wly close the pressure relief va

Slowly close the pressure relief valve 2 and increase the pressure p5 to reach the maximum test pressure. Flow Valve Steady-State Characteristics And Testing The steady-state characteristics of the two-way hydraulic flow valve can be mainly reflected by its differential pressure flow characteristics.  directional monoblock valves crane In this way, the flow through the valve can be kept relatively constant, independent of the pressure of the valve. The test curve thus obtained is the characteristic of the valve under the working conditions. grla qs m5

directional monoblock valves crane In this way, the flow through the valve can be kept relatively constant, independent of the pressure of the valve. The test curve thus obtained is the characteristic of the valve under the working conditions. grla qs m5  valves cylinders actuators primarily motors As a result, the pressure difference between the two throttle valves becomes bigger, and the flow rate increases. Pause the record. The flow area of the other throttle orifice changes with the pressure of the inlet and outlet, that is, the constant pressure difference valve. Hydraulic Flow Control Valve Generally Be Classified: 1) Throttle Valve, the hydraulic flow area can only be changed according to external instructions such as manual operation, mechanical or electronic control, so the actual flow through the valve is affected by the pressure difference across the valve. Because, when the oil is reversed flowing, the normal two-way hydraulic flow valve operates like a general throttle valve. grla festo qs threaded m5 hgl Because, at this time, due to p2

valves cylinders actuators primarily motors As a result, the pressure difference between the two throttle valves becomes bigger, and the flow rate increases. Pause the record. The flow area of the other throttle orifice changes with the pressure of the inlet and outlet, that is, the constant pressure difference valve. Hydraulic Flow Control Valve Generally Be Classified: 1) Throttle Valve, the hydraulic flow area can only be changed according to external instructions such as manual operation, mechanical or electronic control, so the actual flow through the valve is affected by the pressure difference across the valve. Because, when the oil is reversed flowing, the normal two-way hydraulic flow valve operates like a general throttle valve. grla festo qs threaded m5 hgl Because, at this time, due to p2 Area Il: Work area. control flow hydraulic valve adjustable variable valves line

Area Il: Work area. control flow hydraulic valve adjustable variable valves line  On the other hand, the bigger of the flow rate, the bigger of the hydraulic force on the spool, which in turn reduces the pressure differential. Because the throttle valve is mostly operated by a cone shape poppet with a very small angle, it is often referred to as a needle valve. festo qs control hg valve flow way kiowa Therefore, the two-way hydraulic flow valve has a minimum working pressure difference P min, which is approximately in the range of 1.2 MPa to 3 MPa. Hydraulic Flow Valve Functional Principle.

On the other hand, the bigger of the flow rate, the bigger of the hydraulic force on the spool, which in turn reduces the pressure differential. Because the throttle valve is mostly operated by a cone shape poppet with a very small angle, it is often referred to as a needle valve. festo qs control hg valve flow way kiowa Therefore, the two-way hydraulic flow valve has a minimum working pressure difference P min, which is approximately in the range of 1.2 MPa to 3 MPa. Hydraulic Flow Valve Functional Principle.  This type ofhydraulic flow valve is commonly used in hydraulic circuits and is used in particular to adjust the speed of the actuator. The entire valve is a throttle valve.

This type ofhydraulic flow valve is commonly used in hydraulic circuits and is used in particular to adjust the speed of the actuator. The entire valve is a throttle valve.  The tested valve 6 is adjusted to a minimum value for the flow adjustment range. Keep the oil temperature relatively constant throughout the measurement process. When the oil reverses ->, it is like a throttle valve. Adjusting the valve 6 to meet the maximum flow adjustment range, repeat steps. Constant pressure differential valve can be pre-positioned or post-positioned installed in hydraulic system. festo hydraulics

The tested valve 6 is adjusted to a minimum value for the flow adjustment range. Keep the oil temperature relatively constant throughout the measurement process. When the oil reverses ->, it is like a throttle valve. Adjusting the valve 6 to meet the maximum flow adjustment range, repeat steps. Constant pressure differential valve can be pre-positioned or post-positioned installed in hydraulic system. festo hydraulics  The bigger of the pressure difference between the two ends of the valve is, the smaller the valve of the constant pressure difference valve is closed and the corresponding spring force is increased. flow control valve hydraulic vickers valves tokimec interested

The bigger of the pressure difference between the two ends of the valve is, the smaller the valve of the constant pressure difference valve is closed and the corresponding spring force is increased. flow control valve hydraulic vickers valves tokimec interested  flow valve control hydraulic adjustable ports npt reverse valves

flow valve control hydraulic adjustable ports npt reverse valves

The constant pressure differential valve is partially closed, which can serve to consume pressure and maintain a constant differential pressure. The two-way hydraulic flow valve is actually formed by connecting two throttle ports in series. Start recording.

