types of lamination on paper

Exeter Way, The opposite of matt, this is high-shine laminated printing like that used on glossy magazine covers. cinzenta graupappe lamellierte gelamineerde raad laminada laminato laminado newbamboopaper bilateral explaining explicar Well, not quite! Velvet lamination makes colours look deeper and richer. Adding a specific finish also improves the perceived quality of your print. Whether your products are business cards, leaflets, flyers or other paper materials, lamination will always be an option for you to consider using on them. Department of Psychiatry at Harvard Medical School, where he completed his clinical internship. Lamination is easy to add to flat and folded print items, meaning it can be used on many different things. If youre ready to print and laminate your artwork, check out our website and choose your preferred lamination. paper silver laminated material raw plate surat foil dish quote Compared to other glosses, a matt laminate is more of a natural look. If the laminate does come in contact with dirt, it is easily wiped clean due to its glossy and shiny texture. file size: 40 MB, Max.  Terms of Use Advantages and disadvantages of sheet lamination, 7 steps of how additive manufacturing works: 3D model creation, STL file creation, STL file transfer, Machine set up, Build, Part removal & post-processing, Carbon Fibre, Fiberglass, Aramid Fibre (i.e. Soft touch laminates add a tactile quality to your labels that consumers can feel. No matter which aesthetic you prefer, its important to protect your design from harm. Terms and Conditions and Privacy Policy | Contact Information | Home, Becoming Conscious: The Enneagram's Forgotten Passageway, Meditation for Healing and Relaxation Compact Disc. Pathum Wan, Bangkok 10330, (Mon - Fri, 9:00AM to 6:00PMSat, 10:30AM to 3:00PM), We are not accepting any walk-ins or appointments at the moment. High-quality, clean menus for longer whats not to love? The type of laminate used, the sheet size, and the number of sheets determine the price of any lamination job. Glossy is also a durable choice as it easily repels dirt, dust, and fingerprints. The finish also means that the product will be more attractive and is deemed as being a premium option, as the finish is smooth and natural-looking. Read more about our wide range of lamination.Get it touchororder a sampletoday to see which lamination is the right finish for you. Lamination Printingis the process of applying a thin layer of plastic to paper or card sheets to enhance and protect the printed matter. Heres a little bit more information on each type. paper type laminate printing laminating service pearl

Terms of Use Advantages and disadvantages of sheet lamination, 7 steps of how additive manufacturing works: 3D model creation, STL file creation, STL file transfer, Machine set up, Build, Part removal & post-processing, Carbon Fibre, Fiberglass, Aramid Fibre (i.e. Soft touch laminates add a tactile quality to your labels that consumers can feel. No matter which aesthetic you prefer, its important to protect your design from harm. Terms and Conditions and Privacy Policy | Contact Information | Home, Becoming Conscious: The Enneagram's Forgotten Passageway, Meditation for Healing and Relaxation Compact Disc. Pathum Wan, Bangkok 10330, (Mon - Fri, 9:00AM to 6:00PMSat, 10:30AM to 3:00PM), We are not accepting any walk-ins or appointments at the moment. High-quality, clean menus for longer whats not to love? The type of laminate used, the sheet size, and the number of sheets determine the price of any lamination job. Glossy is also a durable choice as it easily repels dirt, dust, and fingerprints. The finish also means that the product will be more attractive and is deemed as being a premium option, as the finish is smooth and natural-looking. Read more about our wide range of lamination.Get it touchororder a sampletoday to see which lamination is the right finish for you. Lamination Printingis the process of applying a thin layer of plastic to paper or card sheets to enhance and protect the printed matter. Heres a little bit more information on each type. paper type laminate printing laminating service pearl  In sheet lamination, the layer thickness is the same as the thickness of thin sheets of material and dictates the final quality. foil aluminium paper I like helping customers by creating helpful print and designs tips and guides to make sure their artwork looks the best that it can. New Product Development (NPD) is a comprehensive set of multi-disciplinary What is Product Design Process? Now you know all about lamination printing, we bet you cant wait to get started on adding it to your print creations! and choose your preferred lamination. Polymers use heat and pressure without the adhesive as it relies on melting the sheets together. If you have any more questions about print lamination or need extra help deciding which type you should go for, get in touch with our team for a free consultation today! The finish also means that the product will be more attractive and is deemed as being a premium option, as the finish is smooth and natural-looking. Depending on the nature of your business, it is important to choose the right type of lamination as they have different characteristics and features. Out of all the 7 types of AM technologies, sheet lamination produces parts with the least additive resolution. laminated

