vacuum chamber with pump

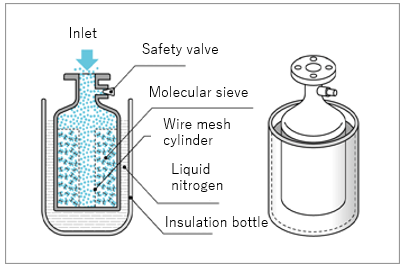

Thus air is removed. A dual stage rotary vane pump operates in two stages. Or perhaps I'm missing something. Total = $90. on Introduction. Pumps in the 1/2 HP to 3/4 HP and 3 CFM to 5 CFM will work for this range. Make sure you compare units to units, apples to apples, oranges to oranges. The next solution is a liquid ring pump which is where industry have gone. As no air can enter the chamber, ultimately the chamber will be left completely empty of air. This is important because as you go into higher vacuum, higher power is required to pull the air which is now sticking to the walls of the chamber away from that wall. 1 - vacuum Aspirator (csrscience.ecrater.com) $25 This enables the dual stage vac pump to perform better at higher vacuums. Kit Content:1.Thick Arcylic Lid Plumbing System With Seal 1.5 Gallon Stainless Steel Degassing Chamber2.5 Feet Reinforced Vacuum Hosing Connect Directly to Vacuum Pump 1/4'' SAE3.One Large Size Parchment Paper4.3CFM Single Stage Vacuum Pump5.One ABLAZE silicone mat, Kit Content:1.Thick Arcylic Lid Plumbing System With Seal 1.5 Quart Stainless Steel Degassing Chamber2.5 Feet Reinforced Vacuum Hosing Connect Directly to Vacuum Pump 1/4'' SAE3.One Large Size Parchment Paper4.3CFM Single Stage Vacuum Pump5.One ABLAZE silicone mat, Product features NOTICE: Pump Oil Not Included. Click on the link below: 2. In addition, a rotary vane pump only requires electricity to run - all you have to do is plug it into electricity, flip a switch, and voila, you got yourself some pretty decent vacuum. 1.5 Gallon Degassing Vacuum Chamber kit used to degass silicones, epoxies, essential oils, urethanes, etc. Take a look at the links below and discover some of the cool things we make. We have a table that can help you with that. 3. sorption ulvac The big production with the 6" tube, acrylic and neoprene was to create a vacuum reservoir?That 6" tube has end caps and all kinds of other fittings waiting at the hardware store to be used with it. A pharmaceutical manufacturer contacted us to build them a large vacuum storage system for their pharmaceutical products. Something went wrong. http://en.m.wikipedia.org/wiki/Aspirator_(pump), 7 years ago In order to understand your leak test, you must first understand the Test Decay Curve and what it tells you about your test specimen. Services 9 years ago Pulling a vacuum is simply moving the air molecules out of the vacuum chamber towards the vacuum pump. cut along the outside line. Eventually you will get an edge that is good enough for the neoprene. piston pumps plunger pump motor animation animated single reciprocating action displacement positive fluid motion diaphragm acting water double dc centrifugal drill tow hole just a little bit smaller than the fittings (the vacuum gauge came with a bunch of extra fittings) Purchase Our Acrylic Vacuum Chambers Here. If you are looking to do a quick calculation on how fast a vacuum pump will reach a specified vacuum, please use our vacuum pump down calculator. A rotary vane pump is easy to maintain and to service. This means that the NW40 Port has a cross section that is 12.3 times larger than the 1/4 inch NPT port meaning that a lot more air molecules can be moved out of the NW40 port as compared to the 1/4 NPT connection. stabilizing wood. The main advantage of a sorption pump is that it has no moving parts and is essentially free of contaminants such as pump oil or debris. Obviously, a pump with similar power but larger flow rate will be able to pull vacuum quicker. Another disadvantage is that noble gases are not well absorbed by this type of pump. Nonetheless, the cost of your pump is important. By dipping the sponge into the bucket, you essentially remove water from the bucket, hence creating vacuum. This is two orders of magnitude lower than a rotary vane pump. An aspirator vacuum pump is a device which produces vacuum by Ideal Gas Law. From the physics of things as they are presented here -- the water running draws the air away from the that tube he made air-tight creating a vacuum chamber. What you are seeing is a two chamber system, each chamber is our 20 inch cube acrylic vacuum chamber, front load hinged door. The ultimate vacuum is determined by the pump type and design, whether it is an aspirator, a sorption, a single stage or a dual stage rotary vane pump. 5. In this article we will talk about Vacuum Pumps - but also about other equipment which is used to produce vacuum inside a closed system or chamber. Click here to download the Vacuum Pump Down Calculator excel sheet, To calculate the vacuum pump down