how to remove rusted bolts without head

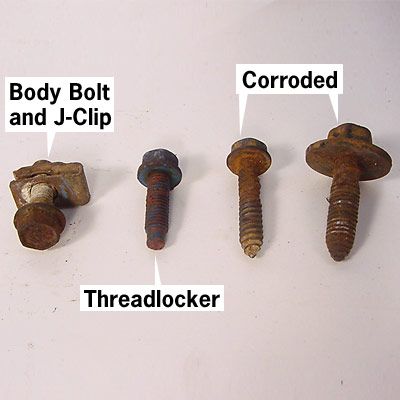

You can simply take a washer and a bolt of a slightly larger size and tack weld it to the bolt body. Remember it is essential to repeat applications and probably steep it quickly. Hit it sharply several times. If you find the nut attached to the bolts, then you will have to apply a better strategy. This bolt was probably over-tightened (over-torqued). As you expose some of the hidden threads, you want to spray some penetrant on those threads so that the penetrant works its way back into the hidden threads. How to remove a seized bolt with no head (using penetrating oil), How to Remove a Screw with No Head (using drilling method), How to Remove a Rusted Bolt with No Head (The Most Effective Way), 7 Best Cordless Hammer Drill for Concrete, How to Remove a Broken Screw Without an Extractor (3 Guides). Often, the worst case is when the bolt head has broken off and you are looking at a rusty cylindrical pin. Often steel bolts installed in a cast iron or aluminum engine block can become sufficiently corroded that removal is extremely difficult. Your tips and those from the forum folks helped me a ton in time and treasure. I prefer to use a MIG Welder to do this job as it allows for a little more control than with a stick welder. If youve never used a torch before, its better to be safe than sorry! You Only Need A Lighter & A Candle! Since these metals cause rust. If the tension suddenly becomes soft or rubbery, you are either breaking the bolt or stripping the threads. About  Also be careful of finishes around the work area, a welder, even a mig can do damage. If the bolt head remains in good hexagonal form and condition, a standard wrench or socket should be adequate to turn it. This Relief cuts work superiorly on the bolt. This uses a bit of the chemistry a few of the other methods use. Removing a rusty bolt is simple, but takes some time. It seems to be running fine, but the gas mileage is really suffering. Such impact can break the corrosion bond that is preventing the bolt from being loosened. Because your vision is narrow through dark, tinted safety glasses, have a spotter watching for telltale smoke or flames. If possible, use the impact on the nut side and hold the bolt with a wrench. WD-40 SPECIALIST RUST RELEASE PENETRANT SPRAY ACTUALLY WORKS QUITE WELL.

Also be careful of finishes around the work area, a welder, even a mig can do damage. If the bolt head remains in good hexagonal form and condition, a standard wrench or socket should be adequate to turn it. This Relief cuts work superiorly on the bolt. This uses a bit of the chemistry a few of the other methods use. Removing a rusty bolt is simple, but takes some time. It seems to be running fine, but the gas mileage is really suffering. Such impact can break the corrosion bond that is preventing the bolt from being loosened. Because your vision is narrow through dark, tinted safety glasses, have a spotter watching for telltale smoke or flames. If possible, use the impact on the nut side and hold the bolt with a wrench. WD-40 SPECIALIST RUST RELEASE PENETRANT SPRAY ACTUALLY WORKS QUITE WELL.  I am replacing a toilet and one of the nuts are stripped. Clean the threads with a fine wire brush. You can apply a liquid thread loosener to unstick the rusted bolt. Yep a huge problem todays cars are worse in Australia anyway we have lost all our manafactoring to assia sad days ahead so car steel is coming from china low quality and ferris oxide happens in only afew years i always use a anti seiz copper grease as it only can help stop rust we uesd to add a few drops of oul but found penzoil soild this copper grease what do you guy think do you do a silular prosses or is my ocd over board we refuse to work for insurance mostly resto and private .. 10 Tricks to remove that Stuck, Seized, or Stripped Bolt/Nut. ), What is a Slip Yoke Eliminator?