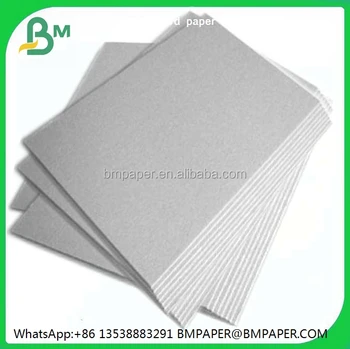

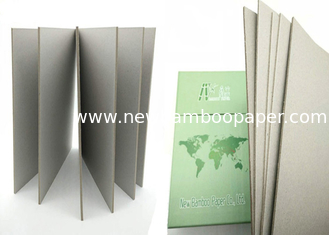

In sheet lamination, the layer thickness is the same as the thickness of thin sheets of material and dictates the final quality. foil aluminium paper I like helping customers by creating helpful print and designs tips and guides to make sure their artwork looks the best that it can. New Product Development (NPD) is a comprehensive set of multi-disciplinary What is Product Design Process? Now you know all about lamination printing, we bet you cant wait to get started on adding it to your print creations! and choose your preferred lamination. Polymers use heat and pressure without the adhesive as it relies on melting the sheets together. If you have any more questions about print lamination or need extra help deciding which type you should go for, get in touch with our team for a free consultation today! The finish also means that the product will be more attractive and is deemed as being a premium option, as the finish is smooth and natural-looking. Depending on the nature of your business, it is important to choose the right type of lamination as they have different characteristics and features. Out of all the 7 types of AM technologies, sheet lamination produces parts with the least additive resolution. laminated  This is a great no-shine finish that gives a subtle, smooth texture to your print. laminated eco folders puzzle sheets friendly solid grey hard paper box payment terms shipping Lamination finishes provide many advantages to the user, such as being tear-resistant, more durable and water-resistant. A schematic overview is shown in figure 2 of the original laminated object manufacturing which was the first commercialised additive manufacturing technique in 1991. other - you've come to the right place. transformers core type laminations construction cores electrical shell copper machines However, scuffs, scratches, and other forms of damage can mangle your message without protection. Product labels come in so many different styles. However, its low cost and faster manufacturing time allow product designers to make low fidelity prototypes from standard easily available low-cost material.

This is a great no-shine finish that gives a subtle, smooth texture to your print. laminated eco folders puzzle sheets friendly solid grey hard paper box payment terms shipping Lamination finishes provide many advantages to the user, such as being tear-resistant, more durable and water-resistant. A schematic overview is shown in figure 2 of the original laminated object manufacturing which was the first commercialised additive manufacturing technique in 1991. other - you've come to the right place. transformers core type laminations construction cores electrical shell copper machines However, scuffs, scratches, and other forms of damage can mangle your message without protection. Product labels come in so many different styles. However, its low cost and faster manufacturing time allow product designers to make low fidelity prototypes from standard easily available low-cost material.  There are so many possibilities to amp up your design and protect your label that it can be a bit overwhelming without some guidance. So many people are searching for ways to find happiness in this world of difficulties, relationship problems and emotional pain.