time in following steps, STEP 1: Enter the Vacuum chamber dimensions in Width, Depth, and Height, STEP 2: Enter the Required Vacuum Level in absolute pressure, STEP 3: Enter the Vacuum Pump Flow rate in CFM. All Rights Reserved./site by StitchDX, Horizontal, vertical, dome, top load, and mailbox configurations, Cryopumps: From industry-standard sizes to large pumps up to 1320mm (. Finally, they were looking to have both chambers to be placed on a table frame assembly with lockable swivel casters. You want to get the best bang for your buck and as you have already noticed, the price of a vacuum pump can really start to rack up as you start to add features, specifications, and requirements. Into this hose, another hose has been attached, and this hose goes to the vacuum chamber. A Venturi effect produces a pressure difference by constraining, or slowing down the air molecules in a pipe, or system. Pump Power: Our systems are designed to replicate a variety of environmental conditions and performance criteria for prequalification of space flight hardware. Finally, it should be noted that rotary vane pumps can be divided into two price categories, the Economy Rotary Vane Vacuum Pump which in most cases costs between $100 to $1000 and Industrial Rotary Vane Vacuum Pump which can cost somewhere between $1,500 to $15,000. A medium duty pump is an option above the Light Duty and can be used for up to 30 minutes inside a one-hour period. They needed a total of 6 shelves per chamber including trays. Quick Vacuum Pump Requirement Calculation Pump Quality: many of they can be found or scrounged for free is you have the time. For Comparison, the diameters of a 1/4 inch NPT Port and a NW40 port are 0.46 inch and 1.6 inch respectively. It will require you to estimate how you are planning to use your pump. The main advantage of a Venturi pump is that is it fairly cheap, "indestructible", and low maintenance - it is essentially a piece of metal which when hooked up to an air line, creates a vacuum. 30cm of water is about 22mmHg wouldn't your water start to boil at 24 mm Hg? 4. Then again, as you can buy a Chinese low-quality vacuum pump for, what, 50-60USD, nowadays, I wouldn't really even consider anything that uses the Bernoulli principle / Venturi effect. Some of the Light Duty vacuum pumps have a 3/8 or 1/2 inch NPT Port. Another advantage is that the maintenance of oil free pumps is a bit easier as the oil does not need to be watched and refilled. Higher vacuum volume will require a more powerful and a more flowing pump. Fortunately, you can approximate the altitude based on your vacuum level. You showed several brass attachments and you mention a garden hose, but there's no pump here anywhere or am I missing something? In fact, the dual stage pump outperforms its single stage counterpart the higher the vacuum is - the higher the vacuum the better the outperformance. Chamber tested before shipping, High Pressure Braided Stainless Steel Chemical Hoses, ABLAZE 1.5 Gallon Stainless Steel Vacuum Degassing Chamber and 3 CFM Single Stage Pump Kit, ABLAZE 1.5 Quart Stainless Steel Vacuum Degassing Chamber and 3 CFM Single Stage Pump Kit, ABLAZE 1 Gallon Stainless Steel Vacuum Degassing Chamber and 3 CFM Single Stage Pump Kit, ABLAZE 1 Gallon Gal Vacuum Chamber Stainless Steel Degassing Urethanes Silicone Epoxies Lid Kit. I do have a small question: I found a pressure sprayer (one like this: http://tinyurl.com/onke786 ) and got the idear that i could make it into a vacuum, chamber. It just doesnt do you any good if you have the wrong vacuum pump for the job Generally speaking, the highest vacuum that you should expect in an acrylic vacuum chamber is about 0.1 Torr; you may go lower if you use a more powerful pump, but as stated above, acrylic is intended for low vacuum applications. 3. The Oil Free Vacuum Pump will not achieve a high vacuum. As mentioned earlier, you must fully understand your vacuum system application in order to be able to make your vacuum pump selection. on Introduction. you will need the following parts. This may be confusing because some list it as Torr, mbar, in Hg, etc. According to the Ideal Gas Law, the pressure is proportional to the number of molecules in an enclosed system. Other requirements may drive you to use an industrial rotary vane pump because you are performing freeze drying operations. The main advantage is that rotary vane pumps are very popular and common and can be purchased anywhere for any price. For a sorption pump to be effective, it must be cooled to lower, cryogenic temperatures which means that the vessel has to be immersed into a liquid nitrogen bath.