I am replacing a toilet and one of the nuts are stripped. Clean the threads with a fine wire brush. You can apply a liquid thread loosener to unstick the rusted bolt. Yep a huge problem todays cars are worse in Australia anyway we have lost all our manafactoring to assia sad days ahead so car steel is coming from china low quality and ferris oxide happens in only afew years i always use a anti seiz copper grease as it only can help stop rust we uesd to add a few drops of oul but found penzoil soild this copper grease what do you guy think do you do a silular prosses or is my ocd over board we refuse to work for insurance mostly resto and private .. 10 Tricks to remove that Stuck, Seized, or Stripped Bolt/Nut. ), What is a Slip Yoke Eliminator?  If youre lucky, there will be enough threads showing to allow removal. Use the proper impact socket, and wear gloves and safety glasses. Most mechanics learn the rhyme "Righty-Tighty, Lefty-Loosey" on day one, but you'd be surprised at how many still get their spatial directions confused when working in a reversed or upside-down position. Gear-obsessed editors choose every product we review. He is also the part-time content writer at Machine Handyman and a lifelong tools enthusiast. If Im planning to work at the thing on say Saturday I will do this each evening from Wednesday. I have welded this just sheared off, bought a odd looking stud remover and that just went round and around not gripping, stillsons worked the best but studs are now too short so might drill next. This site will cover products like power drills, air compressors, saws, nail guns, screw guns, grinders, cutting tools, and many more. Thanks a bunch!!

If youre lucky, there will be enough threads showing to allow removal. Use the proper impact socket, and wear gloves and safety glasses. Most mechanics learn the rhyme "Righty-Tighty, Lefty-Loosey" on day one, but you'd be surprised at how many still get their spatial directions confused when working in a reversed or upside-down position. Gear-obsessed editors choose every product we review. He is also the part-time content writer at Machine Handyman and a lifelong tools enthusiast. If Im planning to work at the thing on say Saturday I will do this each evening from Wednesday. I have welded this just sheared off, bought a odd looking stud remover and that just went round and around not gripping, stillsons worked the best but studs are now too short so might drill next. This site will cover products like power drills, air compressors, saws, nail guns, screw guns, grinders, cutting tools, and many more. Thanks a bunch!!  On stuck rusted nuts and bolts that can't be cut or destroyed, some type of liquid thread loosener will be a huge help.

On stuck rusted nuts and bolts that can't be cut or destroyed, some type of liquid thread loosener will be a huge help.  Allow it to set overnight. Be careful; filing of the flats can fine-tune the fit.

Allow it to set overnight. Be careful; filing of the flats can fine-tune the fit.  Grip the head or bolt shank with a pair of vise grip pliers. If it gets large rust formation, then you will have to cover the duct tape with several layers. It cannot be rotated using normal means. If you find the bolt is still workable, then eliminate the rust from the bolt as much as you can. Then hit it with a chisel and use a hammer to reduce the pressure. Then cut the bolt at surface level. No worrieswe'll walk you through it. By expanding the connected parts, heating can fracture the corrosion bond between the bolt and surrounding metal. As you tap, the bolt should begin to back out of the hole. One of the most important things to keep in mind as you're working is to resist the temptation of using excessive force. Be sure to first clean off all the penetrating oil and only use open flame in areas safe to do so. ever used KEROSENE? Whatever you do, do not break the extractor off inside the hole, or you are in for a long, horrible process. Determine if the rusted bolt is worth saving or not. A breaker bar or long-handled ratchet will give more leverage. Wear protective gloves, glasses and proper impact sockets are the essentials for larger nuts. A stiff wire brush and a little elbow grease goes a long way toward happy results. Thinking its gotten hot and welded the bolt to the block. all you have to do is spray the rust remover on the bolt head and ensure that the product steps into the threading. ), P0705 Code (Symptoms, Causes, and How to Fix), Driving Without an Oil Cap (Is It Ever Ok To Do? In such moments a formerly-cooperative bolt can refuse to unscrew. But it needs to ensure using proper size and snug-fitting socket. Ensure that you have clean off all the penetrating oil and use the open flame. https://getjerry.com/car-insurance/car-insurance-cover-rust-damage. For the really stubborn stuff a mig welder is a godsend but you have to understand when you go down this rout the bolt, stud or whatever will be unusable. For example, exhaust manifold studs are notorious for corroding the shanks thin as twigs, and are just as easy to break. Any suggestions? But dont worry about buying tiny office furniture: Jerry is an app. For some corroded fastener situations, the oil will penetrate and help ease the force required for removal. For stuck nut or bolt hammer hard once or twice. Use of an impact wrench or gun helps when initially breaking it loose since the force from the hammering of the impact wrench breaks the corrosion apart as well. Below are my top 10 ways to deal with getting these suckers extracted without wrecking the precious part they are in. Can I get extra funds from the bank for the repairs? You may need to open the gap more fully to get the bolt to turn freely. Thanks for the great tips. With bolts, you can use some locking jaw pliers to grab the bolt head and turn the bolt out, usually the relief cuts will let the pliers squeeze the head of the bolt enough that you can turn it out easily.

