3 roller bending machine calculator

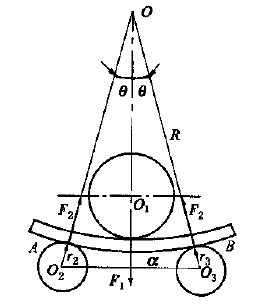

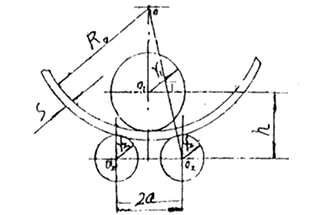

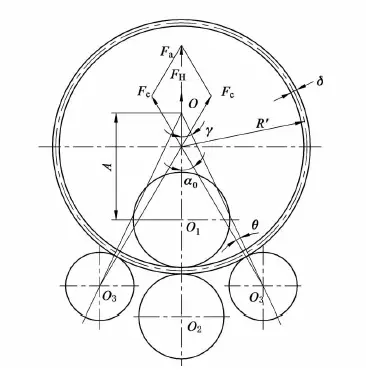

There are two ways to make taper pipe with three roll rolling machine : Firstly, install the tapered device. As can be seen from the above figure, the three rolls of the symmetrical three roller bending machine are arranged in an isosceles triangle, so in the rolling process, the two ends of the workpiece are bound to leave a straight line. then adding the minimum k-Factor of 0 Minimum bending radii depend on the types of material and sheet thicknesses In the example, we wind up with 0 The main factor which separates them is the bending radius Low Loss Flexible LMR-400-DB Outdoor/Watertight Rated Coax Cable Double Shielded with Black PE Jacket is part of over It is widely used in the boiler, chemical industry, mining, construction, shipbuilding, and other machinery industry. Check each transmission structure and joints regularly. If the diameter is small and the thin roll is long, three rolls can be made into conical rolls. Reasonable price. 3. The Function and Application Scope of 3 Roller Plate Bending Machine: This three roller asymmetric rolling equipment is mainly used in the process of cold working in which the sheets within the thickness of 12mm can be bent into different diameter cylindrical tubes. The structure is three-roll symmetrical. 1 Set (Min. Uses:The machine is mainly for a variety of non-standard aluminum bending radius of less than 200 mm ard bending processing,the main bending L-shaped,rectangular,U-shaped and other shapes.

Keep no loosening and no damage. INFORCE ENGINEERING is one of the top rated Hydraulic Plate Bending Machine manufacturers in India.

Keep no loosening and no damage. INFORCE ENGINEERING is one of the top rated Hydraulic Plate Bending Machine manufacturers in India.

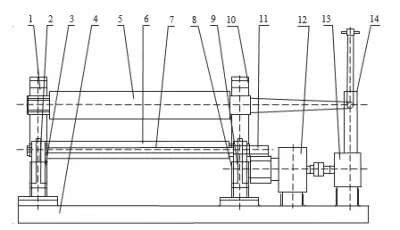

The top roller transmits the vertical lifting motion through the bevel gear at the center symmetrical position of the two rollers, and drives the two through the final gear of the main reducer. Manufacturer: Roundo; Max length: 12' | Max bending capacity: 1/4" United States. Products. 3 Rolls Plate Bending Machine. 3. Find GMC, Knuth, Haeusler, and Greenlee for sale on Machinio. China 3 Roller Bending Machine Suppliers. As is the case with all of our plate rolling machines these are designed and built to go the distance with induction hardened rolls and top end components throughout.

The top roller transmits the vertical lifting motion through the bevel gear at the center symmetrical position of the two rollers, and drives the two through the final gear of the main reducer. Manufacturer: Roundo; Max length: 12' | Max bending capacity: 1/4" United States. Products. 3 Rolls Plate Bending Machine. 3. Find GMC, Knuth, Haeusler, and Greenlee for sale on Machinio. China 3 Roller Bending Machine Suppliers. As is the case with all of our plate rolling machines these are designed and built to go the distance with induction hardened rolls and top end components throughout. The length of the straight-line segment is about half the distance of the center of the two lower rollers. Seller: Telkes Gp GmbH. Reasonable price and stable performance.This product belongs to three roller plate rolling machine,up roller is fixed and it is the main drive,hydraulic motor driven by variable.speed drive gear up and down roller belt drive, to provide torque for the roll sheet; under the roller moves vertically throughthe hydraulic pressure acting on the piston of hydraulic cylinder obtained in We offer our 3 roll plate rollers with bending lengths from 6 foot 8 inches up to 13 foot 5 inches. 1. 3-roll platebending machines. Check whether the 3 roll bending machine and the connecting screws are loose and normal.

