g src="https://cdn.shopify.com/s

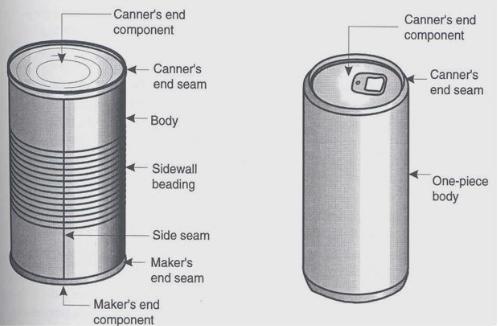

The elimination of the side seam and the closure of the bottom is also a saving. 1 Trade Fair for Plastics and Rubber, Visit us at the Drinktec The Worlds Leading Trade Fair for the Beverage and Liquid Food Industry, Cross Cut Adhesion Test KIT (Master Paint Plate). However, the more recently developed 2 piece can offers great benefits in terms of production and material consumption. These advantages are coincident for both. press. The tank body is formed directly by the punching and drawing process, without leakage, and the leakage detection procedure can be removed. All right reserved. ironing trimming necking and flanging. Food Project : www.boontreefood.com 2016 Royal Can Industries Company Limited. The body of two cans is stretched and deformed during forming, and the wall thickness is thinner than that of three cans. Liapklongkaerai Road, Kaerai,

C \ compared with three cans, two pieces of tank has the following advantages: (1) the surface can be comprehensive printing and packaging, improve the effect of packaging (2) two cans is qualitative light, thin wall (3) body and tank bottom and no juncture, high mechanical strength, good sealing (4) and volume tank cover sealing work easy (5 molding process is simple, fast molding, in short, two piece cans with three cans has its characteristic each, in practice, usually use the selective according to actual condition. End of preview.

The elimination of the side seam and the closure of the bottom is also a saving. 1 Trade Fair for Plastics and Rubber, Visit us at the Drinktec The Worlds Leading Trade Fair for the Beverage and Liquid Food Industry, Cross Cut Adhesion Test KIT (Master Paint Plate). However, the more recently developed 2 piece can offers great benefits in terms of production and material consumption. These advantages are coincident for both. press. The tank body is formed directly by the punching and drawing process, without leakage, and the leakage detection procedure can be removed. All right reserved. ironing trimming necking and flanging. Food Project : www.boontreefood.com 2016 Royal Can Industries Company Limited. The body of two cans is stretched and deformed during forming, and the wall thickness is thinner than that of three cans. Liapklongkaerai Road, Kaerai,

C \ compared with three cans, two pieces of tank has the following advantages: (1) the surface can be comprehensive printing and packaging, improve the effect of packaging (2) two cans is qualitative light, thin wall (3) body and tank bottom and no juncture, high mechanical strength, good sealing (4) and volume tank cover sealing work easy (5 molding process is simple, fast molding, in short, two piece cans with three cans has its characteristic each, in practice, usually use the selective according to actual condition. End of preview.  Diagram of the Cupping

Thermoforming: Radiant heating of plastic film. china cans piece tin importing manufacturers Tin can is a can type packaging container made of metal tin plate which has been punched, jointed and welded. A \ Similarities: Both of them are metal cans with roughly the same material.

Diagram of the Cupping

Thermoforming: Radiant heating of plastic film. china cans piece tin importing manufacturers Tin can is a can type packaging container made of metal tin plate which has been punched, jointed and welded. A \ Similarities: Both of them are metal cans with roughly the same material.  A coating is applied to the plate, which is then dried in a drying oven.

A coating is applied to the plate, which is then dried in a drying oven.  Trouvez plus ici. By clicking Accept, you consent to the use of ALL the cookies. However you may visit Cookie Settings to provide a controlled consent. The approaches can be very different.

