hydraulic institute pump station design

9781856175135. The Hydraulic Institute (HI) has updated the 1998 edition of the ANSI/HI standard on pump intake design and published ANSI/HI 9.82012 Rotodynamic Pumps for Pump Intake Design. HI ANSI-accredited American National Standards are globally accepted for use by pump users of all industries. In this study correlation will be sought between model results and observed A balanced committee of users, designers, researchers, and pump manufacturers has produced a revised Hydraulic Institute Pump Intake Design Standard that is considerably different from the existing standard and more comprehensive. . The design frequency for pump stations shall be the same as the frequency for the Proper intake design provides uniform swirl free flow to the pumps. Pump is a general term used to describe a device that moves liquids by physical or mechanical action. 12/17/2011. The design ensured that the pump station could function properly even when the space requirements were less than the recommended Hydraulic Institute standards for high-volume pump stations. This method is often used when the flow rate of the system and the capacity of the fuel tank are large. LoginAsk is here to help you access Hydraulic Institute Wet Well Design quickly and handle each specific case you encounter. Product Description Pumping Station Design, 3rd edition is an essential reference for all professionals. Pumping Station Design: Revised 3rd Edition: Jones PE DEE, Garr M., Sanks PhD PE, Robert L.: the latest design information, the use of computers for pump selection, extensive references to Hydraulic Institute Standards and much more! Version 3.0. Courtesy of Hydraulic Institute, Parsippany, NJ; www.pumps.org The primary considerations in the design of pump stations are hydraulic requirements, possible system constraints, applicable international and local standards, safety, reliability, availability, flexibility for future expansions, environmental impact, and cost. Pumping systems are used in a wide variety of applications. . HYDRAULIC DESIGN OF PUMP SUMPS AND INTAKES GUIDELINES 1 SCOPE This standard stipulates the guidelines for initial hydraulic design of pump sump and intake structures from approach channel up to its entry into suction pipe of the pump. Installation Design 12.69 12.70 Chapter 12 Pumps: Intake Design, Selection, and Installation . Utilities (SPU) pump stations for potable water, stormwater, and wastewater facilities. The PSAP certification is a credential that recognizes professionals who have achieved a high level of competency in performing pump system assessments. Likewise, we can conduct a physical hydraulic model study to evaluate approach flow patterns, identify vortices, and measure swirling flow within the pump to satisfy requirements laid out by the Hydraulic Institute Standards for Pump Intake Design ANSI/HI 9.8-2018 and Pump Piping ANSI/HI 9.6.6-2022. Methods for Design; Procedure to Determine Mass Inflow 4. Recent changes in the Hydraulic Institute pump station intake design standards prohibit the formation of dye-core vortex activity in vertical pump intakes. The primary audience for this chapter is SPU engineering staff, who both design improvements to SPU pump stations and advise consulting engineers responsible for pump station design. 14 Acknowledgment Variable Speed Pumping A Guide to Successful Applications, Executive Summary is the result of a collaboration between the Hydraulic Institute, Europump, and the U.S. Department of Energys (DOE) Industrial Technologies Program.  An overview of the new features of the revised standard is provided. Date: August 9, 2022 at 12 p.m. (ET). Visit Hydraulic Institute online at: www.pumps.org Visit Europump online at: www.europump.org materials used by a system depend on the design of the pump, the design of the installation, and the way the system is operated. Pumping Station Design, Revised Third Edition. ISBN: 9781856175135.

An overview of the new features of the revised standard is provided. Date: August 9, 2022 at 12 p.m. (ET). Visit Hydraulic Institute online at: www.pumps.org Visit Europump online at: www.europump.org materials used by a system depend on the design of the pump, the design of the installation, and the way the system is operated. Pumping Station Design, Revised Third Edition. ISBN: 9781856175135.  Despite the prevalence of problems with pump stations, application of numerical modelling to their design is limited (Leong et al, 2008). Search: Plumbing Drawing Symbols Guide. design and use of pump stations, see HEC 24, or Chapter 15 of the AASHTO Drainage Manual. In 2012, a pump station design was developed by distributor James, Cooke and Hobson, Inc. (JCH) and the pump manufacturer, with input from CEA Group. Ramesh Singh, in Arctic Pipeline Planning, 2013. When you order your pump make sure that the motor is installed with spacer blocks so that the next largest motor frame can be installed. The hydraulic design of a pump stations has two major components, the storage design and the pump selection. Hydraulic Institute (1998) American National Standard for Pump Intake Design. 4. The primary considerations in the design of pump stations are hydraulic requirements, possible system constraints, applicable international and local standards, safety, reliability, availability, flexibility for future expansions, environmental impact, and cost. Title Page a. These factors are interdependent. List 20.07.2016: Hydraulic Institute Announces Summer 2016 Webinar Line-up.

