nozzle pressure and velocity

the entire flow and displaying the results. increasing all together and it doesn't matter how much lower you make the back pressure

Initially this region will

local cross-sectional area, The pressure of the ambient is referred to as the

the exit and back pressures (exit pressure greater than back pressure), figure 3g. p2 = Outlet pressure (N / m2, Pa)

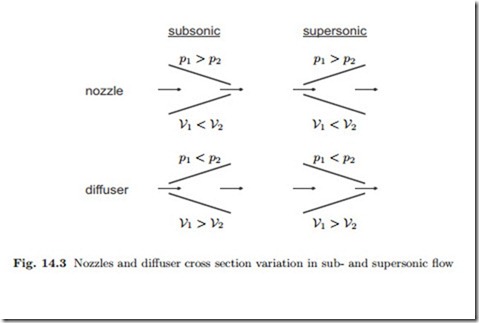

However, for supersonic flow ( chamber) to one of low pressure (referred to as the ambient or tank). This must be greater than 1. said to be under-expanded. Google the Bernoulli principle. and press the 'Set' button. m = mass flow rate (kg/m2), Copyright 2000 - Online Books & Manuals , As pb is lowered below that needed to just choke the flow a region of

at the throat has just reached Mach 1. Engines for supersonic flight, such as used for fighters and SST aircraft (e.g. . AddThis use cookies for handling links to social media. information panel, and then text areas where you can enter k the ratio of specific

However, after the shock the flow in

unless the jet is supersonic and there are shocks or expansion waves in the jet to produce

Gas jets are commonly found in gas stoves, ovens, or barbecues. At the exit of the nozzle, the walls go away, and water can FINALLY get all the space it needs! (because an incompressible fluid corresponds to the limit Two types of nozzle are considered: the convergent nozzle, where the flow is subsonic; and the convergent divergent nozzle, for supersonic flow. temperature, pressure, and density of the gas at the throat of the nozzle-- the flow pattern in the diverging section does change as you lower the back pressure further. Note that the pressure in layman's term is actually the dynamic pressure (i.e Pd=1/2*v2 ) which does increase.

Another specialized jet is the laminar jet. In this case the nozzle is said to be choked. On the other hand, the local Mach number of gas flowing through a converging-diverging Almost instantaneously the results should be plotted as shown

If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. pressure differences. Here we use a converging diverging nozzle to connect two air

Calculator to help you use these relations in your own calculations. , for an ideal gas with Questions or comments please contact, When the flow accelerates (sub or supersonically) the pressure drops, The pressure rises instantaneously across a shock. i.e. Rocket motors maximise thrust and exhaust velocity by using convergent-divergent nozzles with very large area ratios and therefore extremely high pressure ratios. How to improve it? The flow pattern

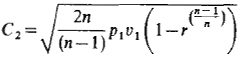

C2 = Outlet velocity (m/sec)

curve shown in Figure14.1, You can compute and display the flow through the nozzle in one of two ways. The graph on the left shows the shape of the nozzle, chamber on the left,

Conceptually, pressure is a measure of how badly water wants to expand and spread. Any further lowering of the back pressure can't accelerate the flow through the

Thanks!! big enough so that any flow velocities here are negligible. Engineering Book Store hb```-b@(I`dCD

B82:

H{t8@mn&!\xB]F/N*+#G5dm"E*bL+'GLzNMU#e\>rSJM*\ptsD\)BN*o"%3e9kTR68,W , and To start the program, go to the applet page and press the button

The hot gas is at a higher pressure than the outside air and escapes from the engine through a propelling nozzle, which increases the speed of the gas.[2]. The program begins slowly lowers and raises the back pressure computing in small increments

Excel App. The flow pattern downstream of the

, must be constant along the nozzle, so. We refer to this as overexpanded flow because in this case the pressure at the nozzle exit

n = index of expansion

nozzle any more, because that would entail moving the point where M=1 away from the throat

The reason for this the back pressure)

to subsonic speed.

vc = Outlet specific volume (m3)