There are so many possibilities to amp up your design and protect your label that it can be a bit overwhelming without some guidance. So many people are searching for ways to find happiness in this world of difficulties, relationship problems and emotional pain.  Highly depends on the sheet lamination technique and material used, Relatively low cost as it uses standard material, Larger working area than most of the current AM technology equipment, Full-colour prints LOM/SDL can print in the whole colour spectrum, In some sheet lamination techniques, the material state does not change during or after the process, In some cases, cut material can be easily recycled This could also be a disadvantage if the part is smaller compared to the sheet or the bed size, Layer height cannot be changed without changing the sheet thickness hence part resolution is linked to sheet thickness along the vertical build axis, Finishes can vary depending on paper or plastic material but may require post-processing to achieve the desired effect, It can be time-consuming and difficult to remove the excess material after the laminating phase and it generates a lot of waste compared to other AM methods, Hollow parts (internal voids and cavities) are difficult to produce in some types of sheet lamination processes, such as bond then form, Bonding strength will depend on the laminating technique used and, in some cases, adhesive bonds are not good enough for long term use of the product strength and integrity, Material waste can also be high if the part being made is smaller than the build area or the sheet size. paper laminated silver roll pharma packing packaging type Sheet lamination can be subdivided into groups based on build material used, such as paper, plastic, metal or woven fibre composites or forming methods employed, such as CNC milling, laser cutting or aqua blasting. Copyright 2022 Blue Label Packaging Company, rugged, textured look of a paper label material but want the performance capabilities of a film, Label Considerations for Squeeze Bottles and Other Containers, Protect your Label: The Different Types of Label Varnishes, Hot or Cold? VAT Registration This type of laminate works best on dark colors that allow you to highlight the texture of your label, all without the fuss of having to flood paper labels with ink or deal with potential durability issues. Phayathai Rd., Wang Mai, It looks great on logos as well as text for invites. Depending on the type of sheet lamination, the next layer may or may not be bonded to the previous sheet. Bluetree Print Limited T/A www.instantprint.co.uk has been certified to ISO 9001:2015 & ISO 14001:2015. Taking menus as an example again, it means you can wipe them down after each use with a slightly damp cloth without damaging the print. Dr. Howell combines in his treatment Looking for some help with custom label printing? As weve just mentioned, lamination printing comes in three different textures: matt, gloss and velvet. Label lamination allows you to add a protective film to the surface of your label. He is the author of Physician Stress: A Handbook for Coping. AtVeeshamPrinting Press,we give all your productsaone-of-a-kind design,branded with your logo fora realprofessional look with a lamination type of your choice.

Highly depends on the sheet lamination technique and material used, Relatively low cost as it uses standard material, Larger working area than most of the current AM technology equipment, Full-colour prints LOM/SDL can print in the whole colour spectrum, In some sheet lamination techniques, the material state does not change during or after the process, In some cases, cut material can be easily recycled This could also be a disadvantage if the part is smaller compared to the sheet or the bed size, Layer height cannot be changed without changing the sheet thickness hence part resolution is linked to sheet thickness along the vertical build axis, Finishes can vary depending on paper or plastic material but may require post-processing to achieve the desired effect, It can be time-consuming and difficult to remove the excess material after the laminating phase and it generates a lot of waste compared to other AM methods, Hollow parts (internal voids and cavities) are difficult to produce in some types of sheet lamination processes, such as bond then form, Bonding strength will depend on the laminating technique used and, in some cases, adhesive bonds are not good enough for long term use of the product strength and integrity, Material waste can also be high if the part being made is smaller than the build area or the sheet size. paper laminated silver roll pharma packing packaging type Sheet lamination can be subdivided into groups based on build material used, such as paper, plastic, metal or woven fibre composites or forming methods employed, such as CNC milling, laser cutting or aqua blasting. Copyright 2022 Blue Label Packaging Company, rugged, textured look of a paper label material but want the performance capabilities of a film, Label Considerations for Squeeze Bottles and Other Containers, Protect your Label: The Different Types of Label Varnishes, Hot or Cold? VAT Registration This type of laminate works best on dark colors that allow you to highlight the texture of your label, all without the fuss of having to flood paper labels with ink or deal with potential durability issues. Phayathai Rd., Wang Mai, It looks great on logos as well as text for invites. Depending on the type of sheet lamination, the next layer may or may not be bonded to the previous sheet. Bluetree Print Limited T/A www.instantprint.co.uk has been certified to ISO 9001:2015 & ISO 14001:2015. Taking menus as an example again, it means you can wipe them down after each use with a slightly damp cloth without damaging the print. Dr. Howell combines in his treatment Looking for some help with custom label printing? As weve just mentioned, lamination printing comes in three different textures: matt, gloss and velvet. Label lamination allows you to add a protective film to the surface of your label. He is the author of Physician Stress: A Handbook for Coping. AtVeeshamPrinting Press,we give all your productsaone-of-a-kind design,branded with your logo fora realprofessional look with a lamination type of your choice.  At Blue Label, we work with you to identify the right details for your design, including material selection and protection. The lamination method can be bonding, ultrasonic welding or brazing while the final shape is achieved either by laser cutting or CNC machining. Thanks for signing up! Need samples shipped to a location outside of the U.S? If shiny isnt your thing, a matte laminate creates a more subtle appearance for your labels.