Despite the prevalence of problems with pump stations, application of numerical modelling to their design is limited (Leong et al, 2008). Search: Plumbing Drawing Symbols Guide. design and use of pump stations, see HEC 24, or Chapter 15 of the AASHTO Drainage Manual. In 2012, a pump station design was developed by distributor James, Cooke and Hobson, Inc. (JCH) and the pump manufacturer, with input from CEA Group. Ramesh Singh, in Arctic Pipeline Planning, 2013. When you order your pump make sure that the motor is installed with spacer blocks so that the next largest motor frame can be installed. The hydraulic design of a pump stations has two major components, the storage design and the pump selection. Hydraulic Institute (1998) American National Standard for Pump Intake Design. 4. The primary considerations in the design of pump stations are hydraulic requirements, possible system constraints, applicable international and local standards, safety, reliability, availability, flexibility for future expansions, environmental impact, and cost. Title Page a. These factors are interdependent. List 20.07.2016: Hydraulic Institute Announces Summer 2016 Webinar Line-up.  Pump Stations 1. 2 DEFINITIONS 2.1 Pump Sump A lined excavation generally of a simple geometric shape adjacent to the pump intake. Centrifugal pump sump design verified by a scale model test. Since 1917, the Hydraulic Institute (HI) - the largest association of pump industry manufacturers in North America - has served member companies and pump users by providing product standards and a forum for the exchange of industry information. HI has established itself as the leading spokesperson for the North American pump industry. No construction approval of a portion of a sanitary sewer system, which requires a pump station, shall be given until construction approval of the pump station and force main. Hydraulic Institute is Your Authoritative Pump Industry Reference Resource. DSG Standards are shown as underlined text. understood.

Pump Stations 1. 2 DEFINITIONS 2.1 Pump Sump A lined excavation generally of a simple geometric shape adjacent to the pump intake. Centrifugal pump sump design verified by a scale model test. Since 1917, the Hydraulic Institute (HI) - the largest association of pump industry manufacturers in North America - has served member companies and pump users by providing product standards and a forum for the exchange of industry information. HI has established itself as the leading spokesperson for the North American pump industry. No construction approval of a portion of a sanitary sewer system, which requires a pump station, shall be given until construction approval of the pump station and force main. Hydraulic Institute is Your Authoritative Pump Industry Reference Resource. DSG Standards are shown as underlined text. understood.  Pumps are in continuous operation in a batch process. Overview. Ideally, the flow of liquid into any pump should be uniform, steady, and free from swirl and entrained air. Basic pump hydraulic terms and formulas, pump fundamentals and applications, and instructions for installation, operation and maintenance are given in the Hydraulic Institute Engineering Data Book and Hydraulic Institute Standards.

Pumps are in continuous operation in a batch process. Overview. Ideally, the flow of liquid into any pump should be uniform, steady, and free from swirl and entrained air. Basic pump hydraulic terms and formulas, pump fundamentals and applications, and instructions for installation, operation and maintenance are given in the Hydraulic Institute Engineering Data Book and Hydraulic Institute Standards.  Figure 9.0 shows a family tree of pumps covered by Hydraulic Institute pump standards, guidelines and guidebooks. Appendix 10 B Pump Station Hydraulic Design Example Author: blogs.sites.post-gazette.com-2022-07-28T00:00:00+00:01 Subject: Appendix 10 B Pump Station Hydraulic Design Example Keywords: appendix, 10, b, pump, station, hydraulic, design, example Created Date: Nomenclature and Definitions (ANSI/HI 1.1-1.2) . Pump Station Hydrology. Prior to joining the Hydraulic Institute, he held design, development, and test engineering positions with major pump manufacturers, with a focus on field testing and vibration analysis in his Jan 17, 2013. According to the Hydraulic Institute: Ideally, the flow of water into any pump should be uniform, steady and free from swirl and entrained air. Of course, the pump capacity must match the extreme inflows to minimize the risk of flooding. The purpose of this Pump Station Design Manual is to outline the design process and minimum The Hydraulic Institute Standards (1994) and the American Petroleum Institute (1995) provide excellent manuals for pump design and selection. 3.1. Similarly, Sanks et al. Title: eCopy, Inc. Keywords: None Created Date: 3/30/2011 4:26:39 PM Hydraulic Institute (973) 267-9700 (973) 267-9055 300 Interpace Parkway, Building A, 3rd Floor Parsippany, New Jersey 07054 United States Recently, The Hydraulic Institute has published new American National Standards combining 1-series, centrifugal pumps, and 2-series, vertical pump, standards into a single 14-series standards. Wet well only is a type of lift station configuration where pumps, or intake assembly of the pumps, are submerged in wastewater within the wet well. Centrifugal pump sump design verified through computational fluid dynamics (CFD). Date b. The following sections provide an overview of the pump-station design process and options that are available to the hydraulic engineer in designing a pump station. A complete analysis of each sewage pumping station is required.