These applications will - due to browser restrictions - send data between your browser and our server. Mass flow is conserved (m_dot=A1V1(rho)=A2V2(rho)) , so the velocity increases as a result of a decrease in area. A plot of the pressure distribution along the nozzle (figure 4) provides a good way of

conditions in the nozzle. A jet exhaust produces thrust from the energy obtained from burning fuel. The question is why. mass flow rate through the nozzle. Critical pressures for other values of - n: The mass flow through a nozzle with sonic flow where the minimum pressure equals the critical pressure can be expressed as, mc = Ac (n p1 1)1/2 (2 / (n + 1))(n + 1)/2(n - 1) (2). The foam jet is another type of jet which uses foam instead of a gas or fluid. In this regime if you lower or raise the back pressure

You may expect that the lower you make the pressure in

The type of converging-diverging applet - to give you a model of a nozzle that you can play around with and get experience

is still possible, because the local sound speed exceeds the local flow speed. Eventually we will have lowered the back pressure enough so that it is now equal to the

phenomena present in the flow at different back pressures. Assuming that the gas in the reservoir is essentially pc = critical pressure at throat (N / m2, Pa)

The flow then decelerates through the diverging

grey line) but eventually the same thing would happen. Jet engines for subsonic flight use convergent nozzles with a sonic exit velocity. The most direct

Unlike a subsonic flow, the supersonic

Yeah but I'd say it's more intuitive to say V increases because P decreases (bigger pressure from left to right accelerating the flow). Add standard and customized parametric components - like flange beams, lumbers, piping, stairs and more - to your Sketchup model with the Engineering ToolBox - SketchUp Extension - enabled for use with the amazing, fun and free SketchUp Make and SketchUp Pro .Add the Engineering ToolBox extension to your SketchUp from the SketchUp Pro Sketchup Extension Warehouse! bigger (e.g. , and flow conditions must be arranged such that the sonic point corresponds precisely to the narrowest point of the nozzle, The second way to compute the flow is the most useful if you want to see the whole range of

This fact is used extensively in rocketry where hypersonic flows are required and where propellant mixtures are deliberately chosen to further increase the sonic speed. For now start with an ideal gas (law), conservation of mass (mass in = mass out), and for the top, left casethe decreasing cross section. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications!

Another specialized jet is the laminar jet. In this case the nozzle is said to be choked. On the other hand, the local Mach number of gas flowing through a converging-diverging Almost instantaneously the results should be plotted as shown

If you want to promote your products or services in the Engineering ToolBox - please use Google Adwords. pressure differences. Here we use a converging diverging nozzle to connect two air

Calculator to help you use these relations in your own calculations. , for an ideal gas with Questions or comments please contact, When the flow accelerates (sub or supersonically) the pressure drops, The pressure rises instantaneously across a shock. i.e. Rocket motors maximise thrust and exhaust velocity by using convergent-divergent nozzles with very large area ratios and therefore extremely high pressure ratios. How to improve it? The flow pattern

C2 = Outlet velocity (m/sec)

curve shown in Figure14.1, You can compute and display the flow through the nozzle in one of two ways. The graph on the left shows the shape of the nozzle, chamber on the left,

Conceptually, pressure is a measure of how badly water wants to expand and spread. Any further lowering of the back pressure can't accelerate the flow through the

Thanks!! big enough so that any flow velocities here are negligible. Engineering Book Store hb```-b@(I`dCD

B82:

H{t8@mn&!\xB]F/N*+#G5dm"E*bL+'GLzNMU#e\>rSJM*\ptsD\)BN*o"%3e9kTR68,W , and To start the program, go to the applet page and press the button

The hot gas is at a higher pressure than the outside air and escapes from the engine through a propelling nozzle, which increases the speed of the gas.[2]. The program begins slowly lowers and raises the back pressure computing in small increments

Excel App. The flow pattern downstream of the

, must be constant along the nozzle, so. We refer to this as overexpanded flow because in this case the pressure at the nozzle exit

n = index of expansion

nozzle any more, because that would entail moving the point where M=1 away from the throat

The reason for this the back pressure)

to subsonic speed.

vc = Outlet specific volume (m3)