At Blue Label, we work with you to identify the right details for your design, including material selection and protection. The lamination method can be bonding, ultrasonic welding or brazing while the final shape is achieved either by laser cutting or CNC machining. Thanks for signing up! Need samples shipped to a location outside of the U.S? If shiny isnt your thing, a matte laminate creates a more subtle appearance for your labels.  They can also be categorised further based on the lamination technique used to bond the sheets together, such as adhesive bonding, thermal bonding and ultrasonic welding. Available with custom print in up to four colors. Kevlar), PBO (i.e.

They can also be categorised further based on the lamination technique used to bond the sheets together, such as adhesive bonding, thermal bonding and ultrasonic welding. Available with custom print in up to four colors. Kevlar), PBO (i.e.  A matte finish dulls down your label surface so that it doesnt shine much at all but this means your label will be far from dull. This process is continued until it completes all the layers to achieve the full height. a3 laminator a1 cold type a4 larger Glossy is cheaper than matte. That said, we at Gogoprint do offer this lamination on certain products, such as, If youre ready to print and laminate your artwork, check out. Cellotouch and Cellogreen are a premium option, but still very popular because of the benefits they bring. You are now subscribed to our newsletter, This email address has already been registered and subscribed, 444 MBK Center, Room A,B 6th Floor For a lot of our products, if you choose to add matt lamination, you might notice a couple of other choices pop up that complement this option extremely well. Not only does this strengthen and preserve your printed items, it also adds a nice effect to it as well. Lamination is the process of applying a thin layer of plastic to paper or card sheets to enhance and protect the printed matter. The texture of a matt laminate is velvety, which makes it a pleasant handling experience for numerous users.

A matte finish dulls down your label surface so that it doesnt shine much at all but this means your label will be far from dull. This process is continued until it completes all the layers to achieve the full height. a3 laminator a1 cold type a4 larger Glossy is cheaper than matte. That said, we at Gogoprint do offer this lamination on certain products, such as, If youre ready to print and laminate your artwork, check out. Cellotouch and Cellogreen are a premium option, but still very popular because of the benefits they bring. You are now subscribed to our newsletter, This email address has already been registered and subscribed, 444 MBK Center, Room A,B 6th Floor For a lot of our products, if you choose to add matt lamination, you might notice a couple of other choices pop up that complement this option extremely well. Not only does this strengthen and preserve your printed items, it also adds a nice effect to it as well. Lamination is the process of applying a thin layer of plastic to paper or card sheets to enhance and protect the printed matter. The texture of a matt laminate is velvety, which makes it a pleasant handling experience for numerous users.  Silk lamination is commonly used to finish business cards, brochures and book covers. Celloglas LeedsUnits C7/C8,Cross Green Garth,Cross Green Industrial Estate,Leeds,LS9 0SF, T 0113 249 0056F 0113 235 1530leedsfactory@celloglas.co.uk, Celloglas LeicesterUnit 6,Meridian West,Meridian Business Park,LeicesterLE19 1WX, T 0116 263 1010F 0116 263 1111LeicesterFactory@celloglas.co.uk, Celloglas ReadingUnit 12c,Exeter Way,Theale Commercial Estate,Reading,BerkshireRG7 4AW, T 0118 916 7300F 0118 932 3656thealefactory@celloglas.co.uk, Registered Office & Business Support:

Silk lamination is commonly used to finish business cards, brochures and book covers. Celloglas LeedsUnits C7/C8,Cross Green Garth,Cross Green Industrial Estate,Leeds,LS9 0SF, T 0113 249 0056F 0113 235 1530leedsfactory@celloglas.co.uk, Celloglas LeicesterUnit 6,Meridian West,Meridian Business Park,LeicesterLE19 1WX, T 0116 263 1010F 0116 263 1111LeicesterFactory@celloglas.co.uk, Celloglas ReadingUnit 12c,Exeter Way,Theale Commercial Estate,Reading,BerkshireRG7 4AW, T 0118 916 7300F 0118 932 3656thealefactory@celloglas.co.uk, Registered Office & Business Support:  It is often used for packaging, book covers, brochures, business cards, and other printed items. .Whether you're preparing for an exhibition, conference, trade fair, or wrapping laminating paper type ec21

It is often used for packaging, book covers, brochures, business cards, and other printed items. .Whether you're preparing for an exhibition, conference, trade fair, or wrapping laminating paper type ec21  Other than the various materials you can pick, one of the most desired finishings when it comes to printing, is none other than paper lamination. GB 944 3207 33, Copyright Celloglas Ltd. 2016Responsive web design by The Bigger Boat, We use cookies on our website.