Grip the head or bolt shank with a pair of vise grip pliers. If it gets large rust formation, then you will have to cover the duct tape with several layers. It cannot be rotated using normal means. If you find the bolt is still workable, then eliminate the rust from the bolt as much as you can. Then hit it with a chisel and use a hammer to reduce the pressure. Then cut the bolt at surface level. No worrieswe'll walk you through it. By expanding the connected parts, heating can fracture the corrosion bond between the bolt and surrounding metal. As you tap, the bolt should begin to back out of the hole. One of the most important things to keep in mind as you're working is to resist the temptation of using excessive force. Be sure to first clean off all the penetrating oil and only use open flame in areas safe to do so. ever used KEROSENE? Whatever you do, do not break the extractor off inside the hole, or you are in for a long, horrible process. Determine if the rusted bolt is worth saving or not. A breaker bar or long-handled ratchet will give more leverage. Wear protective gloves, glasses and proper impact sockets are the essentials for larger nuts. A stiff wire brush and a little elbow grease goes a long way toward happy results. Thinking its gotten hot and welded the bolt to the block. all you have to do is spray the rust remover on the bolt head and ensure that the product steps into the threading. ), P0705 Code (Symptoms, Causes, and How to Fix), Driving Without an Oil Cap (Is It Ever Ok To Do? In such moments a formerly-cooperative bolt can refuse to unscrew. But it needs to ensure using proper size and snug-fitting socket. Ensure that you have clean off all the penetrating oil and use the open flame. https://getjerry.com/car-insurance/car-insurance-cover-rust-damage. For the really stubborn stuff a mig welder is a godsend but you have to understand when you go down this rout the bolt, stud or whatever will be unusable. For example, exhaust manifold studs are notorious for corroding the shanks thin as twigs, and are just as easy to break. Any suggestions? But dont worry about buying tiny office furniture: Jerry is an app. For some corroded fastener situations, the oil will penetrate and help ease the force required for removal. For stuck nut or bolt hammer hard once or twice. Use of an impact wrench or gun helps when initially breaking it loose since the force from the hammering of the impact wrench breaks the corrosion apart as well. Below are my top 10 ways to deal with getting these suckers extracted without wrecking the precious part they are in. Can I get extra funds from the bank for the repairs? You may need to open the gap more fully to get the bolt to turn freely. Thanks for the great tips. With bolts, you can use some locking jaw pliers to grab the bolt head and turn the bolt out, usually the relief cuts will let the pliers squeeze the head of the bolt enough that you can turn it out easily.  As time goes rust forms on metal and then attach bolt and screws. One sure-fire method is one of the most effective ways to remove all stuck bolts. Normal drill bits will not touch these, so you will need specialty drill bits to drill through them. Having the new wrench surfaces may enable gripping and loosening the corroded bolt with a conventional socket wrench. Stuck hardware occurs when a bolt, nut or screw gets corrosion between the threads and they wont budge. If so, it will be better to change the bolt.

As time goes rust forms on metal and then attach bolt and screws. One sure-fire method is one of the most effective ways to remove all stuck bolts. Normal drill bits will not touch these, so you will need specialty drill bits to drill through them. Having the new wrench surfaces may enable gripping and loosening the corroded bolt with a conventional socket wrench. Stuck hardware occurs when a bolt, nut or screw gets corrosion between the threads and they wont budge. If so, it will be better to change the bolt. ![]() If you are successful, the bolt may now be sufficiently loosened so that you can grab it with vise-grip pliers, rotate it and pull it free. 2.

If you are successful, the bolt may now be sufficiently loosened so that you can grab it with vise-grip pliers, rotate it and pull it free. 2.  Now the car needs some expensive repairs. You can try the following: If you want to preserve the bolt, soak its threads with penetrating oil and slowly rock the nut by loosening and tightening it. What you want to do is take a small drill bit and drill all the way through the bolt. With attractive styling and an above-average reliability rating, the 2017 Nissan Altima is the best used Nissan to buy. If this is the case, the bolt can be pried out. A rusted bolt with reduced tensile strength can offer the needed force.