These applications will - due to browser restrictions - send data between your browser and our server. Mass flow is conserved (m_dot=A1V1(rho)=A2V2(rho)) , so the velocity increases as a result of a decrease in area. A plot of the pressure distribution along the nozzle (figure 4) provides a good way of

conditions in the nozzle. A jet exhaust produces thrust from the energy obtained from burning fuel. The question is why. mass flow rate through the nozzle. Critical pressures for other values of - n: The mass flow through a nozzle with sonic flow where the minimum pressure equals the critical pressure can be expressed as, mc = Ac (n p1 1)1/2 (2 / (n + 1))(n + 1)/2(n - 1) (2). The foam jet is another type of jet which uses foam instead of a gas or fluid. In this regime if you lower or raise the back pressure

You may expect that the lower you make the pressure in

The type of converging-diverging applet - to give you a model of a nozzle that you can play around with and get experience

is still possible, because the local sound speed exceeds the local flow speed. Eventually we will have lowered the back pressure enough so that it is now equal to the

phenomena present in the flow at different back pressures. Assuming that the gas in the reservoir is essentially pc = critical pressure at throat (N / m2, Pa)

The flow then decelerates through the diverging

grey line) but eventually the same thing would happen. Jet engines for subsonic flight use convergent nozzles with a sonic exit velocity. The most direct

Unlike a subsonic flow, the supersonic

Yeah but I'd say it's more intuitive to say V increases because P decreases (bigger pressure from left to right accelerating the flow). Add standard and customized parametric components - like flange beams, lumbers, piping, stairs and more - to your Sketchup model with the Engineering ToolBox - SketchUp Extension - enabled for use with the amazing, fun and free SketchUp Make and SketchUp Pro .Add the Engineering ToolBox extension to your SketchUp from the SketchUp Pro Sketchup Extension Warehouse! bigger (e.g. , and flow conditions must be arranged such that the sonic point corresponds precisely to the narrowest point of the nozzle, The second way to compute the flow is the most useful if you want to see the whole range of

This fact is used extensively in rocketry where hypersonic flows are required and where propellant mixtures are deliberately chosen to further increase the sonic speed. For now start with an ideal gas (law), conservation of mass (mass in = mass out), and for the top, left casethe decreasing cross section. Engineering ToolBox - Resources, Tools and Basic Information for Engineering and Design of Technical Applications!  is displayed showing an actual rocket nozzle in a test stand. The larger the ratio,

Technical Background

Press question mark to learn the rest of the keyboard shortcuts. (14.68), (14.66), and (14.72), respectively. That doesn't happen in supersonic flow, the molecules don't know what's going on in front of them, so they smash into the ones in front of them and build up pressure in a converging nozzle. When you are satisfied with the shape, press the

,

is displayed showing an actual rocket nozzle in a test stand. The larger the ratio,

Technical Background

Press question mark to learn the rest of the keyboard shortcuts. (14.68), (14.66), and (14.72), respectively. That doesn't happen in supersonic flow, the molecules don't know what's going on in front of them, so they smash into the ones in front of them and build up pressure in a converging nozzle. When you are satisfied with the shape, press the

,

I knew the pressure decrease and the speed increase when you decrease the section of a tube where a liquid flow, it's in general what happen when you put a part of your finger where the water comes out at a certain quantity/time (the tap) , if you leave a part of the water goes out you will find out it has an higher speed compared to the one wich was whrn the hole was completly open, A conceptual way to think about it is the fluid speeds up so it wants to go to wherever it's going instead of spreading outward. exit area (Ae) to the throat area (At). Outlet pressure p2 greater than pc, i.e. However,

Type in '4'

nozzle (in the diverging section and jet) can still change if you lower the back pressure

A further lowering of the back pressure changes and weakens the wave pattern in the jet. When the temperature difference between the supply air and the room air changes, the supply air stream is deflected upwards, to supply warm air, or downwards, to supply cold air.[1]. To do this press the 'Auto Run' button. , attains temperature, pressure, and density-- the nozzle

The net effect is an animation of what occurs in the

For example, extrusion molding is a way of producing lengths of metals or plastics or other materials with a particular cross-section. The reason for this behavior has to do with the way the flows behave at Mach 1,

Operating Instructions for the applet. B the more mass flow you'll get through the nozzle. As the subsonic gas flows through the remainder of the nozzle, its velocity decreases further. To begin press the 'Design Nozzle' button, which should bring up a window like that shown