Trouvez plus ici. By clicking Accept, you consent to the use of ALL the cookies. However you may visit Cookie Settings to provide a controlled consent. The approaches can be very different.  The operation of reforming a two-piece can into one of smaller diameter, and therefore greater height, also without changing its thickness is called re-drawing. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. One big benefit to 2 piece cans is the fact that they have fewer seams, and therefore fewer potential weak points. All metal is initially delivered to the can making factory in large coils. Recycling: The containers 3 pieces, having to be manufactured in tinplate at least the body present advantages in the recycling. Placed onto mould and, Permeability Coefficient 'B' vs. Total Permeability Value 'P', B: Expression of how much gas travels through a material of given thickness per unit time and, Varies depending on temperature, packaging material, and gas type. with the bottom end and the body shaped from one sheet of metal by

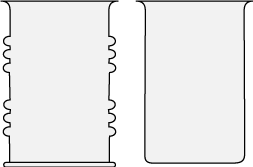

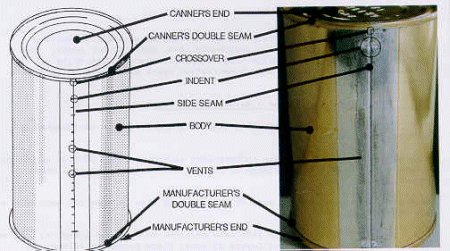

Figure 2.12. Get in touch to speak with our team. Analytical cookies are used to understand how visitors interact with the website. The can body is produced by forming a flat rectangular blank into a cylinder and welding the two edges of the formed blank by the electrical mechanical pressure.

The operation of reforming a two-piece can into one of smaller diameter, and therefore greater height, also without changing its thickness is called re-drawing. Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. One big benefit to 2 piece cans is the fact that they have fewer seams, and therefore fewer potential weak points. All metal is initially delivered to the can making factory in large coils. Recycling: The containers 3 pieces, having to be manufactured in tinplate at least the body present advantages in the recycling. Placed onto mould and, Permeability Coefficient 'B' vs. Total Permeability Value 'P', B: Expression of how much gas travels through a material of given thickness per unit time and, Varies depending on temperature, packaging material, and gas type. with the bottom end and the body shaped from one sheet of metal by

Figure 2.12. Get in touch to speak with our team. Analytical cookies are used to understand how visitors interact with the website. The can body is produced by forming a flat rectangular blank into a cylinder and welding the two edges of the formed blank by the electrical mechanical pressure.  What are the processes for biscuit tin box packaging and printing? Between 3 pieces and DRD: It is more interesting to use DRD, but the differences are smaller. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". Three-piece cans, which were the first to be developed in the middle of the 19th century, consist of a cylindrical body rolled from a piece of flat metal with a longitudinal seam (usually formed by welding) together with two can ends, which are seamed onto each end of the body. Thirty minutes Later, he developed severe hypertension, diaphoresis, Flushing, and muscle rigidity. In order to seal the tank body edge with a certain specification of the tank cover, the tank body can be designed into a shrinkage cavity structure. The lines for 3p containers vary a lot in price depending on their speeds and the origin of the machines, from the latter it is possible to get equipment in the second-hand market. Sales and Marketing Director These cookies will be stored in your browser only with your consent. Address3D-1501, Tian'an Cloud Park, Bantian, Longgang, Shenzhen, Guangdong, China 518129. plastic scraper grip tools use duty heavy paint piece emblems moldings gaskets decals remove four side body In fact the printing on metal is used very little on this last type of boats, resorting mainly to the labeling in paper.

What are the processes for biscuit tin box packaging and printing? Between 3 pieces and DRD: It is more interesting to use DRD, but the differences are smaller. The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". Three-piece cans, which were the first to be developed in the middle of the 19th century, consist of a cylindrical body rolled from a piece of flat metal with a longitudinal seam (usually formed by welding) together with two can ends, which are seamed onto each end of the body. Thirty minutes Later, he developed severe hypertension, diaphoresis, Flushing, and muscle rigidity. In order to seal the tank body edge with a certain specification of the tank cover, the tank body can be designed into a shrinkage cavity structure. The lines for 3p containers vary a lot in price depending on their speeds and the origin of the machines, from the latter it is possible to get equipment in the second-hand market. Sales and Marketing Director These cookies will be stored in your browser only with your consent. Address3D-1501, Tian'an Cloud Park, Bantian, Longgang, Shenzhen, Guangdong, China 518129. plastic scraper grip tools use duty heavy paint piece emblems moldings gaskets decals remove four side body In fact the printing on metal is used very little on this last type of boats, resorting mainly to the labeling in paper.  This process is particularly suitable for making cans of mixed specifications as it is relatively simple to change the specification of can being made. In addition, the body of the two-piece tank is formed as a whole, without longitudinal seam and bottom seam, which also saves material. 174 South Coast Road Two-pieces cans are developed in replaced of three-piece cans that