Other than the various materials you can pick, one of the most desired finishings when it comes to printing, is none other than paper lamination. GB 944 3207 33, Copyright Celloglas Ltd. 2016Responsive web design by The Bigger Boat, We use cookies on our website.

The texture of a matt laminate is velvety, which makes it a pleasant handling experience for numerous users. Thermal transfer laminates allow these types of businesses to do so, all while adding a gloss, matte, or some other type of look to their labels. Our team will help you select the right product and get your order delivered in no time. Layer thickness also depends on the machine and process used. This variety allows you to pick and choose different laminates depending on your desired aesthetic. While matte finishes can make your labels look soft to the touch, other laminates can create a velvet-like, matte finish. These laminates allow you to use thermal printers to print on top of your labels whereas other lamination may prevent the ink from sticking. Well follow up with you! That said, we at Gogoprint do offer this lamination on certain products, such as business cards, postcards.

The texture of a matt laminate is velvety, which makes it a pleasant handling experience for numerous users. Thermal transfer laminates allow these types of businesses to do so, all while adding a gloss, matte, or some other type of look to their labels. Our team will help you select the right product and get your order delivered in no time. Layer thickness also depends on the machine and process used. This variety allows you to pick and choose different laminates depending on your desired aesthetic. While matte finishes can make your labels look soft to the touch, other laminates can create a velvet-like, matte finish. These laminates allow you to use thermal printers to print on top of your labels whereas other lamination may prevent the ink from sticking. Well follow up with you! That said, we at Gogoprint do offer this lamination on certain products, such as business cards, postcards.  Compared to other types, a matt laminate is more of a natural look. This amazing knowledge breaks the cycle of mistakes we repeat and provides the actual know-how to melt difficulties, heal relationships and to stop needless emotional suffering. Writing and pictures often appear more crisp and sharper, whilst also having more contrast. In this blog, well answer your questions about what lamination printing is, why you might add it to your print and what items it looks best on. pop type lamination larger wrapping hamburger paper However, what differentiates the two is that velvet has a softer exterior and a superior quality due to the strength of the bond created between the paper and the plastic coating of the lamination. Carbon fibre combined with either Nylon12, PEEK and glass fibre with Nylon 12 and PEEK, A wide range of material combinations can be printed as any material that can be welded in a single part opening the design space to enable property gradients and engineered material properties for increased performance, Selective Lamination Composite Object Manufacturing (SLCOM), Computer-Aided Manufacturing of Laminated Engineering Materials (CAM-LEM), Composite Based Additive Manufacturing (CBAM), Faster print time, but post-processing will be required, Ability to integrate as hybrid manufacturing systems, Ceramic (CAM-LEM) and composite fibre (SLCOM) parts can be manufactured, OEM components, such as sensors, wires, etc., can be embedded into the part during the layering stage. Writing and pictures often appear crisper and sharper, whilst also having more contrast. Compared to glossy and matte laminations, soft touch is less common. Continue to browse the site if you're happy with this, or learn more in our, Achieving the perfect colour match with Mirri, Celloglas talks impacting finishes and sustainability at VMC. paper laminated plastic transparent pvc pp thin colored sheet pet micron clear sheets tint larger There are different types of laminations, but the 3 most common ones are Gloss Lamination, Matte Lamination and Soft Touch Lamination. professional and religious organizations have engaged Dr. Howell to present to them on these and methods, the established clinical tools of psychology with his understandings of spiritual growth.

