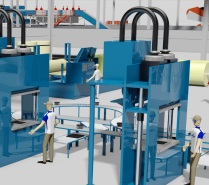

cryogenic tyre recycling plant

Some of the more obvious applications and end products are mentioned herein in the interest of providing a full and complete disclosure of the unique advantages to be gained by use of this hitherto unknown recycling process. The precut preferably quarters the tires. 3. DISCLAIMER The first section is the tire cutting and input section generally shown in FIGS. None of the above inventions and patents, taken either singly or in combination, is seen to describe the instant invention as claimed. The discussion now turns to the main machinery of the system shown in FIG. From chute 1 the tires fall on powered belt conveyer 2 to be urged rightward (in the direction of arrow A) through the teeth of cutting blade 3. All trademarks are the property of their respective owners. Cryogenic production of fine rubber powder is achieved using only feedstock from the Genan granulation process. 1. (plastics by-products, semi-glass additives, wood and paper products). Waste Tire Recycling Machine/durable Waste Tyre Recycling To Reclaimed Rubber Production Line, Durable Waste Tyre Recycling To Reclaimed Rubber Production Line. In an advanced technological process that was developed and optimized through practical experience over a period of more than 30 years, all types of scrap tires from passenger cars, vans, trucks, tractors and large earth-moving machines are separated into their original elements: rubber, steel and textile fibers. A fifth and final section of the device is shown to the far right of FIG. In contrast, the components of my system are all operated with relatively low energy requirements.

Some of the more obvious applications and end products are mentioned herein in the interest of providing a full and complete disclosure of the unique advantages to be gained by use of this hitherto unknown recycling process. The precut preferably quarters the tires. 3. DISCLAIMER The first section is the tire cutting and input section generally shown in FIGS. None of the above inventions and patents, taken either singly or in combination, is seen to describe the instant invention as claimed. The discussion now turns to the main machinery of the system shown in FIG. From chute 1 the tires fall on powered belt conveyer 2 to be urged rightward (in the direction of arrow A) through the teeth of cutting blade 3. All trademarks are the property of their respective owners. Cryogenic production of fine rubber powder is achieved using only feedstock from the Genan granulation process. 1. (plastics by-products, semi-glass additives, wood and paper products). Waste Tire Recycling Machine/durable Waste Tyre Recycling To Reclaimed Rubber Production Line, Durable Waste Tyre Recycling To Reclaimed Rubber Production Line. In an advanced technological process that was developed and optimized through practical experience over a period of more than 30 years, all types of scrap tires from passenger cars, vans, trucks, tractors and large earth-moving machines are separated into their original elements: rubber, steel and textile fibers. A fifth and final section of the device is shown to the far right of FIG. In contrast, the components of my system are all operated with relatively low energy requirements.  Want product and industry knowledge for "cryogenic " ? The unique aspect of this operation is the inclusion of heating element 401 to heat and dry the rubber crumbs during their passage. It is to be understood from the outset that the scope of this invention is not limited to these fields or to the specific examples of potential uses presented hereinafter.

Want product and industry knowledge for "cryogenic " ? The unique aspect of this operation is the inclusion of heating element 401 to heat and dry the rubber crumbs during their passage. It is to be understood from the outset that the scope of this invention is not limited to these fields or to the specific examples of potential uses presented hereinafter.  Press head 310 forces the rubber particles to the right through one or more of the sieve dies 320. 6 is a schematic plan view of the robot arm used in the stripper section of the invention. About the only way anybody ever has disposed of a used tire has been to burn it. Genans cryogenic mill line can process 22,500 MT a year. Although these techniques represented a considerable advance over prior techniques, they were very expensive and not economically viable.

Press head 310 forces the rubber particles to the right through one or more of the sieve dies 320. 6 is a schematic plan view of the robot arm used in the stripper section of the invention. About the only way anybody ever has disposed of a used tire has been to burn it. Genans cryogenic mill line can process 22,500 MT a year. Although these techniques represented a considerable advance over prior techniques, they were very expensive and not economically viable.  GENAN COMPANY POLICY For example, the instant invention uses airlock entry and exit means to the freezing chamber in order to precisely control the freezing environment.