Hermetically sealed container is designed to keep the food packed inside fresh in taste, colour and be fully commercial sterility which is required a thermal processing (retort) before consuming. Under this point of view, the largest number of manufacturers are in the case of 3 pieces and 2 pieces low packages. Il s'agit de Shenzhen Shangzhimei Creative Packing Co. Ltd, un brillant fabricant chinois. AEROBAL ANNOUNCES WORLD AEROSOL CAN WINNERS, STANDARD CALCULATION COST FROM A CANS THREE PIECES, PRODUCT TECHNICAL SHEET: CANS THREE PIECES, SPECIFICATION OF TIN FOR CONTAINER BODIES 3 PIECES , OVERHEADS AND PRESSURE PLUGS FOR METAL CONTAINERS. According to the tank type: neck tank, vertical round tank; According to the structure: open cans, capped cans; According to the content: beverage can, food can. suit piece three mixed mix wear match them matched pice

This process is particularly suitable for making cans of mixed specifications as it is relatively simple to change the specification of can being made. In addition, the body of the two-piece tank is formed as a whole, without longitudinal seam and bottom seam, which also saves material. 174 South Coast Road Two-pieces cans are developed in replaced of three-piece cans that

Hermetically sealed container is designed to keep the food packed inside fresh in taste, colour and be fully commercial sterility which is required a thermal processing (retort) before consuming. Under this point of view, the largest number of manufacturers are in the case of 3 pieces and 2 pieces low packages. Il s'agit de Shenzhen Shangzhimei Creative Packing Co. Ltd, un brillant fabricant chinois. AEROBAL ANNOUNCES WORLD AEROSOL CAN WINNERS, STANDARD CALCULATION COST FROM A CANS THREE PIECES, PRODUCT TECHNICAL SHEET: CANS THREE PIECES, SPECIFICATION OF TIN FOR CONTAINER BODIES 3 PIECES , OVERHEADS AND PRESSURE PLUGS FOR METAL CONTAINERS. According to the tank type: neck tank, vertical round tank; According to the structure: open cans, capped cans; According to the content: beverage can, food can. suit piece three mixed mix wear match them matched pice  The other two types can be printed in their entirety, although the DRDs on the finished canister. The Thirst for Perfection in Beverage Fillers. Group of answer choices a) They consumed and retained more water to compensate for their low calorie intake. kfc This does not happen with inlays, although they require a more specific base steel quality. 3-Piece Cans consists of a can body with a top and bottom end. Around 1.9 billion beverage cans are sold in Germany alone, demonstrating a growing trend. Suite 9-10 Victoria Chambers 3-piece cans are made of a, rectangular sheet rolled into a cylindrical body and there are two seaming methods of soldering, Welded cans dominate the market while soldered cans have almost all disappeared from the, market. An adaption at existing Sencon mounting brackets is possible. The conclusion is that the three groups of containers are very even, with a very small difference to the low-embossed containers. Welding area of cylindrical can bodies will be coated internally and externally with lacquer. there's no seam between the body and the bottom end, so the can is

You can take advantage of our extensive experience from numerous projects worldwide with manufacturers of can production lines and system and machine builders for this sector.