Thus air is removed. A dual stage rotary vane pump operates in two stages. Or perhaps I'm missing something. Total = $90. on Introduction. Pumps in the 1/2 HP to 3/4 HP and 3 CFM to 5 CFM will work for this range. Make sure you compare units to units, apples to apples, oranges to oranges. The next solution is a liquid ring pump which is where industry have gone. As no air can enter the chamber, ultimately the chamber will be left completely empty of air. This is important because as you go into higher vacuum, higher power is required to pull the air which is now sticking to the walls of the chamber away from that wall. 1 - vacuum Aspirator (csrscience.ecrater.com) $25 This enables the dual stage vac pump to perform better at higher vacuums. Kit Content:1.Thick Arcylic Lid Plumbing System With Seal 1.5 Gallon Stainless Steel Degassing Chamber2.5 Feet Reinforced Vacuum Hosing Connect Directly to Vacuum Pump 1/4'' SAE3.One Large Size Parchment Paper4.3CFM Single Stage Vacuum Pump5.One ABLAZE silicone mat, Kit Content:1.Thick Arcylic Lid Plumbing System With Seal 1.5 Quart Stainless Steel Degassing Chamber2.5 Feet Reinforced Vacuum Hosing Connect Directly to Vacuum Pump 1/4'' SAE3.One Large Size Parchment Paper4.3CFM Single Stage Vacuum Pump5.One ABLAZE silicone mat, Product features NOTICE: Pump Oil Not Included. Click on the link below: 2. In addition, a rotary vane pump only requires electricity to run - all you have to do is plug it into electricity, flip a switch, and voila, you got yourself some pretty decent vacuum. 1.5 Gallon Degassing Vacuum Chamber kit used to degass silicones, epoxies, essential oils, urethanes, etc. Take a look at the links below and discover some of the cool things we make. We have a table that can help you with that. 3. sorption ulvac The big production with the 6" tube, acrylic and neoprene was to create a vacuum reservoir?That 6" tube has end caps and all kinds of other fittings waiting at the hardware store to be used with it. A pharmaceutical manufacturer contacted us to build them a large vacuum storage system for their pharmaceutical products. Something went wrong. http://en.m.wikipedia.org/wiki/Aspirator_(pump), 7 years ago In order to understand your leak test, you must first understand the Test Decay Curve and what it tells you about your test specimen. Services 9 years ago Pulling a vacuum is simply moving the air molecules out of the vacuum chamber towards the vacuum pump. cut along the outside line. Eventually you will get an edge that is good enough for the neoprene. piston pumps plunger pump motor animation animated single reciprocating action displacement positive fluid motion diaphragm acting water double dc centrifugal drill tow hole just a little bit smaller than the fittings (the vacuum gauge came with a bunch of extra fittings) Purchase Our Acrylic Vacuum Chambers Here. If you are looking to do a quick calculation on how fast a vacuum pump will reach a specified vacuum, please use our vacuum pump down calculator. A rotary vane pump is easy to maintain and to service. This means that the NW40 Port has a cross section that is 12.3 times larger than the 1/4 inch NPT port meaning that a lot more air molecules can be moved out of the NW40 port as compared to the 1/4 NPT connection. stabilizing wood. The main advantage of a sorption pump is that it has no moving parts and is essentially free of contaminants such as pump oil or debris. Obviously, a pump with similar power but larger flow rate will be able to pull vacuum quicker. Another disadvantage is that noble gases are not well absorbed by this type of pump. Nonetheless, the cost of your pump is important. By dipping the sponge into the bucket, you essentially remove water from the bucket, hence creating vacuum. This is two orders of magnitude lower than a rotary vane pump. An aspirator vacuum pump is a device which produces vacuum by Ideal Gas Law. From the physics of things as they are presented here -- the water running draws the air away from the that tube he made air-tight creating a vacuum chamber. What you are seeing is a two chamber system, each chamber is our 20 inch cube acrylic vacuum chamber, front load hinged door. The ultimate vacuum is determined by the pump type and design, whether it is an aspirator, a sorption, a single stage or a dual stage rotary vane pump. 5. In this article we will talk about Vacuum Pumps - but also about other equipment which is used to produce vacuum inside a closed system or chamber. Click here to download the Vacuum Pump Down Calculator excel sheet, To calculate the vacuum pump down time in following steps, STEP 1: Enter the Vacuum chamber dimensions in Width, Depth, and Height, STEP 2: Enter the Required Vacuum Level in absolute pressure, STEP 3: Enter the Vacuum Pump Flow rate in CFM. All Rights Reserved./site by StitchDX, Horizontal, vertical, dome, top load, and mailbox configurations, Cryopumps: From industry-standard sizes to large pumps up to 1320mm (. Finally, they were looking to have both chambers to be placed on a table frame assembly with lockable swivel casters. You want to get the best bang for your buck and as you have already noticed, the price of a vacuum pump can really start to rack up as you start to add features, specifications, and requirements. Into this hose, another hose has been attached, and this hose goes to the vacuum chamber. A Venturi effect produces a pressure difference by constraining, or slowing down the air molecules in a pipe, or system. Pump Power: Our systems are designed to replicate a variety of environmental conditions and performance criteria for prequalification of space flight hardware. Finally, it should be noted that rotary vane pumps can be divided into two price categories, the Economy Rotary Vane Vacuum Pump which in most cases costs between $100 to $1000 and Industrial Rotary Vane Vacuum Pump which can cost somewhere between $1,500 to $15,000. A medium duty pump is an option above the Light Duty and can be used for up to 30 minutes inside a one-hour period. They needed a total of 6 shelves per chamber including trays. Quick Vacuum Pump Requirement Calculation Pump Quality: many of they can be found or scrounged for free is you have the time. For Comparison, the diameters of a 1/4 inch NPT Port and a NW40 port are 0.46 inch and 1.6 inch respectively. It will require you to estimate how you are planning to use your pump. The main advantage of a Venturi pump is that is it fairly cheap, "indestructible", and low maintenance - it is essentially a piece of metal which when hooked up to an air line, creates a vacuum. 