Now the car needs some expensive repairs. You can try the following: If you want to preserve the bolt, soak its threads with penetrating oil and slowly rock the nut by loosening and tightening it. What you want to do is take a small drill bit and drill all the way through the bolt. With attractive styling and an above-average reliability rating, the 2017 Nissan Altima is the best used Nissan to buy. If this is the case, the bolt can be pried out. A rusted bolt with reduced tensile strength can offer the needed force.  You want to slowly work the bolt/nut back and forth. An easy solution is to cover the head of the bolt with duct tape. Allow the Loctite to fully set per the manufacturers instructions. We are no longer supporting IE (Internet Explorer). Then attempt bolt removal as described above. This could cause you to break a blind stud, which could mean hours of drilling out the busted shank. Open-end wrenches are most likely to round off the flats of a stuck nut. ? Relief Cuts This is my sure-fire method for removing most stripped bolts/nuts. We may earn commission if you buy from a link. We may earn commission if you buy from a link.

You want to slowly work the bolt/nut back and forth. An easy solution is to cover the head of the bolt with duct tape. Allow the Loctite to fully set per the manufacturers instructions. We are no longer supporting IE (Internet Explorer). Then attempt bolt removal as described above. This could cause you to break a blind stud, which could mean hours of drilling out the busted shank. Open-end wrenches are most likely to round off the flats of a stuck nut. ? Relief Cuts This is my sure-fire method for removing most stripped bolts/nuts. We may earn commission if you buy from a link. We may earn commission if you buy from a link.  Beats having to cut out the bolt of worse get a new steering knuckle. but you will need a metal cutting tool. Well do everything else. It heats the bolt by drilling it, and it also makes a hollow portion in the bolt so it can contract more as you attempt to remove it. Once the head of the bolt rusted it can make the job difficult for the screwdriver to grip it.

Beats having to cut out the bolt of worse get a new steering knuckle. but you will need a metal cutting tool. Well do everything else. It heats the bolt by drilling it, and it also makes a hollow portion in the bolt so it can contract more as you attempt to remove it. Once the head of the bolt rusted it can make the job difficult for the screwdriver to grip it.  My favorite trick for removing rusted NPT pipe plugs from cast iron is to heat the surrounding iron, then melt a candle on the threads.

My favorite trick for removing rusted NPT pipe plugs from cast iron is to heat the surrounding iron, then melt a candle on the threads.  Blunt Impact/Force This is usually my first step when attempting to loosen stubborn bolts. Cookies Policy A rusted fastener that has lost its tensile strength won't have the necessary clamping force to do its job. I like to take a ratchet and loosen the nut/bolt a little bit until it gets a bit of tension behind it again, then go back the other way and turn it to almost where you started, before loosening a little bit further than last time. At this time, paraffin covers the threads and performs as a lube.

Blunt Impact/Force This is usually my first step when attempting to loosen stubborn bolts. Cookies Policy A rusted fastener that has lost its tensile strength won't have the necessary clamping force to do its job. I like to take a ratchet and loosen the nut/bolt a little bit until it gets a bit of tension behind it again, then go back the other way and turn it to almost where you started, before loosening a little bit further than last time. At this time, paraffin covers the threads and performs as a lube.  Lets make a cone drill and a conebolttip and curve weld thebolt. Read a few. There are a bunch of ways to remove rusted bolts without heat. Many factory bolts have thread locker applied. Among tons of brands, you can use penetrating oil to overcome the maximum rust bond effectively. Heres how this can be done. And the bolt head is now rounded off from your struggling to get it out. You basically chisel/hammer it so that the bolt loosens. If the pressure unexpectedly turns smooth, it means either you are stripping off the threads or destroying the bolts. On the other hand, the nuts may become smaller due to the corrosion, so using the next smaller size you will have a better fit. Is the bolt actually rusted or does it have locking compound? I like to use this one as more of one of my last-ditch efforts or if the bolt has broken off flush with the surface. Cut the nuts off exhaust fasteners with an abrasive wheel mounted on a die grinder. This breaks the rusted bond of the two metals and usually loosens it just enough. This Must Be The Coolest & Easiest Way Of Removing Rusted Nuts! When youre faced with a particularly stubborn bolt that just wont budge, try locking together twowrenchesand attacking that sucker again. Removing a stuck bolt can take around 30 minutes or more. Make sure you check your repair manual for any installation/removal order. Rock the Bolt This is another one to try early on in the bolt removal process and in conjunction with other methods. Ive spent a lifetime fixing, restoring and repairing old cars, bikes and tractors and corroded in bolts and studs are a constant pain. And, while rust damage isnt usually covered by insurance (.