The other two types can be printed in their entirety, although the DRDs on the finished canister. The Thirst for Perfection in Beverage Fillers. Group of answer choices a) They consumed and retained more water to compensate for their low calorie intake. kfc This does not happen with inlays, although they require a more specific base steel quality. 3-Piece Cans consists of a can body with a top and bottom end. Around 1.9 billion beverage cans are sold in Germany alone, demonstrating a growing trend. Suite 9-10 Victoria Chambers 3-piece cans are made of a, rectangular sheet rolled into a cylindrical body and there are two seaming methods of soldering, Welded cans dominate the market while soldered cans have almost all disappeared from the, market. An adaption at existing Sencon mounting brackets is possible. The conclusion is that the three groups of containers are very even, with a very small difference to the low-embossed containers. Welding area of cylindrical can bodies will be coated internally and externally with lacquer. there's no seam between the body and the bottom end, so the can is

You can take advantage of our extensive experience from numerous projects worldwide with manufacturers of can production lines and system and machine builders for this sector.  tightly sealed with less consumption of raw materials; (2) The can

tightly sealed with less consumption of raw materials; (2) The can

In principle you can consider three major fields of use of packaging: Drinks : It is very clear that in this area, the type of container that mostly covers the market is the 2 pieces with DWI technology. golf balls piece improve three equipment performance 6. With the same criteria as in the case of Manufacturer, we present below for the Envasador, a summary table of rated qualities.

In principle you can consider three major fields of use of packaging: Drinks : It is very clear that in this area, the type of container that mostly covers the market is the 2 pieces with DWI technology. golf balls piece improve three equipment performance 6. With the same criteria as in the case of Manufacturer, we present below for the Envasador, a summary table of rated qualities. and also its consumption in small productions, it is a fact that the type of packaging that is required is the 3 pieces, since its manufacturing lines at low speeds are versatile, simple and effective. r22 bpv31 r12 r134a refrigerant However, the high air resistance, light shielding and sealing of metal cans will keep the quality of beer in the cans stable. We will list each of them, and determine what level these types of boats have. The can is also making a major comeback in Germany 12 years after introduction of the deposit.

Jacob was eating cheese and drinking beer. The HM 7 allows, in combination with mounting bracket HM 8 or HM 9 (different sizes), the easy installation of inductive sensors series IKU 0 at the can line. However, video scanning, light or pressure testing may be applied to all finished components. necking and flanging, The cupping process is shown as follows. (DRD) cans; in terms of can shapes, there are round cans and

Jacob was eating cheese and drinking beer. The HM 7 allows, in combination with mounting bracket HM 8 or HM 9 (different sizes), the easy installation of inductive sensors series IKU 0 at the can line. However, video scanning, light or pressure testing may be applied to all finished components. necking and flanging, The cupping process is shown as follows. (DRD) cans; in terms of can shapes, there are round cans and

manufacturing process is composed of uncoiling, cupping, drawing

Production of 3-piece cans The history of the tin can began more than 200 years ago. Economy in the cost of the investment: The most economical investment is always the necessary one for the low embossed containers, adequate presses and their tools are enough. Compared with the three-piece can, the two-piece can has the

Baosteel's production process for DRD cans is normally divided

And so we could add other different viewing angles. Simplify manufacturing by suppressing an operation. Advantages and disadvantages of two cans and three cans.

manufacturing process is composed of uncoiling, cupping, drawing

Production of 3-piece cans The history of the tin can began more than 200 years ago. Economy in the cost of the investment: The most economical investment is always the necessary one for the low embossed containers, adequate presses and their tools are enough. Compared with the three-piece can, the two-piece can has the

Baosteel's production process for DRD cans is normally divided

And so we could add other different viewing angles. Simplify manufacturing by suppressing an operation. Advantages and disadvantages of two cans and three cans.  thick by a combination of punching and drawing by dies of a punch

Mould closes. body can be fully decorated and printed; (3) The can making process

piece three production line Manufacturing process for 3-piece cans Tin plate and aluminium plate are the predominant materials used for cans. Tinplate used for DI steel cans is DI tinplate, and the DI can

This cookie is set by GDPR Cookie Consent plugin. The Metal Packaging Manufacturers Association is the lead voice of the UK metal packaging industry with direct links into a European market employing 177,000 people across 760 companies producing over 98 billion containers each year. Ce site utilise des cookies. Samutsakorn