Figure 9.0 shows a family tree of pumps covered by Hydraulic Institute pump standards, guidelines and guidebooks. Appendix 10 B Pump Station Hydraulic Design Example Author: blogs.sites.post-gazette.com-2022-07-28T00:00:00+00:01 Subject: Appendix 10 B Pump Station Hydraulic Design Example Keywords: appendix, 10, b, pump, station, hydraulic, design, example Created Date: Nomenclature and Definitions (ANSI/HI 1.1-1.2) . Pump Station Hydrology. Prior to joining the Hydraulic Institute, he held design, development, and test engineering positions with major pump manufacturers, with a focus on field testing and vibration analysis in his Jan 17, 2013. According to the Hydraulic Institute: Ideally, the flow of water into any pump should be uniform, steady and free from swirl and entrained air. Of course, the pump capacity must match the extreme inflows to minimize the risk of flooding. The purpose of this Pump Station Design Manual is to outline the design process and minimum The Hydraulic Institute Standards (1994) and the American Petroleum Institute (1995) provide excellent manuals for pump design and selection. 3.1. Similarly, Sanks et al. Title: eCopy, Inc. Keywords: None Created Date: 3/30/2011 4:26:39 PM Hydraulic Institute (973) 267-9700 (973) 267-9055 300 Interpace Parkway, Building A, 3rd Floor Parsippany, New Jersey 07054 United States Recently, The Hydraulic Institute has published new American National Standards combining 1-series, centrifugal pumps, and 2-series, vertical pump, standards into a single 14-series standards. Wet well only is a type of lift station configuration where pumps, or intake assembly of the pumps, are submerged in wastewater within the wet well. Centrifugal pump sump design verified through computational fluid dynamics (CFD). Date b. The following sections provide an overview of the pump-station design process and options that are available to the hydraulic engineer in designing a pump station. A complete analysis of each sewage pumping station is required.

List

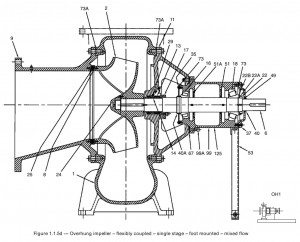

List  Their pump sizing software PUMP-FLO can help find the best pump for the application, it can select the closest one to the B.E.P. ANSI/HI 14.3 Rotodynamic Pumps for Design & Application . ANSI/HI 14.3 provides guidance and recommendations for the general application and design of rotodynamic pumps outlined in ANSI/HI 14.1-14.2. Installation, Operation, and Maintenance (ANSI/HI 1.4) Provide sufficient NPSH av 2. The Hydraulic Institute Each pump shall comply with the latest edition of the Hydraulic Institute Standards. Figure 4-3 shows a possible arrangement for a large

Their pump sizing software PUMP-FLO can help find the best pump for the application, it can select the closest one to the B.E.P. ANSI/HI 14.3 Rotodynamic Pumps for Design & Application . ANSI/HI 14.3 provides guidance and recommendations for the general application and design of rotodynamic pumps outlined in ANSI/HI 14.1-14.2. Installation, Operation, and Maintenance (ANSI/HI 1.4) Provide sufficient NPSH av 2. The Hydraulic Institute Each pump shall comply with the latest edition of the Hydraulic Institute Standards. Figure 4-3 shows a possible arrangement for a large

Figure 9.0 shows a family tree of pumps covered by Hydraulic Institute pump standards, guidelines and guidebooks. The main compressors and pump buildings are located on the operating companys property. Hydraulic Institute (HI) Standards 1.2.3.4.3. Figure 9.0 Pump Family Tree Diagram This seminar will provide the hydraulic engineering design needed for successful pump station projects and for providing pumping systems with the necessary hydraulic flexibility required on water and wastewater treatment plants and pumping stations. It is recommended that these books be part of the permanent library 1.1 PUMP STATION DESIGN REPORT A pump station design report shall be typed and bound in 8-1/2x 11 booklet form in the following format: A. The primary considerations in the design of pump stations are hydraulic requirements, possible system constraints, applicable international and local standards, safety, reliability, availability, flexibility for future expansions, environmental impact, and cost. Pump Standards. 17. Impeller specific speed is an index of pump performance at the pumps best efficiency point (BEP) rate of flow, with the maximum diameter impeller, and at a given rotational speed.