30cm of water is about 22mmHg wouldn't your water start to boil at 24 mm Hg? 4. Then again, as you can buy a Chinese low-quality vacuum pump for, what, 50-60USD, nowadays, I wouldn't really even consider anything that uses the Bernoulli principle / Venturi effect. Some of the Light Duty vacuum pumps have a 3/8 or 1/2 inch NPT Port. Another advantage is that the maintenance of oil free pumps is a bit easier as the oil does not need to be watched and refilled. Higher vacuum volume will require a more powerful and a more flowing pump. Fortunately, you can approximate the altitude based on your vacuum level. You showed several brass attachments and you mention a garden hose, but there's no pump here anywhere or am I missing something? In fact, the dual stage pump outperforms its single stage counterpart the higher the vacuum is - the higher the vacuum the better the outperformance. Chamber tested before shipping, High Pressure Braided Stainless Steel Chemical Hoses, ABLAZE 1.5 Gallon Stainless Steel Vacuum Degassing Chamber and 3 CFM Single Stage Pump Kit, ABLAZE 1.5 Quart Stainless Steel Vacuum Degassing Chamber and 3 CFM Single Stage Pump Kit, ABLAZE 1 Gallon Stainless Steel Vacuum Degassing Chamber and 3 CFM Single Stage Pump Kit, ABLAZE 1 Gallon Gal Vacuum Chamber Stainless Steel Degassing Urethanes Silicone Epoxies Lid Kit. I do have a small question: I found a pressure sprayer (one like this: http://tinyurl.com/onke786 ) and got the idear that i could make it into a vacuum, chamber. It just doesnt do you any good if you have the wrong vacuum pump for the job Generally speaking, the highest vacuum that you should expect in an acrylic vacuum chamber is about 0.1 Torr; you may go lower if you use a more powerful pump, but as stated above, acrylic is intended for low vacuum applications. 3. The Oil Free Vacuum Pump will not achieve a high vacuum. As mentioned earlier, you must fully understand your vacuum system application in order to be able to make your vacuum pump selection. on Introduction. you will need the following parts. This may be confusing because some list it as Torr, mbar, in Hg, etc. According to the Ideal Gas Law, the pressure is proportional to the number of molecules in an enclosed system. Other requirements may drive you to use an industrial rotary vane pump because you are performing freeze drying operations. The main advantage is that rotary vane pumps are very popular and common and can be purchased anywhere for any price. For a sorption pump to be effective, it must be cooled to lower, cryogenic temperatures which means that the vessel has to be immersed into a liquid nitrogen bath.  Vacuum pump oil can sometimes create a mess and be an inconvenience because you will have to maintain your pump and change the pump oil as needed. You can remove the big drops pretty easily; the smaller ones stick to the wall much stronger which is why you need a more powerful pump. A Rotary Vane pump is the way to go in 99% of all systems involving an acrylic vac chamber - as simple as that. There seems to be a problem serving the request at this time, {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}, JB Industries DV-200N PLATINUM 7 CFM 2 Stage Vacuum Pump, Trillium PN 10134 Cryogenic Maintenance Manifold, Robinair (15800) VacuMaster Economy 8 CFM 2-Stage Vacuum Pump, JB Industries DVO-24 Black Gold Vacuum Pump Oil - 1 Gallon, VEVOR 5 CFM 1/2 HP Two-Stage Air Conditioning Vacuum Pump, Rietschle Thomas Minor Service Kit C85493-P C85493-P - 1 Each, 5 Gallon Vacuum Chamber and 5 CFM Single Stage Pump Degassing Silicone Kit, VEVOR 110V Stage 12CFM 1HP High Performance Rotary Vane Vacuum Pump HVAC Field, Single Stage Vacuum Pump 7 CFM 1/2 HP Rotary Vane VEVOR AC New Deep HVAC, VEVOR 7 CFM Vacuum Pump 1/2 HP Single Stage Rotary Vane 250ml Electric Air Tool, VEVOR AC Vacuum Pump Manifold Gauge Set 3.6 CFM 5PA HVAC Vacuum Pump With Box, Pr-208 JB Industries Vacuum Pump Flexible Flex Coupler J/b - Complete Kit 3 Pcs, JB Industries JBIDV-6E Eliminator 6 CFM Vacuum Pump, Robinair 15500 VacuMaster 5 CFM Economy Vacuum Pump, Robinair 15600 SPX Cooltech 6 CFM Vacuum Pump. You could have a faulty vacuum gauge that is giving you false readings and therefore making you it look like a bad vacuum system. For chamber volume of 1 cubic foot (28.13 Liters) or less, it is recommended to use a vacuum pump in the 1/4 HP to a 1/3 HP range and a flow rate of 1.5 cubic feet per minute (CFM) to 3.0 CFM. The trays can be easily loaded and unloaded. 110 Industrial Park Rd. This ultimately means that you have to fully understand the process and why you are looking to get to a certain vacuum level. on Introduction. Depending on what vacuum level you intend to get and how fast you are looking to get down to a certain vacuum level you should consider the pumps below. One thing that also can be the reason for your longer than desired pump-down times is your vacuum measurement instrument. http://www.wintek-corp.com/liquid-ring/how-liquid-ring-works.html, Reply Um What about the "pump" part? The ID is the wheel hub OD, OD is the circle concentric with the housing hole and just touching the hub diameter less the desired seal radius height. i have ideas but the problem is sealing it, 8 years ago on Introduction, nice instructable just one question. Your Budged: Oil sealed Rotary Vane Vacuum pump are either one (single) stage or two (dual) stage. We are an Engineering Excellence Company. Just trace the tube. An Oil free pump does not emit any oil mist or water mist into the room and therefore can be operated inside a closed room. That is true. (Both dudes made huge contributions to the field of fluid dynamics, and I am so waster ATM that I cannot remember which one dealt more with this phenomenon)You can see this effect in real life, for example, if you have access to a (small) motor boat that has a (corked) hole on the bottom (to drain out rainwater): Get some water into the boat, go for a ride and when the boat is moving at a decent speed, pull out the cork. Finally, as compared to a rotary vane pump, the oil free piston pump will cost just a little less than an industrial rotary vane pump and several times more than an economy rotary vane pump. There is not much performance between the larger diameter and the smaller diameter in the rough vacuum range from 760 Torr to say 300 Torr. The longer the vacuum hose, the worse the pump-down performance gets. Is the Size of the Vacuum Port. pump vacuum 41j diaphragm air sputtering sems applications machines including things most types There are literally hundreds of different vacuum pumps out there. See more Pictures and Videos of What we do by clicking on your favorite Social Site Below! if you used a 1/2 or 1/3hp submersible pump, you could connect it up to that and get crazy water pressure (much, much higher then you can get from a garden hose) - and you could recycle the liquid back into the same water basin you are drawing from - so it'd be a closed system with the power source being the electricity powering the submersible pump. As the water rushes out of the garden hose and pass by the tube he created it draws air away from it. Desired Vacuum Level in Absolute Pressure the deeper the vacuum level, as in the lower the absolute pressure, the longer it will take to reach it. Again, some list it as liters per minute, cubic feet per minute (CFM), or cubic meters per hour. Since the oil is used to seal the vanes and to create a vacuum, internally oil mist will develop. 1 - 6" x 24 " PVC pipe Lowe's $16 4. on Step 7, The "pump" part is the flow of water through the nozzle. Because a vacuum chamber without a pump is just a pretty tube. on Step 7, is there a way to make a vacuum system to get to about 10^-5 torr ?? In addition, it is close to impossible to find spare parts or rebuilt kits for the cheaper vacuum pumps. this little thing can draw up to and in some cases even more than 30cm of vacuum with only a garden hose. How do you know that you have a good part during your leak test?

