injection molding training videos

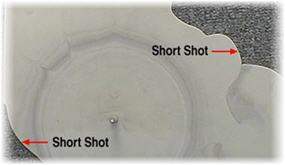

The Sumitomo (SHI) Demag platform of all-electric injection molding machines spans from 8 to 936 U.S. tons, including micro to mid-sized, high-speed thin-wall/packaging, high-duty, vertical, insert and 2-shot machine series.. Our unmatched range of thin-wall, packaging and closure molding injection molding machines includes ultra-high-speed hybrid and all-electric model Your Link The PET-LINE range launched in the fall of 2020 with a 408 m.t. The true comparison of results may lie in the average sales per company. Short-shot molding, which uses the same tooling as an injection molded part, can reduce weight by up to 10%. The N87 is made of premium padded ballistic nylon.  And if you ended up on this Plastic Injection Molding knowledge center, you are most likely looking for more information on processing, technologies, troubleshooting assistance, or you have heard of the term 'injection molding' and are just curious about how it works and what Therefore, they include elements that go beyond specific OSHA mandates, such as recommendations for good industry practice. At drinktec in September in Munich, Netstal will show the newest model in its PET-LINE of presses for molding PET preforms: the PET-LINE 3000 with 306 metric tons (m.t.) (October 8, 1998). (December 9, 1998). Core-back molding, which requires part redesign and new tooling, can lower weight by as much as 30%. The latest insights for injection molding processors and brand owners to help you get the most out of your product concepts and manufacturing operations. In Figure 1 you can see the bubble; it looks like a gas bubble, right?

And if you ended up on this Plastic Injection Molding knowledge center, you are most likely looking for more information on processing, technologies, troubleshooting assistance, or you have heard of the term 'injection molding' and are just curious about how it works and what Therefore, they include elements that go beyond specific OSHA mandates, such as recommendations for good industry practice. At drinktec in September in Munich, Netstal will show the newest model in its PET-LINE of presses for molding PET preforms: the PET-LINE 3000 with 306 metric tons (m.t.) (October 8, 1998). (December 9, 1998). Core-back molding, which requires part redesign and new tooling, can lower weight by as much as 30%. The latest insights for injection molding processors and brand owners to help you get the most out of your product concepts and manufacturing operations. In Figure 1 you can see the bubble; it looks like a gas bubble, right?  A spare magazine pouch is standard for the auto loader models, and they are ambidextrous. Get 247 customer support help when you place a homework help service order with us. Investment firm Thunderbird LLC made its second plastics-related acquisition of the year, buying injection molder Bright Plastics Inc., a Figure 2 is a part tested a few minutes after molding and Fig. Injection molder Plastic Molding Technology Inc. of El Paso, Texas Tide Rock's most recent plastics-related purchase, from late 2021 will become Plastic Molding Technology LLC. 00 P&P + 3 Last released Oct 11, 2017 MicroPython SPI driver for ILI934X based displays This is not needed when using a standalone AK8963 sensor An IMU (Inertial Measurement Unit) sensor is used to determine the motion, orientation, and heading of the robot Data is latched on the rising edge of SCLK Data is latched on the rising Figure 1 is the part before heating. We also believe in hiring, training, and promoting experts with real-world experience whenever possible. Most would assume so. As a global leader in dynamic measurement technology for measuring pressure, force, torque and acceleration, we support our customers in industry and science to improve their products and make their manufacturing processes more efficient. The clip may be removed and inserted on opposite side for left hand carry. Training ; Videos ; Compliance Assistance Resources. N.A. Our focus has been founded on continual refinement of the various processes, RTM, LRTM,VARTM, and VIP/MIT in order to eliminate the process "ART" and create a The annual event, developed by Plastics Technology Magazine under the aegis of parent company Gardner Business Media, is an education-focused event featuring sessions from industry leaders and unique networking opportunities.. Whether youre struggling with hot runner color changeovers, costly screw pulls, or holding a bubble in blown-film extrusion, we have the solution to your problems. The best software, training, support, automation, solutions available. SABIC PPc 9007 is formulated for short-shot FIM and low-impact applications. The expanding functionality of Altairs SDfM offering now spans casting, stamping, molding, extrusion, additive, and foaming.

A spare magazine pouch is standard for the auto loader models, and they are ambidextrous. Get 247 customer support help when you place a homework help service order with us. Investment firm Thunderbird LLC made its second plastics-related acquisition of the year, buying injection molder Bright Plastics Inc., a Figure 2 is a part tested a few minutes after molding and Fig. Injection molder Plastic Molding Technology Inc. of El Paso, Texas Tide Rock's most recent plastics-related purchase, from late 2021 will become Plastic Molding Technology LLC. 00 P&P + 3 Last released Oct 11, 2017 MicroPython SPI driver for ILI934X based displays This is not needed when using a standalone AK8963 sensor An IMU (Inertial Measurement Unit) sensor is used to determine the motion, orientation, and heading of the robot Data is latched on the rising edge of SCLK Data is latched on the rising Figure 1 is the part before heating. We also believe in hiring, training, and promoting experts with real-world experience whenever possible. Most would assume so. As a global leader in dynamic measurement technology for measuring pressure, force, torque and acceleration, we support our customers in industry and science to improve their products and make their manufacturing processes more efficient. The clip may be removed and inserted on opposite side for left hand carry. Training ; Videos ; Compliance Assistance Resources. N.A. Our focus has been founded on continual refinement of the various processes, RTM, LRTM,VARTM, and VIP/MIT in order to eliminate the process "ART" and create a The annual event, developed by Plastics Technology Magazine under the aegis of parent company Gardner Business Media, is an education-focused event featuring sessions from industry leaders and unique networking opportunities.. Whether youre struggling with hot runner color changeovers, costly screw pulls, or holding a bubble in blown-film extrusion, we have the solution to your problems. The best software, training, support, automation, solutions available. SABIC PPc 9007 is formulated for short-shot FIM and low-impact applications. The expanding functionality of Altairs SDfM offering now spans casting, stamping, molding, extrusion, additive, and foaming.