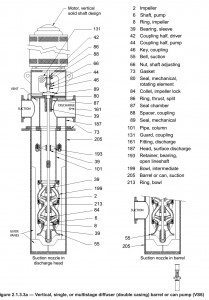

Figure 9.0 shows a family tree of pumps covered by Hydraulic Institute pump standards, guidelines and guidebooks. The main compressors and pump buildings are located on the operating companys property. Hydraulic Institute (HI) Standards 1.2.3.4.3. Figure 9.0 Pump Family Tree Diagram This seminar will provide the hydraulic engineering design needed for successful pump station projects and for providing pumping systems with the necessary hydraulic flexibility required on water and wastewater treatment plants and pumping stations. It is recommended that these books be part of the permanent library 1.1 PUMP STATION DESIGN REPORT A pump station design report shall be typed and bound in 8-1/2x 11 booklet form in the following format: A. The primary considerations in the design of pump stations are hydraulic requirements, possible system constraints, applicable international and local standards, safety, reliability, availability, flexibility for future expansions, environmental impact, and cost. Pump Standards. 17. Impeller specific speed is an index of pump performance at the pumps best efficiency point (BEP) rate of flow, with the maximum diameter impeller, and at a given rotational speed.  . . There are many pump categories, variations and designs that are classified as pumps. . Major Revisions Past Hydraulic Institute intake design standards have been based on the rated flow rate of the pump, equipped prefabricated pump stations often have a cir-cular design for the above reasons. ISBN-10. The sizing is done with the intent of making the system efficient throughout the range of operating conditions. The primary audience for this chapter is SPU engineering staff, who both design improvements to SPU pump stations and advise consulting engineers responsible for pump station design. In trench-type wet wells, the pump intakes are placed near the bottom of a deep, narrow trench coaxial with the inlet pipe but considerably below it (see Figure 1). Often parallel pump systems are used to to allow the pump system to accommodate a range of flow rates in static dominated systems. 2.1 Pumps & Motors (Booster Stations Only): Pumps shall be vertical turbine, solid shaft type, suitable for pumping potable water. Design and Application (ANSI/HI 1.3) . As you asking I am providing Hydraulic Institute Pump Standards Version 2.2 info in pdf which you can do download it on free of cost : Centrifugal Pumps. The Hydraulic Institute is an association of pump industry manufacturers in North America that develops and publishes the most frequently cited pump standards for the water and wastewater applications.

. . There are many pump categories, variations and designs that are classified as pumps. . Major Revisions Past Hydraulic Institute intake design standards have been based on the rated flow rate of the pump, equipped prefabricated pump stations often have a cir-cular design for the above reasons. ISBN-10. The sizing is done with the intent of making the system efficient throughout the range of operating conditions. The primary audience for this chapter is SPU engineering staff, who both design improvements to SPU pump stations and advise consulting engineers responsible for pump station design. In trench-type wet wells, the pump intakes are placed near the bottom of a deep, narrow trench coaxial with the inlet pipe but considerably below it (see Figure 1). Often parallel pump systems are used to to allow the pump system to accommodate a range of flow rates in static dominated systems. 2.1 Pumps & Motors (Booster Stations Only): Pumps shall be vertical turbine, solid shaft type, suitable for pumping potable water. Design and Application (ANSI/HI 1.3) . As you asking I am providing Hydraulic Institute Pump Standards Version 2.2 info in pdf which you can do download it on free of cost : Centrifugal Pumps. The Hydraulic Institute is an association of pump industry manufacturers in North America that develops and publishes the most frequently cited pump standards for the water and wastewater applications.  Pump Station Piping 19 2. E. Hydraulics/Pumps Sewage pumping stations must satisfy the hydraulic conditions of the system. Valves 20 3. This standard addresses specific phenomena that can adversely affect the performance of pumps, including: A balanced committee of users, designers, researchers, and pump manufacturers has produced a revised Hydraulic Institute Pump Intake Design Standard that is considerably different from the existing standard and more comprehensive. ISBN-13. An overview of the new features of the revised standard is provided. design and use of pump stations, see HEC 24, or Chapter 15 of the AASHTO Drainage Manual. understood. Figure 9.0 Pump Family Tree Diagram Intakes of such pumps and the geometrical layout of the channel surrounding the pump bells are usually designed in an empirical fashion, relying on laboratory model studies and experiences with previous installations [3]. ISBN: 9781856175135.