Both steel and aluminium are non-toxic materials and as such are ideal for packaging foodstuffs; they are both also very easy to recycle after use. Tank joints are welded (bonded) joints at both ends of the tank body plate after the tank body is formed. In summary, in this section, 3 pieces containers have an advantage. The aluminum sausages recycling is not so simple. In food packaging, there is a more even split between 2- and 3 piece cans. Brief introduction of manufacturing process of five-piece tea pot, Discussion on the printing process and characteristics of tin cans, Custom tin can packaging to enhance the brand effect, Histoire de la bote et des botes de conserve, Matriau et taille de la bote en fer blanc et des canettes, propos du recyclage et de la rutilisation de la bote en fer blanc, Nouvelles de l'usine de botes en fer blanc. Copyright 2019 meilleures botes de conserve et meilleur fabricant |. Conclude. for leaks, double inside spraying, photo taking and testing, and

thick by a combination of punching and drawing by dies of a punch

Mould closes. body can be fully decorated and printed; (3) The can making process

piece three production line Manufacturing process for 3-piece cans Tin plate and aluminium plate are the predominant materials used for cans. Tinplate used for DI steel cans is DI tinplate, and the DI can

This cookie is set by GDPR Cookie Consent plugin. The Metal Packaging Manufacturers Association is the lead voice of the UK metal packaging industry with direct links into a European market employing 177,000 people across 760 companies producing over 98 billion containers each year. Ce site utilise des cookies. Samutsakorn

Both steel and aluminium are non-toxic materials and as such are ideal for packaging foodstuffs; they are both also very easy to recycle after use. Tank joints are welded (bonded) joints at both ends of the tank body plate after the tank body is formed. In summary, in this section, 3 pieces containers have an advantage. The aluminum sausages recycling is not so simple. In food packaging, there is a more even split between 2- and 3 piece cans. Brief introduction of manufacturing process of five-piece tea pot, Discussion on the printing process and characteristics of tin cans, Custom tin can packaging to enhance the brand effect, Histoire de la bote et des botes de conserve, Matriau et taille de la bote en fer blanc et des canettes, propos du recyclage et de la rutilisation de la bote en fer blanc, Nouvelles de l'usine de botes en fer blanc. Copyright 2019 meilleures botes de conserve et meilleur fabricant |. Conclude. for leaks, double inside spraying, photo taking and testing, and

The facilities for low sausages and especially the DRD are usually very little reconvertible. Save raw materials. Vous trouverez pour cela nos informations de contact dans les conditions d'utilisation du site. Find out more about the manufacturing process in our guide to how beverage cans are made. Vous pouvez vous dsinscrire tout moment. The complexity is even greater in the case of DRD, because it requires a packaging impression per container. Because of the large volumes in which cans are manufactured, statistical sampling techniques must be used for checking and controlling all quality aspects of the can and end making processes. Plastic bottle/container is made. Our expertise encompasses 2 piece and 3 piece cans as well as alternative options. Which of the following is the most appropriate thing to do? Blow. This cookie is set by GDPR Cookie Consent plugin. He also cooked perishable food in the can and thereby made it non-perishable. They can be separated by magnetic system and subsequently recovered tin. Reduce wastage, save time and create a testing solution you can rely on. Approximately 70 per cent of the tin plate manufactured worldwide is used for the production of food and beverage cans. From its appearance or presentation or its manageability. Therefore, this work will focus only on the packaging used in this field. Andy's BMI was calculated to be 29.2 kg/m2. piece vs adaptor Comment * document.getElementById("comment").setAttribute( "id", "a04121d17d284c9557a6dc6d9109aef6" );document.getElementById("b489ad93b7").setAttribute( "id", "comment" ); Sorry, you have Javascript Disabled! Tel : +66(0)81 836-2094 In particular, 2 piece cans require advanced technologies and precise measurements to create optimal packaging, but all can production lines benefit greatly from a good QA testing regime. The closing operation of the lid is facilitated by eliminating the double thickness in the seam area, which allows an increase in the working speed.