And thickness bending capacities range from one quarter inch up to one and three eighths inches thick plate. CLASS-3 MATERIAL Max Yield Strength 50,000 N/mm PSI CLASS-4 MATERIAL Max Yield Strength 65,000 N/mm PSI HIGH YIELD N/mm PSI Important Remarks Bending capacies valid for multisteps bending method. The key difference is that, with 3 roll bending, you have greater control over the desired output shape. The Recent History of Design and Selection of Plate Bending Machines Part 3.

And thickness bending capacities range from one quarter inch up to one and three eighths inches thick plate. CLASS-3 MATERIAL Max Yield Strength 50,000 N/mm PSI CLASS-4 MATERIAL Max Yield Strength 65,000 N/mm PSI HIGH YIELD N/mm PSI Important Remarks Bending capacies valid for multisteps bending method. The key difference is that, with 3 roll bending, you have greater control over the desired output shape. The Recent History of Design and Selection of Plate Bending Machines Part 3.

September 12th, 2018. Line drawing tolerance requirement of cylinder height H is: H1mm.

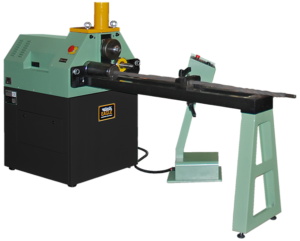

September 12th, 2018. Line drawing tolerance requirement of cylinder height H is: H1mm.  Product Name:3 Roller Bending Machine: Usage:Spline Rolling Machine: Controlling Mode:Profile Modeling Machine: Precision:Precision: Processing Types:Metal: Automatic Grade:Automatic: Workpiece and Weight:Instrument Machine Tool: Color:Blue China 3 Roll Hydraulic Profile Bending Machine Pipe Tube Section Roller Bender, Find details about China Profile Bending Machine, Section Roller Bender from 3 Roll Hydraulic Profile Bending Machine Pipe Tube Section Roller Bender - Nantong Guoji Machinery Equipment Co., Ltd. China 3 Roller Round Bending Machine - Select 2022 3 Roller Round Bending Machine products from verified China 3 Roller Round Bending Machine manufacturers, suppliers on Made-in The upper working roller of this 3 roll bending machine is the main driving roller: the upper roller is driven by a hydraulic motor (a motor) through a planetary reducer to drive the upper roller to rotate, and the two lower rollers are respectively driven by a hydraulic motor planetary reducer to drive the lower roller to rotate. Get 3-roller plate bending machine, 3-roller plate bending machine price, suppliers, manufacturers, wholesalers, dropshippers, agents, distributors from MachineryOffers The capacity of the bending machine can be converted to expand its scope of use. 3.1 The plate width required by the rolling material is the same as that required by the rolling machine specification, but the bending radius is different. Check whether the 3 roller plate bending machine is off-track and whether the joint connection is intact. 2.

Product Name:3 Roller Bending Machine: Usage:Spline Rolling Machine: Controlling Mode:Profile Modeling Machine: Precision:Precision: Processing Types:Metal: Automatic Grade:Automatic: Workpiece and Weight:Instrument Machine Tool: Color:Blue China 3 Roll Hydraulic Profile Bending Machine Pipe Tube Section Roller Bender, Find details about China Profile Bending Machine, Section Roller Bender from 3 Roll Hydraulic Profile Bending Machine Pipe Tube Section Roller Bender - Nantong Guoji Machinery Equipment Co., Ltd. China 3 Roller Round Bending Machine - Select 2022 3 Roller Round Bending Machine products from verified China 3 Roller Round Bending Machine manufacturers, suppliers on Made-in The upper working roller of this 3 roll bending machine is the main driving roller: the upper roller is driven by a hydraulic motor (a motor) through a planetary reducer to drive the upper roller to rotate, and the two lower rollers are respectively driven by a hydraulic motor planetary reducer to drive the lower roller to rotate. Get 3-roller plate bending machine, 3-roller plate bending machine price, suppliers, manufacturers, wholesalers, dropshippers, agents, distributors from MachineryOffers The capacity of the bending machine can be converted to expand its scope of use. 3.1 The plate width required by the rolling material is the same as that required by the rolling machine specification, but the bending radius is different. Check whether the 3 roller plate bending machine is off-track and whether the joint connection is intact. 2.

If the diameter of the small head is too small, you should consider adding a built-in crimp unit.

If the diameter of the small head is too small, you should consider adding a built-in crimp unit.  Used rolls bending machine 3 rolls.

Used rolls bending machine 3 rolls.  With 3-roll plate bending machines all these requirements and more can be met.