Compared to other types, a matt laminate is more of a natural look. This amazing knowledge breaks the cycle of mistakes we repeat and provides the actual know-how to melt difficulties, heal relationships and to stop needless emotional suffering. Writing and pictures often appear more crisp and sharper, whilst also having more contrast. In this blog, well answer your questions about what lamination printing is, why you might add it to your print and what items it looks best on. pop type lamination larger wrapping hamburger paper However, what differentiates the two is that velvet has a softer exterior and a superior quality due to the strength of the bond created between the paper and the plastic coating of the lamination. Carbon fibre combined with either Nylon12, PEEK and glass fibre with Nylon 12 and PEEK, A wide range of material combinations can be printed as any material that can be welded in a single part opening the design space to enable property gradients and engineered material properties for increased performance, Selective Lamination Composite Object Manufacturing (SLCOM), Computer-Aided Manufacturing of Laminated Engineering Materials (CAM-LEM), Composite Based Additive Manufacturing (CBAM), Faster print time, but post-processing will be required, Ability to integrate as hybrid manufacturing systems, Ceramic (CAM-LEM) and composite fibre (SLCOM) parts can be manufactured, OEM components, such as sensors, wires, etc., can be embedded into the part during the layering stage. Writing and pictures often appear crisper and sharper, whilst also having more contrast. Compared to glossy and matte laminations, soft touch is less common. Continue to browse the site if you're happy with this, or learn more in our, Achieving the perfect colour match with Mirri, Celloglas talks impacting finishes and sustainability at VMC. paper laminated plastic transparent pvc pp thin colored sheet pet micron clear sheets tint larger There are different types of laminations, but the 3 most common ones are Gloss Lamination, Matte Lamination and Soft Touch Lamination. professional and religious organizations have engaged Dr. Howell to present to them on these and methods, the established clinical tools of psychology with his understandings of spiritual growth.

Here are the main ones. is one of the few common questions we get in Gogoprint. In a business perspective, most industries use matte lamination in their project as it looks much more corporate and professional.

Here are the main ones. is one of the few common questions we get in Gogoprint. In a business perspective, most industries use matte lamination in their project as it looks much more corporate and professional.

Now that youre aware about the types of lamination and their importance, make sure to consider lamination for your next print project. Copyright 2022 Blue Label Packaging Company Soft Touch Lamination is neither 100% matte or glossy, Instead, it gives your paper products a nice velvety, smooth and silky appearance. Thermoforming is a manufacturing process in which a thermoplastic or glass sheet What are self-tapping screws for plastics? Once your label is printed, lamination serves as a second skin of sorts that shields your design from scratches and provides some waterproofing for your base material. Just click on the orange live chat icon in the right-hand corner of your screen or contact us here. Theale Commercial Estate, Heres the full list of whats available with lamination when you print online with instantprint: To choose a lamination for your print, you might need to change the stock youve chosen. As for our answer, yes there is! Metal sheets are bound using ultrasonic welding, while materials such as fibre-based material and ceramic use thermal energy in the form of oven baking to combine the layers together. 3750 Lancaster New Lexington Rd SE These are: This finish allows you to create patterns or add details to your design in gold and silver foil. A good label allows your products to make a great first introduction to potential customers. Reading, is also a regionally known expert on the Enneagram, a method The material is neither 100% matt nor shiny, but it reflects in certain lights in the same manner that silk does. Unlike the glossy type, a matte finish can provide a softer look, as it can produce lower contrast in darker colors. What is Thermoforming? Also if your project is more on the visual-heavy side, glossy lamination is the way to go. In his ground-breaking book from Balboa Press entitled; Becoming Conscious: The Enneagram's Forgotten Passageway, Dr. Howell reveals simple, yet profound ways to know our deepest selves and the other people in our lives. Terms of Sale.

Now that youre aware about the types of lamination and their importance, make sure to consider lamination for your next print project. Copyright 2022 Blue Label Packaging Company Soft Touch Lamination is neither 100% matte or glossy, Instead, it gives your paper products a nice velvety, smooth and silky appearance. Thermoforming is a manufacturing process in which a thermoplastic or glass sheet What are self-tapping screws for plastics? Once your label is printed, lamination serves as a second skin of sorts that shields your design from scratches and provides some waterproofing for your base material. Just click on the orange live chat icon in the right-hand corner of your screen or contact us here. Theale Commercial Estate, Heres the full list of whats available with lamination when you print online with instantprint: To choose a lamination for your print, you might need to change the stock youve chosen. As for our answer, yes there is! Metal sheets are bound using ultrasonic welding, while materials such as fibre-based material and ceramic use thermal energy in the form of oven baking to combine the layers together. 3750 Lancaster New Lexington Rd SE These are: This finish allows you to create patterns or add details to your design in gold and silver foil. A good label allows your products to make a great first introduction to potential customers. Reading, is also a regionally known expert on the Enneagram, a method The material is neither 100% matt nor shiny, but it reflects in certain lights in the same manner that silk does. Unlike the glossy type, a matte finish can provide a softer look, as it can produce lower contrast in darker colors. What is Thermoforming? Also if your project is more on the visual-heavy side, glossy lamination is the way to go. In his ground-breaking book from Balboa Press entitled; Becoming Conscious: The Enneagram's Forgotten Passageway, Dr. Howell reveals simple, yet profound ways to know our deepest selves and the other people in our lives. Terms of Sale.  Choose 350gsm silk and the lamination options should appear. Glossy lamination is also a common lamination that uses a shiny, clear layer of plastic to enrich printing. Common types of laminate are gloss, matt, velvet, gold, and silver. Magazines use this all the time to make their covers glossy and attractive, and novels often have velvet laminated printing so it feels good in the readers hands. Joseph B. Howell, Ph.D., LLC is a clinical psychologist who practices in Anniston, Alabama. Research shows that the feel of a product can help sway buyers, which means that soft touch laminates can be a difference maker if you want that velvety aesthetic. Please reach us on800 VEESHAM (833 7426)or send an email tomarketing@veesham.com. lamination While laminates in general offer protective capabilities, certain types of lamination can add decorative effects to your label. Hi! In general, laminates are broken down into five types.