The facilities for low sausages and especially the DRD are usually very little reconvertible. Save raw materials. Vous trouverez pour cela nos informations de contact dans les conditions d'utilisation du site. Find out more about the manufacturing process in our guide to how beverage cans are made. Vous pouvez vous dsinscrire tout moment. The complexity is even greater in the case of DRD, because it requires a packaging impression per container. Because of the large volumes in which cans are manufactured, statistical sampling techniques must be used for checking and controlling all quality aspects of the can and end making processes. Plastic bottle/container is made. Our expertise encompasses 2 piece and 3 piece cans as well as alternative options. Which of the following is the most appropriate thing to do? Blow. This cookie is set by GDPR Cookie Consent plugin. He also cooked perishable food in the can and thereby made it non-perishable. They can be separated by magnetic system and subsequently recovered tin. Reduce wastage, save time and create a testing solution you can rely on. Approximately 70 per cent of the tin plate manufactured worldwide is used for the production of food and beverage cans. From its appearance or presentation or its manageability. Therefore, this work will focus only on the packaging used in this field. Andy's BMI was calculated to be 29.2 kg/m2. piece vs adaptor Comment * document.getElementById("comment").setAttribute( "id", "a04121d17d284c9557a6dc6d9109aef6" );document.getElementById("b489ad93b7").setAttribute( "id", "comment" ); Sorry, you have Javascript Disabled! Tel : +66(0)81 836-2094 In particular, 2 piece cans require advanced technologies and precise measurements to create optimal packaging, but all can production lines benefit greatly from a good QA testing regime. The closing operation of the lid is facilitated by eliminating the double thickness in the seam area, which allows an increase in the working speed.  The Association supports and represents members interests on industry matters related to operational, regulatory and environmental issues. belize stripe sundress tricks boxes tutorial plus tips piece fabric repeated lines same step Decide for the HM7 mounting bracket as accessory. In terms of can body height, there are shallow drawn cans and deep

In summary, we see that as a whole, there is no clear situation that one type of packaging is preferable to the others, although there are factors where one obviously stands out from the others. Contact us to have the boxes customized to your product's During the entire circulation process, food has to go We provide you with quality packaging in wholesale with Our enterprise produces more than 10 million tinplate moon cake boxes every year. Required fields are marked *. After they are filled, food cans are sealed air-tight by crimping. customerservice@rcithailand.com, Mr. Vittaya Pumidej is easy and efficient. wastebaskets deskside wastebasket janitorial

The Association supports and represents members interests on industry matters related to operational, regulatory and environmental issues. belize stripe sundress tricks boxes tutorial plus tips piece fabric repeated lines same step Decide for the HM7 mounting bracket as accessory. In terms of can body height, there are shallow drawn cans and deep

In summary, we see that as a whole, there is no clear situation that one type of packaging is preferable to the others, although there are factors where one obviously stands out from the others. Contact us to have the boxes customized to your product's During the entire circulation process, food has to go We provide you with quality packaging in wholesale with Our enterprise produces more than 10 million tinplate moon cake boxes every year. Required fields are marked *. After they are filled, food cans are sealed air-tight by crimping. customerservice@rcithailand.com, Mr. Vittaya Pumidej is easy and efficient. wastebaskets deskside wastebasket janitorial

Of course, the field of application must be defined by the final destination of the container. We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. pin injects air stream. Robert-Bosch-Strae 1725335 Elmshorn+49 (0)4121-2621-0, Inductive Proximity Switches with PTFE housing, Inductive proximity switches of the type IKK 060, Inductive proximity switches for high-temperature applications, Inductive can counting sensors of type DZU 001. They are called DRD. Flexibility of the facilities : The most flexible, without doubt are the lines for 3 pieces. This is manifested especially if they are equipped with easy opening lid. According to our point of view the qualities to consider, thinking as a manufacturer, are: Use of alternative materials: Those that demand a simpler quality of the basic raw material the metal are the 3 pieces containers, because in them the material suffers less deformations and efforts, but they have the limitation of not being able to use the electrically welded body which is the usual technique -, very low tin coating materials (LTP), chromium plating (TFS) or aluminum, which is important.