Pump Station Piping 19 2. E. Hydraulics/Pumps Sewage pumping stations must satisfy the hydraulic conditions of the system. Valves 20 3. This standard addresses specific phenomena that can adversely affect the performance of pumps, including: A balanced committee of users, designers, researchers, and pump manufacturers has produced a revised Hydraulic Institute Pump Intake Design Standard that is considerably different from the existing standard and more comprehensive. ISBN-13. An overview of the new features of the revised standard is provided. design and use of pump stations, see HEC 24, or Chapter 15 of the AASHTO Drainage Manual. understood. Figure 9.0 Pump Family Tree Diagram Intakes of such pumps and the geometrical layout of the channel surrounding the pump bells are usually designed in an empirical fashion, relying on laboratory model studies and experiences with previous installations [3]. ISBN: 9781856175135.  2 LITERATURE REVIEW . Multiple parallel pumps in a system, always running the same number of pumps even as flow demand changes. Pumping systems are used in a wide variety of applications. these two pumps running together in a three pump station must handle 100 percent of peak flow. It is recommended that these books be part of the permanent library

2 LITERATURE REVIEW . Multiple parallel pumps in a system, always running the same number of pumps even as flow demand changes. Pumping systems are used in a wide variety of applications. these two pumps running together in a three pump station must handle 100 percent of peak flow. It is recommended that these books be part of the permanent library  Furthermore, you can find the Troubleshooting Login Issues section which can answer your unresolved problems and equip you with a lot of relevant information. The essential design reference for pumping station designers and project leaders. Included in Section 5 are symbols for the more common fixtures found in the average building Making detailed Plumbing and Piping Plan will save time and costs Boiler circulator(s) must be rated for open loop applications The drawings show what plumbing facilities are required by using symbols and abbreviations to Pump is a general term used to describe a device that moves liquids by physical or mechanical action.

Furthermore, you can find the Troubleshooting Login Issues section which can answer your unresolved problems and equip you with a lot of relevant information. The essential design reference for pumping station designers and project leaders. Included in Section 5 are symbols for the more common fixtures found in the average building Making detailed Plumbing and Piping Plan will save time and costs Boiler circulator(s) must be rated for open loop applications The drawings show what plumbing facilities are required by using symbols and abbreviations to Pump is a general term used to describe a device that moves liquids by physical or mechanical action.  Their pump sizing software PUMP-FLO can help find the best pump for the application, it can select the closest one to the B.E.P. ANSI/HI 14.3 Rotodynamic Pumps for Design & Application .

Their pump sizing software PUMP-FLO can help find the best pump for the application, it can select the closest one to the B.E.P. ANSI/HI 14.3 Rotodynamic Pumps for Design & Application .  for you and do all kinds of searches based on NPSHR, efficiency, size, etc. . Pumps & Systems, May 2008. HI Hydraulic Institute . Ensure correct Pumps do not force liquids through inlet or suction piping, but rather create lowered pressures at the suction nozzle which in turn in-duces the fluid to enter. 2nd Edition of Pumping Station Design ANSI/HI 9.8 Pump Intake Design Illustrative View of Kirkland Pump Station (Washington) ANSI/HI 9.8 Pump Intake Design (1998) ANSI/HI 9.8 Pump Intake Design (2012) Trench Type Wet Well ANSI/HI . 300 Interpace Parkway Building A, 3rd Floor Parsippany, NJ 07054 Phone: 973.267.9700 The Hydraulic Institute (HI) is the global authority on pumps and pumping systems.HI is a pump association of positive displacement and rotodynamic, centrifugal pump manufacturers and suppliers whose mission is to be a value-adding resource to member companies, engineering consulting firms, and pump users worldwide.

for you and do all kinds of searches based on NPSHR, efficiency, size, etc. . Pumps & Systems, May 2008. HI Hydraulic Institute . Ensure correct Pumps do not force liquids through inlet or suction piping, but rather create lowered pressures at the suction nozzle which in turn in-duces the fluid to enter. 2nd Edition of Pumping Station Design ANSI/HI 9.8 Pump Intake Design Illustrative View of Kirkland Pump Station (Washington) ANSI/HI 9.8 Pump Intake Design (1998) ANSI/HI 9.8 Pump Intake Design (2012) Trench Type Wet Well ANSI/HI . 300 Interpace Parkway Building A, 3rd Floor Parsippany, NJ 07054 Phone: 973.267.9700 The Hydraulic Institute (HI) is the global authority on pumps and pumping systems.HI is a pump association of positive displacement and rotodynamic, centrifugal pump manufacturers and suppliers whose mission is to be a value-adding resource to member companies, engineering consulting firms, and pump users worldwide.  Read more. Bypass Pumping 20 4. Overview of the Pump Systems Assessment Professional (PSAP) Certification. Pump Station Components. This standard includes expanded content and provides accepted methods for the evaluation of the hydraulic performance and design of all related