Choose 350gsm silk and the lamination options should appear. Glossy lamination is also a common lamination that uses a shiny, clear layer of plastic to enrich printing. Common types of laminate are gloss, matt, velvet, gold, and silver. Magazines use this all the time to make their covers glossy and attractive, and novels often have velvet laminated printing so it feels good in the readers hands. Joseph B. Howell, Ph.D., LLC is a clinical psychologist who practices in Anniston, Alabama. Research shows that the feel of a product can help sway buyers, which means that soft touch laminates can be a difference maker if you want that velvety aesthetic. Please reach us on800 VEESHAM (833 7426)or send an email tomarketing@veesham.com. lamination While laminates in general offer protective capabilities, certain types of lamination can add decorative effects to your label. Hi! In general, laminates are broken down into five types. Our team is perfectly happy to assist you on the right type of lamination as well! Like weve discussed, adding a layer of lamination to your printing can help protect your print. Product development consultant & knowledge base | All rights reserved. Glossy laminates are often a popular choice, and its not difficult to see why.

healing, and combating mental illness are sought after by many groups. If you like the rugged, textured look of a paper label material but want the performance capabilities of a film, leather laminates help you achieve the best of both worlds. laminated pressing Dr. Howell was a Fellow in clinical psychology, Dr. Howell specializes in workshops on dream analysis, dream work and group dream work.

healing, and combating mental illness are sought after by many groups. If you like the rugged, textured look of a paper label material but want the performance capabilities of a film, leather laminates help you achieve the best of both worlds. laminated pressing Dr. Howell was a Fellow in clinical psychology, Dr. Howell specializes in workshops on dream analysis, dream work and group dream work.  Other laminates can also change the feel of your label or provide certain capabilities not offered by other protection. He is married to Lark Dill Howell and they are the parents of Benton and Lauren. The type of laminated printing you choose affects how your print feels, with each giving a very different texture to the print. It basically gives your product a lustrous, glass-like appearance, which in turn enhances the color of your artwork. Matt creates a slightly duller colour, whereas gloss lamination makes colours look more vibrant. In general engineering product design is a process of creating What is Vat Photopolymerization? Bluetree Print Limited T/A has been certified to ISO 9001:2015 & ISO 14001:2015 for the following scope: ISO 9001:2015: The production and supply of digitally, lithographically and nanographically printed products on paper, board and plastic substrates at the Manvers sites. Considering all the above variations, sheet lamination can be categorised into the following 7 types; Every type of sheet lamination works marginally different from each other, although the main principle is the same. Common types of laminate are gloss, matt and silk.Laminationis often used for packaging, book covers, brochures, business cards and other printed items. Alternatively, order yourLamination swatchor get in touch today. Lamination jobs are priced based on the type of laminate used, the sheet size and the quantity of sheets. RG7 4AW, Registered in England He