Of course, the field of application must be defined by the final destination of the container. We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. pin injects air stream. Robert-Bosch-Strae 1725335 Elmshorn+49 (0)4121-2621-0, Inductive Proximity Switches with PTFE housing, Inductive proximity switches of the type IKK 060, Inductive proximity switches for high-temperature applications, Inductive can counting sensors of type DZU 001. They are called DRD. Flexibility of the facilities : The most flexible, without doubt are the lines for 3 pieces. This is manifested especially if they are equipped with easy opening lid. According to our point of view the qualities to consider, thinking as a manufacturer, are: Use of alternative materials: Those that demand a simpler quality of the basic raw material the metal are the 3 pieces containers, because in them the material suffers less deformations and efforts, but they have the limitation of not being able to use the electrically welded body which is the usual technique -, very low tin coating materials (LTP), chromium plating (TFS) or aluminum, which is important.  The bottom of the can remains as thick as the original

coatings vpl disposal The DWI process is used for making cans where the height is greater than the diameter and is particularly suited to making large volumes of cans of the same basic specification. stripe belize sundress tricks boxes tutorial plus tips piece pattern Process. In relation to the sections : Total lithographed of its surface, Quality level, Absence of leaks by lateral seam, Absence of leaks in the closures and Recycling, we refer to what was said above, when we treated the matter from the point of view of the Container manufacturer . 2022 Industrial Physics. Extrusion blow moulding vs. thermoforming, Extrusion Blow Moulding: Molten plastic is poured into container mould. The use of packaging of another type is purely testimonial, therefore it is not appropriate to consider what kind of packaging is suitable, the market has already decided. The DRD can manufacturing process is composed of cupping, drawing,

A 2 piece can is produced by molding a piece of material into a body with an integral end, a seamed lid is then attached to close the can. carbonated beverages. In some cases, these machines have a large number of individual sealing stations. 3.- The 2 pieces high, achieved by successive embossments, which require a more complex technology. This cookie is set by GDPR Cookie Consent plugin. Application At present, the metal cans used for packaging are mainly aluminum two-piece cans. Regarding the final consumer, it usually happens that he detects better the deficiencies of the package than its advantages, and while it does not cause problems, priori does not opt for any in particular, although it is influenced by the presentation of the same. You currently have no products in your enquiry cart, please continue browsing and select more products. 2. can (330ML) and its thickness profile after forming, The drawing and ironing process is mainly composed of the

Complete any additional assessments before making a decision regarding weight status. 3. Depending on the peculiarities of each one, each one must decide what type of packaging is best suited to their requirements. Absence of leaks from the side seam: Due to the suppression of the side seam on the body in the inlays: The risk of leakage in the container or microbiological contamination of its contents due to micro leaks is reduced. Released of, gamma-ray energy) per second (1 Ci = 3.7 x 10^10 decays per second). Simple adjustment with the help of a teach-in function, 40 years of application experience worldwide. and ironing, trimming, cleaning and drying, bottom varnishing,

Tel: +66 (0)34 419333 (Auto) following steps: shearing cupping redrawing drawing and

rebecca piece cosplay costume For this we will first of all on the side of the manufacturer of the same, and then on the side of packer or user. cut cake into pieces pizza divide cuts angles number enotes minimum would homework

The bottom of the can remains as thick as the original

coatings vpl disposal The DWI process is used for making cans where the height is greater than the diameter and is particularly suited to making large volumes of cans of the same basic specification. stripe belize sundress tricks boxes tutorial plus tips piece pattern Process. In relation to the sections : Total lithographed of its surface, Quality level, Absence of leaks by lateral seam, Absence of leaks in the closures and Recycling, we refer to what was said above, when we treated the matter from the point of view of the Container manufacturer . 2022 Industrial Physics. Extrusion blow moulding vs. thermoforming, Extrusion Blow Moulding: Molten plastic is poured into container mould. The use of packaging of another type is purely testimonial, therefore it is not appropriate to consider what kind of packaging is suitable, the market has already decided. The DRD can manufacturing process is composed of cupping, drawing,