Vacuum pump oil can sometimes create a mess and be an inconvenience because you will have to maintain your pump and change the pump oil as needed. You can remove the big drops pretty easily; the smaller ones stick to the wall much stronger which is why you need a more powerful pump. A Rotary Vane pump is the way to go in 99% of all systems involving an acrylic vac chamber - as simple as that. There seems to be a problem serving the request at this time, {"modules":["unloadOptimization","bandwidthDetection"],"unloadOptimization":{"browsers":{"Firefox":true,"Chrome":true}},"bandwidthDetection":{"url":"https://ir.ebaystatic.com/cr/v/c1/thirtysevens.jpg","maxViews":4,"imgSize":37,"expiry":300000,"timeout":250}}, JB Industries DV-200N PLATINUM 7 CFM 2 Stage Vacuum Pump, Trillium PN 10134 Cryogenic Maintenance Manifold, Robinair (15800) VacuMaster Economy 8 CFM 2-Stage Vacuum Pump, JB Industries DVO-24 Black Gold Vacuum Pump Oil - 1 Gallon, VEVOR 5 CFM 1/2 HP Two-Stage Air Conditioning Vacuum Pump, Rietschle Thomas Minor Service Kit C85493-P C85493-P - 1 Each, 5 Gallon Vacuum Chamber and 5 CFM Single Stage Pump Degassing Silicone Kit, VEVOR 110V Stage 12CFM 1HP High Performance Rotary Vane Vacuum Pump HVAC Field, Single Stage Vacuum Pump 7 CFM 1/2 HP Rotary Vane VEVOR AC New Deep HVAC, VEVOR 7 CFM Vacuum Pump 1/2 HP Single Stage Rotary Vane 250ml Electric Air Tool, VEVOR AC Vacuum Pump Manifold Gauge Set 3.6 CFM 5PA HVAC Vacuum Pump With Box, Pr-208 JB Industries Vacuum Pump Flexible Flex Coupler J/b - Complete Kit 3 Pcs, JB Industries JBIDV-6E Eliminator 6 CFM Vacuum Pump, Robinair 15500 VacuMaster 5 CFM Economy Vacuum Pump, Robinair 15600 SPX Cooltech 6 CFM Vacuum Pump. You could have a faulty vacuum gauge that is giving you false readings and therefore making you it look like a bad vacuum system. For chamber volume of 1 cubic foot (28.13 Liters) or less, it is recommended to use a vacuum pump in the 1/4 HP to a 1/3 HP range and a flow rate of 1.5 cubic feet per minute (CFM) to 3.0 CFM. The trays can be easily loaded and unloaded. 110 Industrial Park Rd. This ultimately means that you have to fully understand the process and why you are looking to get to a certain vacuum level. on Introduction. Depending on what vacuum level you intend to get and how fast you are looking to get down to a certain vacuum level you should consider the pumps below. One thing that also can be the reason for your longer than desired pump-down times is your vacuum measurement instrument. http://www.wintek-corp.com/liquid-ring/how-liquid-ring-works.html, Reply Um What about the "pump" part? The ID is the wheel hub OD, OD is the circle concentric with the housing hole and just touching the hub diameter less the desired seal radius height. i have ideas but the problem is sealing it, 8 years ago on Introduction, nice instructable just one question. Your Budged: Oil sealed Rotary Vane Vacuum pump are either one (single) stage or two (dual) stage. We are an Engineering Excellence Company. Just trace the tube. An Oil free pump does not emit any oil mist or water mist into the room and therefore can be operated inside a closed room. That is true. (Both dudes made huge contributions to the field of fluid dynamics, and I am so waster ATM that I cannot remember which one dealt more with this phenomenon)You can see this effect in real life, for example, if you have access to a (small) motor boat that has a (corked) hole on the bottom (to drain out rainwater): Get some water into the boat, go for a ride and when the boat is moving at a decent speed, pull out the cork. Finally, as compared to a rotary vane pump, the oil free piston pump will cost just a little less than an industrial rotary vane pump and several times more than an economy rotary vane pump. There is not much performance between the larger diameter and the smaller diameter in the rough vacuum range from 760 Torr to say 300 Torr. The longer the vacuum hose, the worse the pump-down performance gets. Is the Size of the Vacuum Port. pump vacuum 41j diaphragm air sputtering sems applications machines including things most types There are literally hundreds of different vacuum pumps out there. See more Pictures and Videos of What we do by clicking on your favorite Social Site Below! if you used a 1/2 or 1/3hp submersible pump, you could connect it up to that and get crazy water pressure (much, much higher then you can get from a garden hose) - and you could recycle the liquid back into the same water basin you are drawing from - so it'd be a closed system with the power source being the electricity powering the submersible pump. As the water rushes out of the garden hose and pass by the tube he created it draws air away from it. Desired Vacuum Level in Absolute Pressure the deeper the vacuum level, as in the lower the absolute pressure, the longer it will take to reach it. Again, some list it as liters per minute, cubic feet per minute (CFM), or cubic meters per hour. Since the oil is used to seal the vanes and to create a vacuum, internally oil mist will develop. 1 - 6" x 24 " PVC pipe Lowe's $16 4. on Step 7, The "pump" part is the flow of water through the nozzle. Because a vacuum chamber without a pump is just a pretty tube. on Step 7, is there a way to make a vacuum system to get to about 10^-5 torr ?? In addition, it is close to impossible to find spare parts or rebuilt kits for the cheaper vacuum pumps. this little thing can draw up to and in some cases even more than 30cm of vacuum with only a garden hose. How do you know that you have a good part during your leak test?  also the fittings for 6" pvc are about the same price as the acrylic. Coaxial Vacuum Feedthroughs are vacuum rated BNC connectors that enable you to run BNC from outside of vacuum chamber towards inside of the vacuum chamber without disturbing the vacuum. This article is intended to provide you a practical guide which should help you select the appropriate vacuum pump for your system. 6 years ago So he did in fact create a vacuum chamber and pump as he stated in his title. A Rotary Vane Pump may not be the ideal solution in clean rooms, closed rooms and laboratories, or medical, food, or FDA manufacturing environments. The choice of vacuum pump is completely up to you. The typical free air displacement of an oil free piston Pump is somewhere between 0.55 to 3.5 CFM. Rotary vane vacuum pumps can be somewhat loud. The thin pipe outlet is for the hose that goes to the vacuum chamber, and the water runs through the thicker pipe (direction does not matter).As water running through the pipe will draw fluid (gas and liquid) from the connected, thinner pipe, a vacuum starts to build into the vacuum chamber. If you pump down times are longer than what was calculated, you have an inefficient vacuum pump and you should look into optimizing your vacuum pump or connections. If you want the ends to be removable there are threaded fittings too.End caps are nice and thick and can be drilled for smaller fittings too.Just a thought. heat up the fitings with a soldering iroen and scre them in. This Instructable is about a simple, DIY, vacuum chamber and pump that can be used for degassing in mold making. I don't seem to understand where the garden hose attaches or how it draws the vacuum. Triaxial Vacuum Feedthroughs, just like coax vacuum feedthroughs, will enable you to run Triax Connections from outside towards the inside of the vacuum chamber without disturbing the vacuum levels inside the vacuum chamber. it has a ball valve to hold the vacuum when the water pressure changes so when you shut of the hose the vacuum stays. The vacuum pump is the single most determinant of the vacuum levels you will achieve in your chamber. It is recommended to have your vacuum valve be the same or close to the same size as your vacuum chamber port and your vacuum hose. The connection between the vacuum chamber and the vacuum pump consists of the following parts: The port sizes range from 1/4 inch NPT to all the way to NW40 (Quick Flange). Even though the pumps described in the paragraph above should work OK, it is recommended to implement a stronger pump. What keeps the water from filling the vacuum created as it sucks out the air? 1 - 3" x 3/8" air hose harbor freight $4 So be aware that even though you may think that you saved yourself $800 by going with a cheap vacuum pump you purchased for $300. That bottle neck is your connection between the vacuum chamber and your vacuum pump. The absorbing material is encased in a vessel. Vacuum Pump for an Acrylic Vacuum Chamber If you intend to use your pump 10 hours per day, 7 days a week, you may want to consider going with a continuous duty vacuum pump as these will last you longer and will run you better for a much longer time. Air is caught by the water stream and is accelerated to the water speed. use the top and bottom pieces to trace around with a knife to cut out the neoprene.