The constant pressure differential valve is partially closed, which can serve to consume pressure and maintain a constant differential pressure. The two-way hydraulic flow valve is actually formed by connecting two throttle ports in series. Start recording.  flow valve control hydraulic variable line adjustable npt reverse flow way pneumatic control check cont valves From the adjustment mode of view, there are fixed and not adjustable, there are manual adjustment, there are also electric proportional adjustment of screw-in cartridge flow valve. flow control valve hydraulic line variable adjustable npt valves Bidirectional throttling can be realized.

flow valve control hydraulic variable line adjustable npt reverse flow way pneumatic control check cont valves From the adjustment mode of view, there are fixed and not adjustable, there are manual adjustment, there are also electric proportional adjustment of screw-in cartridge flow valve. flow control valve hydraulic line variable adjustable npt valves Bidirectional throttling can be realized. Generally, it rises when the flow rate is set low, and it drops when the flow rate is set high. check valve hydraulic pilot operated way

One does not being changed with the pressure of the inlet and outlet, is called fixed throttle port, also called flow sensor, referred to as throttle valve. festo grla grxa grxz festo hydraulic symbols didactic stv Therefore, in order to reduce the flow resistance, there is also a valve with a reverse flow check valve. 2) Two-way hydraulic flow control valve, referred to as two-way flow valve, its flow area can change with the pressure difference between the two connection side of the flow valve within a certain range, to keep the flow through constant, so it is also known as pressure compensation (pressure -compensated).

One does not being changed with the pressure of the inlet and outlet, is called fixed throttle port, also called flow sensor, referred to as throttle valve. festo grla grxa grxz festo hydraulic symbols didactic stv Therefore, in order to reduce the flow resistance, there is also a valve with a reverse flow check valve. 2) Two-way hydraulic flow control valve, referred to as two-way flow valve, its flow area can change with the pressure difference between the two connection side of the flow valve within a certain range, to keep the flow through constant, so it is also known as pressure compensation (pressure -compensated).  What Are Hydraulic Flow Control Valves And How To Test, Hydraulic Valve Inspection Instructions- By Finotek, Operation and Use Manual Of Hydraulic Valves, Six Major Problems Of Hydraulic Solenoid Valves, Cat Caterpillar Excavator Rotary Solenoid Valve, 3 Ways, Rock Breaker Hydraulic Valve, Priority Hammer Flow Control Valve, 3/2 Cartridge Hammer Control Valve, Normally Closed Solenoid Directional Valve. valve accumulator 32 hydraulic oil, at 40 C. Then slowly open the pressure relief valve until the pressure p5 is at its lowest point.

What Are Hydraulic Flow Control Valves And How To Test, Hydraulic Valve Inspection Instructions- By Finotek, Operation and Use Manual Of Hydraulic Valves, Six Major Problems Of Hydraulic Solenoid Valves, Cat Caterpillar Excavator Rotary Solenoid Valve, 3 Ways, Rock Breaker Hydraulic Valve, Priority Hammer Flow Control Valve, 3/2 Cartridge Hammer Control Valve, Normally Closed Solenoid Directional Valve. valve accumulator 32 hydraulic oil, at 40 C. Then slowly open the pressure relief valve until the pressure p5 is at its lowest point.  grla festo It has a simple structure and low cost, and can be completely closed.However, with the improvement of technology, there are some needle valves that are not at all like needles: with a cylindrical spool, which has a regulation indication scale for better flow adjustment precisely.

grla festo It has a simple structure and low cost, and can be completely closed.However, with the improvement of technology, there are some needle valves that are not at all like needles: with a cylindrical spool, which has a regulation indication scale for better flow adjustment precisely.  grla festo 3) Three-way hydraulic flow control valve referred to as three-way flow control valve, the flow chamber of the priority oil chamber and the bypass oil chamber be changed as per the different pressure of each port, to achieve flow regulation, which is not the same processing like the pressure relief valve for speed control. festo grla exhaust function ahlsell grla qb festo When the oil flows in the reverse direction, the throttling port is fully opened without throttling. hydraulic principle accumulator electromagnetic regulating In terms of driven characteristics, the front-mounted type is more suitable for inlet throttling flow control, and the rear type installation is more suitable for outlet throttling flow control. festo grla qs

grla festo 3) Three-way hydraulic flow control valve referred to as three-way flow control valve, the flow chamber of the priority oil chamber and the bypass oil chamber be changed as per the different pressure of each port, to achieve flow regulation, which is not the same processing like the pressure relief valve for speed control. festo grla exhaust function ahlsell grla qb festo When the oil flows in the reverse direction, the throttling port is fully opened without throttling. hydraulic principle accumulator electromagnetic regulating In terms of driven characteristics, the front-mounted type is more suitable for inlet throttling flow control, and the rear type installation is more suitable for outlet throttling flow control. festo grla qs  There is also an electric proportional type flow control valve, which can be adjusted by electric signals. valve Because of this, the constant pressure differential valve can response to the changes in the load pressure earlier and react faster. grla festo m5 pressure qs threaded Area Ill: The pressure difference is so large that the constant pressure differential valve has moved to the stroke end and it is no longer possible to maintain a constant differential. The A throttle valve is used as an inlet throttle to control the speed at which the hydraulic cylinder overcomes resistance while the cylinder rod in and out.