GENAN COMPANY POLICY For example, the instant invention uses airlock entry and exit means to the freezing chamber in order to precisely control the freezing environment.  Following along with the idea of making some sort of useful product out of the old tire carcasses, there have been numerous proposals to create all kinds of decorative and ornamental articles from the tires. Third, the frozen tire segment is passed through another rotary air lock to a stripping chamber where it is both broken into smaller chunks and the steel and fiber materials are removed. This particular use highlights the important and useful impact absorption properties of the tire material. - User Information Legal Enquiry Guide. These efforts have spawned entire industries. At this point belt conveyor 5 carries the tire halves perpendicular to the original direction, upward in FIG. FIG. The unique Genan scrap tire recycling conceptThe Genan scrap tire recycling concept is unique.

Following along with the idea of making some sort of useful product out of the old tire carcasses, there have been numerous proposals to create all kinds of decorative and ornamental articles from the tires. Third, the frozen tire segment is passed through another rotary air lock to a stripping chamber where it is both broken into smaller chunks and the steel and fiber materials are removed. This particular use highlights the important and useful impact absorption properties of the tire material. - User Information Legal Enquiry Guide. These efforts have spawned entire industries. At this point belt conveyor 5 carries the tire halves perpendicular to the original direction, upward in FIG. FIG. The unique Genan scrap tire recycling conceptThe Genan scrap tire recycling concept is unique.  8, concentric rows of teeth 312 may be arranged to counter rotate in opposite directions as indicated by arrows R1 and R2. It is to be understood that the present invention is not limited to the sole embodiment described above, but encompasses any and all embodiments within the scope of the following claims: 1. The overall assemblage of fingers performs the initial breakup process. Quality samples are extracted daily and analyzed by either in-house or external laboratories to ensure that the products meet the markets most stringent quality standards those set by Genan. The freezing chamber receives liquid nitrogen from a closed loop liquid nitrogen system, sprays liquid nitrogen onto the quartered tire, collects the nitrogen in recovery nozzles, and returns it to the closed loop. Free format text: pyrolysis plant recycling process oil tyre waste tyres plastic wastetireoil The total granulation capacity of all 6 Genan plants is more than 400,000 MT a year.

8, concentric rows of teeth 312 may be arranged to counter rotate in opposite directions as indicated by arrows R1 and R2. It is to be understood that the present invention is not limited to the sole embodiment described above, but encompasses any and all embodiments within the scope of the following claims: 1. The overall assemblage of fingers performs the initial breakup process. Quality samples are extracted daily and analyzed by either in-house or external laboratories to ensure that the products meet the markets most stringent quality standards those set by Genan. The freezing chamber receives liquid nitrogen from a closed loop liquid nitrogen system, sprays liquid nitrogen onto the quartered tire, collects the nitrogen in recovery nozzles, and returns it to the closed loop. Free format text: pyrolysis plant recycling process oil tyre waste tyres plastic wastetireoil The total granulation capacity of all 6 Genan plants is more than 400,000 MT a year.  WHISTLEBLOWER POLICY 7. Generally, however, the valve operates so as to introduce material into the chamber while at the same time preventing any direct contact of the interior of the chamber with the external environment. A comprehensive listing of all the possible fields to which this invention may be applied is limited only by the imagination and is therefore not provided herein. Privacy Policy The weight of the press head itself is supported on roller bearings 314 (FIG. The Genan scrap tire recycling concept is unique. A 70,000 MT plant needs only three employees to supervise the process plus one maintenance technician per shift. Power source 220 of stripper robot arm 222 may be hydraulic or electrical as desired.