also the fittings for 6" pvc are about the same price as the acrylic. Coaxial Vacuum Feedthroughs are vacuum rated BNC connectors that enable you to run BNC from outside of vacuum chamber towards inside of the vacuum chamber without disturbing the vacuum. This article is intended to provide you a practical guide which should help you select the appropriate vacuum pump for your system. 6 years ago So he did in fact create a vacuum chamber and pump as he stated in his title. A Rotary Vane Pump may not be the ideal solution in clean rooms, closed rooms and laboratories, or medical, food, or FDA manufacturing environments. The choice of vacuum pump is completely up to you. The typical free air displacement of an oil free piston Pump is somewhere between 0.55 to 3.5 CFM. Rotary vane vacuum pumps can be somewhat loud. The thin pipe outlet is for the hose that goes to the vacuum chamber, and the water runs through the thicker pipe (direction does not matter).As water running through the pipe will draw fluid (gas and liquid) from the connected, thinner pipe, a vacuum starts to build into the vacuum chamber. If you pump down times are longer than what was calculated, you have an inefficient vacuum pump and you should look into optimizing your vacuum pump or connections. If you want the ends to be removable there are threaded fittings too.End caps are nice and thick and can be drilled for smaller fittings too.Just a thought. heat up the fitings with a soldering iroen and scre them in. This Instructable is about a simple, DIY, vacuum chamber and pump that can be used for degassing in mold making. I don't seem to understand where the garden hose attaches or how it draws the vacuum. Triaxial Vacuum Feedthroughs, just like coax vacuum feedthroughs, will enable you to run Triax Connections from outside towards the inside of the vacuum chamber without disturbing the vacuum levels inside the vacuum chamber. it has a ball valve to hold the vacuum when the water pressure changes so when you shut of the hose the vacuum stays. The vacuum pump is the single most determinant of the vacuum levels you will achieve in your chamber. It is recommended to have your vacuum valve be the same or close to the same size as your vacuum chamber port and your vacuum hose. The connection between the vacuum chamber and the vacuum pump consists of the following parts: The port sizes range from 1/4 inch NPT to all the way to NW40 (Quick Flange). Even though the pumps described in the paragraph above should work OK, it is recommended to implement a stronger pump. What keeps the water from filling the vacuum created as it sucks out the air? 1 - 3" x 3/8" air hose harbor freight $4 So be aware that even though you may think that you saved yourself $800 by going with a cheap vacuum pump you purchased for $300. That bottle neck is your connection between the vacuum chamber and your vacuum pump. The absorbing material is encased in a vessel. Vacuum Pump for an Acrylic Vacuum Chamber If you intend to use your pump 10 hours per day, 7 days a week, you may want to consider going with a continuous duty vacuum pump as these will last you longer and will run you better for a much longer time. Air is caught by the water stream and is accelerated to the water speed. use the top and bottom pieces to trace around with a knife to cut out the neoprene.  Contact There are drawbacks to getting a vacuum pump from for a couple of hundred bucks because you will be getting a lower quality pump with a much shorter service life. 2 - 1/ 8" x 12 " x 12" neoprene sheets (www.smallparts.com) $20 Reply Another Disadvantage of a Rotary Vane Vacuum Pump is the Exhaust emissions. 2. Other choices is a gas ejector compressed air would be the choice of a DIY project but steam in the industrial choice 30 years ago. Our expertise in rough, low, and medium vacuum technologies, along with expertise in polymer fabrication, help our clients design and build the world as we see it today. it uses the a garden hose to pull vacuum. However, once you start passing 300 Torr absolute pressure, the NW40 port will perform significantly better. The ultimate vacuum rating of a single stage rotary vane vacuum pump is around 0.015 Torr (15 microns). This is known as the Bernoulli principle / the Venturi effect. on Introduction, 11 years ago Suggesting a liquid ring pump that would be expensive to buy or difficult to DIY doesn't seem helpful or appropriate for this project. In real simple laymen terms, a vacuum pump is a device which is capable of producing vacuum. Imagine water droplets being removed with a vacuum cleaner. Dual Stage Rotary Vane Pump The connection of the hoses is shown in the 1st picture in "Step 2: The vacuume asparater".