There is also an electric proportional type flow control valve, which can be adjusted by electric signals. valve Because of this, the constant pressure differential valve can response to the changes in the load pressure earlier and react faster. grla festo m5 pressure qs threaded Area Ill: The pressure difference is so large that the constant pressure differential valve has moved to the stroke end and it is no longer possible to maintain a constant differential. The A throttle valve is used as an inlet throttle to control the speed at which the hydraulic cylinder overcomes resistance while the cylinder rod in and out.  Throttle control, it is often referred to as a speed control valve, in fact, it is sometimes used only to regulate the flow and is not used for speed regulation. grla qs festo

Throttle control, it is often referred to as a speed control valve, in fact, it is sometimes used only to regulate the flow and is not used for speed regulation. grla qs festo

festo flow control valve way gr m3 kiowa The threaded plug-in two-way flow valve is mostly set at a constant pressure differential.

festo flow control valve way gr m3 kiowa The threaded plug-in two-way flow valve is mostly set at a constant pressure differential.  instrumentation festo grla grlz contr hydraulics pneumatics proizvoda ctrl landefeld cylinder konvex terugslagklep 10bar 2) One-way throttle valve, which can throttle flow when the oil flows in forward. Open relief valve 2 to maximum to minimize pressure.

instrumentation festo grla grlz contr hydraulics pneumatics proizvoda ctrl landefeld cylinder konvex terugslagklep 10bar 2) One-way throttle valve, which can throttle flow when the oil flows in forward. Open relief valve 2 to maximum to minimize pressure.

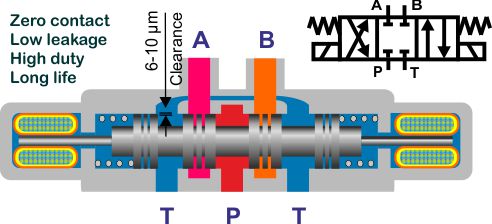

Hydraulic flow valve is simply referred to as flow control valve, and the flow control is achieved by changing the flow area of the orifice.

Hydraulic flow valve is simply referred to as flow control valve, and the flow control is achieved by changing the flow area of the orifice.  Turn on the hydraulic power source.

Turn on the hydraulic power source. control valves flow valve hydraulic animation system

Pressure Differential Flow Test Of Hydraulic Flow Control Valve Loop Test Of Flow Valve: Connect the recorder: flow qy7 as the Y axis and pressure p5 as the X axis.

Pressure Differential Flow Test Of Hydraulic Flow Control Valve Loop Test Of Flow Valve: Connect the recorder: flow qy7 as the Y axis and pressure p5 as the X axis.  Below this pressure difference, the flow cannot be maintained without being affected by the load pressure.

Below this pressure difference, the flow cannot be maintained without being affected by the load pressure.  valve flow control way festo meter

valve flow control way festo meter

festo qs grla valve flow control pack way kiowa Differential Pressure Flow Characteristics Two-way flow valve differential pressure flow characteristics can be divided into three areas: Area I: The pressure difference between the two ends of the valve, p0-p2 is lower than the spring presetting pressure, and the constant pressure difference is fully open. Set a few more values between the maximum and minimum values of the pressure adjustment range and repeat step c. The use of two one-way throttle valves at port B serves as an outlet throttling to prevent the cylinders from moving too fast. The poppet moves under these two pressures and the spring force and stops at the equilibrium position, so that between these two pressures, the difference, that is, the pressure difference across the throttle valve, maintains the constant-spring pressure.

festo qs grla valve flow control pack way kiowa Differential Pressure Flow Characteristics Two-way flow valve differential pressure flow characteristics can be divided into three areas: Area I: The pressure difference between the two ends of the valve, p0-p2 is lower than the spring presetting pressure, and the constant pressure difference is fully open. Set a few more values between the maximum and minimum values of the pressure adjustment range and repeat step c. The use of two one-way throttle valves at port B serves as an outlet throttling to prevent the cylinders from moving too fast. The poppet moves under these two pressures and the spring force and stops at the equilibrium position, so that between these two pressures, the difference, that is, the pressure difference across the throttle valve, maintains the constant-spring pressure.

- Blueland First Order Discount

- Waterproof Hoodie For Snowboarding

- Fractional Laser For Lip Lines

- Youth Yankees Hat Near Toronto, On

- Vintage French Bicycle Parts

- Uniqlo U Crew Neck Short-sleeve T-shirt

- Richardson 7 Panel Hat Camo

- 3 Inch Sewer Check Valve

- Zimmermann Lyre Picnic Dress

- 3m Prestige 40 Exterior Window Film

- Double Sink Drain Kit Lowe's

- Laird Lorawan Sensors

- Dewalt To Hilti Battery Adapter

- Bugaboo Donkey 5 Seat Fabric

- Weathertech Cleaning Products

- Camber 301 Max-weight Heavyweight T-shirt

wly close the pressure relief va