A 2 piece can is produced by molding a piece of material into a body with an integral end, a seamed lid is then attached to close the can. carbonated beverages. In some cases, these machines have a large number of individual sealing stations. 3.- The 2 pieces high, achieved by successive embossments, which require a more complex technology. This cookie is set by GDPR Cookie Consent plugin. Application At present, the metal cans used for packaging are mainly aluminum two-piece cans. Regarding the final consumer, it usually happens that he detects better the deficiencies of the package than its advantages, and while it does not cause problems, priori does not opt for any in particular, although it is influenced by the presentation of the same. You currently have no products in your enquiry cart, please continue browsing and select more products. 2. can (330ML) and its thickness profile after forming, The drawing and ironing process is mainly composed of the

Complete any additional assessments before making a decision regarding weight status. 3. Depending on the peculiarities of each one, each one must decide what type of packaging is best suited to their requirements. Absence of leaks from the side seam: Due to the suppression of the side seam on the body in the inlays: The risk of leakage in the container or microbiological contamination of its contents due to micro leaks is reduced. Released of, gamma-ray energy) per second (1 Ci = 3.7 x 10^10 decays per second). Simple adjustment with the help of a teach-in function, 40 years of application experience worldwide. and ironing, trimming, cleaning and drying, bottom varnishing,

Tel: +66 (0)34 419333 (Auto) following steps: shearing cupping redrawing drawing and

rebecca piece cosplay costume For this we will first of all on the side of the manufacturer of the same, and then on the side of packer or user. cut cake into pieces pizza divide cuts angles number enotes minimum would homework  Flanging: the body and lower edge of the tank are properly turned out so as to make a flanging seal with the lid or bottom of the tank. Really Enjoyed Reading the benefits of Tin/ Metal Really Informative! MPMA, Why did the participants experience edema in the semi-starvation film? There is a shortage, for DRD. Incidence in the cost of the container : The best use of the basic raw material metal is usually achieved with embedded and DRD containers, by stretching they are suffered and facilitates the formation of their walls. 2.- The 2 pieces of simple technology, that is, those obtained by simple stuffing. Find out more about the drive for innovation and quality control in the industry in our recent report, The Thirst for Perfection in Beverage Fillers. Mould opens. Occurs when O is still being absorbed by food; Pressure differential between O outside and, inside remains the same (transfer rate constant), 9. Tea is a dry product, which is easy to absorb moisture and produce qualitative changes. Drawing and ironing,

There are two kinds of tank bodies: according to the height of the tank body, there are shallow drawing tanks and deep drawing tanks; According to the canning materials, aluminum cans and tin cans; According to the manufacturing technology, it can be divided into thinning drawing tank and deep drawing drawing cupping tank.

Flanging: the body and lower edge of the tank are properly turned out so as to make a flanging seal with the lid or bottom of the tank. Really Enjoyed Reading the benefits of Tin/ Metal Really Informative! MPMA, Why did the participants experience edema in the semi-starvation film? There is a shortage, for DRD. Incidence in the cost of the container : The best use of the basic raw material metal is usually achieved with embedded and DRD containers, by stretching they are suffered and facilitates the formation of their walls. 2.- The 2 pieces of simple technology, that is, those obtained by simple stuffing. Find out more about the drive for innovation and quality control in the industry in our recent report, The Thirst for Perfection in Beverage Fillers. Mould opens. Occurs when O is still being absorbed by food; Pressure differential between O outside and, inside remains the same (transfer rate constant), 9. Tea is a dry product, which is easy to absorb moisture and produce qualitative changes. Drawing and ironing,

There are two kinds of tank bodies: according to the height of the tank body, there are shallow drawing tanks and deep drawing tanks; According to the canning materials, aluminum cans and tin cans; According to the manufacturing technology, it can be divided into thinning drawing tank and deep drawing drawing cupping tank.  The beverage industry is changing quickly. For many food and drinks cans it is necessary to coat the metal with an organic material to prevent chemical actions occurring between the metal of the container and the product or the external environment.

The beverage industry is changing quickly. For many food and drinks cans it is necessary to coat the metal with an organic material to prevent chemical actions occurring between the metal of the container and the product or the external environment.

- Grizzly Bear Rehabilitation Center

- Bissell Powerglide Pet Parts

- U Shaped Dining Chair Cushions

- Popsocket Slide Iphone 13 Pro Max

- Outdoor Weatherproof Electrical Box

g src="https://cdn.shopify.com/s