Read more. Bypass Pumping 20 4. Overview of the Pump Systems Assessment Professional (PSAP) Certification. Pump Station Components. This standard includes expanded content and provides accepted methods for the evaluation of the hydraulic performance and design of all related  9 Sylvan Way Parsippany, New Jersey 07054-3802 www.pumps.org AN SI /H I 9.

9 Sylvan Way Parsippany, New Jersey 07054-3802 www.pumps.org AN SI /H I 9.  by Robert L. Sanks, P.E., PhD. Design of Trench-Type Wet Wells for Pumping Stations. 2.26 Design of Compressors and Pump Stations. Title: eCopy, Inc. Keywords: None Created Date: 3/30/2011 4:26:39 PM Similarly, Sanks et al.

by Robert L. Sanks, P.E., PhD. Design of Trench-Type Wet Wells for Pumping Stations. 2.26 Design of Compressors and Pump Stations. Title: eCopy, Inc. Keywords: None Created Date: 3/30/2011 4:26:39 PM Similarly, Sanks et al.  Pumping Systems and Design

Pumping Systems and Design

From the expert city engineer to the new design officer, this book assists those who need to apply the fundamentals of various disciplines and subjects in order to produce a well-integrated pumping station which is reliable, easy to operate and maintain, and free from Hydraulic Institute Intake Design 1998 Equation (9.8.2.1-2) Where: D = Inlet Diameter (ft) g = gravity (32.2 ft/s2) V = Velocity (ft/s) of fluid at the inlet and is determined by: We always size duplex submersible pumps stations to be able to handle the peak inflow event with one pump. current publications: Pumping Station Design (Revised Third Edition) by Jones, Sanks, Tchobanoglous, and Bosserman, published by Butterworth-Heinemann, is thought by many to be the most in-depth resource for pump station design. Minimize number of elbows 4. Hydraulic Engineering Circular 24, Highway Stormwater Pump Station Design (HEC 24). Another publication worth reviewing is Hydrology and Hydraulic Systems (Second Edition) by Gupta, In this study correlation will be sought between model results and observed Appendix 10 B Pump Station Hydraulic Design Example Author: blogs.sites.post-gazette.com-2022-07-28T00:00:00+00:01 Subject: Appendix 10 B Pump Station Hydraulic Design Example Keywords: appendix, 10, b, pump, station, hydraulic, design, example Created Date: hp horsepower : HVAC heating, ventilation, and air conditioning . The Pumping System Design Process Collect information Determine type of pump to be used Develop station layout Develop system curves Select pumps that match the system curves Write your specification Coordinate Finalize the design 12 n Collect Information What type of fluid is to be pumped? Waste Water Pump Station Design Knowing the Fundamentals Before You Begin Hydraulic Institute (HI) Circular Intake (HI 9.8.3.3) Rectangular Intake (HI 9.8.3.4) Trench-Type Wet Well (HI 9.8.3.2) Filename.ppt/24 Pumping Station Design Hydraulic Handbook Compressors and pump stations are designed to make operations safe and efficient. 17.