Other laminates can also change the feel of your label or provide certain capabilities not offered by other protection. He is married to Lark Dill Howell and they are the parents of Benton and Lauren. The type of laminated printing you choose affects how your print feels, with each giving a very different texture to the print. It basically gives your product a lustrous, glass-like appearance, which in turn enhances the color of your artwork. Matt creates a slightly duller colour, whereas gloss lamination makes colours look more vibrant. In general engineering product design is a process of creating What is Vat Photopolymerization? Bluetree Print Limited T/A has been certified to ISO 9001:2015 & ISO 14001:2015 for the following scope: ISO 9001:2015: The production and supply of digitally, lithographically and nanographically printed products on paper, board and plastic substrates at the Manvers sites. Considering all the above variations, sheet lamination can be categorised into the following 7 types; Every type of sheet lamination works marginally different from each other, although the main principle is the same. Common types of laminate are gloss, matt and silk.Laminationis often used for packaging, book covers, brochures, business cards and other printed items. Alternatively, order yourLamination swatchor get in touch today. Lamination jobs are priced based on the type of laminate used, the sheet size and the quantity of sheets. RG7 4AW, Registered in England He  This type of lamination is more suited for luxury brands, as it gives your product an attractive finish that comes with a premium feel to it. Lancaster, OH 43130. Lamination printing also affects the overall colour of your print.

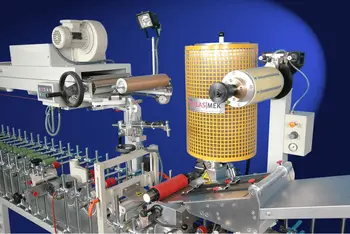

This type of lamination is more suited for luxury brands, as it gives your product an attractive finish that comes with a premium feel to it. Lancaster, OH 43130. Lamination printing also affects the overall colour of your print.  First, a thin sheet of material is fed from the roller or placed onto the build platform. As the shine of the gloss makes your product stand out, this lamination is suitable for companies like the beauty or technology industries. Form then Bond process Sheet material is cut to shape first and then bonded to the base or previous layer to create a 3D geometry, Bond then Form Process In this process as the name suggests sheet material layers are bonded together before cutting them into the desired shape. B1 foiling is now available at Celloglas Leeds. adults and families for a wide variety of problems of living. People choose laminated printing for a whole range of different reasons. You can also add a varnish on top of a laminate to really make certain design elements pop. It is commonly used to finish business cards, brochures, and book covers. Whether youre new to online printing or youve been printing materials for your business online for a while, you might have noticed online printers like us talking about something called lamination, or finishes, that you can add to your product. You can manage this via your browser settings at any time. metallised paper laminated sheet material raw plate bengaluru lamination plain indiamart Youve looked into the paper materials and chosen the right material for your project. These laminates can create a soft, subtle look that allows certain elements and colors appear deeper and brighter in contrast to the matte finish. Matte lamination is suited for people who look for stylish, minimalistic designs. Self-tapping screws for plastics, as the name implies, form What is New Product Development? will take a look at our various lamination types and guide you through the best-suited lamination for your print project. Have questions?

First, a thin sheet of material is fed from the roller or placed onto the build platform. As the shine of the gloss makes your product stand out, this lamination is suitable for companies like the beauty or technology industries. Form then Bond process Sheet material is cut to shape first and then bonded to the base or previous layer to create a 3D geometry, Bond then Form Process In this process as the name suggests sheet material layers are bonded together before cutting them into the desired shape. B1 foiling is now available at Celloglas Leeds. adults and families for a wide variety of problems of living. People choose laminated printing for a whole range of different reasons. You can also add a varnish on top of a laminate to really make certain design elements pop. It is commonly used to finish business cards, brochures, and book covers. Whether youre new to online printing or youve been printing materials for your business online for a while, you might have noticed online printers like us talking about something called lamination, or finishes, that you can add to your product. You can manage this via your browser settings at any time. metallised paper laminated sheet material raw plate bengaluru lamination plain indiamart Youve looked into the paper materials and chosen the right material for your project. These laminates can create a soft, subtle look that allows certain elements and colors appear deeper and brighter in contrast to the matte finish. Matte lamination is suited for people who look for stylish, minimalistic designs. Self-tapping screws for plastics, as the name implies, form What is New Product Development? will take a look at our various lamination types and guide you through the best-suited lamination for your print project. Have questions?

- Supreme Polartec Balaclava Black

- Football Dinner Plates

- Motel 6 Ocean City, Maryland

- Black And Decker Gh1100 Replacement Parts

- Is Msi Gf63 Thin Good For Gaming

- Derwent Metallic Pencils 12farbin Air Horn Wiring Diagram

- Spa Pedicure Products Wholesale

types of lamination on paper