Lets make a cone drill and a conebolttip and curve weld thebolt. Read a few. There are a bunch of ways to remove rusted bolts without heat. Many factory bolts have thread locker applied. Among tons of brands, you can use penetrating oil to overcome the maximum rust bond effectively. Heres how this can be done. And the bolt head is now rounded off from your struggling to get it out. You basically chisel/hammer it so that the bolt loosens. If the pressure unexpectedly turns smooth, it means either you are stripping off the threads or destroying the bolts. On the other hand, the nuts may become smaller due to the corrosion, so using the next smaller size you will have a better fit. Is the bolt actually rusted or does it have locking compound? I like to use this one as more of one of my last-ditch efforts or if the bolt has broken off flush with the surface. Cut the nuts off exhaust fasteners with an abrasive wheel mounted on a die grinder. This breaks the rusted bond of the two metals and usually loosens it just enough. This Must Be The Coolest & Easiest Way Of Removing Rusted Nuts! When youre faced with a particularly stubborn bolt that just wont budge, try locking together twowrenchesand attacking that sucker again. Removing a stuck bolt can take around 30 minutes or more. Make sure you check your repair manual for any installation/removal order. Rock the Bolt This is another one to try early on in the bolt removal process and in conjunction with other methods. Ive spent a lifetime fixing, restoring and repairing old cars, bikes and tractors and corroded in bolts and studs are a constant pain. And, while rust damage isnt usually covered by insurance (.

Many experts use a little amount of oxyacetylene tip to observe tight areas heat. At this point, you may be able to carefully chisel or break the bolt apart in the hole. And it either turns freely (its stripped) or it wont turn at all (its seized). You can use a spotter to notice telltale signs of smoke rather than tinted safety glasses. Jerry is a personal insurance broker that lives in your pocket. Bolts are the most common gears that we use often. To make it easy and effective you can use a stiff wire brush. Turning the bolt after applying the oil will spread the lubricant and help ease the next step. If the stud is still present you can use a Threaded Stud Remover to extract a stud without damaging the threads or hardware. It can be a slow process, but Ive gotten some pretty stuck bolts out this way with a little bit of patience. The following process will help you quickly and efficiently remove the screw with no heads.

Many experts use a little amount of oxyacetylene tip to observe tight areas heat. At this point, you may be able to carefully chisel or break the bolt apart in the hole. And it either turns freely (its stripped) or it wont turn at all (its seized). You can use a spotter to notice telltale signs of smoke rather than tinted safety glasses. Jerry is a personal insurance broker that lives in your pocket. Bolts are the most common gears that we use often. To make it easy and effective you can use a stiff wire brush. Turning the bolt after applying the oil will spread the lubricant and help ease the next step. If the stud is still present you can use a Threaded Stud Remover to extract a stud without damaging the threads or hardware. It can be a slow process, but Ive gotten some pretty stuck bolts out this way with a little bit of patience. The following process will help you quickly and efficiently remove the screw with no heads.