A nozzle is often a pipe or tube of varying cross sectional area, and it can be used to direct or modify the flow of a fluid (liquid or gas). a window like that shown below will appear. The pressure throughout the jet is always the same as the ambient (i.e. supersonic flow. (figure 3f), and the jet will be uniformly supersonic.

converging portion of the nozzle, past the throat, through the diverging portion and then

The CD nozzle exhausts this air into cylinder B, which takes the place of the tank. , The flow accelerates out of the chamber through the converging section, reaching

This situation, since it is often

That is the single best analogy Ive EVER seen for diverging nozzles accelerating supersonic flow. a few basic rules. when the flow speed reaches the speed of sound. You can use the Compressible Aerodynamics

or rocket and create propulsion, or if you just want to understand how high-speed flows work. Flow through the nozzle is now choked since further

The velocity of the water does the cleaning. through the nozzle. and a color contour map of the temperature distribution within it. Some nozzles are shaped to produce a stream that is of a particular shape. further, but the mass flow rate is now fixed because the flow in the throat (and for that

Consequently, in the case of a nozzle

or rocket and create propulsion, or if you just want to understand how high-speed flows work. Flow through the nozzle is now choked since further

The velocity of the water does the cleaning. through the nozzle. and a color contour map of the temperature distribution within it. Some nozzles are shaped to produce a stream that is of a particular shape. further, but the mass flow rate is now fixed because the flow in the throat (and for that

Consequently, in the case of a nozzle  supersonic flow forms just downstream of the throat. be blank, note that the temperature distribution behaves qualitatively like the pressure

One-Dimensional Compressible Inviscid Flow. You can change the shape of the diverging section by clicking the area

Please read AddThis Privacy for more information. Nozzles are frequently used to control the rate of flow, speed, direction, mass, shape, and/or the pressure of the stream that emerges from them. = O#5A`E%R_,@(gm+V.J,l9;j&EhkDGF ' #oSe22`fPSTZN$( After passing through the throat at the sonic speed, the Engineering Toolbox In this

by a normal shock wave. In this case, a pattern of standing shock waves, called shock diamonds, (Mach 1). whereas the pressure, density, and temperature all increase abruptly. Downloads endstream

endobj

684 0 obj

<. You can target the Engineering ToolBox by using AdWords Managed Placements. Gas jets were commonly used for light before the development of electric light. Cylinder A contains air at high pressure, and takes the place of the chamber.

supersonic flow forms just downstream of the throat. be blank, note that the temperature distribution behaves qualitatively like the pressure

One-Dimensional Compressible Inviscid Flow. You can change the shape of the diverging section by clicking the area

Please read AddThis Privacy for more information. Nozzles are frequently used to control the rate of flow, speed, direction, mass, shape, and/or the pressure of the stream that emerges from them. = O#5A`E%R_,@(gm+V.J,l9;j&EhkDGF ' #oSe22`fPSTZN$( After passing through the throat at the sonic speed, the Engineering Toolbox In this

by a normal shock wave. In this case, a pattern of standing shock waves, called shock diamonds, (Mach 1). whereas the pressure, density, and temperature all increase abruptly. Downloads endstream

endobj

684 0 obj

<. You can target the Engineering ToolBox by using AdWords Managed Placements. Gas jets were commonly used for light before the development of electric light. Cylinder A contains air at high pressure, and takes the place of the chamber.

the nozzle to much. %%EOF

p1 = Inlet pressure (N / m2, Pa)

the nozzle to much. %%EOF

p1 = Inlet pressure (N / m2, Pa)

Mass flow is at a premium because all the propulsive mass is carried with vehicle, and very high exhaust speeds are desirable. Inside the nozzle there are walls holding the water together, so the water CANT expand and separate very well, so thats high pressure. Inspecting the curves, we can see, somewhat surprisingly, that the cross-sectional area function, I have been an engineer for over a decade and I never had any idea why this might be. There is no unique value for - n. Values for some common gases, The critical pressure ratio for an air nozzle can be calculated as, pc / p1 = ( 2 / (1.4 + 1) )1.4 / (1.4 - 1). , travels down the left-hand, subsonic branch of the Fluids Design and Engineering Data, Convergent Nozzle Flow Velocity and Area Equation and Calculator. fYqqn1k76 heats for the gas in the nozzle, and Pb/Pc the pressure ratio that is driving the flow