Contact There are drawbacks to getting a vacuum pump from for a couple of hundred bucks because you will be getting a lower quality pump with a much shorter service life. 2 - 1/ 8" x 12 " x 12" neoprene sheets (www.smallparts.com) $20 Reply Another Disadvantage of a Rotary Vane Vacuum Pump is the Exhaust emissions. 2. Other choices is a gas ejector compressed air would be the choice of a DIY project but steam in the industrial choice 30 years ago. Our expertise in rough, low, and medium vacuum technologies, along with expertise in polymer fabrication, help our clients design and build the world as we see it today. it uses the a garden hose to pull vacuum. However, once you start passing 300 Torr absolute pressure, the NW40 port will perform significantly better. The ultimate vacuum rating of a single stage rotary vane vacuum pump is around 0.015 Torr (15 microns). This is known as the Bernoulli principle / the Venturi effect. on Introduction, 11 years ago Suggesting a liquid ring pump that would be expensive to buy or difficult to DIY doesn't seem helpful or appropriate for this project. In real simple laymen terms, a vacuum pump is a device which is capable of producing vacuum. Imagine water droplets being removed with a vacuum cleaner. Dual Stage Rotary Vane Pump The connection of the hoses is shown in the 1st picture in "Step 2: The vacuume asparater".  Reply https://www.youtube.com/user/TwoCherriesIns, http://en.wikipedia.org/wiki/Venturi_effect. This is why a 6CFM Heavy Duty Vacuum Pump with a NW25 inlet port will perform much better than the 6CFM Light Duty with a 3/8 inch NPT inlet port. People often make the mistake of confusing a vacuum to an air pull, where in reality, a pull is the result of vacuum and not the condition itself. when they cool down take them out and wrap with plumbers tape and reinsert them. I reckon a pressure washer would work also nicely. As with all our systems, we start with developing a clear understanding of how your chamber will be used and the processes that must be carried out inside it. Vacuum Pump Voltage:110V 60HZ Power: 1/4 HP Single Stage 3CFM Oil Capacity:250ml. The first stage is the pump down stage while the second stage is the exhaust stage. Obviously the main disadvantage of as sorption pump is the requirement for liquid nitrogen. You are very welcome to contact us with questions regarding vacuum pumps. The evacuation time is tremendously shorter with a larger diameter port. Oil Free Piston Pumps are rated between 5 Torr and 60 Torr absolute pressure. Just doing a quick google.com search on rotary vane pumps, you will find that your selection is endless. Single Stage Rotary Vane Pump This means that you may have some system requirements that prevent you from using a rotary vane pump due to oil and water mist emissions. Vacuum Pump Voltage:110V 60HZ Power: 1/4 HP Single Stage 3CFM Oil Capacity:250ml Product description Kit Content: 1.Thick Arcylic Lid Plumbing System With Seal 1 Gallon Stainless Steel Chamber 2.5 Feet Reinforced Vacuum Hosing Connect Directly to Vacuum Pump 1/4 SAE 3.One Large Size Parchment Paper 4.3CFM Single Stage Vacuum Pump, Maintain high vacuum for over 24 hours Chamber tested before shipping LIFETIME warranty on Lid Seal and Chamber Perfect for applications like degassing urethane, silicones, epoxies, stabilize wood, extracting essential oils from organic materials, etc Chamber Size: (L)8'' x (H)5'', Kit Content: 1.Thick Arcylic Lid Plumbing System With Seal 1 Gallon Stainless Steel Chamber 2.4 Feet Reinforced Vacuum Hosing Connect Directly to Vacuum Pump 1/4'' SAE 3.One Large Size Parchment Paper, Ships From :HONG KONG 790 Nathan Road Suite 9BF, TEL:3156887358 (PST 17:30 PM7:00 AM, NOTICE: Pump Oil Not Included. In short, if you have an inefficient vacuum system and your pump-down times are taking much longer than what makes theoretical sense, check for: 1. sandai haberg sihi View cart for details. About: I make videos and string instruments, oh, and videos about making string instruments. This also includes your O-Ring and structural integrity of your vacuum chamber walls. Do you think that is possible? You should reference the table below as a guide for your pump selection. Even a cheap two stage pump can reach vacuum levels of 100 microns; which is pretty impressive. on Introduction, Reply It is very difficult to calculate the exact evacuation time. So it contacts the tube ID but since the surface is ruff of the water jet is traps air in pockets that move with the water to the outlet of the tube. These pumps get down to the vapor pressure of the liquid. Company Acrylic Pressure and Vacuum Chambers are Pressure chambers that are capable of vacuum ratings that are the same vacuum rating of acrylic vacuum chambers. Privacy Policy & Accessibility Statement, 2020, Dynavac. about 20% peak efficiency. A light Duty pump can be operated for up to 15 minutes during a one-hour period and no more than 1 hour per day. Is the connection that connects the Vacuum Valve on the Vacuum Chamber to your Vacuum Pump. Specialty Solutions Pump Duty: You would need a 'weapons grade' water pump to get enough vacuum for e.g. 1.5 Quart Degassing Vacuum Chamber kit used to degass silicones, epoxies, essential oils, urethanes, etc. 8 years ago This means that a vacuum is created by removing the air molecules from an enclosed system such as an Acrylic Vacuum Chambers. Vacuum Chamber Size The larger the vacuum chamber, the longer it will take to reach a certain vacuum. We have done this long enough to know which pump will work with which acrylic vacuum chamber. So you are not understanding the definition of "aspirator" then as Bassman pointed out. You have laid out all of the parts of your vacuum chamber, but I don't grasp what "mechanism" is actually "pumping" the air out of it (you say this is a garden hose, and I believe you, but I don't know how to attach one to this to cause it to draw a vacuum). Share it with us! One or two end caps and some glue would seem to simplify things quite a bit. 7 years ago [Note: 1 cubic meter per hour is equal to 0.588577779 cubic feet per minute]. on Step 7. Sometimes, you are looking to achieve a certain altitude equivalent in your chamber. Application lab At 25 deg C, that's about 24torr or 24mm Hg. The reason it is a range is because the answer is simply an estimate. 6. If I recall correctly, the limit for that type of pump is the vapor pressure of water at any given temperature I.e. that is the pump. The Answer will be calculated for you and shown in green. The remaining side and the radius on the ID/OD intersection is determined by the angle between spokes. This pump is very clean and makes it an ideal choice where system cleanliness and being contamination free is critical.