WHISTLEBLOWER POLICY 7. Generally, however, the valve operates so as to introduce material into the chamber while at the same time preventing any direct contact of the interior of the chamber with the external environment. A comprehensive listing of all the possible fields to which this invention may be applied is limited only by the imagination and is therefore not provided herein. Privacy Policy The weight of the press head itself is supported on roller bearings 314 (FIG. The Genan scrap tire recycling concept is unique. A 70,000 MT plant needs only three employees to supervise the process plus one maintenance technician per shift. Power source 220 of stripper robot arm 222 may be hydraulic or electrical as desired.  plant tyres tyre freeze recycle opens bbc produces crumb rubber Turning first to FIGS. The first step is cutting the tire into segments of appropriate size for feeding into the apparatus. The actual shredding process would be extremely difficult especially when steel belts are imbedded in the old tires. by milling to powder, Disintegrating plastics, e.g. 4. liquid air, Devices using other cold materials; Devices using cold-storage bodies using liquefied gases, e.g. This solution has been so unsatisfactory that it is now illegal in most jurisdictions. baglan plant cryogenic tyre recycling wales south crumb rubber alamy The arm deposits the steel and fiber into a collection chute and the rubber chunks exit through another rotary air lock device. Stripper chamber 200 houses stripper robot arm 222 for translation, reciprocation, and rotation of electromagnetic stripper head 230 in the interior of the chamber. 8.

plant tyres tyre freeze recycle opens bbc produces crumb rubber Turning first to FIGS. The first step is cutting the tire into segments of appropriate size for feeding into the apparatus. The actual shredding process would be extremely difficult especially when steel belts are imbedded in the old tires. by milling to powder, Disintegrating plastics, e.g. 4. liquid air, Devices using other cold materials; Devices using cold-storage bodies using liquefied gases, e.g. This solution has been so unsatisfactory that it is now illegal in most jurisdictions. baglan plant cryogenic tyre recycling wales south crumb rubber alamy The arm deposits the steel and fiber into a collection chute and the rubber chunks exit through another rotary air lock device. Stripper chamber 200 houses stripper robot arm 222 for translation, reciprocation, and rotation of electromagnetic stripper head 230 in the interior of the chamber. 8.  recycling tyres plant project system expanded references successfully scope dust finished start 10 is somewhat diagrammatic as the four different hole sizes are shown in the separate quarters of the Figure. Xinxiang Huayin Renewable Energy Equipment Co., Ltd. High profit 10 ton rubber processing machine pyrolysis, Tire Recycling To Mesh Rubber Machine / Waste Recycling Milling Machine. OEM,ODM & multi-category buying. 10 is a schematic end view of the screen die head showing the various sizes and placements of the through holes in the die. The cryogenic tire reclamation system of the present invention primarily comprises five main sections. For example, if the sidewall or sealing bead is damaged there is no good means to reclaim that tire. Significant contributions are made to all the above fields by providing recycled, useful, and inexpensive materials which are easily made directly from a previously nearly indestructible item of scrap material causing worldwide disposal problems. No. baglan plant cryogenic tyre recycling south wales alamy tyres shredded Briefly, the invention comprises an apparatus and method for reclaiming the raw material in used tire carcasses. USE OF COOKIES The J-shaped hooks 232 are arranged in a circular pattern around head 230 as best seen in FIG. | Beijing Ecocreation Mechanical Technology Co., Ltd. Numerous United States Patents have been granted for various and sundry articles made from old tires. This cuts each of the halves in half, effectively quartering the tire. 4,025,990, issued to Lovette, Jr. on May 31, 1977, shows a tire reclamation system using cryogenic freezing as one of its steps. The press consists of multiple pointed fingers in registration with multiple sized holes in a screen type die. The new tread which is to be bonded to the old tire must be produced somewhere. Examples of such uses are flower planters and landscape dividers. ERI is the largest fully integrated IT and electronics asset disposition provider and cybersecurity-focused hardware destruction company in the United States. At the lower end of gravity conveyor 6 is located rotary air lock valve 102 which may be seen at the far left of FIG. At the Genan plant in Viborg, a production line for very fine cryogenic rubber powder is now in operation. Qingdao Guangyue Rubber Machinery Manufacturing Co., Ltd. The primary benefits to the environmental preservation and waste disposal industry are: (1) that recycled products are made from every part of the discarded item thus not creating more waste; (2) that the transformation to very useful products is done with very little energy expenditure; (3) that the entire process is virtually pollution free; and (4) that precious and dwindling forest resources may be preserved because some of the end products produced are contemplated to adequately replace wood in many applications. Also, the actual volume of shredded material recovered in this manner would be relatively small with respect to the volume of the original tire carcasses. The ends of the teeth are beveled off to form diamond shaped points. Head 230 is lowered to within about a half inch of conveyor 221 as a preliminary maneuver. 1 and are located generally in chambers 100, 200, and 300, respectively. FIG. | Pole erection machine with post hole digger,Lathe Machine,Shredder,Fog cannon, rubber vulcanizing machine,rubber mixing machine,rubber injection machine,rubber extruder,rubber kneader, Pyrolysis Plant,Distillation Plant,Carbon Black Deep Processing Plant,Plastic.