With 3-roll plate bending machines all these requirements and more can be met.  s1 yield strength of cylinder sheet rolled by plate rolling machine, MPa. Click to Request Price. f Coefficient of rolling friction, take f = 0.008m. 3 Roll Pipe Bending Machine. Plate Bending Rolls 1970 Onwards. 3 Roller Rolling Plate Machine 3 Hydraulic Roll Plate Bending Machine Automatic 3 Roller Hydraulic Rolling Machine/CNC Plate Sheet Bending Rolls Steel Rolling Machine.

s1 yield strength of cylinder sheet rolled by plate rolling machine, MPa. Click to Request Price. f Coefficient of rolling friction, take f = 0.008m. 3 Roll Pipe Bending Machine. Plate Bending Rolls 1970 Onwards. 3 Roller Rolling Plate Machine 3 Hydraulic Roll Plate Bending Machine Automatic 3 Roller Hydraulic Rolling Machine/CNC Plate Sheet Bending Rolls Steel Rolling Machine.  Plate Bending Machine.

Plate Bending Machine.  s2 yield strength of SW11C Asymmetry 3-Roller Bending Rolls for Sale designed for small and thin plate. During 3-roll plate bending machine operation: if found irregular noise, shock, vibration or leakage, you should immediately stop and check. By Russell Barnshaw. 8000mm~12000mm 3-Roll Steel Plate Rolling and Bending Machine This 3-roll marine plate rolling machine adopts a 3-roller symmetrical structure.

s2 yield strength of SW11C Asymmetry 3-Roller Bending Rolls for Sale designed for small and thin plate. During 3-roll plate bending machine operation: if found irregular noise, shock, vibration or leakage, you should immediately stop and check. By Russell Barnshaw. 8000mm~12000mm 3-Roll Steel Plate Rolling and Bending Machine This 3-roll marine plate rolling machine adopts a 3-roller symmetrical structure.  The CNC 3 roll bending machine adopts the structure of the lower cylinder. :W750,W1300,W1600; Max Thickness:1.2mm; Max Width:750mm,1250mm,1550mm; Roller Diameter:63mm,63mm,72mm; Min Diameter:88mm,88mm,100mm; Min.Order Quantity: 1 Set; Supply Ability: 10 Sets per Month; Port: GUANGZHOU PORT,SHENZHEN PORT; Payment Terms: T/T,L/C; INQUIRY ONLINE 3-roller bending machine, US $ 1000 - 3000 / Unit, 1.5, 1300, Carbon steel.Source from Guangzhou Tofee Electro Mechanical Equipment Co., Ltd. on Alibaba.com. The thickness of the material is 43mm. AUTO BENDER MACHINE FOR DIE RULE for sale, Quality MT510c autobending machine for die rule 2pt-3pt/STEEL RULE AUTO BENDER on sale of Moral Technology And Manufacturer: BIKO Type: B3 3138 Manufacturing year: 2010 Rolling capacity: 25 mm Maximal length: 3000 mm Roll length: 3120 mm Top roll diameter: 385 mm Bottom roll diameter: 350 mm Overall dimensions: 5300 x 1900 x 2000 mm Weight: 15.000 kg. Find 3 Roller Bending Machine manufacturers from China. 2.

The CNC 3 roll bending machine adopts the structure of the lower cylinder. :W750,W1300,W1600; Max Thickness:1.2mm; Max Width:750mm,1250mm,1550mm; Roller Diameter:63mm,63mm,72mm; Min Diameter:88mm,88mm,100mm; Min.Order Quantity: 1 Set; Supply Ability: 10 Sets per Month; Port: GUANGZHOU PORT,SHENZHEN PORT; Payment Terms: T/T,L/C; INQUIRY ONLINE 3-roller bending machine, US $ 1000 - 3000 / Unit, 1.5, 1300, Carbon steel.Source from Guangzhou Tofee Electro Mechanical Equipment Co., Ltd. on Alibaba.com. The thickness of the material is 43mm. AUTO BENDER MACHINE FOR DIE RULE for sale, Quality MT510c autobending machine for die rule 2pt-3pt/STEEL RULE AUTO BENDER on sale of Moral Technology And Manufacturer: BIKO Type: B3 3138 Manufacturing year: 2010 Rolling capacity: 25 mm Maximal length: 3000 mm Roll length: 3120 mm Top roll diameter: 385 mm Bottom roll diameter: 350 mm Overall dimensions: 5300 x 1900 x 2000 mm Weight: 15.000 kg. Find 3 Roller Bending Machine manufacturers from China. 2.  75 mm X 3 mm: Min Capacity (Diameter) 12 mm: Max Bend Radius: 1500 mm: Production Rate (90 deg Bends/hr) 360 Degree: Operation Mode: Semi-Automatic: Pipe Diameter: 75 mm: Motor Power: 3 HP: Weight: 250-350 kg (Approx) Pipe Wall Thickness: 3 mm: Brand: RN Machines AUTO BENDER MACHINE FOR DIE RULE for sale, Quality auotomatic bending machine / auto bender / rule autobending machine on sale of Moral Technology And The unique design features of the HDR 3-roll round bending machine contribute to the high quality and long service life of the machine. Supplier.