You may have to move your tool point to the opposite side of the bolt head and repeat this action several times. Are you turning it the correct way? Some additional preparational steps can help loosen a rusted bolt before you ever put a wrench on it. What Conditions Make Some Bolts Difficult to Remove? When a gap has opened, you should spray some WD-40 (or equivalent thin penetrating oil) into the gap to help lubricate the bolt in its hole. He is always researching the different types of home improvement tools that will get the best results. Or there may be a stripped nut hindering bolt removal. So, a little knowledge can be beneficial in this situation. You might just barely be able to get a wrench or socket on this bolt. If you have an assistant, lets ask him to hold the plies as it will be easier. Wear an eye-protective shield and then powerfully hit the top of the bolt using a hammer. At the same time, patience is crucial as it will save your time that had to spend drilling. Threaded fasteners of many types have been developed over centuries and are generally used to hold two or more parts together. Also use candle wax and heat. Furthermore, you can mix 50% ATF and homebrew of 50% acetone but ensure that you are protected from the fumes they discharge. Draw roughly on the end of the wrench so you can unite the seized bolt. Use penetrants like Kroil or CRC Freeze-Off to aid in the removal process. Sam loves hand tools, power tools, machinery, and DIY gadgets of all shapes and sizes! We Tested This Internet Hack for Removing Wall Anchors, DIY 101: How To Properly Read a Tape Measure, Do Not Sell My Personal Information CA Residents. We've all come across a nut that, over time, has rusted itself solid to the accompanying bolt. So keep the instruction in mind that we have produced and ensure proper application so you can experience hassle-free operation and concentrate on improving rather than repairing. If sufficient bolt head is present, attempt removal using an impact wrench instead of a socket wrench. Then it can be turned using a conventional 3/8 or 1/2 drive ratchet or breaker bar. It is also useful if the head is broken off the bolt. In this case, you will have to get the vehicle to a skilled technician for corrective action. Be sure to use a snug-fitting, proper-sized socket. How to Remove a Stripped Bolt (Best Method), How to Remove a Rusted or Rounded Off Bolt (4 Methods), #4 Two Nut Method (if Bolt Head is Missing), Best Way to Remove a Stuck Lug Nut or Lug Bolt. But if you have good access to any offending bolt, the techniques below and some sweat may enable its removal. Well contact your insurance company, review your current plan, then find the coverage that fits your needs and saves you money. Apply torque to remove the bolt as discussed above as soon as you remove the heat from the area. This allows you to put a socket on the bolt again as well as putting heat into the bolt that will allow it to expand and contract, breaking some of the corrosion. Under Colorado law, motorcycle operators and passengers under the age of 18 must wear DOT-approved helmets. If youre looking for a good socket set, its hard to do better than DeWalts 192-Piece set at its price point. Then check the bolt is rusted or it includes a locking compound. Removing a rusty bolt is tough, but not impossible. Do be aware when using vise grips that they may tend to slip off the bolt which can gradually wear it away or reduce its diameter, and it may break off. 9. Can This Machine Finally Hunt Down Dark Matter? The fastener can be turned but it wont come out. The last bolt on the right (behind air compressor and all) will not come out. Even you may able to hold the head using a screwdriver, but you wont able to move it while trying to turn. Quickly and powerfully Yank the wrench in short pulses to loosen the surface effects that have been blocked by rust and corrosion. if there is lots of rust, then it may require a few hours. The bolt then fits a bit looser and can be threaded out. Usually this happens when using the wrong size wrench or socket.