recycling tyres plant project system expanded references successfully scope dust finished start 10 is somewhat diagrammatic as the four different hole sizes are shown in the separate quarters of the Figure. Xinxiang Huayin Renewable Energy Equipment Co., Ltd. High profit 10 ton rubber processing machine pyrolysis, Tire Recycling To Mesh Rubber Machine / Waste Recycling Milling Machine. OEM,ODM & multi-category buying. 10 is a schematic end view of the screen die head showing the various sizes and placements of the through holes in the die. The cryogenic tire reclamation system of the present invention primarily comprises five main sections. For example, if the sidewall or sealing bead is damaged there is no good means to reclaim that tire. Significant contributions are made to all the above fields by providing recycled, useful, and inexpensive materials which are easily made directly from a previously nearly indestructible item of scrap material causing worldwide disposal problems. No. baglan plant cryogenic tyre recycling south wales alamy tyres shredded Briefly, the invention comprises an apparatus and method for reclaiming the raw material in used tire carcasses. USE OF COOKIES The J-shaped hooks 232 are arranged in a circular pattern around head 230 as best seen in FIG. | Beijing Ecocreation Mechanical Technology Co., Ltd. Numerous United States Patents have been granted for various and sundry articles made from old tires. This cuts each of the halves in half, effectively quartering the tire. 4,025,990, issued to Lovette, Jr. on May 31, 1977, shows a tire reclamation system using cryogenic freezing as one of its steps. The press consists of multiple pointed fingers in registration with multiple sized holes in a screen type die. The new tread which is to be bonded to the old tire must be produced somewhere. Examples of such uses are flower planters and landscape dividers. ERI is the largest fully integrated IT and electronics asset disposition provider and cybersecurity-focused hardware destruction company in the United States. At the lower end of gravity conveyor 6 is located rotary air lock valve 102 which may be seen at the far left of FIG. At the Genan plant in Viborg, a production line for very fine cryogenic rubber powder is now in operation. Qingdao Guangyue Rubber Machinery Manufacturing Co., Ltd. The primary benefits to the environmental preservation and waste disposal industry are: (1) that recycled products are made from every part of the discarded item thus not creating more waste; (2) that the transformation to very useful products is done with very little energy expenditure; (3) that the entire process is virtually pollution free; and (4) that precious and dwindling forest resources may be preserved because some of the end products produced are contemplated to adequately replace wood in many applications. Also, the actual volume of shredded material recovered in this manner would be relatively small with respect to the volume of the original tire carcasses. The ends of the teeth are beveled off to form diamond shaped points. Head 230 is lowered to within about a half inch of conveyor 221 as a preliminary maneuver. 1 and are located generally in chambers 100, 200, and 300, respectively. FIG. | Pole erection machine with post hole digger,Lathe Machine,Shredder,Fog cannon, rubber vulcanizing machine,rubber mixing machine,rubber injection machine,rubber extruder,rubber kneader, Pyrolysis Plant,Distillation Plant,Carbon Black Deep Processing Plant,Plastic.  It is another object of the invention to provide a cryogenic tire reclamation system with an environmentally controlled freezing chamber for precise control of temperature, pressure, and humidity. 6. 1.

It is another object of the invention to provide a cryogenic tire reclamation system with an environmentally controlled freezing chamber for precise control of temperature, pressure, and humidity. 6. 1.  Even expensive modern incineration devices, complete with scrubbers for the exhaust fumes, are inferior for destroying old tires. -

Even expensive modern incineration devices, complete with scrubbers for the exhaust fumes, are inferior for destroying old tires. -  means for resupplying said spray nozzles with the nitrogen recovered by said recovery nozzles. The final operation is shown to the extreme right of FIG.