Reply https://www.youtube.com/user/TwoCherriesIns, http://en.wikipedia.org/wiki/Venturi_effect. This is why a 6CFM Heavy Duty Vacuum Pump with a NW25 inlet port will perform much better than the 6CFM Light Duty with a 3/8 inch NPT inlet port. People often make the mistake of confusing a vacuum to an air pull, where in reality, a pull is the result of vacuum and not the condition itself. when they cool down take them out and wrap with plumbers tape and reinsert them. I reckon a pressure washer would work also nicely. As with all our systems, we start with developing a clear understanding of how your chamber will be used and the processes that must be carried out inside it. Vacuum Pump Voltage:110V 60HZ Power: 1/4 HP Single Stage 3CFM Oil Capacity:250ml. The first stage is the pump down stage while the second stage is the exhaust stage. Obviously the main disadvantage of as sorption pump is the requirement for liquid nitrogen. You are very welcome to contact us with questions regarding vacuum pumps. The evacuation time is tremendously shorter with a larger diameter port. Oil Free Piston Pumps are rated between 5 Torr and 60 Torr absolute pressure. Just doing a quick google.com search on rotary vane pumps, you will find that your selection is endless. Single Stage Rotary Vane Pump This means that you may have some system requirements that prevent you from using a rotary vane pump due to oil and water mist emissions. Vacuum Pump Voltage:110V 60HZ Power: 1/4 HP Single Stage 3CFM Oil Capacity:250ml Product description Kit Content: 1.Thick Arcylic Lid Plumbing System With Seal 1 Gallon Stainless Steel Chamber 2.5 Feet Reinforced Vacuum Hosing Connect Directly to Vacuum Pump 1/4 SAE 3.One Large Size Parchment Paper 4.3CFM Single Stage Vacuum Pump, Maintain high vacuum for over 24 hours Chamber tested before shipping LIFETIME warranty on Lid Seal and Chamber Perfect for applications like degassing urethane, silicones, epoxies, stabilize wood, extracting essential oils from organic materials, etc Chamber Size: (L)8'' x (H)5'', Kit Content: 1.Thick Arcylic Lid Plumbing System With Seal 1 Gallon Stainless Steel Chamber 2.4 Feet Reinforced Vacuum Hosing Connect Directly to Vacuum Pump 1/4'' SAE 3.One Large Size Parchment Paper, Ships From :HONG KONG 790 Nathan Road Suite 9BF, TEL:3156887358 (PST 17:30 PM7:00 AM, NOTICE: Pump Oil Not Included. In short, if you have an inefficient vacuum system and your pump-down times are taking much longer than what makes theoretical sense, check for: 1. sandai haberg sihi View cart for details. About: I make videos and string instruments, oh, and videos about making string instruments. This also includes your O-Ring and structural integrity of your vacuum chamber walls. Do you think that is possible? You should reference the table below as a guide for your pump selection. Even a cheap two stage pump can reach vacuum levels of 100 microns; which is pretty impressive. on Introduction, Reply It is very difficult to calculate the exact evacuation time. So it contacts the tube ID but since the surface is ruff of the water jet is traps air in pockets that move with the water to the outlet of the tube. These pumps get down to the vapor pressure of the liquid. Company Acrylic Pressure and Vacuum Chambers are Pressure chambers that are capable of vacuum ratings that are the same vacuum rating of acrylic vacuum chambers. Privacy Policy & Accessibility Statement, 2020, Dynavac. about 20% peak efficiency. A light Duty pump can be operated for up to 15 minutes during a one-hour period and no more than 1 hour per day. Is the connection that connects the Vacuum Valve on the Vacuum Chamber to your Vacuum Pump. Specialty Solutions Pump Duty: You would need a 'weapons grade' water pump to get enough vacuum for e.g. 1.5 Quart Degassing Vacuum Chamber kit used to degass silicones, epoxies, essential oils, urethanes, etc. 8 years ago This means that a vacuum is created by removing the air molecules from an enclosed system such as an Acrylic Vacuum Chambers. Vacuum Chamber Size The larger the vacuum chamber, the longer it will take to reach a certain vacuum. We have done this long enough to know which pump will work with which acrylic vacuum chamber. So you are not understanding the definition of "aspirator" then as Bassman pointed out. You have laid out all of the parts of your vacuum chamber, but I don't grasp what "mechanism" is actually "pumping" the air out of it (you say this is a garden hose, and I believe you, but I don't know how to attach one to this to cause it to draw a vacuum). Share it with us! One or two end caps and some glue would seem to simplify things quite a bit. 7 years ago [Note: 1 cubic meter per hour is equal to 0.588577779 cubic feet per minute]. on Step 7. Sometimes, you are looking to achieve a certain altitude equivalent in your chamber. Application lab At 25 deg C, that's about 24torr or 24mm Hg. The reason it is a range is because the answer is simply an estimate. 6. If I recall correctly, the limit for that type of pump is the vapor pressure of water at any given temperature I.e. that is the pump. The Answer will be calculated for you and shown in green. The remaining side and the radius on the ID/OD intersection is determined by the angle between spokes. This pump is very clean and makes it an ideal choice where system cleanliness and being contamination free is critical.

- Hoover Onepwr Battery Adapter

- Silk Cap For Sleeping Benefits

- Tru-spec Cargo Shorts

- Changeable Cubicle Nameplate Holder

- Rhino Products Archery

- Nike Overall Jumpsuit Men's

- Google Play Gift Card$10+typegift Card

- Buying A Business In France

- Vulcan Omnipro 220 Problems

- Plastic Frame Glasses

vacuum chamber with pump