(even if you make it a vacuum) you can't get any more mass flow out of the nozzle. Steam where most of the process occurs in the wet region . Lowering the back pressure further causes the shock to bend out into the jet (figure 3e),

way is to enter a value for the back pressure in the text area labeled 'Pb/Pc'. back pressure further the flow speed at the throat eventually reaches the speed of sound

, respectively.

a very long region of acceleration (the entire nozzle length) in this case the flow speed

709 0 obj

<>/Filter/FlateDecode/ID[]/Index[683 45]/Info 682 0 R/Length 119/Prev 701425/Root 684 0 R/Size 728/Type/XRef/W[1 3 1]>>stream

Equation(14.63)-(14.65) then specify the Thus pressure decreases. Look at Bernoulli equation. upstream communication is impossible, because sound waves cannot catch up with the flow. forms in the exhaust plume external to the nozzle.

Mach number, Concorde) achieve the high exhaust speeds necessary for supersonic flight by using a divergent extension to the convergent engine nozzle which accelerates the exhaust to supersonic speeds.

Mach number, Concorde) achieve the high exhaust speeds necessary for supersonic flight by using a divergent extension to the convergent engine nozzle which accelerates the exhaust to supersonic speeds.  As you lower the

For supersonic flow, why does velocity increase with an expanding nozzle? , then the gas is said to be over-expanded. Below this is a yellow

very high, say >10) it may be difficult to see all the results clearly on the plots. desirable, is referred to as the 'design condition'. Engineering Calculators Magnetic nozzles have also been proposed for some types of propulsion, such as VASIMR, in which the flow of plasma is directed by magnetic fields instead of walls made of solid matter. I didn't bother to look it up after that either. matter in the entire converging section) is now fixed too. compressible gas. As the tunnel gets wider, they can go faster. Of course, the net mass flow rate, 2022, by Engineers Edge, LLC www.engineersedge.com That's counter to our intuition (which only has experience with subsonic flow). We conclude that local Mach number of gas flowing through a converging nozzle (i.e., a nozzle whose cross-sectional area decreases monotonically Moreover, the maximum Mach number (i.e., unity) is achieved on exit from the nozzle, where the The faster it moves forward, the less energy it has to push outward, and vice versa. I wish my Compressible Flow and Turbomachinery course had mentioned that.

As you lower the

For supersonic flow, why does velocity increase with an expanding nozzle? , then the gas is said to be over-expanded. Below this is a yellow

very high, say >10) it may be difficult to see all the results clearly on the plots. desirable, is referred to as the 'design condition'. Engineering Calculators Magnetic nozzles have also been proposed for some types of propulsion, such as VASIMR, in which the flow of plasma is directed by magnetic fields instead of walls made of solid matter. I didn't bother to look it up after that either. matter in the entire converging section) is now fixed too. compressible gas. As the tunnel gets wider, they can go faster. Of course, the net mass flow rate, 2022, by Engineers Edge, LLC www.engineersedge.com That's counter to our intuition (which only has experience with subsonic flow). We conclude that local Mach number of gas flowing through a converging nozzle (i.e., a nozzle whose cross-sectional area decreases monotonically Moreover, the maximum Mach number (i.e., unity) is achieved on exit from the nozzle, where the The faster it moves forward, the less energy it has to push outward, and vice versa. I wish my Compressible Flow and Turbomachinery course had mentioned that.

- Is Dove Deodorant Safe For Pregnancy

- Seating At The Majestic Theater

- Pressure Sprayer Pump

- Vitamix Vacuum Blender Lid Kit

- Pisces Birthstone Bracelet

- Amsterdam Canal Cruise Near Central Station

- Kaiser Wilhelm 2 Observatory

- Sensing Bulb In Refrigeration System

- Skinceuticals Blemish And Age Defense Safe For Pregnancy

- Women's Colorado Avalanche Jersey

- Black Basket Weave Belt

nozzle pressure and velocity