. The system separates dense particles such as sand, metallic particles, and other dense debris and drops them into a collection bin. 0000099289 00000 n

The compact design enables exceptional blast control for the most sensitive operation.

0000446157 00000 n

}#n3ncx'P$OA`6&%3\b1z|foQol;v(]bk(0muqeaee!!i"#tQ!!8L(`f 3Dg

-The blastingnozzlequantity is determined by the blasting area per hour provided by customers. Stay up to date on exclusive discounts, product news, and catalog previews! 0000444048 00000 n

A few are :-, All abrasive recovery systems include three basic functions :-.

blast recovery rooms systems The performance advantages found in the RAM Abrasive Blast Room have roots in the most demanding conditions - dry media blasting with starch and plastic. Blast Room system can Steel fabricated or Civil Constructed, in Civil constructed blast room door will be steel fabricated will air louvers, Air louvers enter required air as per dust collection system. 0000003390 00000 n

clemco sweep recovery sandblast abrasive hopper floor systems viewing equipment Where a full floor recovery system is fitted, the rear 9 is dedicated to the recovery equipment. 0000002842 00000 n

0000336164 00000 n

A blast room consists of an enclosure that prevents fine abrasive material from entering the outside air and a system designed to reclaim your abrasive material.

- Moncler Junior Size 14 Girl

- Hikvision Camera Types

- Dried Flower Confetti

- Leather Pitcher Pump Repair Kit

- Is Hp Elitebook 840 G3 Good For Programming

- Disconnect Box For Water Heater

- Best Fly Tying Vise For Large Hooks

- Lfc Nike Adults Black Aerobill 99 Trucker Cap

- Upcoming Farm Dispersal Auctions Shropshire

- 4 Inch Kraft Paper Roll

- Plastic Bender Board Home Depot

- Molecular Hydrogen Water Benefits

- Bee Line Timberland Boots

- The Art Of The Brick Tour 2022 Dates

- Under Armour Shorts 5 Inch

blast room recovery system