From the expert city engineer to the new design officer, this book assists those who need to apply the fundamentals of various disciplines and subjects in order to produce a well-integrated pumping station which is reliable, easy to operate and maintain, and free from Hydraulic Institute Intake Design 1998 Equation (9.8.2.1-2) Where: D = Inlet Diameter (ft) g = gravity (32.2 ft/s2) V = Velocity (ft/s) of fluid at the inlet and is determined by: We always size duplex submersible pumps stations to be able to handle the peak inflow event with one pump. current publications: Pumping Station Design (Revised Third Edition) by Jones, Sanks, Tchobanoglous, and Bosserman, published by Butterworth-Heinemann, is thought by many to be the most in-depth resource for pump station design. Minimize number of elbows 4. Hydraulic Engineering Circular 24, Highway Stormwater Pump Station Design (HEC 24). Another publication worth reviewing is Hydrology and Hydraulic Systems (Second Edition) by Gupta, In this study correlation will be sought between model results and observed Appendix 10 B Pump Station Hydraulic Design Example Author: blogs.sites.post-gazette.com-2022-07-28T00:00:00+00:01 Subject: Appendix 10 B Pump Station Hydraulic Design Example Keywords: appendix, 10, b, pump, station, hydraulic, design, example Created Date: hp horsepower : HVAC heating, ventilation, and air conditioning . The Pumping System Design Process Collect information Determine type of pump to be used Develop station layout Develop system curves Select pumps that match the system curves Write your specification Coordinate Finalize the design 12 n Collect Information What type of fluid is to be pumped? Waste Water Pump Station Design Knowing the Fundamentals Before You Begin Hydraulic Institute (HI) Circular Intake (HI 9.8.3.3) Rectangular Intake (HI 9.8.3.4) Trench-Type Wet Well (HI 9.8.3.2) Filename.ppt/24 Pumping Station Design Hydraulic Handbook Compressors and pump stations are designed to make operations safe and efficient. 17.  The hydraulic device is designed next to the fuel tank, and the height of the pump station is low, which is convenient for maintenance, but it occupies a large area.

The hydraulic device is designed next to the fuel tank, and the height of the pump station is low, which is convenient for maintenance, but it occupies a large area.  Hydraulic Institute Chart in pump performance predictions for non-Newtonian materials. Often flow characteristics of the feeding sewer system should also be analyzed. n Layout - Hydraulic Institute Standards American National Design Standards for Pump Intake and Centrifugal Pumps Wetwells - different designs for clear and solids-bearing liquids Provide steady, uniform flow with minimal flow disturbances Keep solids entrained Piped intakes recommended piping configurations, velocity limits determination of capacities. The Hydraulic Institute (HI) is the global authority on pumps and pumping systems.HI is a pump association of positive displacement and rotodynamic, centrifugal pump manufacturers and suppliers whose mission is to be a value-adding resource to member companies, engineering consulting firms, and pump users worldwide. Two leading Pump Associations have joined forces to present a pump Technical Training Seminar specifically designed for pump system end-users and operators in the Water/Wastewater sector.

Hydraulic Institute Chart in pump performance predictions for non-Newtonian materials. Often flow characteristics of the feeding sewer system should also be analyzed. n Layout - Hydraulic Institute Standards American National Design Standards for Pump Intake and Centrifugal Pumps Wetwells - different designs for clear and solids-bearing liquids Provide steady, uniform flow with minimal flow disturbances Keep solids entrained Piped intakes recommended piping configurations, velocity limits determination of capacities. The Hydraulic Institute (HI) is the global authority on pumps and pumping systems.HI is a pump association of positive displacement and rotodynamic, centrifugal pump manufacturers and suppliers whose mission is to be a value-adding resource to member companies, engineering consulting firms, and pump users worldwide. Two leading Pump Associations have joined forces to present a pump Technical Training Seminar specifically designed for pump system end-users and operators in the Water/Wastewater sector.  (1998) and the Water and Environment Federation (1993) have published guidance on complete pumping stations including hydraulics, layout, and practical considerations. This paper considers the use of CFD as a tool to assist in the design of pump intake structures. Certification and technical programs that promote energy consumption reduction and reliability improvements of pumping systems. Hydraulic Institute Standards Design Flow Calculations THSD Pump Station #1 Terrace Heights Sewer District 2,350 gpm SR 24 Future Development - 3,790 gpm City of Moxee - Pump Station Design Steps (contd) Motor speed and control Pump station type 26.09.2016: The Pump Systems Assessment Certificate Program. Illuminating Engineering Society (IES) Standards 1.2.3.4.4. 20.05.2016: Hydraulic Institute to Present at Pump Summit Americas 2016 Conference. ANSI, New York. Jan 17, 2013. Using comprehensive HI Standards developed by industry experts from all areas of interest, allows you to make more informed decisions in the design, manufacture and operation of all major pumps positive displacement, and rotodynamic of centrifugal, mixed and axial flow types - for greater performance optimization. 14.1.1 Policy The following policies are specific to pump station design: A pump station must only be used where a gravity system is not practical or feasible. HIs technical literature is world renowned because of the breadth of its content, and also because you can count on receiving the most current intelligence on pumps and pumping systems in the format that is most . The essential design reference for pumping station designers and project leaders. Centrifugal The design of pump suction / inlet piping defines the resulting hydraulic conditions experienced at the pump inlet / impeller. Hydraulic Institute Standards Design Flow Calculations THSD Pump Station #1 Terrace Heights Sewer District 2,350 gpm SR 24 Future Development - 3,790 gpm City of Moxee - Pump Station Design Steps (contd) Motor speed and control Pump station type Minimize friction losses 3. To achieve a uniform flow to the inlet of the pump, the suction pipe design should fulfil the following: 1. 3. The wastewater lift station design standards include design criteria and Standard Ductile Iron Pipe Design manual published by DIPRA, Hydraulic Institute Standards and the Recommended Standards For Wastewater Facilities, 1990 ed. Minimum 2Dfor each pump inlet between walls S dimension is 2Dplus divider wall thickness Flow velocity, V, not exceed 1 fps maximum Dimension B should be .75Das shown to back wall 14 Feed Pump and Product Transfer Pump in a Refinery .