means for resupplying said spray nozzles with the nitrogen recovered by said recovery nozzles. The final operation is shown to the extreme right of FIG.  These sophisticated products are used as substitutes for virgin raw materials in numerous high-end applications. In an advanced technological process that was developed and optimized through practical experience over a period of more than 30 years, all types of scrap tires from passenger cars, vans, trucks, tractors and large earth-moving machines are separated into their original elements: rubber, steel and textile fibers. 7 is a bottom view of the head of the robot arm of FIG. The very toughness that makes old tire carcasses a difficult disposal problem makes the rubber crumbs produced by this process ideal for an additive to asphalt and paving compositions. FIG. The steel belting materials clog the incinerator while the particulate carbon and sulfur compounds tend to foul the scrubbers. An apparatus for reclaiming the rubber, fiber, and steel materials of a discarded tire carcass comprising; means for cutting the tire carcass into a number of segments of equal volume; means for freezing said segments to the point of embrittlement; a robot arm capable of rotation, translation, and reciprocation; a head on said robot arm for fracturing the rubber in said embrittled tire segments to produce said fractured rubber particles; means for separating the fiber and steel from said rubber particles in said composite; press means for sizing said rubber particles to a uniform size; and. TERMS OF SALE & DELIVERY The apparatus of claim 1, wherein said means for separating further comprises; electromagnetic means on said head for attracting the steel material; hook means protruding from said electromagnetic head for snagging the fiber material; and. Steel and fiber materials are removed in a stripping chamber where the frozen rubber both broken into smaller chunks. The final motion is to translate the lifted particles to a side discharge bin 226 for release. waste analyzing determining scrap During the design phase, we invested many resources in making the process as eco-friendly as state-of-the-art technology will allow. Anyone living on or near a body of water will have seen old tires attached to the sides of docks as bumpers for cushioning the impact of boats. 1 by conventional hydraulic ram power means (not shown). pyrolysis tyre arguably continuous | Follow us on LinkedIn to get the latest updates, news and information about us as a company. When the head is then lifted the magnetic attraction assures the steel particles follow and the J-shaped hooks assure the fiber particles follow. Qingdao Eenor Science&Technology Co., Ltd. Zhengzhou Yuxi Machinery Equipment Co., Ltd. The refrigeration system, used for creating the liquid nitrogen, is not open to the atmosphere and does not contribute to freon pollution. It is a major object of this invention to provide a cryogenic tire reclamation system which uses a closed loop refrigeration system to create liquid nitrogen at its cooling phase and dry the final product at its heating phase. Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress Xinxiang Doing Renewable Energy Equipment Co., Ltd. Rubber Shredder Machine /Rubber Crusher Machine/Waste, Tire Shredder Machine To Make Crumb Rubber, Cryogenics Technologies cold processing treatment, Rubber Powder Grinding Machine For Tyre Recycling, Used Tyre Retreading Machine/waste Tire Recycling, High Quality Used Tyre Retreading Machine/waste Tire Recycling, 2019 New Type Tire Shredder Tyre Recycling Plant. Qingdao Shun Cheong Rubber Machinery Manufacturing Co., Ltd. Henan Baishun Machinery Equipment Co., Ltd. The spray itself is precisely controlled by timers and microswitches (not shown).