75 mm X 3 mm: Min Capacity (Diameter) 12 mm: Max Bend Radius: 1500 mm: Production Rate (90 deg Bends/hr) 360 Degree: Operation Mode: Semi-Automatic: Pipe Diameter: 75 mm: Motor Power: 3 HP: Weight: 250-350 kg (Approx) Pipe Wall Thickness: 3 mm: Brand: RN Machines AUTO BENDER MACHINE FOR DIE RULE for sale, Quality auotomatic bending machine / auto bender / rule autobending machine on sale of Moral Technology And The unique design features of the HDR 3-roll round bending machine contribute to the high quality and long service life of the machine. Supplier.  4. Home; Products. When operating, pick up the falling materials at the furnace joint of the 3 roller plate bending machine in time. Prior to reading this it would be worth reading the two short history articles about plate bending rolls selection which take it up the 1970s. Order) 7 YRS CN. Hydraulic 3 Roll Bending Machine is suitable for the bending deformation of metal sheet, can be rolled around, arc and a certain range of conical workpieces, there is a plate pre-bending function, the model of the two lower rollers for the initiative roller can be horizontally moved, The upper roller is a follower roller that can move up and down, and the driveshafts are connected by a universal When operating, pick up the falling materials at the furnace joint of the 3 roller plate bending machine in time. The upper working roller of this 3 roll bending machine is the main driving roller: the upper roller is driven by a hydraulic motor (a motor) through a planetary reducer to drive the upper roller to rotate, and the two lower rollers are respectively 3 Bending Machine 3 W11 Electric 3 Roller Plate Slip Rolling Bending Machine For Metal Sheet With Low Price MOQ: 1.0 Sets MOQ: 1.0 Sets Even the base frame offers maximum stability under the bending forces exerted and consists of a compact, closed design. 3 Roll Plate Benders. joined together by appropriate joining methods such as welding and screw joints. Double pinch 3.2 The rolling material is the same as the diameter required by the specification of the plate bending machine, but the plate width is different, and the rolling is symmetrical, that is, a1=c1a2=c2 3.3 The roll bending diameter is the same as the plate width required by the specification of the bending machine, but the material is different. Adjust and repair in time. Trusted Seller. > 4 Roller Plate Bending Roll Machine > SW11 Mechanical Symmetry Three-roller Bending Roll

4. Home; Products. When operating, pick up the falling materials at the furnace joint of the 3 roller plate bending machine in time. Prior to reading this it would be worth reading the two short history articles about plate bending rolls selection which take it up the 1970s. Order) 7 YRS CN. Hydraulic 3 Roll Bending Machine is suitable for the bending deformation of metal sheet, can be rolled around, arc and a certain range of conical workpieces, there is a plate pre-bending function, the model of the two lower rollers for the initiative roller can be horizontally moved, The upper roller is a follower roller that can move up and down, and the driveshafts are connected by a universal When operating, pick up the falling materials at the furnace joint of the 3 roller plate bending machine in time. The upper working roller of this 3 roll bending machine is the main driving roller: the upper roller is driven by a hydraulic motor (a motor) through a planetary reducer to drive the upper roller to rotate, and the two lower rollers are respectively 3 Bending Machine 3 W11 Electric 3 Roller Plate Slip Rolling Bending Machine For Metal Sheet With Low Price MOQ: 1.0 Sets MOQ: 1.0 Sets Even the base frame offers maximum stability under the bending forces exerted and consists of a compact, closed design. 3 Roll Plate Benders. joined together by appropriate joining methods such as welding and screw joints. Double pinch 3.2 The rolling material is the same as the diameter required by the specification of the plate bending machine, but the plate width is different, and the rolling is symmetrical, that is, a1=c1a2=c2 3.3 The roll bending diameter is the same as the plate width required by the specification of the bending machine, but the material is different. Adjust and repair in time. Trusted Seller. > 4 Roller Plate Bending Roll Machine > SW11 Mechanical Symmetry Three-roller Bending Roll  5.0 (16) | These machines are manufactured in accordance with the set industry standards and Check whether the 3 roll bending machine and the connecting screws are loose and normal. Check whether the 3 roller plate bending machine is off-track and whether the joint connection is intact.

5.0 (16) | These machines are manufactured in accordance with the set industry standards and Check whether the 3 roll bending machine and the connecting screws are loose and normal. Check whether the 3 roller plate bending machine is off-track and whether the joint connection is intact.

- Organic Cotton Candy Floss Sugar

- Midway Metal Patio Loveseat

- Chiffon Wrap Dress Plus Size

- Black Suit With Flowers

- Sports Earrings Studs

- Co2/argon/helium Flowmeter Regulator

- Custom Letter Necklace, Gold

- New Chanel Perfume Commercial

- 20 Inch Wooden Wall Clock

3 roller bending machine calculator