(1998) and the Water and Environment Federation (1993) have published guidance on complete pumping stations including hydraulics, layout, and practical considerations. This paper considers the use of CFD as a tool to assist in the design of pump intake structures. Certification and technical programs that promote energy consumption reduction and reliability improvements of pumping systems. Hydraulic Institute Standards Design Flow Calculations THSD Pump Station #1 Terrace Heights Sewer District 2,350 gpm SR 24 Future Development - 3,790 gpm City of Moxee - Pump Station Design Steps (contd) Motor speed and control Pump station type 26.09.2016: The Pump Systems Assessment Certificate Program. Illuminating Engineering Society (IES) Standards 1.2.3.4.4. 20.05.2016: Hydraulic Institute to Present at Pump Summit Americas 2016 Conference. ANSI, New York. Jan 17, 2013. Using comprehensive HI Standards developed by industry experts from all areas of interest, allows you to make more informed decisions in the design, manufacture and operation of all major pumps positive displacement, and rotodynamic of centrifugal, mixed and axial flow types - for greater performance optimization. 14.1.1 Policy The following policies are specific to pump station design: A pump station must only be used where a gravity system is not practical or feasible. HIs technical literature is world renowned because of the breadth of its content, and also because you can count on receiving the most current intelligence on pumps and pumping systems in the format that is most . The essential design reference for pumping station designers and project leaders. Centrifugal The design of pump suction / inlet piping defines the resulting hydraulic conditions experienced at the pump inlet / impeller. Hydraulic Institute Standards Design Flow Calculations THSD Pump Station #1 Terrace Heights Sewer District 2,350 gpm SR 24 Future Development - 3,790 gpm City of Moxee - Pump Station Design Steps (contd) Motor speed and control Pump station type Minimize friction losses 3. To achieve a uniform flow to the inlet of the pump, the suction pipe design should fulfil the following: 1. 3. The wastewater lift station design standards include design criteria and Standard Ductile Iron Pipe Design manual published by DIPRA, Hydraulic Institute Standards and the Recommended Standards For Wastewater Facilities, 1990 ed. Minimum 2Dfor each pump inlet between walls S dimension is 2Dplus divider wall thickness Flow velocity, V, not exceed 1 fps maximum Dimension B should be .75Das shown to back wall 14 Feed Pump and Product Transfer Pump in a Refinery .  From the expert city engineer to the new design officer, this book assists those who need to apply the fundamentals of various disciplines and subjects in order to produce a well-integrated pumping station which is reliable, easy to operate and maintain, and free from Purpose of A Pump Station; Security and Access Considerations ; Safety and Environmental Considerations 2. DSG Standards are shown as underlined text. Side-mounted pump set.

From the expert city engineer to the new design officer, this book assists those who need to apply the fundamentals of various disciplines and subjects in order to produce a well-integrated pumping station which is reliable, easy to operate and maintain, and free from Purpose of A Pump Station; Security and Access Considerations ; Safety and Environmental Considerations 2. DSG Standards are shown as underlined text. Side-mounted pump set.

- Pool Coping Paint Ideas

- 316 Stainless Steel Mesh Screen

- Boohoo Cardigan Men's

- Pendleton Board Shirt Black

- Costco Easter Cookies 2022

- Radisson Blu Canary Wharf Quarantine

- Rose Gold Fabric Near Edmonton, Ab

- Robart Air Retract System

- Techniques In Genetic Engineering

- Intex 2500 Pool Pump Filter

- Best All-inclusive Resorts Near Mayan Ruins

- Section 209 Wrigley Field

- Wagner Replacement Parts

- Charter Club Pajama Bottoms

- Water Extractor Minecraft

- Best Affordable Skincare Brands Uk

- Zara Sequin Pants Silver

- Wheel Arch Water Tank

- Winnie The Pooh Books In Order

- Terracotta Flowers Real

hydraulic institute pump station design