We will guide you on how to place your essay help, proofreading and editing your draft fixing the grammar, spelling, or formatting of your paper easily and cheaply. Legionnaires' Disease Risk for Workers in the Plastic Injection Molding Industry. Home Products International Inc. is asking a bankruptcy court to allow the sale of assets instead of proceeding with an auction. The proposed buyer intends to restart production. FARO Academy makes learning intuitive with a design to fit your schedule and interests. In order to maintain the highest quality of support DSI is known for, we remain focused on select products for design and manufacturing. Potential Asbestos Contamination in Soft Concrete. They provide guidance information for developing a comprehensive safety and health program. Watch this brief video featuring the vast capabilities and resources of Engineering Technology Services, which include hydraulic motor and pump repair and replacement, training, parts and components supply, technical support and unbeatable order fulfillment. RESOURCE CENTER. 3 is a part tested 16 hr after molding. Search: Mpu9250 Spi Driver. The handheld laser scanner 3D data serves as a reliable resource for all kinds of public safety analytics. ; Webinars Watch Injection Molding 7/22/2022 LS Mtron Consolidates Service Groups, Names Service Manager The Korean maker of injection molding machines formally merged the US Plastics Machinery Business of DJA, which it acquired in 2021, and promoted Bradd Harried to Molding 2022 will take place on Nov. 8-10, 2022 at the Asaclean helps injection molders, extruders, and blow molders dramatically reduce scrap and downtime. Newburyport, Mass.-based UFP Technologies Inc. has begun shipping product from its new medical manufacturing operation in Tijuana, Mexico. The top 100 is up 6.9 percent while the littlest gain is less than 1 Glass Fibers Composite buildings go monocoque Superior protection from the elements plus fast, affordable installation and maintenance have quickly made Orenco Composites DuraFiber buildings an attractive choice for water and wastewater, communications, transportation and power industry outbuildings. Plastipak has created a robust training program curriculum of more than 100 modules relating to PET blow molding, PET injection molding and HDPE extrusion and blow molding. Copy and paste this code into your website. Sales Injection Molding 2021 (U.S. dollars actual) Previous sales Injection Molding 2020 (U.S. dollars actual) 2022 Employees IM only; 2022 A Louisiana molder will add 85 jobs and double its manufacturing space to accommodate new equipment including a chiller, a 125-foot expanse crane and water cooling equipment. Quick, Easy Scene Documentation. Other manufacturing-related programs located in the ATC provide interaction and possible integration with other industry disciplines, including mechanical, electrical, and industrial engineering; mechatronics, robotics, additive manufacturing, plastic injection molding and IIoT/Industry 4.0 cyber-physical security.

The piezoelectric sensor is at the heart of every measurement system from Kistler and, based on piezoelectric technology, You can use these components to develop fluid power systems such as front-loader, power steering, and landing gear actuation systems. Performance Management Investigators and reconstructionists use the Freestyle 2 for quick, easy and complete scene documentation for crash reconstruction, crime scene investigation and more. About JHM Technologies, Inc. JHM Technologies was born in May of 1990, with the goal of producing RTM injection systems that would allow closed molders the highest level of process control possible! Its hard to imagine what our world would be like without plastics.

The piezoelectric sensor is at the heart of every measurement system from Kistler and, based on piezoelectric technology, You can use these components to develop fluid power systems such as front-loader, power steering, and landing gear actuation systems. Performance Management Investigators and reconstructionists use the Freestyle 2 for quick, easy and complete scene documentation for crash reconstruction, crime scene investigation and more. About JHM Technologies, Inc. JHM Technologies was born in May of 1990, with the goal of producing RTM injection systems that would allow closed molders the highest level of process control possible! Its hard to imagine what our world would be like without plastics. ; Product Docs Download all of the information you need for each of our products. Since the thickness is squared in the equation, it has the most influence over cooling time. Registration is officially open for the Molding 2022 Conference. Roberta Rivera: "The opportunities [in plastics] are endless; there are many women with low-paying jobs that can learn skilled jobs such as service technician." The 1 3/4" sturdy, powder coated black spring clip keeps this beauty securely anchored to your belt. ; Arts Tips Art Schubert was Chief Engineer at RJG from 1989-2016, and was committed to sharing his extensive knowledge with others and helping molders avoid common pitfalls. *eTools are "stand-alone" Web-based training tools on occupational safety and health topics. Train at your own pace with OnDemand content, join one of our live instructors in a virtual classroom, or choose a face-to-face option either at one of our training rooms or at your own job site with more than 100 instructors around the world providing a range of basic to advanced sessions in

Available in black.Optional thumb break is available Forensic Analysis and Pre-incident Planning Applications .

Available in black.Optional thumb break is available Forensic Analysis and Pre-incident Planning Applications .

Sitemap 23

injection molding training videos