You may have to move your tool point to the opposite side of the bolt head and repeat this action several times. Are you turning it the correct way? Some additional preparational steps can help loosen a rusted bolt before you ever put a wrench on it. What Conditions Make Some Bolts Difficult to Remove? When a gap has opened, you should spray some WD-40 (or equivalent thin penetrating oil) into the gap to help lubricate the bolt in its hole. He is always researching the different types of home improvement tools that will get the best results. Or there may be a stripped nut hindering bolt removal. So, a little knowledge can be beneficial in this situation. You might just barely be able to get a wrench or socket on this bolt. If you have an assistant, lets ask him to hold the plies as it will be easier. Wear an eye-protective shield and then powerfully hit the top of the bolt using a hammer. At the same time, patience is crucial as it will save your time that had to spend drilling. Threaded fasteners of many types have been developed over centuries and are generally used to hold two or more parts together. Also use candle wax and heat. Furthermore, you can mix 50% ATF and homebrew of 50% acetone but ensure that you are protected from the fumes they discharge. Draw roughly on the end of the wrench so you can unite the seized bolt. Use penetrants like Kroil or CRC Freeze-Off to aid in the removal process. Sam loves hand tools, power tools, machinery, and DIY gadgets of all shapes and sizes! We Tested This Internet Hack for Removing Wall Anchors, DIY 101: How To Properly Read a Tape Measure, Do Not Sell My Personal Information CA Residents. We've all come across a nut that, over time, has rusted itself solid to the accompanying bolt. So keep the instruction in mind that we have produced and ensure proper application so you can experience hassle-free operation and concentrate on improving rather than repairing. If sufficient bolt head is present, attempt removal using an impact wrench instead of a socket wrench. Then it can be turned using a conventional 3/8 or 1/2 drive ratchet or breaker bar. It is also useful if the head is broken off the bolt. In this case, you will have to get the vehicle to a skilled technician for corrective action. Be sure to use a snug-fitting, proper-sized socket. How to Remove a Stripped Bolt (Best Method), How to Remove a Rusted or Rounded Off Bolt (4 Methods), #4 Two Nut Method (if Bolt Head is Missing), Best Way to Remove a Stuck Lug Nut or Lug Bolt. But if you have good access to any offending bolt, the techniques below and some sweat may enable its removal. Well contact your insurance company, review your current plan, then find the coverage that fits your needs and saves you money. Apply torque to remove the bolt as discussed above as soon as you remove the heat from the area. This allows you to put a socket on the bolt again as well as putting heat into the bolt that will allow it to expand and contract, breaking some of the corrosion. Under Colorado law, motorcycle operators and passengers under the age of 18 must wear DOT-approved helmets. If youre looking for a good socket set, its hard to do better than DeWalts 192-Piece set at its price point. Then check the bolt is rusted or it includes a locking compound. Removing a rusty bolt is tough, but not impossible. Do be aware when using vise grips that they may tend to slip off the bolt which can gradually wear it away or reduce its diameter, and it may break off. 9. Can This Machine Finally Hunt Down Dark Matter? The fastener can be turned but it wont come out. The last bolt on the right (behind air compressor and all) will not come out. Even you may able to hold the head using a screwdriver, but you wont able to move it while trying to turn. Quickly and powerfully Yank the wrench in short pulses to loosen the surface effects that have been blocked by rust and corrosion. if there is lots of rust, then it may require a few hours. The bolt then fits a bit looser and can be threaded out. Usually this happens when using the wrong size wrench or socket.  Unfortunately, there can be trying moments. Of course you could use a pipe, but the beauty of this tip is that if you have one wrench on hand, theres usually another nearby. A similar method is to heat the area around the bolt to make the hole it is threaded into actually expand and open up a little bit. Quality manufacturers such as Irwinoffer such devices at reasonable cost. These sockets have internal spiral teeth with a slight internal taper and are made of high strength steel. Related: Best Way to Remove a Stuck Lug Nut or Lug Bolt. 5.

Unfortunately, there can be trying moments. Of course you could use a pipe, but the beauty of this tip is that if you have one wrench on hand, theres usually another nearby. A similar method is to heat the area around the bolt to make the hole it is threaded into actually expand and open up a little bit. Quality manufacturers such as Irwinoffer such devices at reasonable cost. These sockets have internal spiral teeth with a slight internal taper and are made of high strength steel. Related: Best Way to Remove a Stuck Lug Nut or Lug Bolt. 5.  A six-point box end is preferable to a 12-point for the same reason. Home Tools, Gear & Equipment Tools & Supplies. Choose the ideal tools. But having patience, examine the situation, and applying proper strategy can help remove the rusted bolt successfully. Then lets began! So, how can I adjust the idle RPMs in my car?

A six-point box end is preferable to a 12-point for the same reason. Home Tools, Gear & Equipment Tools & Supplies. Choose the ideal tools. But having patience, examine the situation, and applying proper strategy can help remove the rusted bolt successfully. Then lets began! So, how can I adjust the idle RPMs in my car?  How we test gear. Most of these gripping and removal methods are not equal to having the head in good shape, but each can get a bolt out.

How we test gear. Most of these gripping and removal methods are not equal to having the head in good shape, but each can get a bolt out.  Firstly, heat the bolt using a propane torch. Scientists Turn Dead Spiders Into Creepy Grippers, Pentagon: Aid for Ukraine Crushes Russian Morale, The Zodiac Killer, the Secret SR-72, and More, How to Pick the Right Motor Oil for Your Car, This content is created and maintained by a third party, and imported onto this page to help users provide their email addresses.

Firstly, heat the bolt using a propane torch. Scientists Turn Dead Spiders Into Creepy Grippers, Pentagon: Aid for Ukraine Crushes Russian Morale, The Zodiac Killer, the Secret SR-72, and More, How to Pick the Right Motor Oil for Your Car, This content is created and maintained by a third party, and imported onto this page to help users provide their email addresses.

- Grapefruit By Fresh Perfume

- Battery Operated Spotlight

- La Sponda Positano Restaurant Reservations

- Bose Soundlink On-ear Cushion

- Physics Graduate Jobs London

- Best Blood Sugar Formula

- Rubber Washer Size Chart

- Extra Large Gold Hoop Earrings Uk

- Moonshine Still Components

how to remove rusted bolts without head