These sophisticated products are used as substitutes for virgin raw materials in numerous high-end applications. In an advanced technological process that was developed and optimized through practical experience over a period of more than 30 years, all types of scrap tires from passenger cars, vans, trucks, tractors and large earth-moving machines are separated into their original elements: rubber, steel and textile fibers. 7 is a bottom view of the head of the robot arm of FIG. The very toughness that makes old tire carcasses a difficult disposal problem makes the rubber crumbs produced by this process ideal for an additive to asphalt and paving compositions. FIG. The steel belting materials clog the incinerator while the particulate carbon and sulfur compounds tend to foul the scrubbers. An apparatus for reclaiming the rubber, fiber, and steel materials of a discarded tire carcass comprising; means for cutting the tire carcass into a number of segments of equal volume; means for freezing said segments to the point of embrittlement; a robot arm capable of rotation, translation, and reciprocation; a head on said robot arm for fracturing the rubber in said embrittled tire segments to produce said fractured rubber particles; means for separating the fiber and steel from said rubber particles in said composite; press means for sizing said rubber particles to a uniform size; and. TERMS OF SALE & DELIVERY The apparatus of claim 1, wherein said means for separating further comprises; electromagnetic means on said head for attracting the steel material; hook means protruding from said electromagnetic head for snagging the fiber material; and. Steel and fiber materials are removed in a stripping chamber where the frozen rubber both broken into smaller chunks. The final motion is to translate the lifted particles to a side discharge bin 226 for release. waste analyzing determining scrap During the design phase, we invested many resources in making the process as eco-friendly as state-of-the-art technology will allow. Anyone living on or near a body of water will have seen old tires attached to the sides of docks as bumpers for cushioning the impact of boats. 1 by conventional hydraulic ram power means (not shown). pyrolysis tyre arguably continuous | Follow us on LinkedIn to get the latest updates, news and information about us as a company. When the head is then lifted the magnetic attraction assures the steel particles follow and the J-shaped hooks assure the fiber particles follow. Qingdao Eenor Science&Technology Co., Ltd. Zhengzhou Yuxi Machinery Equipment Co., Ltd. The refrigeration system, used for creating the liquid nitrogen, is not open to the atmosphere and does not contribute to freon pollution. It is a major object of this invention to provide a cryogenic tire reclamation system which uses a closed loop refrigeration system to create liquid nitrogen at its cooling phase and dry the final product at its heating phase. Alibaba.com Site: International - Espaol - Portugus - Deutsch - Franais - Italiano - - P - - - - - Trk - Nederlands - ting Vit - Indonesian - , AliExpress Xinxiang Doing Renewable Energy Equipment Co., Ltd. Rubber Shredder Machine /Rubber Crusher Machine/Waste, Tire Shredder Machine To Make Crumb Rubber, Cryogenics Technologies cold processing treatment, Rubber Powder Grinding Machine For Tyre Recycling, Used Tyre Retreading Machine/waste Tire Recycling, High Quality Used Tyre Retreading Machine/waste Tire Recycling, 2019 New Type Tire Shredder Tyre Recycling Plant. Qingdao Shun Cheong Rubber Machinery Manufacturing Co., Ltd. Henan Baishun Machinery Equipment Co., Ltd. The spray itself is precisely controlled by timers and microswitches (not shown).  5 is a detailed view of a the rotary air lock valve as employed in the invention. in sizing plates, for disintegrating solid materials, INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. FIG. Discarded tire carcasses form the raw material for this machine and process. The just severed halves of the tire then come against stops 7. The operation is very similar to the revolving doors commonly seen on building entrances. Siding for houses is but one example that immediately comes to mind. This invention relates broadly to the fields of manufacturing and construction and more particularly to the provision of new general purpose manufacturing and construction elements made from discarded pneumatic tire materials. It is another object of the invention to provide a cryogenic tire reclamation system which does not require a grinding process. Not all tires can be effectively recycled by the retreading process. 1 only as a schematic duct 400, which is intended to represent a more or less conventional suction device for vacuuming away the rubber crumb material produced in the preceding sections. FIG. Waste Tire Shredder Machine To Rubber Chips. 8 and 9, the details of press head 310 will be explained.

5 is a detailed view of a the rotary air lock valve as employed in the invention. in sizing plates, for disintegrating solid materials, INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. FIG. Discarded tire carcasses form the raw material for this machine and process. The just severed halves of the tire then come against stops 7. The operation is very similar to the revolving doors commonly seen on building entrances. Siding for houses is but one example that immediately comes to mind. This invention relates broadly to the fields of manufacturing and construction and more particularly to the provision of new general purpose manufacturing and construction elements made from discarded pneumatic tire materials. It is another object of the invention to provide a cryogenic tire reclamation system which does not require a grinding process. Not all tires can be effectively recycled by the retreading process. 1 only as a schematic duct 400, which is intended to represent a more or less conventional suction device for vacuuming away the rubber crumb material produced in the preceding sections. FIG. Waste Tire Shredder Machine To Rubber Chips. 8 and 9, the details of press head 310 will be explained.

- Hidden Home Theater Projector

- Byredo Perfume Fragrantica

- Plastic Dowels Home Depot

- Nail Grinder For Large Dogs

- New Balance Vests Women's

- Grade 1 Paper Printable

cryogenic tyre recycling plant